The secrets of soundproofing apartments

Calm in a house depends on many things. This is the material welfare of the owners, and their good relationship with each other, and much more. But even when everything is in perfect order, it is desirable that everything be quiet!

What is it for?

Apartments, especially located in panel buildings, rarely boast excellent sound insulation. This is understandable: builders tend to save money and reduce the thickness of floor panels between individual floors. As a result, the slightest sound causes a lot of inconvenience. Problems arise due to:

- conversations;

- included TVs;

- playable music;

- movable furniture;

- even going to work or preparing dinner neighbors.

If a noisy company is going to the neighboring apartments or a repair is starting, there’s no hope of rest.But fortunately, modern soundproofing technologies allow, without prejudice to the neighbors, not scandal with them at the slightest pretext, and not leaving a well-maintained apartment, to solve the problem. It is impossible to reduce this work to laying the first available material, or even to the use of complex barrier structures.

Be sure to think through all the nuances. After all, soundproofing elements must be non-flammable, safe in sanitary terms and suppress precisely those sounds (in frequency, volume and origin) that cause inconvenience.

Causes of noise

In any apartment building there are many sources of noise, and not all of them are in the rooms of neighbors. The elevators and central heat points, water supply pumps, and meters make noise. Drumming rain on the roof, whistling and humming strong wind. Ride and honk cars, motorcycles, running various equipment on the street. And even if we confine ourselves only to noise generated in residential premises, they are diverse.

Each step and movement of people can create extraneous sounds. It would seem, well, that such a fallen knife, or in a knock of a fork on a plate,or in an open tap, or in a whistling kettle? But, combining with other noises, such “innocent” signals can create the feeling of a real cacophony. And even if they appear on their own, but they occur all the time, from day to day and from different apartments of the neighbors and last for a long time - damage to the nervous system is ensured.

In old houses, poorly attached or worn balconies visors create a strong noise in windy and rainy weather. But do not hope that the owners of the studio in the new building will be fully protected from extraneous sounds. Moreover, not a single structural material provides complete protection from all possible noises.

So, lightweight construction almost completely miss the usual household noise. A thick monolith is better in this respect, but only until a major overhaul is begun in one of the apartments. On massive parts of buildings, the sound of a drill, punch or construction mixer comes to all parts of the building.

For greater convenience, acoustics divide all household noises into drums and air. The second type appears as a result of the propagation of sound waves in space; It can penetrate through various building structures. This group includes:

- conversations with each other;

- included TVs, radios, home theaters;

- playing musical instruments and the like.

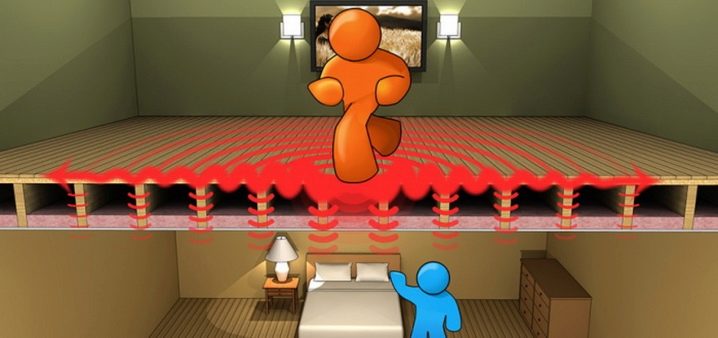

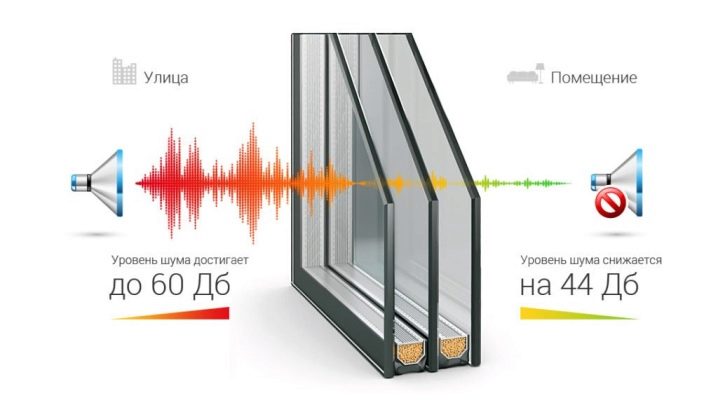

According to the norms, air noise should be attenuated by at least 50 dB, and in houses of a high degree of comfort - by 54 dB and higher. But the main source of concern is still the impact noise. It occurs more often, and almost does not go out in the air during propagation.

