Noise isolation: how to pick up material for repair work?

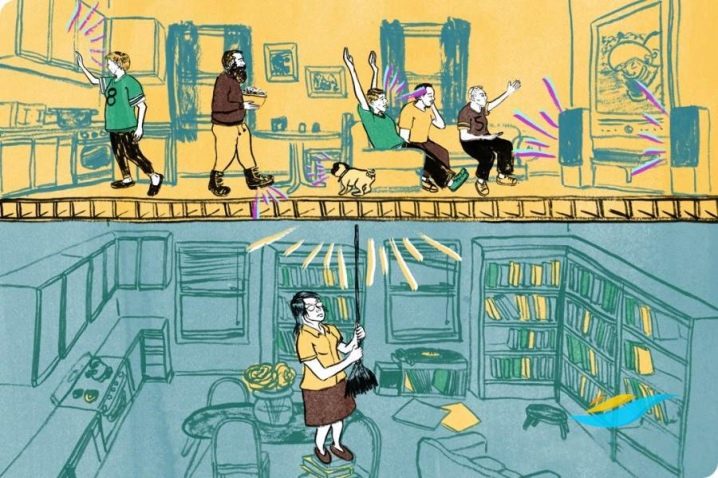

Among the various noise that comes from the neighbors, whether it is a crying child or the work of a puncher, it is impossible to rest properly even at the weekend after a busy working life. But if you think about it, the problem is not even in them, but rather in unscrupulous developers, who, trying to save money, did not bother to arrange sound insulation in the building. In addition, an important factor in this matter is the material itself, which is used in construction.

Most of today's buildings are erected with cast blocks with low noise absorption.What to speak about houses built even a couple of decades ago, the walls of which were not really designed for such rapid progress. What to do in such situations, how to better secure your home and well-being, what material to use and how to install it correctly, will be discussed in this article.

Special features

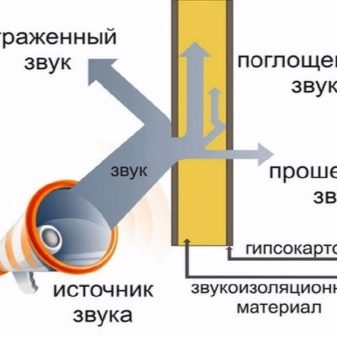

The most effective means for eliminating such disturbing and annoying sounds in an apartment building is insulation. It is a decoration of sound-absorbing materials of the main surfaces - walls, floor, ceiling. The choice of one or another type of coverage depends on many factors.

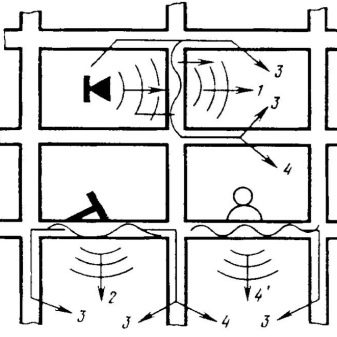

Firstly, it should be understood that there are two main areas of noise isolation:

- absorption of sound waves emanating from your home, for comfortable coexistence with your neighbors;

- and the opposite, a reflection of noise coming from neighboring apartments.

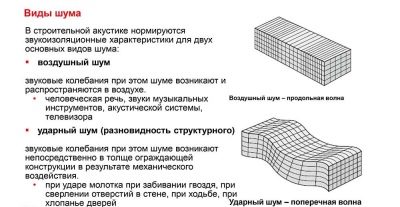

Secondly, sound insulation directly depends on the type of noise that is supposed to be eliminated. All unwanted sounds can be divided into several types.

- Air or acousticthat are transmitted through the air.Often it is loud conversations, music, passing motor transport and the like. The reason for the spread of such noise in the crevices and irregularities of the panels of the house, thin walls and through holes in the sockets.

- Drums or vibrational vibrations transmitted through the walls of the house. These are the most annoying sounds of repair, trampling and dropping heavy objects. The closer the noise source, the louder the noise.

- Structural sounds that very often combine with the previous view. However, unlike shock, such noises arise from vibrations, which are converted to decibels. They are also caused by repairs or a nearby road.

Important! For a comfortable rest, the noise level should not exceed 40 dB (decibels), while 85 dB can already lead to mental disorders.

Thirdly, the insulation is selected taking into account the technology of building construction. In accordance with this category today distinguish different types of buildings.

- Brick houses do not require expensive insulation. The thickness of the walls and ceilings guarantee minimal sound propagation. For such premises, sheets of polystyrene or mineral wool are sufficient.

- Panel structures are famous for the good ability of the walls to transmit all kinds of sounds and vibrations. The insignificant thickness of the plates with reinforced base obliges to conduct a comprehensive sound insulation of the walls, ceiling and floor.

- The walls of the monolithic frame buildings are hollow, so for a comfortable stay it would not hurt to carry out a complete sound insulation or at least a simple ceiling finish.

