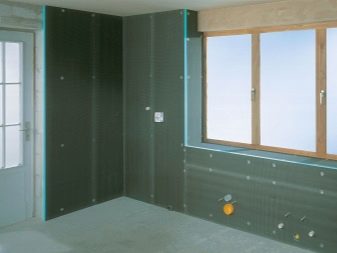

Application of ZIPS sandwich panels

The issue of sound insulation of buildings is a priority for those living in apartment buildings and in private buildings. As in the first, and in the second case, the tasks associated with noise insulation, the owners decide on their own. An excellent solution to the problem is the choice of sound insulation panels.

What it is?

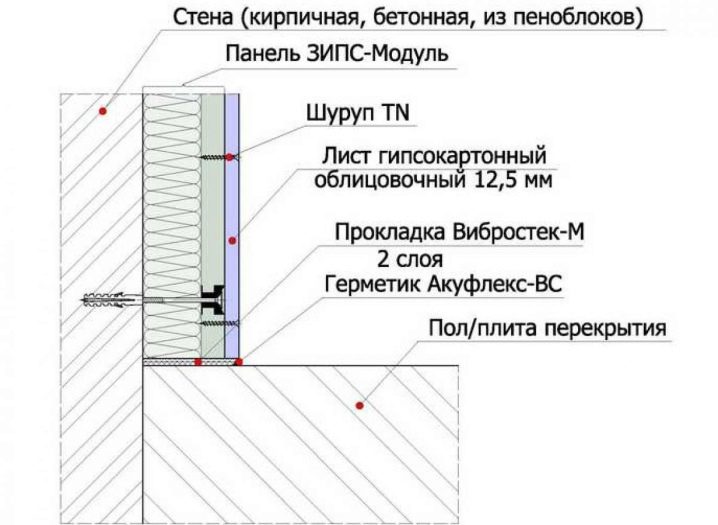

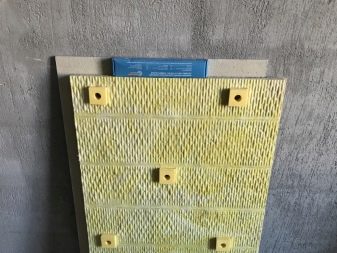

ZIPP panels are frameless soundproof construction. When there is no need to make panels without a frame, it is possible to make a quick installation of sound insulation. The panel fastening system is unique, patented. Vibration knots built into the panels not only make it possible to fix the plane, but also prevent the transmission of sound vibrations to the outer part of the structure.

Structures are multi-layered panels, which are currently widely used in the modernization of buildings and structures, as well as allow to increase the sound insulation of surfaces. The sound insulation is influenced by the composition of the panel, which includes the alternation of soft and dense layers, and a facing covering on top of them. The number of layers may vary due to the modification of the panel view. Panels can be mounted to all surfaces: walls, ceiling, floor. You can use dowels 5 cm long and screws with conical washers. The ends of the panels are glued to special elastic pads, and vibro-acoustic sealant is used as an adhesive.

The professional soundproofing system ZIPPS is suitable for soundproofing load-bearing walls and partitions in various premises. With the help of the system, the standard sound insulation indicators are achieved. The panels can easily cope with household noise, reduce the impact of intense noise in the range from 80 to 125 Hz. The soft base of the soundproofing material is fiberglass, the hard layer is gypsum fiber.The system comes into contact with the surfaces of their bricks, concrete, and also the gypsum plasterboard of partitions and ceilings through strip-type gaskets made of vibro-fiberglass. The system retains the basic acoustic principles laid down in building codes. Currently, IPPC is sold in several modifications that differ in acoustic efficiency.

Specifications

Frameless system is suitable for sound insulation of interior partitions, which are known to have extremely low insulation. Gypsum blocks with a frame system for such partitions are not suitable, since the thickness of these walls is usually small. The low insulation of partitions with a thickness of up to 75 cm is due to the low surface density. More partitions retain a pronounced resonance phenomenon. The wave phenomenon at critical frequencies affects the insulation efficiency of all building structures. If, on either side of the partition, sound insulation panels of the IPPS are mounted, they will significantly reduce the sound radiation of the partition in the operating frequency range.

The principle of operation of the panels is based on antiresonant resistance.Panels do not require additional use of gaskets and elastic sealants. The fastening units of the soundproofing panels can be patched with any putty suitable for gypsum fiber sheets. For example, the placement of the panel increases the sound insulation of the structure from 6 to 10 dB. Moreover, the less isolation the partitions initially possess, the more significant it can be increased.

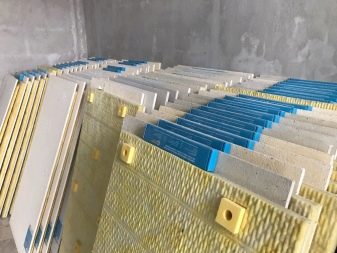

Installation of panels is very simple, the event is quite effective. IPPS panels are launched under the appropriate trademark, and therefore have such a name. The panel produced is ready for use without any modifications. For mounting the panel, special vibroulles are provided, which are performed at the production stage. The panel itself is a combination of dense and lightweight materials that vary in thickness. The range offered by the manufacturer includes several types with which it is possible to insulate walls with different characteristics.

