Soundproofing the floor in the apartment under the screed: how to do it yourself?

The designs of multi-storey buildings, as a rule, do not differ much. The floor and the ceiling of the apartment are interconnected from below, so sounds from neighboring apartments are easily transmitted. Soundproofing the floor - the process is simple, but time consuming and takes a long time. However, it does not require special skills and allows you to get rid of the noise of neighbors for many years.

Special features

Before installation, it is necessary to analyze and identify what caused the appearance of noise. It is also important to understand what effect you are planning to achieve. For example, if the noise of the neighbors interferes with the bottom, then it is necessary to install sound insulation on the floor. And if you are a music lover and want to listen to music at any time of the day, then it is necessary to conduct a comprehensive sound insulation in the room.

A simple way to keep silence in the apartment is to lay a soft covering on the floor - carpet or carpet. But this method will give only a softening effect. Noise isolation does not completely relieve the noise of neighbors living on the floor below, but will reduce the number of extraneous sounds by an order of magnitude.

Noises are classified according to their origin: air, shock, vibrations and others, they are characterized by different frequencies and decibels. Sound insulation allows you to muffle the sounds coming from other rooms.

By soundproofing the floor, you protect the neighbors living on the floor below from the sounds of falling objects, moving furniture and heels and your house from extraneous sounds. In other words, The materials used to isolate the floor can absorb and dampen noise.

At the same time, the very device of the floor in the apartment, the characteristics of the screed laid between the base and the top surface coating, are important.

Types of screed

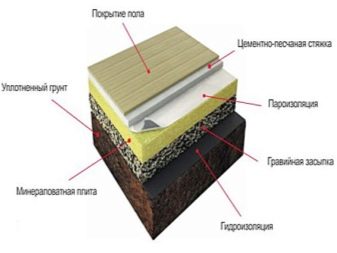

The coupler is made from different materials, so the methods and types are different. Feature Floating technology is that the screed is poured directly on the floor slab, but before that it is necessary to cover the surface with cellophane.That is why the screed has received such a name - it has no rigid adhesion neither with overlapping, nor with the walls. With this method, the floor seems to float on the soundproofing layer. Thus, the floating screed is insulated from all surfaces.

This type of screed provides excellent noise insulation. On top of the film is covered with foam or polystyrene foam, which will perform the function of sound insulation.

Dry and semi-dry screed are performed using claydite and sand. Granules of different sizes are tightly poured on the floor, and on top they are covered with sheets of gypsum fiber. When choosing such a tie, cellophane or oilcloth creeps onto the overlap itself, and the edges bend upward and fasten to the walls. With semi-dry technology, a metal mesh is laid out on top of the insulation layer, and another 2 centimeters of a mixture of cement and sand are poured in from above in a ratio of 1: 3. After complete drying, you can proceed to sanding the floor.

Cork is a great way to isolate a room from extraneous sounds. This is a natural material that is many times denser than a film. A decorative coating is produced from cork, which is laid on the floor according to the principle of laminate flooring, tile or roll - everything depends on the manufacturing technology.At the same time noise level decreases approximately by 2 times.

Material selection

The main materials for sound insulation of the floor are divided into 4 types:

- Polymer and plastic - this group includes foam, liquid polymers and reflective materials.

- Mineral - cement mortars, expanded clay, sand, mineral wool.

- Chipboard - sawdust, plywood and wood shavings.

- Silicate - glass wool.

Main characteristics and properties of soundproof materials

Styrofoam

- Choose the most dense foam. Cheap and soft material may crack or burst, besides, it may shrink with time, and in this case there will be no sound insulation.

- The width of the foam must be at least 5 cm, otherwise the noise will not be absorbed.

Minvat or glass wool

- It has excellent sound insulation properties and, in addition, reduces heat loss in the room.

- It has a certain volume, so it will “raise” the floor to a certain height.

- Mineral wool is not afraid of fire and does not emit allergens.

- The material is afraid of moisture, so before installing the screed it is necessary to cover the structure with plywood sheets.

Teksaund

- Modern elastic and flexible insulation material with a thickness of 3.7 mm.

- Great for noise insulation in residential areas and quickly mounted.

- Non-flammable, resistant to temperature extremes and not susceptible to mold.

Ecowool

- Provides excellent sound insulation and warms the room.

- For installation, a special inflatable installation is used and cotton wool is sprayed on the floor surface.

When choosing a material for sound insulation of the floor, you need to know how much noise comes from the outside. From this will depend on the type of material and screed.

Manufacturers Overview

Soundproofing the floor - this is a complex multi-layer construction, or, as experts say, "pie". We give a brief overview of the properties and characteristics of materials from different manufacturers.