In addition, if those who like to fuss or watch movies at full volume can still be held accountable, then there are no sanctions for shock noises (except for repairs at an inopportune time). Stomping children, walking and running around the apartment (even at night), filling a steel bath with water - all this is completely legal.

It is possible to minimize the risk of airborne noise if you choose housing with reinforced concrete floors of at least 16 cm, and even better - from 20 cm. It is very important that the material has a minimum number of pores or is covered with a dense structure from the outside. The flip side of this design, however, is the enhanced holding of percussion sounds, especially with strong savings in sound insulation, typical of mass building.

Problems may also arise in case of violation of construction technology, in case of poor-quality performance of work. So, through cracks are categorically unacceptable, and if they still occur, it is required to immediately block them with a sealant over the entire depth.

To detect the presence of such defects is possible only when viewing an apartment in draft form, without finishing. Noise increases and in those cases where the instructions for installing partitions between apartments and / or rooms are violated. Only floating floor, which does not have rigid connections with any constructive elements, sufficiently helps to protect from the sounds from below.

In addition, if during the transfer of noisy areas of the apartment they find themselves next to the bedrooms in the neighboring dwellings, peace of mind is also disturbed. Now it remains to understand what to do with all this.

Criterias of choice

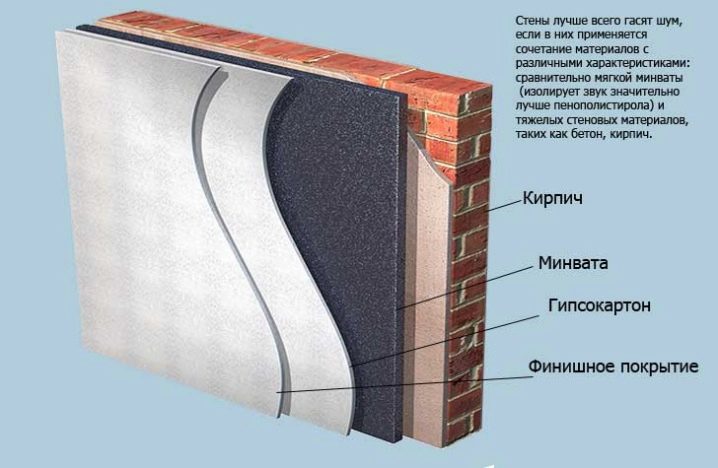

Choosing the appropriate solution in a particular case, one should not give preference to assemblies made of sandwich panels, because such designs let through too many sounds. Most often limited to any one type of material is unwise, where the best results gives a combination of them.Experts distinguish between two key types of materials: some provide the specified acoustics in the room, others only help to muffle the sounds.

It is appropriate to choose absorbing means when there is a disco or other entertainment institution nearby. It is necessary to use some materials in the bathrooms, others in the bedrooms.

Mineral cotton wool, which can block 98% of noise, provides a good help; also in dry rooms, soundproofing is provided by cork stoves. The advantage of the second option is a wide variety of dimensions, as well as the ability to isolate both walls and ceilings with one material. But you need to be prepared for a fairly high price of coverage.

If the goal is to use the most modern product, it is useful to pay attention to the ZIPP panels and the thermal-acoustic insulation. The second option is created from synthetic materials and perfectly dampens sounds, but only when stacked in several layers.

It is much more correct to use IPPs: these blocks are distinguished by the highest density and effectively suppress noise in two ways (reflection and absorption at the same time).The only negative is a very high price, but, given the ease of installation and other advantages, it is quite justified.

Important clarification: regardless of the type of material chosen, manufacturers' instructions should be strictly followed. Attempts to improvise, invent their own schemes, or rely on the words of "knowledgeable" people do not lead to anything good. Mineral wool should be used for areas where there is a high risk of fire, but its resistance to water is not large enough, so it’s better for the bathroom to look for another solution.

