Frameless insulation of walls: the advantages of technology and methods of installation

In most cases, the construction of modern apartments of high-quality sound insulation is not given due importance. Therefore, installation of additional materials is required to reduce high sound levels. Frameless insulation of walls is one of the ways to solve this problem.

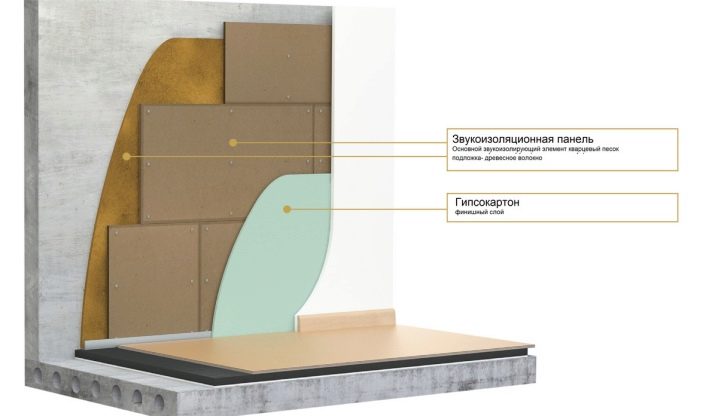

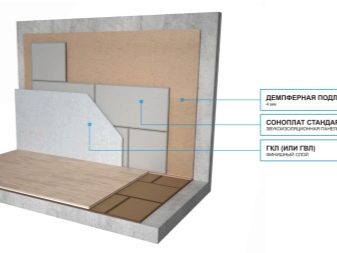

System device

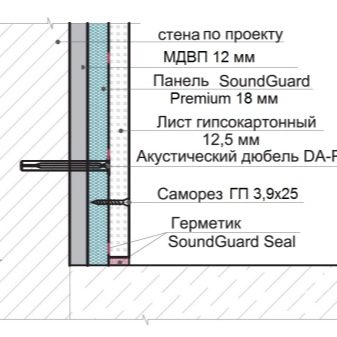

To reduce the penetration of extraneous sounds, it is necessary to create a structure in the form of a slab of sound-insulating layer and drywall. Fix it with mounting holes and acoustic dowels, through which the noise does not pass. Install the panel through tongue-and-groove connection. This is convenient and eliminates the distance between the sheets.

The thickness of such a protective system varies from 20 to 120 mm. At the expense of one or other parameters, sound reduction by 9–18 dB follows. To completely eliminate the gaps between the plates, in addition to the seams, a tape with soundproofing properties is used.

A feature of the frameless soundproofing technology is the fact that its implementation and further functionality directly depend on the quality of the preparatory work.

Materials

For the construction itself, gypsum-fiber sheets with sound-absorbing properties are used. To minimize the sound level, you need an impressive thickness of this material. Basalt or mineral glass wool is used for sound insulation.

These materials differ in their characteristics.

- Each panel has a vibration-proof assembly for secure fixing.

- The joints of the plates can be taped or glued with a sealant that does not allow noise.

- Panels should not be too tightly connected to the flooring.

This type of sound insulation is optimal in the apartment, as it involves the involvement of a smaller area compared to the frame option.

After installation, facing works are carried out using drywall sheets. For sound insulation, you should not use products made of gas-filled materials based on polystyrene, polyurethane and cellular plastic products (for example, foam plastic). They do not always comply with fire safety standards, they are not effective enough as sound insulators, they are more suitable for thermal insulation. Isoplat is the thinnest sound insulation plate. Its dimensions range from 12 to 25 mm. Gypsum fiber has a thickness of from 40 to 120 mm.

Technology benefits

The main advantage of such a system is the lack of a frame, which significantly reduces the budget and saves time for its construction.

There are other advantages:

- Frameless method is suitable for apartments (including small ones), since the panels have a minimum thickness.

- The tongue-and-groove system allows you to quickly and firmly dock the fragments of sound insulation.

- No need to buy and use anti-vibration mounts.

- Plates are fixed directly to the surfaces.

- After assembly, you can immediately begin finishing work.