Company Rokvul Akustik Butts produces excellent sound insulation materials made of stone wool. Extruded panels are easy to install and absolutely fireproof, so materials can even be used on wooden floors.

Manufacturer Tecsound produces modern rolled insulation materials of great strength. All products meet European and Russian quality standards.And the composition of the produced materials does not include phenol-containing substances.

Under the brand name Soundguard the plate for a noise isolation of a floor is issued. The design includes gypsum board, a mineraquartz-filled slab and a frame profile. The whole "pie" guarantees excellent sound insulation characteristics: impact noise is reduced to 36 decibels, air - up to 60 decibels.

Which is better?

The most affordable and effective material - mineral wool. It is made from stone wool or old glass. This material perfectly absorbs noise and is not afraid of fire, so it can even be used in a house with wooden beams. And besides, cotton wool is hypoallergenic.

Styrofoam also has excellent properties and is made from polystyrene, which foams and forms dense balls with a single mass. But it is inferior to modern insulating materials. Instead of simple foam, professionals recommend choosing a denser material - polystyrene foam. For him, the width of the substrate is about 3 cm.

Schumanet and noise stop - Modern materials have excellent noise insulation properties.They are easy to install, have a small thickness and are ideal for floating screed. For laying it is only necessary to dismantle the floor and clean the floor slabs from debris and dust.

Surface preparation

Dismantling the old surface is necessary in order to verify the quality of the floors. Any damage to the structure, such as potholes, cracks and holes, may deteriorate the insulation.

There are only two types of flooring in the houses - cement screed and wood flooring. For each material has its own methods and technologies obeshumlivaniya. And to make high-quality sound insulation, it is necessary to dismantle the floor. Dismantling of the old screed must be done before the floor slabs. The wood cover is also completely removed.

The surface is checked for elevation differences. The floor is carefully cleaned with a vacuum cleaner, then you can begin to install the sound insulation layer. Then you need to assemble a new floor with insulating properties.

Noise isolation do it yourself

After surface preparation, you can proceed to the main work. Staged work in an apartment building with a cement screed:

- Separate the slabs and walls from the screed.. To do this, you can use cellophane, polystyrene film or tape, place strips over the entire surface and along the walls. The film must completely cover the floor, it will protect the ceiling of the apartment on the floor below from leaking solution. The walls should also be covered a few centimeters.

- Thereafter soundproof material.

- The final stage of preparation under the screed is installation of metal mesh with cells 50x50 or 100x100. It performs the function of reinforcement and protects the lower layer from deformation.

- Then with the help of lighthouses and level screed poured into the apartment. To do this, you need to install beacons with the help of modern mounts. But it is also possible to work according to the old method - to make pre-holes in the surface of the material and build in beacons. But in this case, the insulation will decrease, the material may change shape or structure, and the beacons may move.

As beacons, you can use fittings, slats, profiles, pipes or boards.

- Now it remains for the small - wait until the solution brightens and dries completelyUp to this point in the room is better not to go in, so as not to deform the surface and not push through soundproof material.

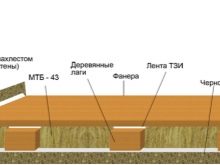

Features of works with a wooden floor:

- Noise isolation in this case is carried out using a special dry screed. The basis of the wooden floor are beams / logs. After dismantling the wooden floor, check the condition of the log. With age, they can deform or shrink.

- Wooden logs are covered with antiseptic and securely fixed to the floor with the help of U-shaped brackets. They are also used when working with plasterboard.

- After this, the space between the lags is filled with mineral insulation. And then boards are fastened to the lags, the flooring is laid between them. Then you can proceed to the installation and reading of the floor.

Useful tips

7 tips that will facilitate the process of work:

- All wires and cables on the floor must be insulated using protection systems.

- Metal mesh, which stands to strengthen the whole structure should be 3 mm thick. And the thickness of the cement screed itself should not be less than 5 cm, otherwise the layer will crack after drying.

- The softer the insulation material, the better it provides noise insulation. But under load, it should not shrink by more than 5 mm, otherwise compression will cause deformation and destruction of the screed.

- When creating a multi-layer structure, the topmost layer must be the toughest.

- When working in a wooden house, give preference to mineral insulation, rather than the usual foam. Although the foam has excellent sound insulation properties and is cheaper, it is not suitable for wooden floors, because it does not allow steam and does not promote air circulation, causing the coating to quickly rot and require replacement.

- If you are disturbed by the noise of neighbors living on the same site, you should not immediately resort to the whole complex of repair work. Sometimes it is enough to eliminate cracks and chips in the wall to reduce noise and vibration.

- After completion of the work with the floor plinth necessarily attached to the wall or floor. Otherwise they will serve as an additional noise conductor.

How to make sound insulation of the floor using noise-stop materials, see the following video