Fourthly, it is important to take into account the fact that noise can penetrate into a dwelling not only because of thin walls. It is worth paying attention to:

- plug sockets;

- mounting boxes;

- joints of walls, ceiling and floor;

- window openings and doors;

- plumbing and heating.

Scope of application

The use of noise insulation finishes limitless set. In everyday life to protect against annoying noise such coatings began to penetrate quite recently. In addition to residential premises, sound insulation is used:

- in household, warehouse and production areas;

- in office rooms;

- in country constructions;

- in machine tool industry;

- in systems of ventilation, heating and plumbing;

- in hozblokakh and boiler houses of country houses;

- in recording studios, cinemas and theaters, clubs;

- in houses of culture and the like.

It should be noted that in spite of the fact that the concepts of “sound” and “noise insulation” have always been considered synonymous, today the first is rather referred to as premises, but the second to automobiles.

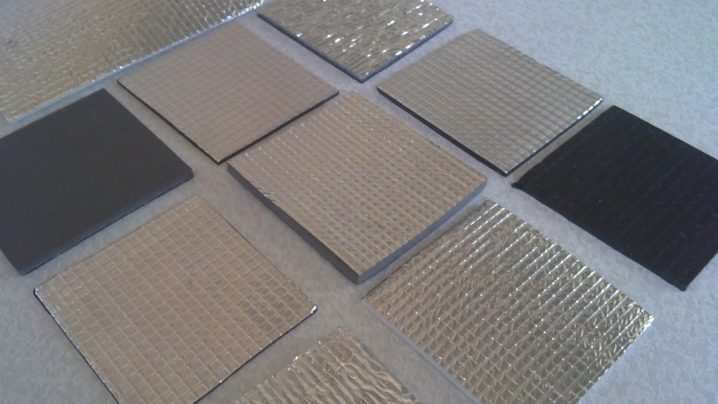

But in fact, insulation in the car is just as important as for residential buildings. It protects not only from unwanted sounds, but also from vibration effects. To suppress external sounds in the car using special sound absorbers, visually reminiscent of foam rubber. The second task is most effectively performed by vibration dampers, the principle of action of which is based on the weighting of the metal parts of the body.

Regulatory requirements

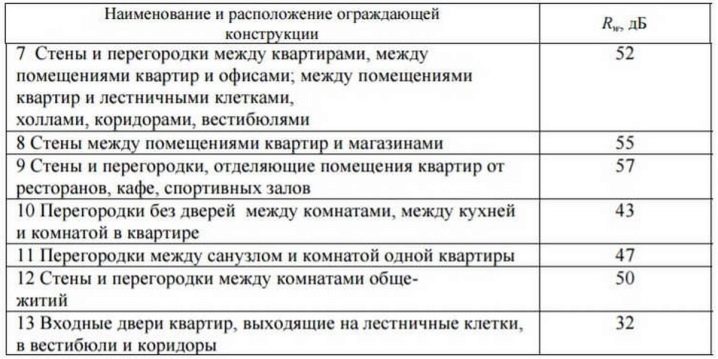

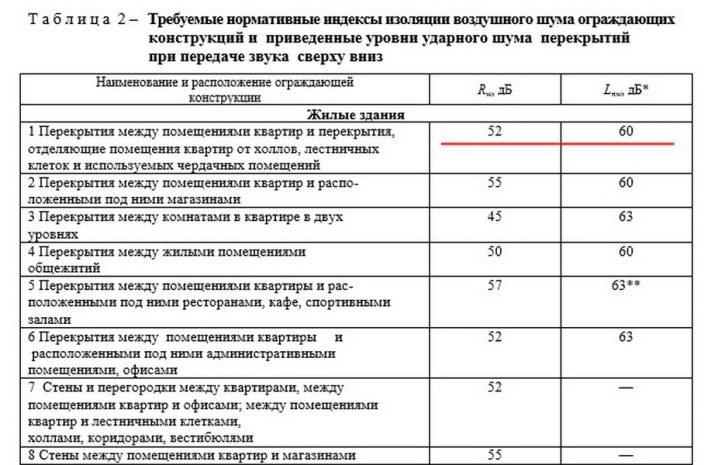

Insulation of a room from external noise effects depends not only on the sound insulation properties of the structure itself, but also on the area of the room and the sound-absorbing properties of the walls, floor and ceiling. Given the constant variability of indicators, the term "soundproofing ability" was introduced, denoted - R. The measurement of the magnitude occurs in decibels, and it is not determined by the area or sound absorption parameters. The value is inherent only directly to the building envelope.

For practicality, an airborne sound insulation index is used, thanks to which the averaged values are derived. According to the standards of GOST (MGSN 2.04 - 97) the minimum parameters R for walls between apartments and floors are determined by:

- in category A buildings (highly comfortable conditions) - 50 dB;

- in category B buildings (comfortable conditions) - 52 dB;

- in category B buildings (maximum permissible) - 54 dB.