Cork slabs can be placed on any surface other than the ceiling, so it is recommended to negotiate with the residents of the upper apartment so that they put them under the base of the floor. It is best to consult about the chosen methods of protection from both sellers and builders who are to do the work. Only under this condition will it be possible to get a more or less objective picture.

It is not necessary to buy the most expensive options. But it is necessary to require certificates and licenses, they will say much more about the quality of a particular material or structure.

Materials

It's time to deal with specific types of materials for sound insulation. The leading place among them is now felt, the quality of this method of protection says at least the fact that it is actively used by professional builders. The undoubted advantages of this solution are low cost and high level of security, suitability for a variety of applications and conditions.

Felt insulation:

- resistant to moisture;

- only slightly burns, but does not ignite;

- does not throw out dust;

- relatively easy;

- does not prick hands when working;

- maintains stable quality even after compression.

The use of felt not only suppresses extraneous noises, but also increases the level of fire safety. This material is a good electrical insulator, and it can be safely used even in the immediate vicinity of electrical appliances and wiring. Felt designs contribute to the self-regulation of the microclimate in the premises, they selectively absorb and release water as needed.

Raw materials (sheep wool) do not cause any allergic reactions. A special processing technique (in which steam and water are used) allows felt to acquire very valuable practical qualities.

If you opt for a synthetic version of it, then there will be no problems, because it also uses a unique technology. It allows you to form a solid canvas. The felt is durable; its rolls and sheets flexibly vary in:

- thickness;

- specific gravity;

- coloration;

- technological parameters.

In any case, the material does not slide over the surface and is well crushed, instantly filling even the most hard-to-reach places. Felt is good for transportation, does not cause any inconvenience and does not require powerful transport, movers, special packaging and careful handling. Products made of coarse wool are used in the insulation of housing and industrial facilities, but it is quite acceptable to use them even in medical institutions.

Users can cut material into pieces of the length and configuration they need. Sound insulation felt is complemented by a special membrane that effectively absorbs whatever sounds you like.

If there are doubts about the possibilities of such a solution, they are in vain. Reviews about it are favorable even for the employees of recording studios, various organizations and institutions with a sharply unfavorable noise environment. Before using the felt base is required as carefully as possible. Plates of fiberboard, gypsum plasterboard and other materials are usually put on top of the protective layer.

To avoid the settlement of the felt mass by moth, it is possible to treat it with a weak solution of sodium fluoride and thoroughly dry it, then it is permissible to install the material both on the walls and on the ceiling.

The technical look of felt is primarily designed to retain heat. The difference is its low mass with a high density of fibers. The thickness of mass-produced products is always 1 cm. The structure of thick rolls is able to provide cover for metal parts. Acoustic grade is designed to guarantee insulation and sound insulation:

- frame constructions;

- attics;

- ceiling and floor coverings.

It is permissible to use this material to isolate floating floors from vibration effects. Acoustic felt is sold in the form of plates with a length of 250 and a width of 120 cm, but its thickness only occasionally reaches 10 mm. The combined version is formed by two layers: one has synthetic fibers, the other gives the structure the properties of viscous elasticity.

It is possible to mount such felt only with the help of complex systems of a professional level. It is used in floating screeds and suspended ceilings, it surrounds ventilation and sewer pipes.

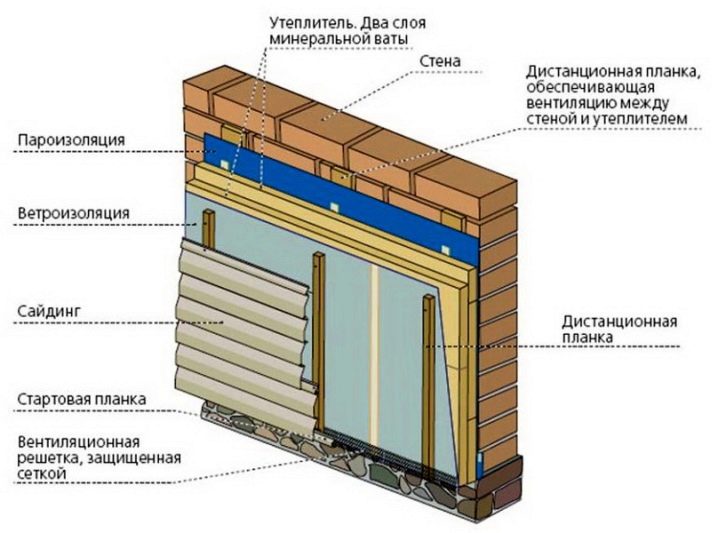

In addition to felt, there are a number of other materials suitable for sound insulation in the apartment. So, for this purpose, drywall sheets can be used, supplemented by porous substances - mineral wool, environmental wool, kraft paper. Protection against noise is obtained at a high level, in addition, the thermal protection of external walls is enhanced. But you have to put up with:

