Soundproofing ceiling: the subtleties of the choice of materials

What can be done to improve the sound insulation of the apartment? This question is asked by many tenants of new buildings. Special discomfort experienced by the owners of apartments in panel houses, as the walls in them are very thin. However, no one is immune from such troubles. Even in a monolithic or brick house the first time will be noisy, because all the neighbors must make repairs, bring furniture and much more.

According to sanitary standards, the daytime allowed noise level from neighbors should not exceed 65 dB, and from 23: 00 to 7: 00 - 45 dB. But in practice, few people follow these rules. These indicators characterize the limit safe for health, however, you cannot call it comfortable either. Most often, the neighbors above are the troublemakers.

If you do not want to hear other voices, footsteps or the sounds of a working television, then you should think about good sound insulation of the ceiling. Going to the hardware store, learn in advance the types of modern materials designed for these purposes. At present, their range is so great that without knowledge in this area, you can make a mistake and make the wrong choice.

Special features

To pick up sound-proof materials, it is necessary to take into account various nuances. This is the thickness of the ceiling plate, the type of noise you would like to muffle, etc.

If you are not lucky enough to live in a panel house with fringe neighbors, the feasts will be annoyed day and night, which means that the insulation will require the most serious. If the neighbors above are quite adequate people and usually follow the rules of living in an apartment building, then we can restrict ourselves to standard methods.

For example, install acoustic stretch ceiling. He well “extinguishes” the sounds of footsteps, electrical appliances and other household noises.

Types of noise

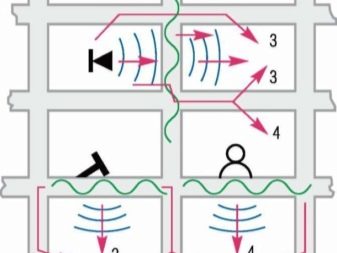

Noise can penetrate into an adjacent apartment from the bottom along the ceiling, through the slots, holes for pipes. To answer the question of how best to soundproof this or that apartment, you need to decide what sounds bring discomfort to its owners.

Consider the classification of noise coming from the neighbors above:

- Airy These include conversations, sounds of music or television, and other such sounds.

- Drums. They arise as a result of mechanical impact - for example, it can be sounds from the loud trampling of children or nailing a nail into the wall.

- Structural. This category includes noises, which, as a rule, are not connected with the actions of people. These are sounds of ventilation, elevators, water pipes and other communications.

- Acoustic. This group of noises can be singled out quite arbitrarily, since it is usually a problem for a particular apartment, and not for the house as a whole. It can be solved by the owners themselves when they fill the apartment with furniture and there is less free space in it.

Surface preparation

The installation of sound absorbers for ceiling construction is done in a variety of ways. They are planted on glue, laid between the guides of the batten or fixed with “fungi” dowels. Sometimes it makes sense to use several fixing methods at once, in particular, if the surface of the ceiling is not ideally even. So glued or mounted between the guide plates can also be fixed with "fungi".

No matter what type of sound insulation you prefer, you should prepare the ceiling surface before work. This will help to prevent mold sticking or mold. If the ceiling is so well painted and fairly even, then you can start installing sound insulation materials right away - a painted layer will be used as a primer. If the ceiling is damaged, then its covering should be completely or partially removed.

Next, go around the ceiling with a stiff brush to brush away the dust and particles of the old coating, which prevents high-quality grip when sticking. Now proceed to priming the surface of the ceiling and walls 100-150 mm from their joint. To do this, use special compounds with antiseptic. Couples-triples will be enough. At the same time, it is important that each of them is applied after the previous one is completely dry.

The joints of the ceiling and walls, as well as the corners should be handled at a particularly high quality This is where mold is usually wound up. The primer forms a durable film on the surface that protects against the development of dampness. In addition, it improves the adhesion of materials.

Selection of materials

The range of materials to create "acoustic comfort" in the house is constantly updated, but their main types remain the same. These are drywall, construction wool, polystyrene foam, drywall, wood and cork. Among the materials of the new generation are membrane, liquid sound insulation, felt, coconut filler.