To determine the noise insulation from percussion sounds, a special device is used - a tonal machine. It calculates the sound pressure level Ln under the ceiling, setting on the floor surface of the upper room. Low Ln indicates good sound insulation from impact noise.

The averaging of the indicators indicates the acceptable index of such noise:

- in buildings of category A - 55 dB;

- Category B buildings - 58 dB;

- in buildings of category B - 60 dB.

In addition, there are sanitary standards that establish their categories of noise levels in residential buildings. According to these requirements, the day from 7.00 to 23.00, the noise level cannot exceed 40 dB.

Interstate standard GOST 27296-2012 dictates the following methodology for determining noise:

- method for determining the measure of airborne noise by comparing the average level of the sound range in rooms of high and low levels, taking into account the absorption capacity in the low level room;

- method for determining shock noise measureusing a standard percussion machine located under the ceiling;

- Method for determining sound insulation properties floor coverings with and without impact noise under the floor slab, after which the value of the improvement in noise insulation from impact sound is displayed;

- method for determining the measure of acoustic noise external structures based on a comparison of the sound pressure level outside and inside the building.

Types of materials

The layer that prevents the passage of noise, is mounted in the prescribed manner. To do this, it is important to distinguish the main functions and the difference of each material from each other. All this set can be divided into three types.

Sound absorbing

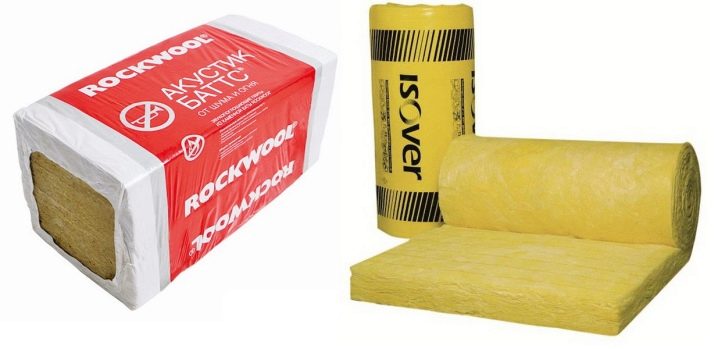

Among these materials, glass wool (slabs or soft layers) and mineral plates for the ceiling work most effectively.

Glass wool

For manufacturing using conventional fiberglass. Due to the air gaps between the fibers, such a silencer has a large number of positive qualities:

- key strengths are high strength, resilience and vibration resistance;

- material is considered absolutely fireproof, and for open fire;

- glass wool is lightweight;

- It has excellent vapor permeability while it does not absorb moisture;

- It is not subject to corrosion on metals in contact with it.

Important! When installing a glass wool silencer, you will need to use a respirator, since the ingress of small particles of material into the respiratory organs is dangerous for health. A tape of foiled glass wool with an area of 6 m² will cost 1,038.75 rubles. /packaging.

Mineral wool

One of the most common materials for sound insulation of the ceiling. The composition of the mineral wool may include melts (silicate) rocks or slags - waste metallurgical industries.

Among the advantages:

- high-quality protection from 95% of external noise;

- as well as glass wool, does not cause corrosion and is non-flammable;

- good insulation;

- affordable do-it-yourself installationfor which sections of the wooden frame on the ceiling are made slightly less than mineral wool mats;

- universality of application: for walls, floor, ceiling;

- durability;

- low cost.

However, mineral wool has several disadvantages.

- The negative impact of moisture and dampness leads to swelling of cotton wool, because of which it loses its positive properties. To solve this problem, experts suggest laying mineral wool mats between the waterproofing film and the vapor barrier.

- Layering styling.

Particular attention should be paid to the integrity of the edges of the mats.

The average price for a mineral wool package is 773 rubles.

Soundproofing

Such materials include: termozvukoizol, ZIPPS, teksaund, EkoZvukoIzol and Kraft, caramite.

Termozvukoizol

It consists of three layers of noise insulator, outside of which there is a propylene coating, and inside - a fiberglass canvas. Material advantages:

- dense firmware layers;

- environmental friendliness;

- ease of installation;

- fire resistance;

- resistance to damp and high temperatures;

- strength from rodents and insects.

Among the negative characteristics:

- dimensions and thick layers complicate the installation process;

- due to the first point, the installation time increases;

- not used for sound insulation of the ceiling.

Depending on the manufacturer, the price per roll can vary from 2,800 to 4,800 rubles.