Positive reviews about this method confirm that it is effective for apartments, private, residential buildings, small offices, educational institutions.Many users share that the assembly can be carried out independently, without possessing special knowledge. However, many people point out that it is not always this kind of noise isolation that makes it possible to completely get rid of annoying noise.

To install sound insulation without crates is possible only when the walls are almost flat.

Training

Proper and consistent preparation work is extremely important, therefore, you need to know everything about this process.

Before installing sound insulation will need:

- patch up any existing flaws (cracks, crevices and holes);

- conduct a thorough isolation of the electrical cable, pipes, ventilation ducts;

- notches in the zone of switches and sockets should be sealed with sound-proof materials with a porous structure (mineral wool).

Since the insulation is fixed to the wall with foam or glue, it is important that the surface is as flat as possible. The more scrupulous these requirements are met, the tighter and more reliable the connection of materials providing noise insulation.

If the surface is prepared, the mounting methods differ only in the type of adhesive base and how it is used.

- If foam is used, it is applied with a snake over the entire area and in the middle.

- Special adhesive composition for thermal insulation lay out dots every 30 cm with a thickness of 3 cm.

At the same time the smooth side is intended for finishing facing. Glue is applied on the rough side of the surface. After gluing, it is necessary to fix the sheets with self-tapping screws, the holes for them are additionally puttied

Installation

Upon completion of electrical wiring insulation, surface preparation and other necessary processes, sound insulation is carried out in accordance with the requirements of the selected system and according to the established technology.

- Carry out the arrangement of the acoustic substrate. The material is rolled on the wall, starting from the top and down. Then fixed with dowels, taking into account the fact that then remove them.

- Install the panel, they are fixed through sound-proof materials using plastic dowels in pre-drilled holes.

- Next, make the sealing of the joints around the perimeter, carefully close up the gaps around podozetnikov.

- All connections are additionally glued with noise insulating tape.

Now you can do the plating with GKL or GVL plates, securing them with ordinary (universal) self-tapping screws.

Systems

Premium Premium system refers to premium ready-made kits. Basically it is used to increase sound insulation in residential areas. It is especially relevant when there is a shortage of excess space. The combined panels have a thickness of 38, 2 mm.

Having excellent technical characteristics, such insulation is mounted quickly and easily.

This is due to the high quality of the materials used.

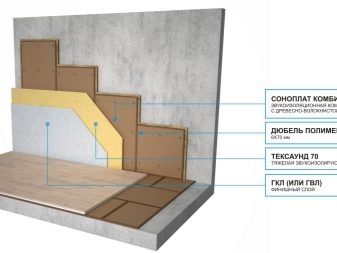

- Soundproof panels "Sonoplat Combi" - multi-layer plates for quick, direct installation. Three layers are a combination of mineral sand, woody porous texture and flexible elastic substrate. This allows you to install the panel on a straight surface of the walls and floors. The material reduces all types of noise (up to 62 dB).

- Inexpensive and reliable material for sound insulation "Teksaund" has a high density. Such a membrane is combined with Sonoplat Combi panels before final finishing.

- Special soundproofing plugs and vibro-acoustic sealant complete the set of modern, high-performance materials.

Similar properties are possessed by the Slim P system, the main component of which is the Sonoplat Combi stove. The thickness of this skin is only 34.5 mm, the isolation index in all frequency ranges reaches 59 dB. The plastic dowel included in the package makes transmission of sound vibrations minimal. The sonic anti-vibration sealant optimally fills all gaps between the panels.

There are other soundproofing structures that are more suitable for larger premises, as they have a more impressive thickness:

- "Vector" - 53 mm, insulation index 9-11 dB;

- “Module” - 83 mm, 12-14 dB;

- Cinema - 133 mm, up to 18 dB.

These are ready-made systems that can be mounted directly on prepared planes. In terms of their effectiveness, it is difficult to compare them with the Premium or Slim P options, but they perform their tasks. Soundproofing with frameless systems is a convenient and easy way to protect a room from various types of noise. Judging by the excellent recommendations of the professionals, it fully justifies itself.

For more details on frameless sound insulation of the ZIPS module walls, see below.