Sound insulation panels: a pledge of peace and tranquility of your home

Today, your own home is not only a guarantee of security, but also a place where you can isolate yourself from the hustle and bustle of the city. However, modern residential high-rise buildings can not always provide good sound insulation. In order to increase the level of comfort of housing and to isolate as much as possible from extraneous noise, various types of sound insulation panels are used.

Description

Solving problems related to noise absorption is an urgent task for modern cities.This is due to the specificity of the buildings, which implies a large number of people living in multi-dwelling complexes. This leads to the fact that the noise penetrates into the dwelling not only from the street, but also through walls and interfloor ceilings from neighbors living on all sides.

That is why, in recent times, many have begun to look for opportunities to minimize external sound stimuli by installing soundproofing structures in the apartment, called panels. For the performance of such plates various modern materials are used, as well as products that have long been widely used in construction.

Noise-absorbing materials in the construction market are in great demand, since sound insulation problems affect not only apartment owners in new buildings, but also people living in houses built for a long time, as well as residents of private buildings.

Experts identify two main ways with which you can reduce the noise load:

- stick on the walls of ultra-thin roll materials that can reflect sound waves;

- to sheathe the bases in the dwelling with sound-absorbing products, which are presented for sale in the form of porous mattresses.

But as practice shows, using together both methods of isolating an apartment or house from noise, you can get the most effective protection.

Starting to work on sound insulation of premises, it is first necessary to determine the sources of noise exposure in order to avoid unnecessary expenses for materials that cannot cope with the problem, as well as for additional insulation of the bases that do not need sound insulation.

There are several types of noise.

- Airborne noise is the most common form that prevents residents of apartment buildings. To it can be attributed loud conversations, sounds from the TV, dog barking and so on.

- Impact noise that arises from the mechanical impact on the structural components of the house. This may be, for example, repair work, the movement of pieces of furniture.

- Structural type of sounds - it is formed in the form of vibrations and focuses in the ventilation shafts or pipes.

- Acoustic noise - is an echo that occurs in empty rooms.

It is on the basis of the type of noise that is necessary to select the type of material for sound insulation.

Types and composition

It is a mistake to assume that the issue of the presence of extraneous noise is not so important a nuance, since the conditions of modern life in cities turn additional noise, even slightly exceeding the permissible rate, into a factor threatening a person. Since it is he who will interfere with the person to fully relax, which ultimately is fraught with nervous exhaustion.

Sound-proofing materials are produced on the basis of natural and synthetic raw materials, intended for laying on different types of surfaces, including walls, ceilings and floors.

They may differ in density, moisture resistance, resistance to temperature fluctuations, as well as installation method.

Among the having a range of sound-insulating panels stands out a few basic types.

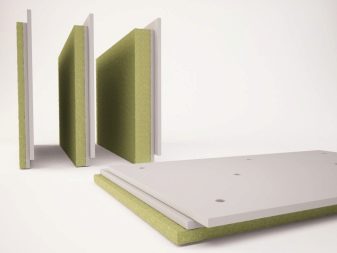

- Fiberglass plates and slabs of mineral wool. Typically, this material has a thickness of about 3 cm. Most often, this raw material forms a kind of sandwich in combination with gypsum board and gypsum fiber.

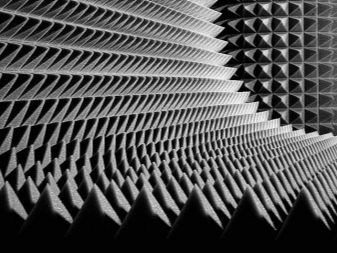

- Polyurethane panelswhich have the second name - acoustic foam rubber. Installation of such products is carried out using ordinary glue, so the installation of materials of this type is easy to do with your own hands.In addition, for the installation of polyurethane products there is no need to further align the work surface.

- Liquid soundproofing - it is notable for the fact that the method of its use is reduced to applying a material on the base of the material with a dense layer followed by leveling in order to strengthen the sheets of gypsum cardboard on top of the panel or to perform a decorative finish.

- Natural cork panels or cork film. This type of material belongs to the decorative finishing materials, however, due to its thickness of about 1 cm, it is used as sound insulation. When working with cork sheets, it is necessary to pay attention to the diameter of the product, which should be no more than 3 mm.

In addition, it is worth highlighting also soundproof sheets:

- Gypsum plasterboard and gypsum fiber used in conjunction with the main grooves.

- PIPS - consisting of the inner layer, represented by mineral filler, most often quartz sand acts as this component. Products require processing of the edge by sealing it with scotch tape, because when cutting products from panels, the filler can be poured out.

- Acoustic boards DVP and GSP - they are presented in the form of a layered structure containing a waterproofing, mesh for reinforcement, as well as polystyrene foam.