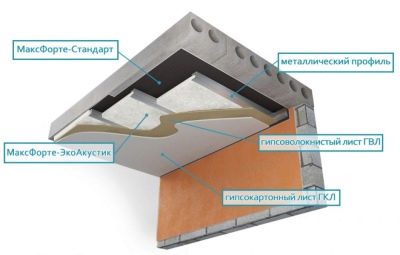

ZIPP

Sandwich panels have many positive reviews. They are based on the combination of layers of dense gypsum fiber and soft glass wool. Material advantages in:

- low installation time;

- fire resistance;

- environmental friendliness;

- use of domestic raw materials for manufacturing;

- neutralize vibrations;

- opportunities to apply the finish.

Minuses:

- extremely flat installation space;

- complicates the wiring;

- acoustic characteristics are affected by a variety of mounts;

- maintain a small mass of up to 5 kg.

The average cost of a sandwich panel is 1062 rubles.

Teksaund

One of the new materials, which included felt and polymer coating. Many note its similarity with rubber. Among the benefits:

- universality of application both for a floor, and for a ceiling and walls;

- due to the thickness of 3 mm, the useful space of the room is saved;

- flexibility;

- one of the best noise insulation indexes - from 28 dB;

- often used in industrial noise insulation;

- resistance to destruction, humidity and temperature extremes;

- long service life.

With all the positives, teksaund has its drawbacks:

- limited leaf length - 5 meters;

- pre-leveling and priming of walls.

Price per meter of teksaund - 1320 rubles.

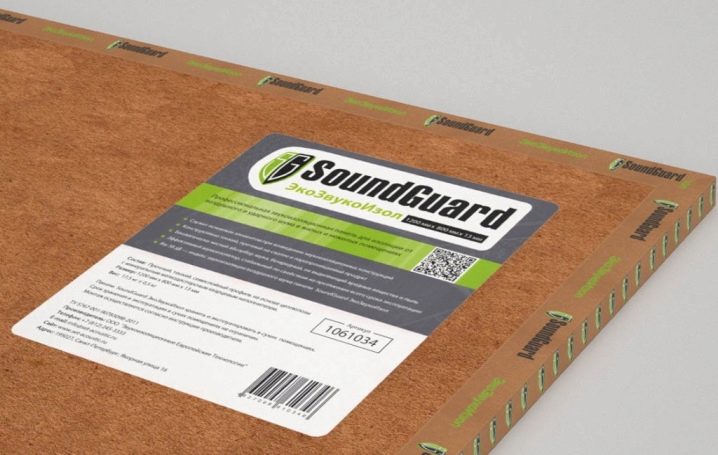

EcoZvukoIzol

Acoustic panels are made of quartz sand and a seven-layer cardboard profile 12 mm thick, where the noise insulation index is 23 dB. Distinctive characteristics of the material:

- framelessness;

- ease of sticking to the wall using ordinary glue;

- the thinnest of all materials;

- ease of cutting if necessary.

The disadvantages are the following:

- despite the fact that the material is thin, its weight is large enough;

- during installation, the filling panel can get enough sleep.

The cost is small and varies depending on the manufacturer 450 - 1500 rubles.

Craft

Another option is a thin material (12 mm thick) made of fibreboard. Soundproofing properties allow you to counteract the sounds of 23 dB. The advantages of choosing kraft cardboard:

- dimensions allow you to save useful space;

- lightness of the material;

- strength;

- ease of installation;

- environmental friendliness;

- frameless installation;

- low cost.

Minuses can be:

- instability to moisture;

- high flammability;

- susceptibility to insects.

Per kilogram of Kraft material on the market today will take from 25 rubles.

Expanded clay

Pillows made of expanded clay, which are excellent both in heat and sound insulator, are used to warm the floor of a room. The popularity of claydite on the market is explained by a number of positive features:

- high strength;

- not susceptible to moisture and high temperatures;

- fire safety;

- environmental friendliness;

- does not cause reproduction of microorganisms.

Disadvantages of expanded clay coating:

- for horizontal installation, it is necessary to use the substrate due to the fact that it is very dusty;

- loses its insulating properties when wet;

- for high-quality insulation coating will require from 15 to 40 cm of material, due to which the height of the room decreases.

Noise insulation

The materials of this category with their small thickness combine the characteristics of the two previous types: absorb and protect from unwanted sounds. There are quite a few such materials. Consider the main ones.

Polyurethane foam

It is a fairly high-quality sound insulator. High adhesion strength is provided by special slots. The advantages include:

- fire resistance;

- non-toxicity;

- not exposed to acids and alkalis;

- moisture resistance;

- low weight;

- durability of service.

Among the important cons:

- "Afraid" of the sun's rays;

- Installation is carried out exclusively on a dry and warm surface;

- after some time it gets dark.

Polyurethane sandwich panels will cost a minimum of 1,138 rubles. per m².

PE foam

It is considered to be the cheapest option to protect against external noise. It is also called polyethylene foam, which is a soft roll with good thermal insulation properties (10 mm of material replace 15 cm of masonry with bricks or 15 mm of mineral wool). It is necessary to distinguish several varieties of such a sound insulator.

