Isoplat: windproof and heat and sound insulating plates for house plating

Today, the construction market is pleased with an abundance of materials, applying which you can simultaneously solve several problems. As such can be considered isoplat - insulating plates with the effect of noise insulation and wind protection. Where and how is this product used?

Special features

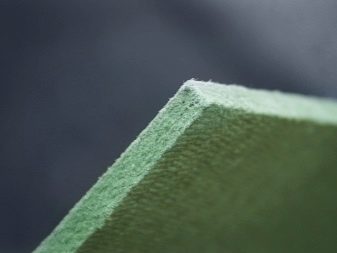

Isoplatas are plates for external and internal works, possessing heat-insulating and wind-shelter characteristics. The material is produced by the Estonian manufacturer Skano Fibreboard.

The basis of the product is a soft fiberboard (MDVP) undergoing treatment. First of all, the raw materials are treated with steam, after which they are soaked in water. The next stage is the grinding of the composition to obtain a liquid fiber mixture, which is fed to the conveyor. By means of vacuum, excess moisture is pumped out of it, after which the web is pressed and dried in chambers. The production process is completed by cutting the material into sheets.

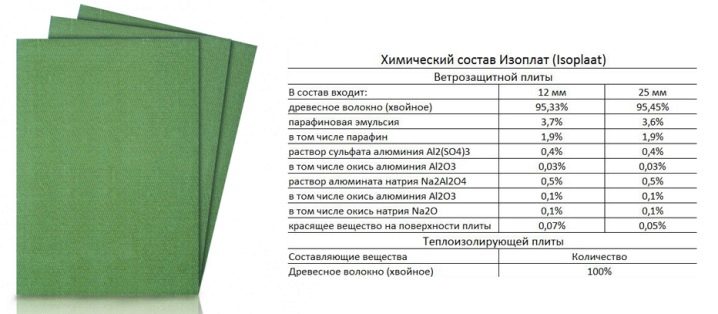

There is no glue in the composition. The coupling element occurs due to the resins entering the wood - the material is made from coniferous species.

For a brief video review of the composition, manufacturers and scope of isoplat, see the following video.

Specifications

The release form - panels 4-50 mm thick. Sheet size depends on its purpose.

- The standard parameter is 2700 x 1200 mm.

- The tongue-and-groove version has smaller dimensions - 2400x800 mm. TO

- Level material is available in several sizes - 2500 for 750, 1875 for 1200 and 1800 for 600 mm with sheet thickness of 12-50 mm.

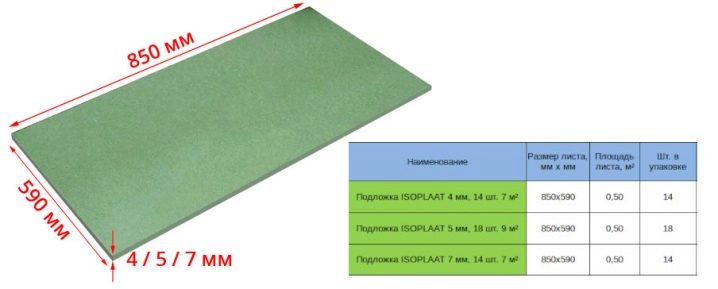

- Sheets for interior decoration thinner (4-7 mm).

- The dimensions of the material for floor heating are 850x590 mm.

The density of the material is 230-270 kg / m3.

Isoplat plate for its heat efficiency is similar to mineral wool - the indicator of its thermal conductivity is 0.045 W / (m * K).However, the material has a small thickness (4-50 mm), so it can not be used as the main heat insulator, it is usually used as a support for the main insulation.

The material is characterized by good vapor permeability due to wood fiber structure. This makes it the best protection for "capricious" wooden surfaces, eliminates the organization of an additional vapor barrier layer.

One of the main advantages of isoplat is a high coefficient of sound insulation. Its use allows for 23-26 dB to reduce the noise level in the room.

Possessing a paraffin layer panels have a sufficiently high moisture resistance. However, even their manufacturer does not recommend to be stored outdoors for more than 2 months, as this will lead to moisture penetration into the material. Similar is fraught with a change in the geometry of the sheet.

If during external mounting such changes are not critical, then during internal lining they entail a warping of the finishing layer, opening of seams, heaving. That is why the installation of the product involves a secure fixation of the panel to the wall and sizing reinforcing tape all joints.

Despite the fact that the material is based on wood, it is distinguished by sufficiently high fire resistance, which is achieved by interfering with flame retardants in the raw materials. Under the influence of high temperatures, charring of the upper layer of the plate occurs, and the ash formed during this blocks the fire from accessing the next layers of material.

Isoplat is considered absolutely safe material from an environmental point of view. This is due to the fact that it is based on coniferous wood. This, in turn, eliminates the use of adhesives, as adhesion is provided by natural polymers.