Each material designed to combat extraneous noise, has certain characteristics. In terms of functionality, they are divided into two main groups: sound absorbing and sound insulating.

Sound-absorbing materials are soft, have a fibrous or porous structure. When a sound wave comes into contact with them, it first stops and then completely dissolves. The prims of such sound absorbers are known to all - mineral wool, construction paralon, felt. Sound insulation materials on the contrary differ in density, they reflect the sound. This is concrete, brick and other analogues.

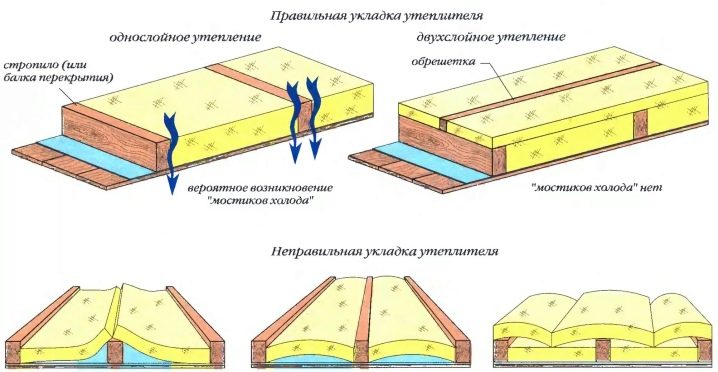

The best option is the simultaneous use of materials from the first and second groups. It turns out a kind of sandwich with two layers of sound insulation on the outside and the core of the sound absorber inside.In general, in the case of sound insulation, multi-layered structures are always a better option. They not only more effectively cope with the task, but also allow you to create more secure and durable structures.

In high humidity rooms, mineral wool may become damp and moldy.and if you add a membrane layer to the structure, this will not happen. Those who fear using cotton wool because it can release harmful particles should be covered with a layer of drywall. Judging by the reviews, such designs are very popular due to the good value for money and functionality. By this principle, SPTA panels are made, which are widely used for sound insulation of rooms.

Plasterboard constructions can also be filled with natural materials: a reed plate made of ordinary reeds, cork or coconut. The price for such a silencer will be much higher, but for those who like eco-repair this option will have clear advantages. To make the choice is to examine in detail the various materials for sound insulation. We will tell about the most popular of them in detail.

Styrofoam

This material is made from foamed plastic. Its varieties - polystyrene foam and polyurethane foam - have long been used in interior decoration, including for the suppression of noise coming from neighbors. It is inexpensive, while having good heat and sound insulating properties. Make it a ceiling structure is quite simple. Thanks to its porous structure and low weight, it can be easily mounted on any surface using “liquid nails”. However, it is believed that in the absence of a tight overlap over time, the foam can move away from the surface, which negatively affects the functionality of this material.

Installation of sound insulation of foam in the apartment - not the best solution. This material has significant drawbacks. When the room is heated, it begins to emit harmful substances into the air. Moreover, for this process, even a slight increase in the usual temperature is sufficient. In addition, all materials based on foam are flammable. With the advent of more modern materials, it began to be used less and less.At a frequency of 500 Hz, it neutralizes 40% of the sound, and at higher frequencies, this figure can reach 100%.

Mineral wool and acoustic plates

It is widely used for sound insulation of mineral wool, which is made from rock melts. It can be purchased in plates of a suitable size, but this sound-proof material has a rolled release form. A sheet of cotton 50 millimeters thick dampens the sound with a frequency of 1000 Hz by 75%. Unlike foam, it does not burn, but if you do not take care of waterproofing, it can become damp and become a source of mold. In addition, when wet, cotton wool does not do its job well.

Minwatu should not be used in the room where the installation of point and mortise fixtures. It prevents the removal of heat energy, which can lead to damage to lamps and the melting of the wiring. A regular chandelier or invoice lamp "make friends" with this material is much better. You need to work very carefully with mineral wool, especially if you are using glass wool instead of stone - it is capable of emitting small particles. To ensure safety, use a respirator as well as gloves and goggles.