- Molecules unstitched polyethylene foam is not connected to each other in a chemical bond. Reduces the level of external sounds by 3-4 dB. This option has the lowest cost.

- Some molecules of physically cross-linked material are combined into a rather dense structure.That is why sound insulation with such material is slightly higher. Due to this, the sound insulation capacity increases - the noise level is reduced by 5-6 dB. Such material is often used to insulate ceilings.

- Molecules chemically cross-linked, respectively, are formed in a reliable chemical compound. In this connection, the sound insulation performance is much higher than the previous varieties.

However, regardless of the type of material, polyethylene is excellent as a sound insulation material for parquet and laminate boards or for installation of concrete screed. And also it is used to strengthen the joints.

Among the general advantages:

- durability and reliability;

- chemical resistance;

- moisture resistance, which sometimes leads to mold;

- low cost.

The disadvantages are:

- combustibility;

- reacts negatively to ultraviolet, because of which protective properties are subsequently lost;

- wearability

Cork backing

Laminated material, which is made of pressed oak bark and other wood elements. The decorative layer can be made in different colors and texture. The protective layer is wax.

There are several variations on the shape and size of the coating.

- Wallpaperwhich are quite simple and quick to install. In addition, the great advantage is the possibility of acquiring such a material with a self-adhesive base. Do not differ in high cost in comparison with the materials possessing the same characteristics, and will be suitable both for office, and for premises.

- Roll coatingwhose minimum thickness is 2 mm. Unlike the previous version, the roll coating is more durable, however, the gluing process is much more complicated. Here, for the installation, you can use only the adhesive composition.

- Wall plates are made from the remnants of the two previous options, but they do not lose in quality. A significant advantage is the ease of mounting and elementaryness in the preparatory work - gluing does not require alignment of the walls.

Among the general advantages of sound insulation stopper:

- absolute environmental friendliness;

- not exposed to moisture;

- does not conduct electric current and does not accumulate charge;

- variability in the choice of color and shade;

- resistance to mold and mildew;

- does not keep an unpleasant smell and dust;

- non-standard appearance;

- excellent sound insulation;

- can be used as a heat insulator for rooms;

- high-strength and wear-resistant material, despite the fact that it is quite elastic;

- incombustible with special treatment;

- does not need special care.

Disadvantages:

- in spite of the fact that the arrangement of a room with other noise-insulating materials with similar characteristics will cost more, you will have to spend a lot on natural cork insulation: the cost per package of 2x2 m is 360 rubles;

- subject to mechanical stress;

- flammable without proper handling;

- burns out over time;

- difficult dismantling.

Styrofoam

It is produced by saturating the polymer mass of polystyrene with gas, after which it increases in size and fills the entire space. The market can be found in the form of mats with a thickness of 2 to 10 cm. Absorbs up to 25 dB of noise. It is fixed to the surfaces with the help of special glue, polyurethane foam or liquid nails. Other features include:

- due to its low thermal conductivity, it is a good insulant; 11 cm of this material replaces a wall of silicate bricks two meters thick;

- resistance to dampness;

- durability till 60 years and durability, despite differences of temperatures;

- not affected by fungal growths and molds;

- environmental friendliness of material that can be used even for products;

- Expanded polystyrene is very light, so that transportation and installation will take not so much time and effort;

- fire-resistant varieties of material at a fire temperature of + 490ºС have the property of self-damping and reflow, so that the fire does not spread;

- low vapor tightness;

- it is not affected by alcohol or ether, but it is better to protect the surface from solvents;

- resistant to mechanical stress;

- it is universal in the sphere of use: water pipes, roof, floor, slopes of doors and windows, walls.

Sound absorbing membrane

This versatile material is a flexible polymer in the form of rolls. Mounted on a wooden crate between the two slats, because of what you need to install a two-level frame, which will take from 6 cm to 10 cm of room space. Therefore, it is better to use such a noise insulator in a room with high ceilings.

Membrane features:

- Great for all kinds of surfaces;

- at a thickness of 3 mm, 26 dB of sound is absorbed;

- possible combination with other noise insulation coatings;

- resistant to tearing and damage;

- flexible and flexible;

- environmental friendliness;

- long service life.

The disadvantages include:

- considerable weight, when installing it is better to use three or four people;

- high cost - the price of a roll of membrane 6.1 m² - from 8,473 rubles.

Acoustic plasterboard membranes

The functions of the material include not only noise isolation, but also damping, preventing reflections from surfaces. This action is achieved through the through holes that play the role of resonators, due to which the sound waves fall into the "trap". Acoustic drywall is often used in recording studios, rehearsal rooms, cinema halls, and lecture halls.