In terms of its environmental friendliness, the product is comparable to natural wood, therefore it is suitable for interior decoration, including bedrooms and children's rooms.

The bio-resistance of the material also becomes the reason for its positive assessment by buyers. Coniferous wood itself is able to resist the effects of insects thanks to the polymers and essential oils that make up it. In addition, in the process of manufacturing the plates are treated with steam, which allows you to destroy all insect larvae, germ spores and other life forms in the thickness of the material.Thus, it is possible to talk about the biostability of isoplat.

Due to moisture resistance and vapor permeability, the risk of material wetting, mold and fungus on its surface is reduced.

High performance characteristics ensure the durability of the material. The manufacturer claims a 50-year lifetime of its product.

The material is easy to use - it has a small weight, convenient for mounting dimensions, if necessary, easily cut with a hacksaw. The joint “thorn-groove”, which is available on the panels for exterior decoration, is designed to optimize the laying of the material, to ensure the tightness of the coating.

In more detail about the physicomechanical characteristics of the isoplat plates will tell the following video.

Scope of application

The material is characterized by a wide range of use. First of all, it should be noted that there are variations for external and internal insulation. The latter are thinner (up to 7 mm) and demonstrate their effectiveness as a warm rough substrate for parquet, laminate and some other types of flooring. Plates for external insulation have an additional paraffin layer, which provides water resistance to the material.

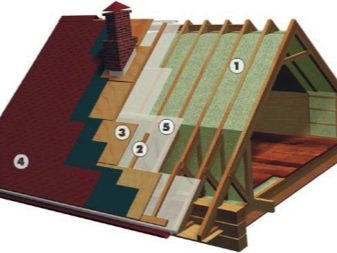

The main purpose is windproofing (including in houses of frame type), heat insulation of walls, roofs.

The material is installed before the installation of the facade finish. The layer of the board is laid to insulate the roof, on top of it is the laying of metal or shingles, slate or sheet roofing. Thanks to the thorn groove mechanism on roofing and front panels, installation takes less time and effort.

Plates for internal thermal insulation are not sprayed with liquid paraffin and docking mechanisms. They are characterized by a more even, smooth surface under the finish.

Isoplat can be used for the following tasks:

- internal heat and sound insulation in rooms with low and medium humidity levels;

- heat and sound insulation, as well as wind protection of the exterior walls of the building, roofing;

- heat and sound insulation flooring;

- thermal insulation and windscreen frame houses;

- strengthening of the main insulating material.

When used from the outside of the facade, the slabs are covered with facing material (mounted on the batten) or subjected to contact treatment (painting, plaster).Floor substrates are covered with a coating like laminate, and when laying the board on the roof, tile or roofing sheet is laid on top of it.

When the walls are insulated with these plates from the inside, their surface can be covered with wallpaper, plastered, painted. You can also hem the material with plasterboard and already on its surface to produce lining.

By the way, in this case, even with the use of plates of small thickness, noise insulation is significantly improved.

The use of wall panels, which are fixed to the frame, is allowed. Finally, it is possible to leave the isoplat in its original form, protecting the varnishes. Such decor is appropriate to look in a country house with a natural wood trim or imitation under it.

Installation

Inner lining

If you plan to insulate the space inside the room with an isoplat, then you should choose a material of greater thickness and high density - it is less susceptible to change due to humidity. Before use, the sheets are kept for several days in room conditions (ideally in the room where they will be installed).

This will avoid strong deformation of the plates after sticking.

It is possible to fix sheets on assembly foam or glue for gypsum cardboard. The adhesive composition is applied both on the material itself (retreating 3 cm from the edges) and on the working surface. The panel impregnated with glue is pressed against the wall, leveled and held for some time for fixing.

After 20-30 minutes or after gluing the panels over the entire surface, they should be secured more securely. For this, the plates are fixed to the wall with galvanized dowels, the caps of which are pressed into the isoplatas by 1-2 mm.

The entry points of the dowels are puttied, the joints are reinforced with tape. Then a layer of primer is applied, after it dries, the surfaces are puttied or painted.

Exterior trim

If you decide to sheathe the facade or roof of the house with an insulation board, crate of the frame structure, for fixing the plates, use stainless steel construction brackets, galvanized screws or nails, the caps of which should be flat.

Laying plates should be maintained with a gap of 2-3 mm between them.

The thickness of the material directly affects the pitch of the batten. So, for sheets with a thickness of 12 mm, the pitch width should not exceed 30 cm, for analogues - with a thickness of 25 mm - 60 cm.It is important to drive in nails and staples at a distance of at least 20 mm from the edge of the plate. At the edges, nails are driven in with an interval of at least 10 cm, in the central part with an interval of up to 20 cm.