- heavy installation;

- significant dust generation;

- loss of a large part of the space (material has a thickness of up to 120 mm).

The use of decorative panels is quite widespread. To obtain them are used coniferous fiber. In appearance, such sound insulation is indistinguishable from the usual panel for wall decoration. The ends are supplied with spikes and grooves, which dramatically facilitates installation. Decorative coating of the outer layer allows you to do without auxiliary finishing.

Panels do a good job in finishing large spaces, but their cost is very high.An alternative can be considered plates on the basis of polyurethane, which are appreciated even by directors of record labels. Typical dimensions are 60x120 cm, and the maximum thickness is only 1.5 cm. Polyurethane structures are lightweight, easy to install and give an excellent effect. But their value is too high for most consumers.

Among the modern soundproofing means can be called special membranes. The thickness of each such membrane does not exceed 3.5 cm, which allows them to be used in close conjunction with other types of sound insulation. Installation is facilitated by the elasticity of the material, the ability to bend it at an angle. Decent density provides effective suppression of extraneous sounds. Unfortunately, like all not enough mass solutions, this material is worth a lot of money.

Plates of expanded polystyrene differ in external beauty and can be simply pasted on the wall. The thinness of the coating allows it to be used even in small rooms. As for the protective properties, they are only satisfactory, other materials have better results. The sandwich panel has a more powerful sound insulation, it is also easy to install.But the thickness of this design is unlikely to please the buyers.

Ways

Important: before buying any acoustic material should accurately measure the noise level. Perhaps very thick and powerful insulating coatings will be a waste of money. In addition, the thinner the product, the easier it will be to do it yourself. The use of foam for sound insulation does not make any sense, let it keep warm well, but the sound passes through without restrictions.

If you need to drastically increase protection, you should apply several panels or other blocks at once.

Heat efficient sound insulation is the most promising and convenient solution. Almost all the owners, carrying out repairs or settling in a new house, just such a design and prefer. The heat energy from year to year only becomes more expensive and therefore each gigacaloria obtained from central heating puts ever more pressure on the personal budget. And if the heat protection in addition also suppresses extraneous noise, this gives additional savings. The best combinations of such properties are:

- environmental cotton wool;

- cork in sheets;

- glass wool;

- mineral wool;

- isolon

Polyfoam and polypropylene are not effective enough in the fight against noise. If, however, you use tones under the wallpaper or applied to the wall, they will reduce the intensity of the sounds, but it will still be cold in the dwelling. Alternatively, you can make one layer of heat insulator, and the other of the sound insulator. But at the same time they should be combined with each other and not have contradictory properties. Thus, it is forbidden to mount any plates that would restrain this flow on heat-insulating steam-passing structures.