The distinctive features of the membranes from the usual drywall are special openings that provide sound absorption and a coating of non-woven soundproofing cloth for installation. In addition, all materials are environmentally friendly and

Benefits:

- effectively corrects the background sound for low frequencies;

- easy and short installation;

- the possibility of painting in any color;

- refers to the material of the so-called dry construction;

- safe and environmentally friendly.

Despite the positive side, there are such minuses:

- decorative coatings are contraindicated, because of this, the material may lose its key properties;

- exposure to moisture;

- the difficulty in installing additional items on the coating due to the fragility and a large number of holes.

The cost of a sheet of acoustic drywall - from 1 100 rubles.

Acoustic foam rubber

Quite popular today material due to high-quality absorption and dispersion of sound vibrations. Such a noise insulator is especially effective in panel houses. In addition, there are different variations in thickness - from 25 to 100 mm, and on the relief surface.

Advantages of acoustic foam rubber:

- universality of use on various planes;

- possibility of use both in combination with other materials, and independently;

- easy and easy installation with simple glue or double-sided adhesive tape;

- small weight;

- high sound absorption index.

Among the minuses:

- subject to accumulation of dust;

- service life of not more than 7 years;

- The room, insulated with acoustic foam, most often looks darker.

Fiberglass

Resilient and eco-friendly modern sound absorber. In its composition has a fiberglass yarn that glue chaotically, and organic resin. As a result, a material is formed with a porous surface and without any pattern.

Very often it is also called “cobweb”, the main advantages of which are:

- anti-corrosion properties;

- does not cause an allergic reaction;

- durability and reliability;

- fire resistance;

- allows you to level the surface;

- not subject to mechanical stress;

- resistance to temperature extremes;

- not afraid of moisture and mold;

- ease of use;

- does not save electric charge;

- good steam capacity;

- possible staining;

- affordable pricing policy.

The only significant drawback of fiberglass is that the particles in the composition of the material can harm a person, so when installing it is important to always use gloves (during cutting) and protect the respiratory and vision organs.

Aerated concrete

It belongs to the class of environmentally friendly materials and is considered an ideal option to minimize the size of interblock joints. The remaining space is filled with special glue.The main materials of noise insulation for aerated concrete are: polyurethane foam, polystyrene foam and cork slabs.

The use of aerated concrete is advisable due to:

- fire safety;

- high vapor permeability;

- environmental friendliness;

- long service life;

- simple processing and cutting;

- excellent sound insulation properties with a ratio of 43-44 dB.

Distinctive flaws are represented by:

- negative influence of moisture and high level of frost resistance, due to which block deformation occurs;

- mechanically weak, as a result of which there is a need to use special expensive fasteners;

- The declared low cost and durability is actually overestimated by manufacturers.

The price per cubic meter of aerated concrete blocks starts from 2500 rubles. / m³

Foam blocks

The most popular material for a reliable, durable, soundproofed and heat retaining home. The uniqueness of the material in flat and closed pores filled with air. This is the best sound and heat insulation. With norms SNIPa not less than 41 dB for interroom partition characteristics of the foam block fully comply with the requirements. As well as positive qualities are:

- reasonable price and profitability;

- environmental friendliness;

- good thermal conductivity;

- fire resistance and fire safety.

The disadvantages include:

- with increasing strength of the foam block decreases air space in it;

- absorbs moisture well, because of which thermal insulation properties suffer;

- does not let the air through, therefore it is said about such buildings that the building “does not breathe”;

- unsatisfactory level of rigidity and density for multi-storey buildings;

- the negligent attitude of many manufacturers in the manufacture of foam blocks of the same size, because they are visually identical blocks, but in fact with a difference of up to 3 cm, which significantly affects the sound insulation properties of the material.

The price of one foam concrete block is from 40 rubles. However, it all depends on the size, density, method of manufacture and raw materials. Therefore, the cost can reach up to 240 rubles.

Today it is increasingly possible to encounter the so-called CIP panels. The buildings of this material are called "Canadian", since it was in the harsh climate of Canada that this technology was formed. The method of erection of CIP panels is used for fast and inexpensive construction of a frame structure.It is a structural insulating panel, which includes a layer of insulation and sheets of OSB on both sides.

Polyurethane glue is used to join the layers when using a press with a pressure of 18 tons. The insulation material already mentioned is polystyrene foam. However, despite the fact that this method has been used for a couple of decades, many still are incredulous about the construction of CIP panels.

Among all the others, soundproofing is a separate kind, which comes to the rescue when the wallpaper is already glued. To solve this problem, you can use carpet on the floor or on the wall, install a furniture wall against the wall, from which there is noise and hang curtains with thick curtains. This option will reduce the noise level by 30%.

Manufacturers

When choosing a sound insulating material, it is important to focus not only on the price, but also on reviews of manufacturers. The modern market is rich in a range of products, both domestic and foreign firms. Among them:

- Russia - MaksForte, Acoustic Group, Techno Sonus, TechnoNicol;

- Ukraine - AcousticWool;

- France - Isover, Texdecor;

- Germany - Wolf Bavaria;

- Italy - Mappy;

- Sweden - Ecophon;

- Denmark - Rockwool.