To install the material on the facade using the starting plate, having it not less than 40 cm from the ground. Laying panels with a straight edge is carried out vertically. Sheets with quadrilateral groove mounting are mounted in a horizontal direction.

Providing high-quality vapor barrier allows the arrangement of a ventilated gap between the isoplat and the facade layer. To this end, the mounted lattice is fixed on the mounted panels, onto which the facing materials are fixed. The basis of the counterbribe - wooden logs with a height of 30-50 mm.

They should be pre-treated with flame retardants and antiseptic compounds.

Laying isplat on the floor

Laying isoplaty on the floor as a substrate is made on a dry and flat surface. To prevent seams between the flooring and insulation plates, the latter are mounted at an angle of 45 degrees with respect to the direction of the floorboard or laminate.

To improve adhesion, a little glue can be applied to the floor. Between the walls and the substrate, it is important to maintain a gap of 5 mm in order to eliminate the swelling of the floor when the geometry of the plates changes.

Before using the substrate, as well as wall plates for interior decoration, kept for several days in room conditions.

Reviews

Despite the fact that the material appeared on the construction market relatively recently, it is quite in demand. At the same time, buyers are getting a higher appreciation for plates for outdoor work, while analogues for internal use have complaints.

First of all, users note the discrepancy between the actual consumable glue and the volume declared by the manufacturer. A large number of reviews on this topic allows us to conclude that the adhesive composition has been overrun.

In addition, the gluing of thin plates is possible only on perfectly flat surfaces, even with slight differences in height, the material shows a deterioration in adhesion.

The inconvenience is also caused by the fluctuation of the linear dimensions of the sheets under the influence of moisture. After gluing and precise docking after a few days, you may find that the joints have diverged. After some time they return to their original form.To level this disadvantage allows the use of reinforcing tape, which entails additional costs and increases the complexity of the process.

Finally, due to the high hygroscopicity of the material, it actively absorbs plaster, which entails significant expenses for its purchase. An unpleasant surprise can be the fact that even a thorough multi-layer plaster is not a guarantee of good adhesion of the wallpaper to the surface.

However, this feature can not be considered a disadvantage, since initially the plate was not intended for pasting with wallpaper. This technology is not used at home in Estonia. More experienced users recommend first applying a breathable paint on the plates (for internal use it is better on an acrylic basis), and after it dries, start pasting the plates with wallpaper. However, if you know in advance about the nuances of working with the material, the results of the insulation are quite good.

Users note that the use of slabs in standard panel and brick apartments has made it possible to achieve noticeable heat in the room, and improve sound insulation.

People who are prone to allergies, as well as having children, in addition to good thermal insulation characteristics, note the ecological purity of the products. Due to the vapor barrier properties of the material in the insulated room does not create a greenhouse effect (the main trouble in most cases, the internal insulation of rooms).

On the Net you can find a few negative reviews, telling that even after installing the plates in the rooms it has not become warmer. The reason for such phenomena, according to experts, may be hiding, firstly, in the purchase of low-quality non-original products (fake), and secondly, in violation of the principles of warming.

The fact is that not all heat losses occur on the walls, most of the heat leaves the house through doors, windows, floor and ceiling. It is important to make sure that there are no other sources of heat loss, other than walls, in the room.

For these purposes, it is convenient to use a thermal imager, and you need to carry out such an analysis before buying a heater.

Having determined the zones of the greatest heat losses, it is from them that the warming should begin. In addition, it is important to avoid the formation of "cold bridges", which in most cases remain between the warmed wall and the floor, wall and ceiling, in the area of window openings.Only their complete elimination can increase the temperature indicators inside the building.

Material for thermal insulation of the floor, roof and facades has a smaller number of negative reviews. Perhaps the only inconvenience is the presence of a straight edge in sheets with fastening "thorn-groove". The arrangement of frame racks under them has to be mounted in such a way that the joints are in their center. This, in turn, leads to a reduction in pitch racks. The standard width of insulation (for example, mineral wool sheets 600 mm wide) no longer fit into the interspace, they have to be cut.

Tips and tricks

As already mentioned, isoplat plates are not suitable for wrapping them with wallpaper. However, to solve these construction problems, there are analogues, for example, sheets of isotex, produced under the same trademark.

They are designed for internal heat and sound insulation, suitable for wallpapering, textiles, decorative plaster.

When choosing a material, make sure that it does not have any external defects and forms a whole (no seams should be seen in the thickness of the material should not be)

The cost of plates depends on its size and thickness, destination, the number of plates in the package. So, heat and sound-proof products with dimensions of 2700 by 1200 mm with a thickness of 12 mm are 10-15% more expensive than a similar plate with a thickness of 10 mm.

In this regard, it is important to accurately calculate the required thickness of insulation, since this will allow you to optimize costs and avoid buying too thin or unnecessarily thick products. In addition, you get a warm and stylishly decorated room.