Ways soundproofing sockets

Many are aware of the "zero" sound insulation in most of the pre-built prefab houses. Most often the sources of extraneous sounds in the apartment are electric points. This can be verified by approaching the ear to the outlet. The article discusses the methods of soundproofing sockets.

Special features

The manufacture of slabs of reinforced concrete involves the formation of loose cracks to simplify the work of wiring wiring. Repairmen carry out connection of several power cables to them. They connect a pair of flush-mounted sockets in the neighboring apartments.Sometimes they do not bother with elementary gasket with a soundproofing result.

Tenants need to eliminate this imperfection of standard construction using their own resources, otherwise their coziness will become stable and not always harmonized by the roar of neighbors. Through the air duct, bad odors, allergens, tobacco smoke and microbes are constantly being sucked into the apartment. Sound insulation sockets can be done on their own or use the services of specialists.

Upon detailed consideration, it turns out that the problem is resolved in one of the following ways:

- carrying built-in power sockets to a more suitable location;

- change the built-in outlet to the invoice;

- laying soundproof foundations under the outlet.

The first option is implemented by itself during the production in the apartment repair. When dividing and optimizing the lumen, the owners move the electric points from typical locations to more suitable places for connecting.

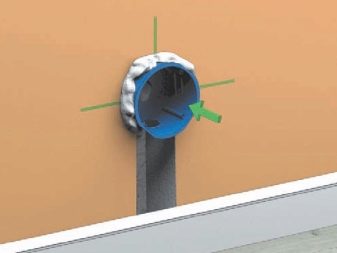

Hidden, internal or built-in called outlet, built into the wall. Outside is only the invoice decoration-protective console.Built-in sockets are used when dismantling hidden wiring. Their strobing is a time-consuming event, although they look neater. You can move the hidden outlet by drilling another hole next to the old one and running the wire under the wire.

The laid on socket is fastened on top of the wall surface under the external wiring. Its mini-body rises by 5 cm, but it is not always necessary in new buildings. When repair is not intended, it is more profitable and cheaper to produce sound insulation of an already existing hidden electrical socket. This is not as hard to do as it seems: the socket and the box are removed from the socket hole, the sound-proof base is placed in the slot, and the design is put in place.

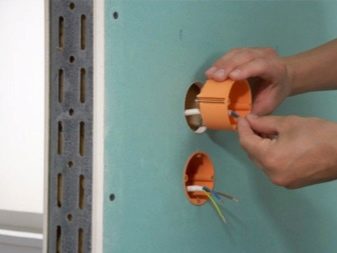

Removing the built-in outlet

First you need to remove the outlet. For this you need:

- To coordinate with the neighbors, because you can inadvertently knock over their outlet, causing a short circuit.

- Disconnect the electrical supply of the apartment on the panel.

- Check the mains voltage with a multimeter - there is no guarantee that the repairmen will correctly connect the power cable to the apartment.

- Remove the cover plate.

- To amortize the two screws clamping the adjustable feet.

- Remove the power socket design. Here you can see a few wires with ends rolled up in the terminals. The power cable traditionally protrudes from the top of the wall surface.

- Loosen the screws on the terminals and remove the socket strip. The ends should be wrapped with electrical tape.

- Here you can find the electrical (installation) box in a glass-shaped configuration that you need to get. The current boxes are made of plastic, the old structures - metal.

- Directing a flashlight, you can see the box outlet neighbors. When detecting the buildup of building solution, it is necessary to clean them, removing dust and pollution.

Methods

For built-in power sockets

Knojplity from reinforced concrete for panel houses have a thickness of 12-16 cm. The depth of immersion in the socket outlet is 6-8 cm. 4.5 cm of them will be filled by the installation box. If the neighbor gives permission for the right to fill in the insulation and its half, then it will be possible to get additional space of 2-8 cm in depth. When it comes to the basis of the soundproofing of the electrical socket, almost everyone thinks about the mounting foam. But in no case can it be used for a number of reasons:

- Filled from the outside, the foam will enter the neighborhood outlet. And the neighbors just do not like it.

- Combustible material If contacts sparkle in the socket, then dry polyurethane foam will burn out.

- Foam well eliminates drafts, but its sound insulation properties are weak.

There are other more comfortable and less dangerous sound-proofing materials in the assortment:

- building composition;

- corrugated cardboard;

- basalt wool;

- basalt cardboard;

- gypsum cardboard;

- sound insulation membrane.

They can be used at electrical points.