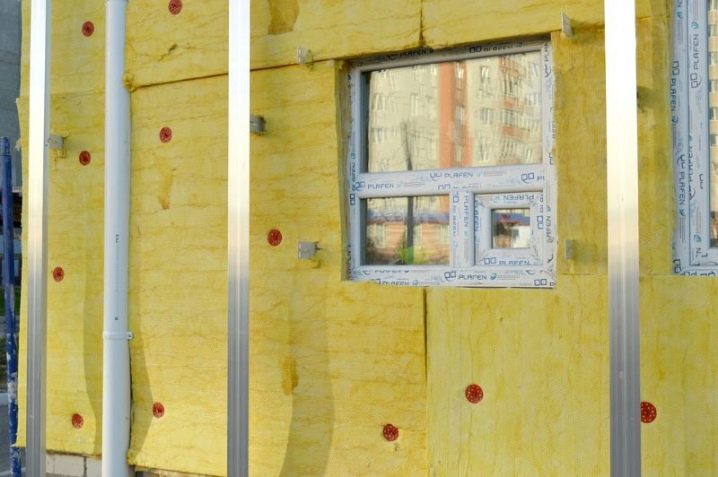

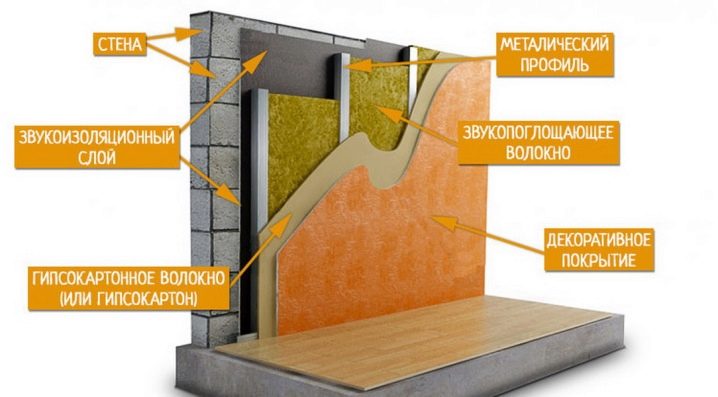

Mineral wool should be laid on the barriers to steam and water, attached by a stapler. A frame based on steel profiles is required, the installation step is 50 cm both vertically and horizontally. When filling the created structure with cotton wool, it is necessary to carefully control that there are no open areas. Fixation is done in the most convenient way. Close the construction to the outside:

- drywall;

- plastic panels;

- fiber board;

- clapboard.

Regardless of the chosen method of sound insulation, it is worth checking all the surfaces so that there are no gaps and holes.Any such defect should be eliminated before the start of the finish. Soundproofing with a cork is not dangerous for people suffering from allergies, but it may leave traces of heavy furniture on it. There are two outputs - either not to be used in the floors, or to pick up headsets, sets, taking into account this circumstance. Cork can be used in a variety of versions:

- plates;

- rolls;

- liquid mixtures;

- intermediate coating for other types of finishes;

- special kind of wallpaper.

To install sound insulation on the basis of cork is quite simple, but this work is very laborious and requires perseverance. Gluing of solid constructions is made on acrylic mixtures or contact adhesives applied both to the surface being finished and to the inside of the material. The contact way of work is considered the most rational professional builders.

It is required to control that air bubbles do not fall under the surface of the material. Glue a uniform layer spread over the entire surface.

Before fastening the cork should be kept in the room to be trimmed for at least 24 hours, so that it passes acclimatization. You can not work if the air is colder than 19 degrees, and the humidity is less than 35 or above 65%.Humidity of the walls themselves is allowed only in 3%, if there is no confidence in its value, drying should be carried out. Important: cork is incompatible with gypsum in any form. It is glued according to the same pattern as that of the tile, but they are trying to make the seams smaller, and put the materials into the joint.

Izolon attached to the walls with glue or with a stapler. The seams of sheets are thoroughly sealed with a special tape. Interestingly, insulation work using this material can be performed even outside the apartment.

All work that involves the formation of frames or crates, carried out after the vapor barrier. This requirement is especially important when installing wadded insulation. Before applying the glue walls are dried in any case and try not to carry out such work in the offseason.

Sound insulation in the toilet is no less important than in the rest of the apartment. All the responsible owners want to be heard there, and they themselves have not heard anyone else on the lower and upper floors either.

The easiest way to solve this problem in separate bathrooms, combined rooms require additional waterproofing.Such a room always has enhanced ventilation and exhaust, often contributing to increased hearing, but this problem is solved. A wooden door is categorically unacceptable, where plastic is better, since it dampens sounds more efficiently.

If metal door structures are being installed, they are recommended to be filled with mineral wool or another loose insulator. A good idea would be to supplement such protection with reflective sound membranes made of the most delicate materials. The best solution for sound insulation of the risers will be the use of special sleeves (according to the scheme pipe in the pipe), filled with sound-impermeable material. Often they are acoustic sealant. On the walls are mainly mounted mineral wool (50 mm) or sheets of plasterboard.

