Sound-proof foam rubber: types and features of application

Foam rubber (polyurethane) - an amazing and curious material, firmly included in the current life of people. Almost all consumers every day interact with all sorts of variations of foam rubber. The article describes in detail the sound-insulating foam: its properties, features, types and applications.

About the origin

At the company Dunlop, one of the researchers in 1929 made the first copies by means of latex. Such foam rubber was first used after ten years in order to form rubber foam. Soon, most natural options for foam rubber replaced styrene butadiene rubber. It became the first widely used for commercial purposes.

Its current name foam (polyurethane) was due to the Soviet company supplier Porolon.

Sound insulation foam has basically only positive feedback.Mineral wool or mats have a sound-absorbing layer that allows you to make your privacy quieter and more comfortable.

Where is it used?

Foam rubber is needed in many industrial areas.

- Transport. Almost everywhere in the transport sphere (cars, trains, airplanes, ships, etc.) there are component components, based on foam rubber.

- Building. Currently, there is a huge variety of polyurethane mounting foams, without which not a single construction site can do today.

- Furniture manufacturing. A common property of foam rubber is the ability to absorb sounds. It is thanks to this feature of foam rubber that it is possible to create a room with acoustic clarity and sound insulation.

Foam rubber is used in the equipment of home and professional recording studios, general production premises of industrial enterprises.

Properties

In fact, noise is a collection of sound waves of frequency distribution. Waves are absorbed or displayed from them. The smooth wall surface in the room reflects the sound wave, which begins to maneuver among the obstacles. So the echo is reached.

Upholstered furniture or carpets reduce the energy of the sound waves: they partially absorb it and convert the result of friction into heat.

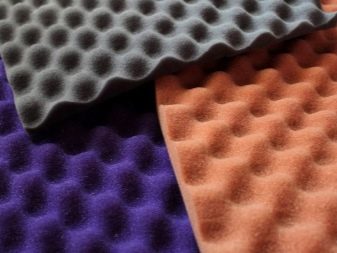

Sound-proof foam was created to smooth out the noise in the rooms. The design of foam rubber is formed by a myriad of polyurethane cells. Inside them - the air that is detected when considering the foam under a magnifying glass.

The formal name of foam rubber is elastic polyurethane foam. This is a material with an open cellular structure, which makes it easy to absorb liquids and absorb air. When forming the average material thickness, the sound wave is repeatedly displayed from its micropores and loses its energy. The higher the density of foam and the smaller the size of the cells - the higher its sound insulation properties.

The main premises, the sound insulation of which has a practically useful value, include:

- company / office;

- residential building / apartment;

- recording studio.

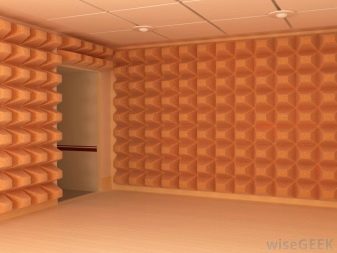

An office is an item of significant concentration of a huge number of employees who fulfill established obligations and form serious noise pollution.At the same time, an atmosphere is created in which employees' productivity declines and inattention increases. Significant noise reduction can be achieved with panel distribution.

Apartment house, apartment - a place for rest, recuperation. But you will only have to dream of peace if the house is located on a festive street, and the neighbor started repairs. It is impossible to fully restore strength in such a situation.

In the elimination of the problem will help soundproof foam plates. They wonderfully cope with the passage of extraneous sounds in the room. Sound isolation will be especially useful for those who have little children. It will help preserve the atmosphere of calm and comfort.

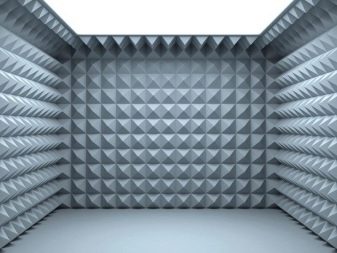

It is almost impossible to imagine recording studios without sufficient isolation from noise. The characteristics of the recorded sound is negatively affected by any third-party noise and sounds.

Sound insulation panels in them are installed not only on the walls, but also on the ceiling.

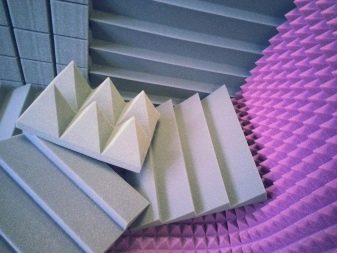

Species

When planning the acoustic subspace room should not forget about the rules. At their observance the maximum effect is reached:

- sound images are eliminated;

- the necessary degree of sounding of acoustic systems is formed.

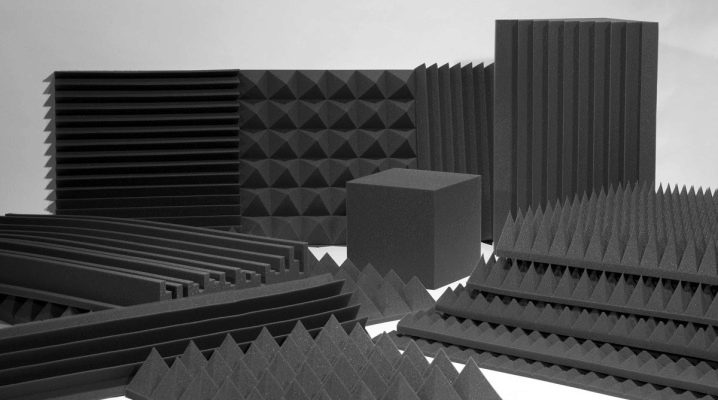

Soundproof foam panels are divided into two main categories:

- for the absorption of low frequencies (LF);

- absorbent medium and high frequencies (C / HF).