Solution

The density of the building mixture is close to concrete. You can use a handful of the finished composition, dilute with water and, in a certain number of ways, form a strong, cemented joint between the ducts. But first you need to place a thin cardboard or plastic lining in the hole, otherwise the water can cause a closure in the network of neighbors.

The solution is quite inexpensive and quite effective for a long time, because even a mixture of alabaster requires a certain time for solidification.

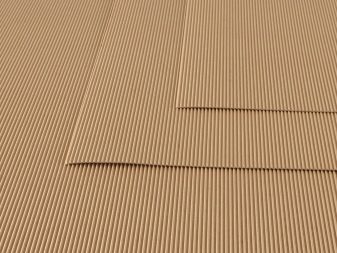

Corrugated cardboard

Corrugated cardboard - material, always available at hand, is produced in the form of packaged boxes. The thickness of a three-layer corrugated cardboard is from 1.1 to 3.4 mm, five-layer - 5.5-7.0 mm. Corrugated cardboard provides good fire safety. In the temperature ratio, its combustion is 25 8С, which is an excellent indicator. Under the solution for soundproofing sockets, you can use a cement, plaster or water-alabaster mixture.

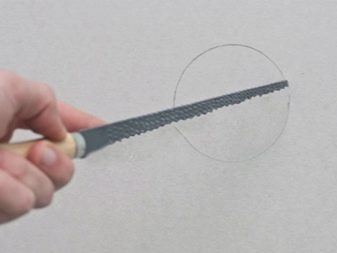

- Use a circular knife or scissors to cut a 3-4 circle (in the wall panel, the holes are 1 mm smaller in diameter). The combined thickness of the cardboard-plastic gaskets should be at least 5 mm from the socket clearance.

- Mugs should be placed in the depth of the rosette space - they can be fixed along the edge with silicone sealant.

- Then you should prepare a solution (1/2 cup), mask the washer and the walls of the hole.

- After that, you need to stretch the ends of the wire into the mounting glass.

- The glass fits in the hole.

- Following the drying of the solution, you need to insert and pinch the ends of the wires in the socket terminals.

- Then you need to turn up the wires: the block should be evenly distributed in the box.

- Following this, it is necessary to strengthen the outlet and re-adjust.

- The whole event ends with the insertion of an overlay panel.

Basalt wool or basalt cardboard

At performance of sound insulation of the socket from professional materials it is best to use mineral wool. It is used to insulate wall and roof structures and is completely safe. A circle made of a hard stone wool slab 50 mm thick will fit if the gap between the sockets is palpable. It is necessary to cut the washer by 2-3 mm wider holes in the wall. You need to press it with your fingers and insert it into the depth of the hole.

If the gap between your and the neighbor's socket is less than 5 cm, you need to take a five- or ten-millimeter basalt cardboard and cut a few circles. Basalt insulating base is an effective solution, but if no one you know warms the walls or the roof, then you simply cannot get a small piece of stone wool - it is not for sale.

Cardboard

Often after the repair there are pieces of gypsum cardboard. They can be used in the absence of basalt insulation. This material does not burn, but the sound insulation is weaker.From a sheet of sheet 12 mm thick, you need to cut a through circle of a slightly smaller diameter and fit into the depth of the rosette clearance. You can fix the sealant, then lubricate the solution. Insulation is also important for podrozetnikov, which can be obtained in this way.

Use of membranes

Builders often use membranes as excellent sound insulation. This polymer material in rolls with a thickness of 2-13 mm. In this layer, the sound insulation index Rw is 28 dB. On several layers, the rate increases. For isolation, it is necessary to cut several circles out of the membrane. They can not be joined, but they can be stacked separately - the elastic semi-rigid material itself is retained.

Power outlet

If you want to change the built-in outlet on the invoice, you will need patience. To do everything right, it will take several days. It is necessary to fill the cleared deepening with a solution in a few steps, wait for the area to dry and only after that screw in the new socket. If it is necessary that the moved electrical socket is also hidden, you will have to pierce the concrete for the wiring and drill a niche under the socket.

The nature of the methods and materials used for soundproofing of the interroom outlets is determined by the circumstances and possibilities of the owner. Solving the problem will require little financial and time costs. But without a stock of information and wiring experience this will be difficult.

By analogy with the deep sockets, you can make soundproofing of the mounting box with a new wiring in the apartment. Usually it is located directly under the ceiling - in the middle of a common wall with its neighbors. But in this place it is necessary to engage a professional electrician - without it, it is easy to confuse the wires and combine the wrong ends. It is unlikely that in the foreseeable future will change the special technology of manufacturing wall panels. Owners should immediately after settling perform sound insulation of the outlet openings.

How to make soundproofing sockets, see the following video: