Sound insulation sandwich panels “ZIPPS-III-Ultra”: characteristics and application

Noise isolation of premises for various purposes, both residential and industrial, has long ceased to be a rarity. Installation of sound insulation material in the walls, ceilings and ceilings makes staying in the room more comfortable. Noise isolation not only protects the inhabitants of the apartment from unwanted sounds, but also gives you the opportunity not to worry that their own household noises will disturb their neighbors. In this article, we will discuss one of the most effective at the moment panel systems soundproofing of the last generation.

A bit of history

The ZIPPS-III-Ultra panels represent the newest generation of frameless noise-insulating systems. The first developments in this direction were successfully mastered and introduced into production back in 1999. The innovative sound insulation system at that time was created and patented by the specialists of the company Akustik Group.

New soundproofing material received the name of IPPS (soundproof panel system). High rates of noise suppression and simplicity of the most insulating panel design immediately made this type of noise-reducing panels a leader in the market of similar building materials.

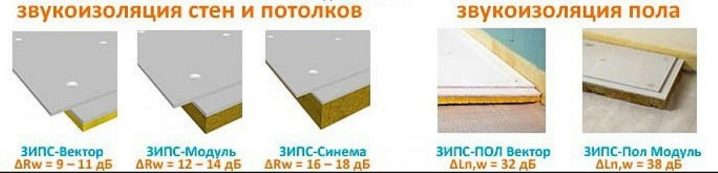

Despite the success of the first line of sandwich panels, manufacturers did not stop at the achieved result and continued to improve the quality indicators of their sound insulation systems. Soon the market came the construction of the second generation. These are soundproof panels "Cinema", "Vector", "Module".

In 2015, an improved line of third-generation noise insulation panels was released, dubbed “ZIPPS-Ultra”.

Special features

Despite the considerable external similarities with soundproof structures of the previous lines, the latest generation of IPPs have a lot of differences.These new qualities allowed these insulation systems to quickly get ahead in the market for building materials of this type and receive positive feedback from a huge number of buyers.

ZIPS Ultra panels include several components.

- The top layer of the structure is an AKU-line drywall sheet with a thickness of 12.5 mm.

- The basis of the insulation system is a two-layer sandwich panel. This panel includes a sheet of gypsum fiber and material "Shumostop", made on the basis of water-repellent fiber. Both materials, which are 2 layers of the same thickness, provide high levels of noise insulation properties of the structure.

It is also necessary to consider the specifics and main characteristics of the ZIPS-III-Ultra systems.

- The sound insulation system of ZIPPS-III can be used both in residential and in industrial premises. The range of this noise insulating material is 100 Hz.

- The panels showed high efficiency in suppressing a wide range of household and moderate industrial noise. These include: human speech, animal and bird voices,sounds of working household appliances and sound-producing equipment (radio, record player, TV, etc.), moderate building-level construction noise, medium-intensity percussion noises.

- The noise-absorbing design of the ZIPP has a convenient frameless attachment to the base, as well as a tongue-and-groove connection of the layers of the sandwich panel.

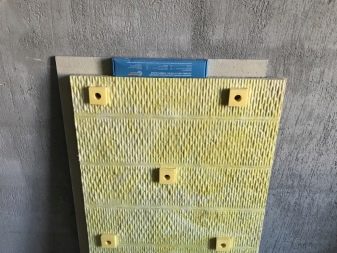

- The system has more advanced, in comparison with the previous lines, vibration-proof fastener assemblies (eight on each panel).

- The index of the additional noise absorption index is 11-13 dB.

- The system is recognized as the most effective and justified in the ratio "thickness / noise insulation index".

ZIPS-III panels are by far one of the thinnest, but at the same time high-quality and effective noise absorption systems.

- Third generation IPPCs are used for sound insulation of building structures made of single-layer materials: walls made of plaster, brick, concrete, partitions of various thickness, reinforced concrete floors.

- The size of the panels is 1200 x 600 mm, thickness - 42.5 mm.

- The weight of insulating sandwich panels is 19 kg.

- The thickness of the system, taking into account the finishing layer - 55 mm.

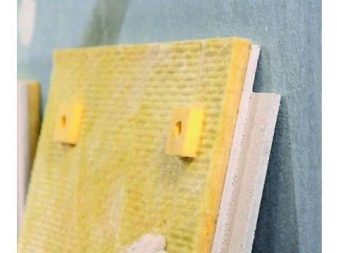

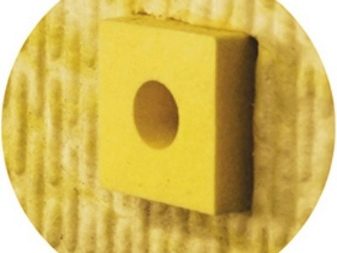

- The IPPS Ultra has 8 pillars located on the back side of the sheet of insulating material. They are made of elastomer. Each support has a thickness of 33 mm.This feature allows you to leave a distance of approximately 2 mm between the wall and the sound-absorbing sandwich panel. The resulting gap is an additional absorber of sound vibrations.

- This noise-canceling design is unique and protected by the RF patent № 2140498.

Completion of the ZIPPS-III-Ultra system:

- self-tapping screws (8 pieces);

- Fisher type dowels (8 pcs);

- metal anchors (4 pieces);

- washers-M5 (8 pieces), M8 (2 pieces);

- self-tapping screws GVL (10 pcs.), oxide (25 pcs.).

Rules for mounting structures

The ZIPP system is distinguished by its easy attachment to walls, ceilings, partitions or ceilings. In order that installation was made qualitatively, You should pay attention to some features of mounting and installation.

- As mentioned above, the sound insulation system of IPPM can be attached to any material. For the foundation there is only one requirement - its thickness should not be less than 80 mm.

- The ZIPPS-III-Ultra panels are mounted from bottom to top. It is also important to observe the mounting procedure from left to right.

- On the surface of the base should not be significant irregularities. A deviation of no more than 10 mm per 1 running meter is acceptable.

- Sandwich panels should not adhere to the flooring.It must be cut in advance, exposing the ceiling at the base of the wall to the desired thickness.

- All parts of the junction at the end of the installation are glued with anti-vibration tape.

- It is important to familiarize yourself with the installation instructions for soundproof panel structures and to comply with all requirements during installation of the system.

You will learn more about the installation of the ZIPS-III-Ultra panels by watching the following video.

Storage requirements

Sound-insulated panels ZIPP should not be stored in rooms with high humidity. It is important to exclude the ingress of water, condensate or precipitation on their surface. Storage is allowed in enclosed spaces with adequate ventilation.

The panels must be laid on the lining material, which may be wooden pallets or boards. It is also necessary to exclude sagging of panel structures.