French manufacturer Isover –One of the world's top 100 industrial groups. The company focuses on sound-proof material in the form of rolls or plates, made from special high-quality Thermistar fiberglass. With an insulation thickness of 5 cm, noise absorption of 45 dB is ensured. And also commercially available acoustic ceilings. The cost is fully justified by the quality.

Ecophon - Swedish company producing sound insulation for various surfaces and rooms based on mineral wool. Among the distinctive features - simplicity and speed as the installation and dismantling. In addition, they are easy to clean, it is possible to choose the desired level of noise insulation - offered from 25 dB to 50 dB. However, one must be prepared to pay for such a material the price is above average.

Rockwool - It is considered the world leader in the manufacture of stone wool noise insulation. The materials of this company are fireproof, durable, moisture resistant and have excellent sound insulation. Among the wide range and plates, absorbing sounds and warming the room. Cost is available.

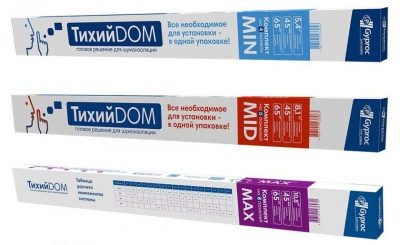

The innovative system “Quiet House” of the world famous brand is popular in the Russian market today. Gyproc. The manufacturer focuses on creating comfortable conditions for work and leisure of the consumer. "Quiet House" allows you to provide high-quality sound insulation and reduces the degree of airborne noise up to 12 dB.

The insulation panel, which is 1.5 cm thick, is a super-durable acoustic sheet and a soundproof, high-density mineral wool plate that are glued together. The kit includes all accessories and detailed instructions for installation. Besides the fact that all materials are environmentally friendly and absolutely safe for humans, the system is highly durable and can withstand up to 65 kg on one dowel-butterflies.

How to choose?

To select a sound insulation system is important:

- determine what kind and direction of noise is supposed to be eliminated;

- select the category of building to which the room belongs;

- decide how many centimeters of space are ready to lose;

- set a budget.

In addition, before starting work, you should familiarize yourself with some common noise insulation myths.

- Myth I. To isolate from external noise, it is enough to mount the material exclusively on the wall, from which the sound comes. Unfortunately, this will not be enough. Noise isolation muffle the sound, but the work will not be done until the end. For high-quality insulation, it is important to pay attention to interfloor joints, communications systems and technological openings, and other weak points.

- MYTH II. Manufacturers strongly advise costly thin but effective noise insulation rolls. In fact, membrane technology is ineffective, and in practice the application will be effective only in conjunction with traditional methods of noise insulation. To a greater extent, it just turns out to be a commercial, since high-quality sound insulation with such material will require a minimum of 10 cm of coverage.

- MYTH III. To solve the noise problem, only sound-absorbing material is needed. To answer this question, you just need to understand what is the time between the sound insulation and sound-absorbing coating. The first protects against external noise, and the second absorbs sounds that occur indoors, and prevent the appearance of echo.

- MYTH IV. For sound insulation of the premises is only enough foam.Such advice can only give an illiterate expert. Expanded polystyrene is rather rigid in structure and differs in a closed cellular structure, which is why contact with the wall can lead to a resonance of mid-frequency sound waves. And since they are inherent in the human voice, the neighbors are likely to be heard even better.

- MYTH V. To choose a high-quality sound insulation system, it is important to initially pay attention to the airborne sound insulation index. Since the calculation of the index was carried out in Soviet times, and therefore mainly focused on speech and television noise. Today, low-frequency noises from subwoofers, home theaters and home appliances have been added to this list. It is because of this, in addition to noise absorbing material, a thick lining layer is required.

Installation

Installation is preceded by some preparatory operations:

- dismantling of old wallpaper or decorative panels;

- dismantling of sockets and switches, previously de-energized wiring;

- pull electrical wiring out of boxes and sockets;

- expand the dimensions of the wiring to the width of the noise insulation;

- isolate exposed wiring during repair;

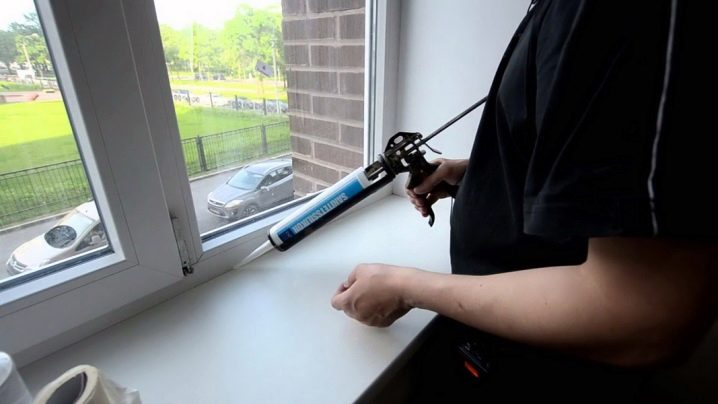

- using mounting foam, fill the slots and box;

- see the presence of cracks in the walls, if they are detected, use a solution of cement.