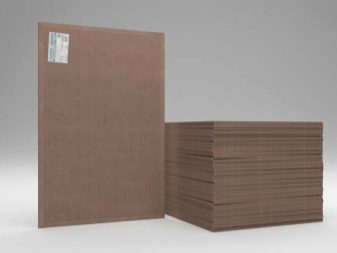

- Wood-fiber panels - coniferous woods act as raw material for the manufacture of the material. Despite the fact that the products are not very thick, the products provide good sound insulation.

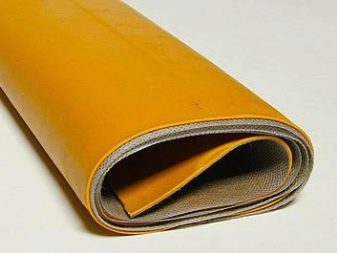

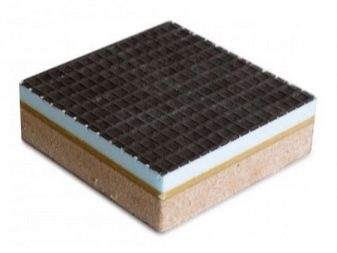

- Membranes that have a high level of density.

Characteristics and parameters

Deciding in favor of the acquisition of a particular type of sound insulation panels should be based on the advantages and disadvantages of the material. Therefore, it is necessary to highlight the following features of the above products:

- The design includes sheets of plasterboard and porous materialfor example, mineral wool, ecowool or cellulose filler, has positive advantages - the panel provides a high level of protection against noise, and also provides thermal insulation of external bases. The disadvantages of products include the difficulty of installing products, in addition, in the process of work, a large amount of dust is formed. This design should be installed only in those roomswhere square meters will allow it, since the thickness of the panels can reach 15 cm.

- Decorative products made softwood, are a set of wall panels with special spikes and grooves for mounting. They are popular due to their surface, which already has a certain design, as a result of which there will be no need for additional decorative finishing of the wall. In addition, the material is made from natural raw materials and is completely safe for humans.

According to consumer reviews, this type is perfect for installation in rooms with a large area. A minus of products is their high cost.

- Slabs polyurethane have excellent sound insulation properties, thanks to such features, the material is widely used in recording studios. Products are marketed in a standard size of 600x1200 mm with a slab thickness of not more than 15 mm. A positive feature of the product is the convenience and speed of installation, a high level of protection against noise. However, the products are quite expensive.

- Noise insulation membranes - are the material of a new generation, its thickness is about 35 mm, so that products can be easily combined with other heat and sound insulating raw materials. Membranes are very easy to install, in addition, they are plastic and can be bent at a certain angle. Despite the small thickness and flexibility, such products create a high-quality and reliable barrier that prevents the passage of sound. The disadvantages of products also include its high cost.

- Wall cork panels they are distinguished by their beautiful appearance; they do not require the use of specific technologies during installation, since they simply stick to the base. Most often the products have a minimum thickness. The disadvantages include the sound insulation properties of the material, which, in comparison with other noise insulation materials, have lower rates.

- Sandwich panels include fiberglass material between two sheets of plaster. As practice shows, these products provide a high level of sound insulation in the room, they are also easy to install. But it is necessary to take into account a rather impressive thickness of the panels, which is very important for small apartments and houses.

Manufacturers Overview

Quite a lot of materials for sound insulation of residential premises, in addition, they are represented on the market by a huge number of domestic and foreign manufacturers.

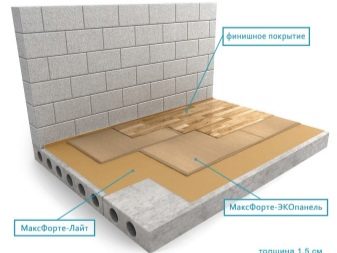

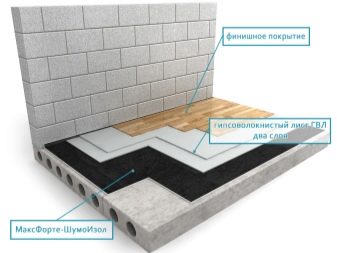

Domestic manufacturer "Maksforte" specializes in the implementation of innovative sound-proofing materials. Among the line of products presented are the following products - EcoPanel, ShumoIzol, Standart. All presented goods are safe for humans, therefore they are approved for use in civil and industrial construction.

Sound insulation panels from the company LLC "Rus" Korda " represented by multilayer products. Fiberglass is used as a soundproofing layer, and the outer layer is made of a spunboard. Materials vary in thickness. The advantage of the panels is flexibility and elasticity, which allows the use of products for fastening to various beams and floors. The material does not burn and provides an additional level of insulation.