Acoustic plates are made on the basis of cotton, but have “built-in” protection against water and the release of particles. This function is performed by additional overlaps located on both sides. For a more reliable waterproofing they are impregnated with a special compound. One of the most popular varieties of this product is the Shumanet plate. With a thickness of 50 mm, it is able to absorb up to 100% of the sound.

In general, many people consider mineral wool unsafe for health. But its sound insulation properties are so high that its popularity does not decrease. For those who are still afraid to use this material in his apartment, you can advise ecowool. She appeared on the building materials market relatively recently, but has already gained popularity as an effective and safe sound absorber. According to the manufacturers, its sound absorption coefficient reaches almost 100% with a sheet thickness of only 25 mm, while only cellulose with antimicrobial and fireproof impregnation is used as a component. This makes ecowool acceptable for use in children's and other living rooms.

Soundproofing materials based on wood and cork

For many, the tree is a favorite building material, since at all times it was highly valued for its reliability and high environmental friendliness. Today it has found application in the production of sound insulation. One of the popular options is the Isoplat panels.

Boards consisting of wood fibers do not contain glue and harmful additives. Available in various thicknesses - 12 and 25 millimeters, there are options both with moisture-resistant paraffin impregnation, and without it. At 25 mm slabs, the sound absorption coefficient is 0.95, that is, 95%. An improved version of "Izotex" is a "sandwich" with layers of decorative coating.

To mount them enough to use the "liquid nails." Additionally, the panels are grooved for better grip. However, it is important to take into account that they are mounted not on the ceiling itself and not on the frame of the suspended structure, but on drywall.

Membrane and liquid sound insulators

Membranes are materials not to absorb sound, but to reflect it. They are made on the basis of rubber, polymers and minerals and very effectively combined with a wadded or woody sound absorber.A popular varaint from this category of products is the Teksaund membrane. This thin, but heavy coating is more expensive than the above soundproof materials. Suitable for the manufacture of both frame and frameless systems.

Liquid membrane analogues are based on polymers or bitumen. They are produced in the form of tubes, like “liquid nails” or polyurethane foam. One of the most famous brands that produce liquid insulation - Green Glue.

Installation of structures

Make a good sound insulation of the ceiling is not so easy. As a rule, in order to achieve tangible results, it is necessary to mount impressive structures, and the soundproof material becomes “stuffing” in them. Installation can be done by hand, but if your experience in repair work is not enough, then you should entrust this responsible job to a special team.

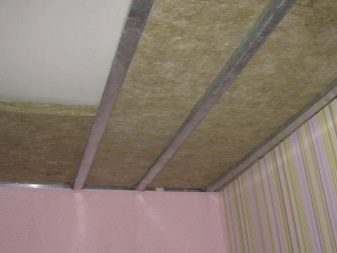

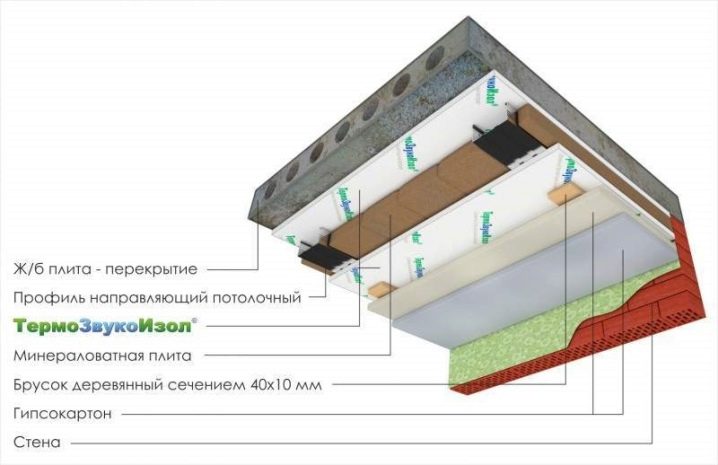

Suspended systems are a very popular and reliable way to solve a problem. extraneous sounds. Thanks to them, a cavity appears between the floor slabs and the plasterboard ceiling layer, and all the material for sound absorption is placed in it. For greater efficiency behind the false ceiling,The formed niche is filled with porous material, which suppresses sound vibrations. The leader among such materials can be called Minvu and its derivatives. Usually its thickness is 50-100 mm.