Next, you can conduct noise insulation in accordance with the type of surface.

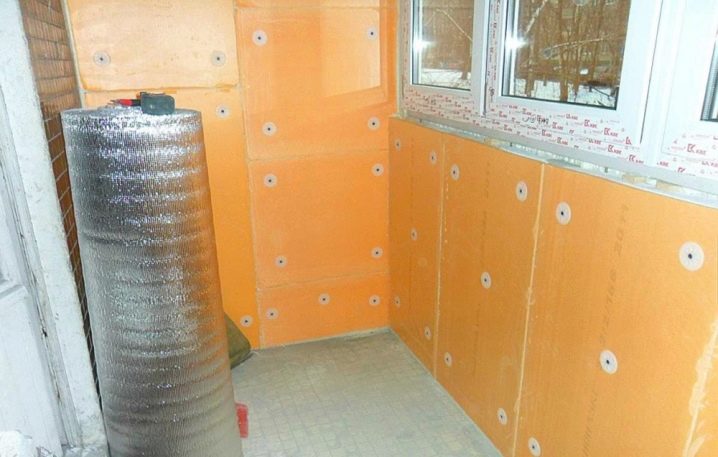

Soundproofing walls

Initially, you will need to design the frame of the steel profile. The joints are sealed with an elastic substance (rubber and the like) to eliminate the penetration of vibrations. As soon as the frame is ready, the wall is completely covered with sound insulating material. The wider the formation, the more reliable the isolation of the room will be. The next step is to screw the sheets of drywall.

Soundproofing ceiling and floor surfaces

The ceiling is soundproofed in the same way as the walls - on a frame structure with rubber gaskets at the joints. And then the space inside is filled with a material that absorbs noise, using either a glass mat or foam rubber, sound insulation plates, mineral or basalt wool. Given the fact that the thickness of this design is small, it will reliably save neighbors from above from such an annoying stamping.

Sound absorbing materials such as fiberglass, special paper, foamed polymer or other synthetic fiber are used in soundproofing the floor. Taking into account the small thickness of these materials, the layer is placed under the screed or laminate during installation. This design will dampen all vibrations. And if a sound-insulating layer is laid on top, then between them it is necessary to place a film for waterproofing.

Soundproofing installation boxes and sockets

As mentioned above, the isolation of this part of the surface is also an important stage in the complete protection of the apartment from noise. However, this stage of repair is still better to entrust to specialists. Having de-energized, having disassembled and having pulled out the socket, a dense sound-absorbing gasket is placed in the hole. It can be mineral wool, asbestos cloth or a thick scrap of cardboard. The final step is to cement the hole using a plaster mix.

In the same way, the sound insulation of the installation boxes, most often located under the ceiling, passes. A plastic plug is removed from it, a noise insulation washer is installed and cemented. Before installation, make sure that the network is free of voltage.

Soundproofing joints, windows and doors

In soundproofing joints, you will need a screwdriver or chisel.With the help of tools cracks gently expand, thoroughly cleaned, primed and plastered on top. After drying, the area is covered with acrylic sealant. To eliminate the gaps between the surfaces of the floor and the wall under the baseboard used silicone sealant, which is pasted over with a special tape. Eliminating sounds from the street contributes to the installation of soundproof glass with triple-glazing technology, while reliably sealing the gaps between the wall and the glass.

It is logical that a thick door will let through a smaller amount of noise. In addition, for high-quality insulation around the perimeter of the door, you can use a gasket in the form of rubber gaskets.

Useful recommendations

Experts recommend to carry out sound insulation at the very first, rough stage of repair of the room. And a few more helpful tips:

- strictly observe the established installation technology, performing in detail each stage;

- for the development of the project of noise insulation with minimal space reduction, it is better to contact the specialists in this field in order not to lose the useful area;

- installation of insulation from the sounds to begin with the surface of the wall, then proceed to the ceiling and then - the floor;

- It is important to remember that soft and lightweight material does not belong to the soundproofing contrary to the declared qualities of the manufacturers, it acts as a sound absorber;

- The basic rule for sound insulation is the multi-layer and heaviness of the material;

- the metal frame should not touch the wall; all parts must be glued with a damping vibration damping tape;

- all seams must be sealed with a soundproofing sealant;

- insulation materials must be environmentally friendly and anti-allergenic.

On how to soundproof a wall with your own hands, see the following video.