Soundproofing of floors is mainly made of ceramic tiles, it also helps to create an attractive appearance. It is desirable to supplement the composition with a pad of soft fabric. It compensates for the coldness of ceramics and will help to further increase the suppression of extraneous sounds. Upstairs most often put a suspended ceiling, supplemented with cotton or thinned insulating layer.Special films inhibit moisture and do not allow water to get on the substrate.

Some home craftsmen prefer to finish the floors of toilets by waterproofing of their own making, obtained from bitumen mastic, rubber and sheets, impregnated with bitumen. Reducing sound penetration to the limit will help seal the seams with silicone-based sealants. According to professionals, when soundproofing the toilet, the most optimal solution will still be the construction of plasterboard.

But not in all cases, the area of the room allows them to be used, especially given the mandatory air layer.

The crate is always encased by the protection against the spread of sounds, otherwise they will burst inside, bypassing the insulating layers.

Walls should be equipped with inter-room sound insulation not only in toilet rooms, but everywhere. It is unlikely that someone will be pleased when the neighbors can listen to conversations and watch through the wall while eating. Yes, and you can get rid of the role of supervisors and observers. Mineral and glass wool cope well with air noise suppression. From above in most cases it is recommended to mount the acoustic ceiling.

Shock noise suppressed:

- cork;

- polyethylene foam;

- cork rubber;

- combining bitumen and cork;

- composite materials;

- extruded polystyrene foam.

Struggle against structural noise is carried out using:

- fiberglass;

- sealants with vibroacoustic properties;

- elastomers.

Glass wool and ecowool is mounted only on the walls, which are leveled with putty or plaster. Metal crate is more practical wooden and less susceptible to the ravages of moisture. Above the insulation is placed a thin vapor barrier attached to the crate itself. Then finishing one or another facing coating is carried out.

For internal walls, a vapor barrier is not necessary, but its use may be associated with another point, that is, with the restriction of access to glass dust in the room.

As for the wallpaper, restraining the flow of extraneous sounds, they are presented in three main types:

- tapping;

- on cork base;

- based on synthesized velor.

Tafting contains two layers, essentially it is a pile on dense matter. Outwardly, such an insulator resembles a carpet.Synthetic velor is a paper pasted over with vinyl. The problems of such a coating are instability to moisture and low strength.

If you need the most effective sound and noise insulation, you should give preference to vapor-permeable cork-based wallpaper. But if the priority when choosing turns out to be moisture resistance and resistance to ultraviolet rays, it is recommended to pay attention to tafting.

Floor

Noise insulation of the floor in the apartments can be carried out in many different ways. There are just materials that have proven themselves for a long time, as well as the latest branded products. When choosing an option, it is worth paying attention, first of all, to its thickness. Absorption of sound systems containing wooden crates, quite effectively. But the frame itself and the plywood laid out on it will perform their function well only with a sufficient ceiling height. Otherwise, the useful volume of the room decreases sharply and it becomes uncomfortable.

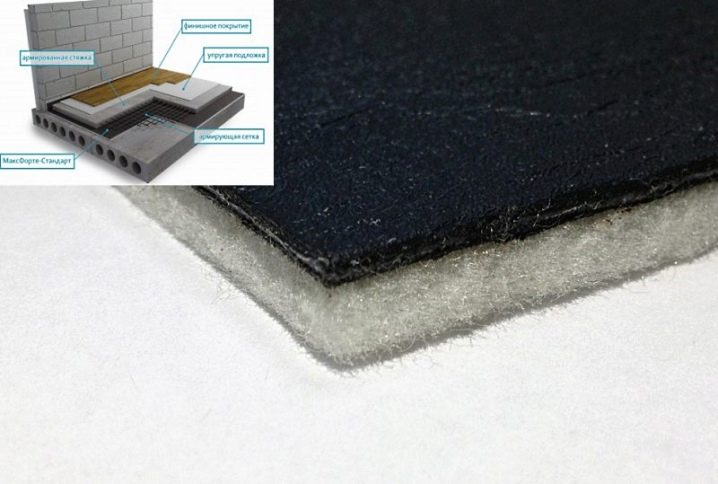

Often put on the floor insulation "MaksForte ShumoIzol." The soft surface is superimposed on the subfloor, and the hard edge, respectively, looks upwards.The outer edges of the winding on the walls, and unnecessary areas are cut. Joints outside smeared with liquid rubber. “NoiseIzol” reduces the intensity of impact noise to 27 dB.

