Acoustic foam rubber: soundproofing for the ceiling

Any multi-family housing presupposes the presence of many different extraneous sounds. They can not only distract, but also affect the state of human health. Therefore, it is important to create comfortable living conditions in your home that will not be affected by external factors.

One solution to this problem is sound insulation of the ceiling and walls. For such works, several approaches and materials are used, among which special attention should be paid to acoustic foam rubber.

Basic concepts

Conventionally, all materials today can be divided into sound-absorbing and sound-reflecting. Acoustic foam rubber belongs to the first group of substances capable of qualitatively dissipating sound waves within its structure.It is made of polyurethane foam or polyester, which during technological processes are transformed into a lightweight porous material.

But do not confuse this product with conventional foam, as they have many distinctive properties.

Among the advantages of this product are several features:

- High-quality absorption of a wide range of sound waves. The reflection of sound practically does not occur, which makes it possible to obtain pure oscillations within a certain isolated zone (living room, recording studio, and so on).

- Simplicity and versatility. The material can be mounted on almost any type of surface. But often acoustic foam rubber is used for ceilings to minimize external noise loading. Installation of foam rubber does not require special skills and can be done even by an unprepared specialist.

- Resistance to damage. The substance does not rot, and also does not collapse under the influence of various fungi and microclimatic factors. It allows to operate foam rubber throughout a long time.

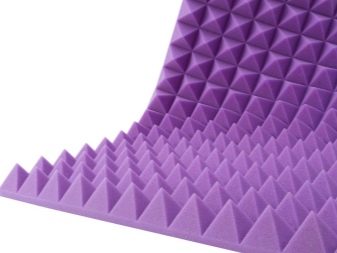

- Unique design. The panels can be complemented by different structure and color shades.Therefore, they are often not closed, as they fit well into the overall style of the room.

But acoustic mats cannot absorb low frequency sound. Therefore, you need to additionally use special "bass" traps. Such a complex is used only in recording studios, where the quality of acoustics plays an important role.

Environment of use

Sound insulation of premises is not always needed. If the noise level is significant, then you can resort to the installation of protective acoustic systems.

Foam rubber of this type is used as a sound insulation material in various places:

- Industrial premises. Especially often it is found in places where there are many different machines that produce not only noise, but also vibration.

- Enclosures mechanisms. Foam rubber is often inserted inside industrial air conditioners, as well as in diesel generators. But their lifespan is limited, as the material is quickly clogged with dust.

- Cinemas, television and so on. In such places, acoustic foam rubber is almost always used for sound insulation of ceilings and walls. Recording studios create “clean” rooms where you can hear and record your own voice with no impurities.

- Residential buildings. Very often in buildings of panel type the noise level is high.It spreads in most cases through the ceiling or walls, which are covered with such a substance.

Substances of this type are universal material. It should be understood that its characteristics do not depend on the place of attachment of foam rubber.

Principle of operation

Acoustic foam rubber has a porous structure. But its distinguishing feature is the presence of open pores, which are interconnected by microscopic channels.

The principle of sound absorption by this substance can be described by several actions:

- Sound wave hits the top layer of foam rubber. Often it has an uneven surface. This causes the flow to fight back and penetrate into the structure.

- The sound, getting inside the pores, begins to change the direction of its movement and begins to fade. This is achieved due to different air resistance, which reduces the amplitude of the waves.

Please note that the quality of sound absorption depends on many of the physical characteristics of foam rubber. Some of them are designed to work with medium, and some with high frequencies. Specific characteristics can only be specified by the manufacturer of this product.

Types of foam rubber

Technical characteristics of foam rubber depend on its surface structure. Depending on this, there are 2 main groups:

- Relief panels. The top layer is smooth, without any protrusions. This type of slab is universal, as it is used to eliminate any kinds of sounds. Inside, they are rarely used. From such foam rubber create sound-proof screens which protect people from noise on automobile highways. To extend the life of these structures, foam rubber needs to be periodically cleaned from dust.

- Relief panels. The main purpose of these products is to combat noise, as well as high-quality correction of acoustic indicators inside buildings. The substance absorbs sound waves well. Another advantage of the relief foam can be considered the ability to suppress oscillatory pulses. They can work with waves of different power.

The top layer may differ by the presence of different profiles. Today the market presents foam in the form of "waves" and "pyramids". But some manufacturers give it another structure that changes the properties of the product.

The color shades of these products may vary depending on the needs of the client. But many manufacturers produce black or gray foam, as in most cases it hides behind the finishing layer.

The thickness of the foam plates may also vary. Today, this value varies in the range of 5-100 mm. This parameter affects the sound-absorbing parameters, which allows you to create the necessary indicators inside the rooms.

Mounting technology

Many experts argue that it is possible to increase sound insulation in an office or residential area by installing foam rubber tiles on the ceiling.

This process is relatively simple and takes place in several sequential steps:

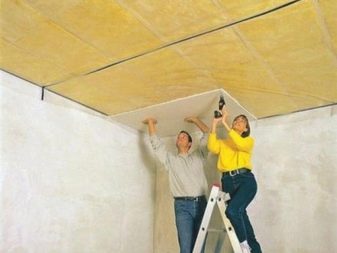

- Construction formwork. Here, the same approach is used as when wall cladding with insulating materials. Several wooden planks are nailed on the ceiling. The distance between them depends on the size of the panels themselves. It is desirable to align all the strips in the same plane, which will simplify their further decoration.

- Cleaning the ceiling. Theoretically, you can glue foam rubber on any material. For this purpose, special adhesives are used.But if the base is heavily contaminated, then it will not turn out to form a strong bond between the components. Therefore, it is desirable to thoroughly clean the ceiling before fixing the material.

- Mounting foam rubber. The process is relatively simple and involves applying glue to the surface of the ceiling, followed by fixation of the material. It is only important to evenly distribute the composition in order to ensure strong adhesion.

- Decorative trim. The process is completed by covering the ceiling with sheets of drywall. This material also absorbs sound waves well, so you can achieve unique and quality indicators of this design.

If this “embedded” system does not suit you, you can glue foam rubber mats directly to the ceiling without a frame. But this option does not always allow you to create a beautiful interior.

This is suitable for offices or cinemas, where all design attributes are customized to the same style.

Acoustic foam rubber is a unique product that can categorically change the level of sound insulation in the house. Before using this product it is important to consult with a specialist who will select the optimal type of panels,able to solve specific tasks.

How to equip a room for a home recording, see the following video.