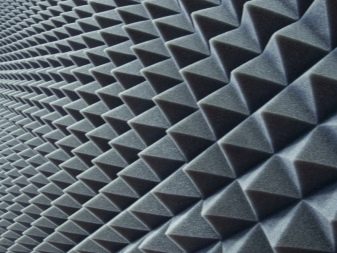

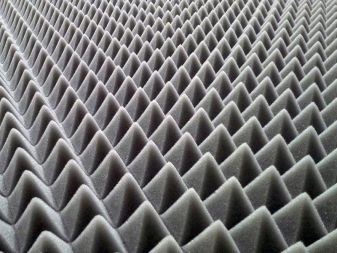

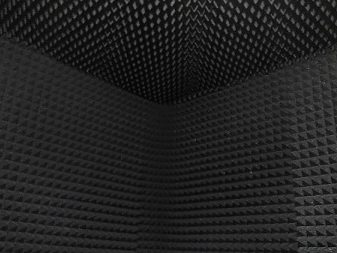

Panels of the first type affect the absorption of low frequencies. They are performed as bass traps and cubes. Neutralizers of averaged and high frequencies are presented by sound-insulating panels of the type “Wave”, “Pyramid”, etc..

The most important task of sound insulation material is the elimination of sound signal mappings and compression of its “loops”. Foam rubber will not help if you need to completely eliminate the found frequency of sound: its task is to eliminate the results of problematic frequencies in the lumen.

In the corners of the room accumulate low frequencies, heading towards the listener with a conditioned delay. Therefore, the main importance of bass traps is to eliminate the accumulation of low energy.

At the same time, the relief of the panel is not significant. The size of the sound insulation panel of this type depends on the size of the room and the expected total.

From the weight and shape of the panel in the selection will directly depend on its properties.Thus, the relief "Wave" brings a velvety sound-absorbing effect. Such panels can completely fill the room.

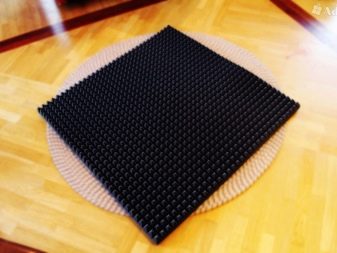

A panel of "Pyramid" bring the best result with a small number and are located in the designated areas of the room. Foam rubber is widely used in acoustic devices as a change in conventional padding polyester. They fill the distance inside the speakers and subwoofers. It gives an improved sound of sound waves of medium and high frequency range.

Other soundproofing panels differ mainly in configuration and certain degrees of efficiency.

They do an excellent job with the complexity of building rooms of any size: from small apartments to industrial premises.

Specifications

During the work with sound-proof foam rubber there is no need for special skills or abilities. It is simple in cutting, and because of the barely perceptible weight, it can be fixed to double-sided tape.

Some factors of propagation and absorption of sound waves are taken into account.

- Distance. The energy scattered at a distance of sound waves is attenuated if you use sound-proof material.

- Damping. Sound insulation material is effective for reducing reciprocal fluctuations in the room, absorption, diffusion or reproduction. Absorption of sound by foam panels contributes to lower sound levels. Diffusion or reproduction consistently convert the undesirability of sounds into utility.

- Absorption. Sound insulating foam plates convert the energy of sound waves into heat with a consistent reduction. Absorption of sound in certain frequency bands is especially important for listening rooms or recording studios.

Foam absorbers with open-type pores act on the principle of noise absorption in the structure of the material. They effectively absorb the noise in the microwave. The absorption of foam panels is staggering even at low frequencies.

Subtleties of installation

Exposure to external noise can be easily reduced or eliminated under normal conditions. The main interest in sound insulation in modern homes are windows.

To reduce the sound, you can use cellular airbags or foam. Cellular structures (with the number of cells from 1 to 3) make it possible to achieve a high degree of sound attenuation.

Soundproofing panels can be a ceiling or wall part - to reduce the sound level from neighbors.

It is attached as a separate layer.

In addition, the installation of sound-proof material achieves the effect of reducing noise in rooms with a large number of workers and office equipment. Reducing noise contributes to increased work capacity and productivity of employees. In production workshops, soundproof material gives a tangible reduction in overall volume and sound reflections from working equipment.

The thickness of such panels can be from 5 to 100 mm. When choosing the thickness, one should choose the panels according to the following principle: the noise level is higher - the noise insulation layer is thicker. For housing, apartments or offices suitable panel thickness of 50-70 mm.

Typical panels have a grayish or brownish tint, but if necessary, you can order panels of the desired shades.

When installing sound-insulating foam rubber it is strictly necessary to observe the following rules:

- the panel cannot be crushed or deformed due to a perceptible decrease in its useful qualities;

- attach the foam to the base with glue or double-sided tape;

- foam panels are installed only for fastening indoors;

- The panels are located under sex compensation, inside the walls or in the construction of a suspended ceiling.

The material is not whimsical to the rules of use and is almost an eternal material.

Thus, it remains to add that the panels of sound-proof foam rubber do not need any maintenance and repair, the period of their use is not limited.

The soundproofing panel is vacuumed. Repeatability of cleaning depends on the purpose of the room.

The impeccability of the sound and the absence of noise pollution depends not only on decent and expensive equipment, but also on the appropriate decoration of the room where the sound-proof foam is fixed.

You will learn more about sound insulation foam from the following video.