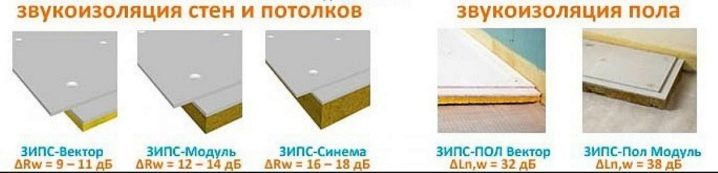

The lineup

"Ultra"

The ZIPS Ultra Ultra panel system is suitable for increasing the sound insulation of gypsum, brick, concrete walls and partitions.And also a sandwich can be applied to overlappings from reinforced concrete. The plate has been tested both in residential premises and in offices and technical premises. The physical and technical parameters of sound insulation are as follows:

- noise insulation thickness is 4.25 cm, and the entire system - 5.5 cm;

- sandwich panel weight - 19 kg;

- surface density - 36 kg / m²;

- construction efficiency;

- small thickness of the system;

- frameless mount;

- special anti-vibration nodes;

- The index of additional isolation of airborne noise is 11–13 dB.

The system includes special finishing GKL Akulain. In addition, inside the panel contains a combination of grooved-middle GFVS and glass fiber with a thickness of 20 mm. For mounting on the wall in a single sheet contains eight special vibration isolators. Supports protrude above the plane, but tightened during installation. The material has a certificate of conformity conducted acoustic tests.

"Vector"

IPDS "Vector" refers to the category of soundproofing panel system of the initial level. This is the thinnest additional sound insulation for walls and ceilings. It increases the insulation performance of existing brick, concrete walls, partitions, as well as reinforced concrete floors.It is usually used for additional isolation of verticals in private homes and technical premises. The effectiveness of the system was tested in the presence of low-noise household noise: speech, crying, sound equipment of small power.

Physical and technical characteristics of "Vector" are as follows:

- panel thickness is 4 cm;

- thickness of the entire system - 5.3 cm;

- weight - 19 kg;

- density - 36 kg / m²;

- fastening method - frameless;

- vibration-insulating nodes, tongue-and-groove joint;

- sound insulation index - 9–11 dB.

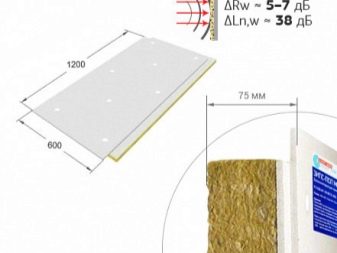

"Module"

ZIPS "Module" effectively solves the problem of sound insulation of existing walls and ceilings. The system copes with the noise level of 100 Hz. It is successfully used not only in residential apartments, but also in public buildings. The system is suitable for walls made of concrete, brick, reinforced concrete, as well as for the insulation of partitions. Cafes, offices, restaurants, shops, other establishments where background music is present, engineering equipment is used, and the system was appreciated. ZIPS "Module" includes panels with a thickness of 7 cm and a GKL finish coat. The layer of GFVL is 2 cm, and the mineral fiber plate is 5 cm.The panel includes 8 attachment points.

The physical and technical parameters of sound insulation are as follows:

- panel thickness - 7 cm;

- the thickness of the entire system is 8.3 cm;

- panel weight - 19.5 kg;

- surface density - 37 kg / m²;

- fastening method - frameless;

- index of additional insulation - 12-14 dB.

"Cinema"

ZIPS "Cinema" is an insulation system with high performance, suitable for special premises. The system is suitable for public premises with intense noise, as well as for insulation of residential premises. The operating parameters are 80 Hz. "Cinema" increases the insulation parameters, if the walls are made of plaster, brick, concrete. Cinema has been tested in recording studios, concert halls and in home theaters.

Physical and technical parameters of the panel are as follows:

- leaf thickness - 12 cm;

- system thickness - 13.3 cm;

- weight - 21 kg;

- density - 30 kg / m²;

- fastening method - frameless;

- index of additional insulation - 16-18 dB.

The advantages of the range are as follows:

- the ability to use indoors without carrying out "wet" finishing;

- good insulating properties against impact noise;

- good airborne sound insulation;

- affordability.

As with any other material, the IPPs panels also have disadvantages, such as:

- taking into account the dimensions of the panels, the cost of soundproofing a small room will be rather big;

- The use of ZIPP panels causes difficulties with mounting shelves, wall cabinets, mirrors. If you later need to hang something on the walls, it is better to apply the frame technology;

- There are difficulties with installing sockets and wiring.

Dimensions

Overall parameters of sandwich panels are as follows:

- "Vector" has 1200х600х40 mm;

- “Module” –1200х600х70 mm;

- “Cinema” - 1200х600х120 mm.

Application

For low-budget repairs, experts advise, nevertheless, to apply frame installation schemes of panels. Frameless technology has shown the best performance in sound insulation of the floor and ceiling. The floor in the apartment is soundproofed using two components: an elastic material and a leveling screed. If the base of the floor is even, then a clean floor covering can be used on top of some elastic materials.