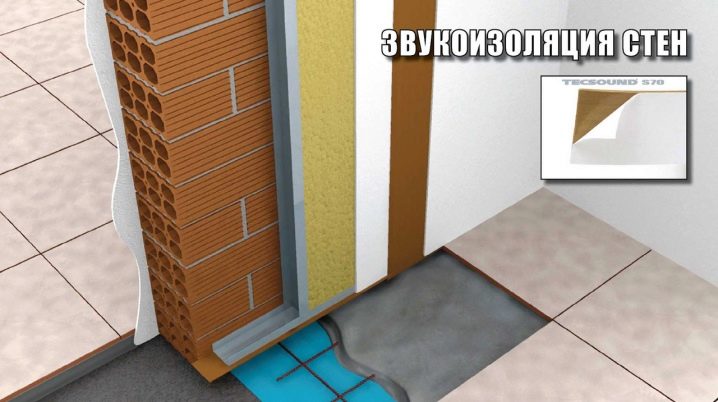

Sound insulation membranes Tecsound spanish manufacturer Texsa, can be used as a separate material to absorb noise or in combination with other sound insulators.Such material is recommended to perform sound insulation of the floor.

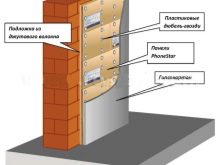

In addition, you can select a brand of materials for noise insulation Phonestar, which is a solid panel, the outer layer of which is made of extruded corrugated cardboard.

Noise insulation Knauf refers to the elite class of materials, because it has high quality characteristics. Knauf soundproofing compares favorably with other materials with ease of installation and high operating life. The most popular products of the German company is considered "New Acoustics" Knauf.

In addition to the above manufacturers, it is worth noting the products of the following companies - "Quiet House", "TekhnoNIKOL", Acoustic Group, Isoplaat, Ruspanel.

How to choose?

The main criterion on the basis of which sound insulation material will be purchased, in addition to the type of noise, is the financial component. It is not necessary to purchase expensive panels, since, having carefully studied the issue, you can choose an inexpensive, but reliable and efficient material. A very important point is the principle of installation of products, because for fixing some products will require the involvement of professional builders, which is fraught with additional costs.

The maximum preservation of the usable floor space will play a significant role in the selection of products. But preferring thin materials, you can make a mistake, because some products will provide high-quality sound insulation only in combination with other products.

Principles of sound insulation

It is impossible to speak with confidence about the high level of efficiency of this or that sound-insulating product, selecting one leader. This is due to the need for an integrated approach to noise isolation, where the principles of suppressing different types of noise are important.

The principle of absorption of airborne noise is possible due to the soundproof construction of this type - “massiveness-absorption-massiveness”. That is, the first sound surface will be assumed by the first solid surface, which will be quite difficult to bring into oscillation.

After that, a soft, porous or fibrous inner material will partially absorb a wave of noise. And the last layer will act as an additional barrier that will take on the remnants of the noise wave, which will minimize the transmission of noise.

To create protection against impact-type noise, a slightly different approach is used.In this case, you need raw materials with high viscosity. The most acceptable solution to the issue will be a product with the name teksaund. Regardless of the minimum thickness, this mineral-based material perfectly absorbs vibrational vibrations.

How to organize yourself?

The choice of the optimal variant of sound insulation panels should be carried out taking into account the architectural features of the house. An important role is played by the layout, the number of rooms, the material from which the grounds are made in the room, as well as the exterior finish. Some products, such as SIP-panels, as an independent material already provide sound insulation.

To create the maximum sound insulation, made with your own hands, you should take care of sealing all the gaps and gaps in the walls and other grounds. For such works, voids in the flooring are embedded, as well as all existing cracks at the joints. For work is usually applied sound-absorbing sealant.

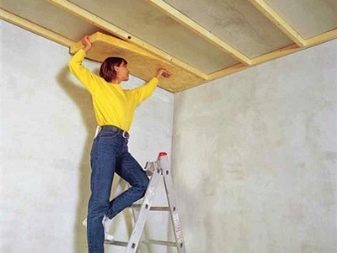

To cover the surfaces with acoustic panels, a number of preparatory work should be carried out, which include the elimination of the old delaminated finish, disconnection of electrical networks, as well as the dismantling of the plinth.

The cladding technology is laying the sheets face down on a wall. Fixing products occurs with glue pads that can be applied only after priming surfaces. Glue also needs to process the panel itself, and then with an effort to press it against the wall. When installing products it is necessary to leave small gaps between the sheets. After completion of the work with the panels they are treated with putty.

Works with sheets of drywall and mineral wool involve the installation of wool to the surface, followed by plasterboard plating. First of all, the construction of the lathing for GCR sheets is carried out, the material is fastened to it, the filler is installed inside such a panel.

Soundproofing of the living room is possible when using a frame wall. The main product of this design is lumber. Mineral wool is usually located between the racks, then plasterboard sheets are placed in two layers. This option is necessary for residential premises located near high noise sources.

Sound insulation of the floor with your own hands can be done when laying mineral wool under the floor board close to the logs.

Ceilings are insulated by arranging the suspended structure.Any soundproofing material can be placed in the formed cavities. To save the height of the ceilings, you can install small cavities in which the wool is laid, sheathing the structure with a double layer of drywall.

In the next video, you are waited by the advice of professionals on sound insulation of walls of ZIPs panels.