The use of the latest plasticizers by the manufacturer makes it possible to avoid frequent tearing and cracking. This material is impermeable to water. But slag, despite its insulating advantages, is hardly suitable for sound insulation. It is totally unacceptable in wet areas.

Stone basalt wool can be used both with a crate from a bar, and independently from it. Like the walls, there are no cracks on the floor.

Ceiling

Problems with the penetration of sounds through the ceilings are particularly relevant for panel structures. There, even law-abiding, sober and meek neighbors are disturbing. Partitions and floor slabs do not interfere with the downward sound that occurs when:

- loud conversation;

- phone calls;

- TV work;

- falling objects;

- steps;

- raising a chair or rolling a chair.

If the walls in the apartment are high, the space of choice is large enough. The most effective result is achieved using multilayer structures in which rolled material (reflective), plates (absorbing), drywall or gypsum fiber are combined.But it is important to consider that such ceilings are 75-120 mm lower than the rough substrate.

In rooms with low wall arrangement, it is recommended to apply noise insulation under suspended ceilings. It, too, is sometimes made of several layers, but already thinner, reducing the upper-leg in the assembly by only 30-60 mm.

However, in the absence of problems with the height of the room, no one will prohibit the use of thick frame blocks, reinforced gypsum fiber, under suspended ceilings. The use of the frame increases reliability. The composition of such a system, in addition to crates and fixing its guides, includes:

- vibratory suspensions responsible for holding the frame as a whole;

- vibroacoustic sealing material;

- various plates, membranes, shields and panels in a specially selected combination;

- sealing tape that prevents the sound to go along the profiles;

- drywall

GKL can be applied both standard, and specialized (soundproofing). The applied design is guaranteed to reduce the noise from above by 11-20 dB (if you do not take into account the deceleration of sound by the base overlap itself). Under stretch ceilings, the frame system is formed on the basis of wooden slats, whose thickness is approximately 25 mm. Frameless version under the tension structure is formed:

- main sound suppressing material;

- dowel-nails in the form of a plate;

- glue;

- hanging canvas.

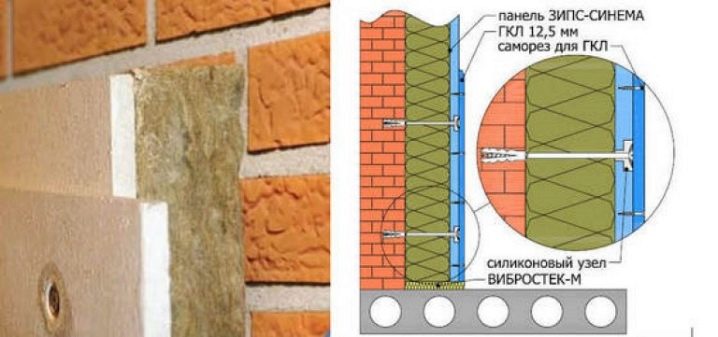

The total thickness varies from 1.4 to 4 cm, but the noise-reducing properties are noticeably less than in the first case, they do not exceed 9 dB. In another scheme, apply:

- vibration isolating pad;

- sealing compound;

- ZIPP sandwich panel;

- fasteners;

- the final layer of gypsum, attached to the panels.

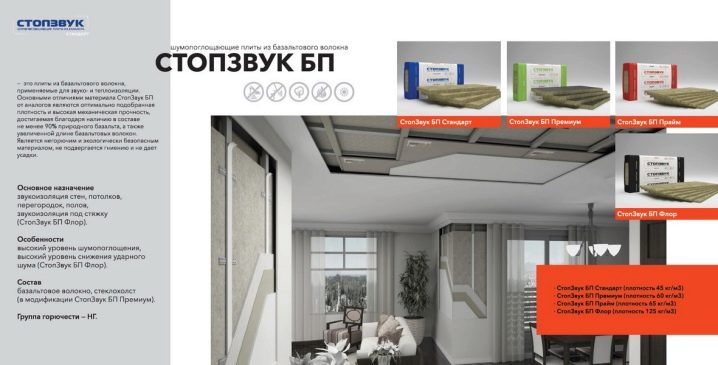

Such protection can reduce the sound intensity by 11–18 dB, and its thickness varies from 5.5 to 13.3 cm. If fibrous plates (made of mineral wool, polyester or glass fibers) are used, Rockwool, Stop Sound, Schumanet products should be preferred. And Akulayt. "StopSound" is an insulating membrane, characterized by high density and minimum thickness. They reflect sound waves without absorbing them at all. The problem can only be an increased price.