Laminate flooring or parquet can be laid on leveling floor “Shumaplast”, “Schumanet-100Hydro”, “Schumanet-100Kombi”, “Shumostop”. In this case, the thickness of the soundproofing base is only 1 cm, and the design will have a good ability to isolate. At the same time, the isolation of impact noise will have values up to 43 dB, and the isolation of air noise - 8–10 dB. To improve the performance around the perimeter of the room, special edge plates are laid, and the seams between the materials are sealed with sealant.

Faster work can be done if you use the fast-assembled soundproofing panel system of ZIPS floor. The main elements of the system are as follows:

- ready sandwich panels;

- acoustic layer "Soundline";

- finishing plywood sheet.

Acoustic Triplex Soundline - This is a special three-layer material, which is a combined moisture-resistant gypsum-fiber sheets. Sheet dimensions are 1200x1200x17.5 mm. The material is characterized by high fire safety. An IPDS floor can be applied locally without damage to premises that do not require repair. The model range of ZIPS floor includes such systems as:

- "Vector". It is the thinnest system that provides standard sound insulation;

- "Module". The system has a thickness of 11 cm, provides effective insulation.

For walls suitable ZIPPA panels that need to be selected based on the characteristics of the model range. Ceiling materials can be divided into sound insulation and sound absorbing. The first option has a decent mass, and the second - usually a fibrous composition. Insulating materials reflect sound waves, and the latter - inhibit sound waves. It is considered that constructions with sound-absorbing material inside and sound-insulating material outside possess the greatest efficiency. For sound insulation of ceilings, the IPSU “Module”, “Vector”, “Cinema” or “Ultra” are used. With a thickness of 5 cm, the design provides additional insulation for airborne noise from 11 to 13 dB.

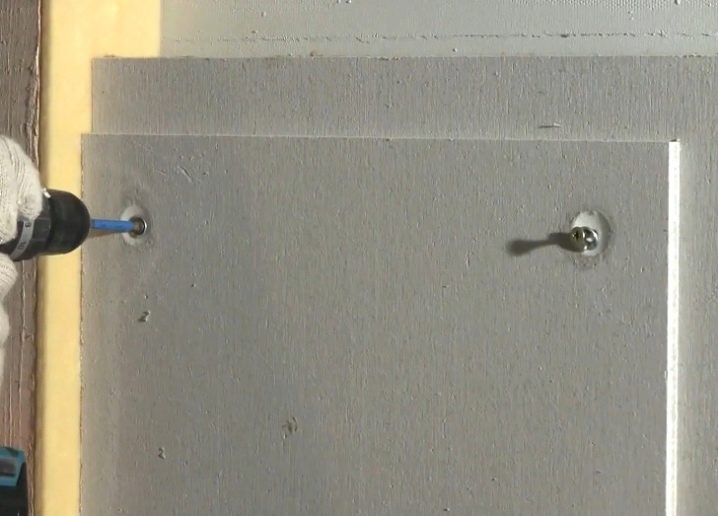

Installation

Mounting of ZIPP is possible by means of vibration-isolating units. If you need to fix the panel to the supporting wall, you can use six vibration dampers, leaving the central nodes loose. If the panels are fixed to the ceiling, then it is advisable to use anchor screws for the central units. When floor laying experts advise the use of hydro - and vapor barrier layers. Fastening screws through the nodes to minimize the effect of sound waves and vibrations.Installation work with the ZIPP panels is easy to do by hand. Any technological equipment and tools will not be required. One has only to consider, the weight of one plate is about 20 kg, so installation alone is almost impossible.

The installation stages of the ZIPP panels are as follows:

- fencing structures need to be treated with a layer of gasket type "vibro". For fixing applied sealant brand "Aculex";

- To fix the panels, you need dowels with self-tapping screws 5 cm long and 8 mm in diameter. Self-tapping screws must have an addition in the form of conical type washers;

- Mounting of ZIPP panels is performed from bottom to top. With each first panel, ridges are cut from both the length and the short side. The following panels of the first row need to be trimmed only on the long side;

- the first panel should be attached to the wall and, using a perforator, make holes in the vibration-insulating units with a depth of about 6 cm. Hammer in all the prepared fasteners with a hammer. Tighten the screw with a washer in the vibro node;

- All joints of the panels must be treated with Vibrosil sealant.

Recommendations

Reviews of the IPPCs are mostly positive.For example, users have noted good long-term insulating characteristics of the material. Residents of small apartments in central urban areas appreciated this material. People living in the center complain about noises from events, construction works. The IPDS successfully solves problems with street noise, but does not take valuable square meters.

Some users note the damage from the panels, which can occur during operation, as the AIPS cannot hold the weight of objects on the wall. It is noted that such a minus is not present in the frame system. Experts advise inconvenience in operation by installing additional GCRs over panels. Many users celebrate the free delivery of ZIPP panels ordered from official outlets.

For information on how to install the ZIPP sandwich panels, see the following video.