The problem that occurs when using mineral wool is a restriction on the choice of ceiling lights. The reason is that the space, without good ventilation, the space under the ceiling becomes unsuitable for removing thermal energy. As a result, the lamps emitting it can easily burn out, and if the wiring is melted, the situation will become completely fire-hazardous. It is necessary to abandon the mortise fixtures, instead of them it is recommended to install simple chandeliers and overhead fixtures. If you plan to decorate the ceiling with a scattering of spotlights, then take another silencer.

Another method involves fastening the silencer on the ceiling and installing over the design of the stretch ceiling. It is necessary to take care that the cotton particles do not crumble. To do this, use a vapor barrier. Together with cotton, it is fixed to an additional frame of laths or metal.

If you do not want to install complex structures, you can try to install an acoustic stretch ceiling. Quality products of this class are able to neutralize noise from neighbors for 90% of the sounds. These designs include three layers. These are special minplates from basalt, cloth with micro-holes and membrane properties and baguettes. The installation of the acoustic ceiling begins with the fastening of the minplit, and then follows the usual pattern — a baguette is installed, and then the decorative canvas itself is distributed using a gas gun.

Membrane use

The canvas of this modern material has a thickness of only 3-5 mm, while it is able to absorb 20-25 dB of sound. The membrane is especially good for muting low frequencies and can be combined with any other materials. Mounting it looks specifically, so tell about it separately. It should be noted that it will not be easy to mount this coating alone, since it has a rather large weight.

- The crate is fastened to the ceiling using a 20x30mm bar.

- In order not to hold the membrane with hands, it is fixed under the ceiling with the help of hooks and thin tubes.

- Now it can be attached with screws to the crate with the second row of a wooden bar.

- The seams between the sheets and technological cuts are glued with a special tape.

Keep in mind that as a result, the ceiling will decrease by 6-8 cm, and the same amount will go to the suspended ceiling.

Tips

Do not neglect the primer, because on concrete ceilings there are rarely small cracks, which adversely affects the silence in the apartment. In addition, glue will lie better on the primed and dried surface.

Building products with similar names may have completely different specifics. For example, the soundproofing material "Shumanet-BM" is intended specifically for partitions, and "Shumanet-100" - for floors.

When laying the noise absorber in the suspension system, it must completely fill the ceiling, it is better to even take it with a small margin. If the "stuffing" will be at least a little less than necessary, the result may disappoint you and all the work will go to the smarka.

If we are talking about soundproofing a private house, especially wooden, it is important to choose fireproof materials. After all, if a dangerous situation arises, the owners may be absent, and then there will be no one to take action in a timely manner.

The most effective sound insulation is provided not by a specific material, but by a correctly assembled multilayer system. It should not only include various materials, but also be airtight, that is, not have gaps through which extraneous sounds will leak. Pay attention to the joints between the canvases. In places where the coating does not fit very tightly or where the existing method of fastening is not enough, you can use construction glue.

Also, the distance between the fastenings of materials should not be too large, usually a step is taken about 10-15 cm, otherwise they may sag. As a result, voids are formed that violate the integrity of the insulating structure.

Ceiling sound insulation is a very important process that requires a responsible approach and attention to detail. However, in order to achieve the best result, experts advise to make a complex sound insulation of an apartment - that is, not only the ceiling, but also the walls and the floor. Only with such an approach, complete silence will reign in your apartment at any time of the day.

On the intricacies of the choice of materials for sound insulation of the ceiling, see the following video.