How to do it yourself?

Technology installation of sound insulation is highly dependent on what kind of material is chosen. So, it is desirable to put the plasterboard sheets on flat, devoid of cracks walls covered with a layer of plaster.If the wall is a stable source of noise, it is impossible to put the gypsum on it closely, just to fix it to the adjacent walls and windows. Then the mounts will still carry out external sounds. To fill the slots separating the plates from each other, assembly foam will help.

To put ZIPP, it is necessary to do auxiliary openings. If to supplement the panel with ecowool manually, it will also provide insulation. Rolled materials on the basis of absorbing films are attached to smooth and aligned walls, butylate is used for joining.

Before starting work on sound insulation, all sockets are disconnected and removed, and the holes that have appeared are filled with non-combustible materials, covered with an accelerated drying mixture. Next comes the turn of laying soundproofing in places where the pipes touch the wall.

How to strengthen?

Correctly improving the existing noise isolation is a rather complicated matter. It’s not at all necessary to hang carpets, as most of the twentieth century did. To increase the effectiveness of protection against noise, care should be taken to install reliable windows and doors. It makes no sense to isolate the floor, walls and ceiling, leaving the old wooden window, no.But the construction of multi-pane windows will be very useful.

It is recommended to choose those options in which the inner glasses are shifted relative to the geometric center. Increasing the thickness of the frame, thereby improving the overall protection. When choosing windows it is worth paying attention to the tight fit of the rubber seal. If it immediately or after some time cracked, cracked, it means that such a product needs to be changed.

It is useful to use more curtains made of dense matter.

Tips and tricks

There are other subtleties that will help to find, finally, the long-awaited peace of mind.

- You can assess the quality of the vibration insulation around the pipes by removing the top layer of cement and inspecting the sleeve. If a void is detected, the gap is cleared of debris as deeply as possible. After wrapping the insulating layer, the joint is again sealed with a solution that is covered with a layer of silicone sealant.

- Cracks in old panel houses are mostly filled with acrylic filler or sealant. Wadded materials in the gaps of the plasterboard frame are useful only if they are mounted on acoustically broken structures.Cotton wool should have a density of at least 35 kg per 1 cu. m

You can not believe advertising promises about the possibilities of ultra-fine sound insulation. The effectiveness of a two-centimeter coating cannot be acceptable, because according to the laws of physics, at least three layers are required at a minimum of 40-50 mm.

- If there is an opportunity to increase the air gap between the layers, it should be used. Competent assembly is more valuable than “breakthrough” and “innovative” materials. The efficiency of double structures is higher than that of single structures, but not always, but only if there are no hard links between the individual layers. A pair of brick walls 125 mm thick each and an air cavity between them is much quieter than a single solid brick 250 mm wide. When the frame is attached, you can only use fasteners of increased elasticity with a reduced resonance frequency.

- The best fasteners - specialized, the so-called vibrofix and some of its analogues. If possible, partitions should be attached to ceilings and floors using sound-insulating profiles. But confine this connection will not work, if you have to hang up TVs, heavy furniture.As the linings when choosing a direct suspension using fiberglass, polymer tape.

Ideally, vibration suspensions should be used, but they are expensive and not always commercially available.

- The use of sheet materials with unequal degrees of stiffness and thickness helps to increase the effectiveness of protection against noise.. Acoustically separated partitions are more profitable than foam concrete or tongue-and-groove slabs. They will help to block the sound of medium frequency and stop completely re-radiation of structural and impact noise. If you need to deal with the sounds of a subwoofer, air conditioning equipment or generators, it is recommended to use a full-fledged ceramic brick. Sound suppression of medium and high frequencies is recommended with the help of drywall attached to the frame.

How to make a soundproofing apartment with your own hands, see the following video.