MaxForte: modern sound insulation for home

MaxForte is a modern soundproofing for the house, which has all the properties for eliminating extraneous noise. Products even with a minimum thickness of the material can provide a high level of sound insulation, due to which it is in wide demand in the market.

Special features

MaxForte is a manufacturer of noise insulation material with its own production facilities. The company is a leader in this field and offers its customers effective and safe products that help in the fight against noise.

MaxForte noise isolation is considered to be a composite roll material, with which you can equip your apartment, offices and recording studios. Products are manufactured to work with walls, ceilings and floors. Products are ideal for small apartments where every free centimeter is important.

All products are easy to install, along with high acoustic performance. The manufacturer performs quality control at each stage of production, therefore, the products comply with the requirements of SNiP dated March 23, 2003 according to the clause “Protection against noise”.

Advantages and disadvantages

MaxForte soundproofing material is the only material that combines four qualities:

- Sound absorption. The product holds and absorbs vibration and shock type noise. Such sounds include repair, beats on the upper floors, the sound of footsteps, the creak of parquet.

- Soundproofing. The manufacturer guarantees the effectiveness of its products, if compared with other brands. Products provide good protection against airborne noise. These include conversations and quarrels of neighbors, loud music, TV.

- Acoustics. MaxForte offers acoustic comfort material. This quality is relevant for a half-empty and not equipped room in which there is an echo.

- Waterproofing. Waterproofing qualities are achieved through a thin rubber base.

The following advantages of the material should also be noted:

- Environmentally friendly, as there are no volatile and formaldehyde resins in the ingredients list.

- Insulating quality. Products correspond to GOST.

- The material is characterized by flexibility and elasticity.

- Low degree of susceptibility to burning. Products are resistant to moisture, mold.

- The product does not undergo the process of decay and has antiseptic properties.

- Durability. This material has no expiration dates.

- The manufacturer provides a lifetime warranty.

Among the shortcomings, some users point out only the high cost of the product, which is fully compensated by the quality of the products.

Characteristics of materials

Specifications may vary depending on the type of products. A review of popular materials will allow you to compare the characteristics and make the right choice:

- Slabs MaxForte SoundPRO They have dimensions of 500 x 1400 x 12 mm. The area in the roll is 7 square meters at 0.1 cu. m. The mass of the roll is 16 kg. The manufacturer produces material in white and black color scheme.

- "EKoplita" 60kg / m3. The dimensions of the products are 1000 x 600 x 50 mm. The package consists of 4 pieces; the package dimensions are 2.4 m2 / 0.12 m3. Packaging weighs 7 kg.

- Eco-Plate 80kg / m3. The dimensions of the product are 1000 x 600 x 30 mm. Packaging weighs 7 kg.

- "Standard". The dimensions of the material are 600 x 1400 x 12 mm, the area in the roll is 4.4 m2 / 0.1 m3. The roll weight is 22 kg.

- "ECO panel". Dimensions: 1200 x 800 x 12 mm. The area of one panel is 0.96 square meters. m. The mass of the product is 19.7 kg.

- Vibroacoustic sealant. The product is made from high quality Belgian raw materials. Sealant is characterized by light extrusion, increased elasticity and adhesion on any surface.

- Damping tape sold in a roll, whose length is 30 meters, thickness 3 mm, weight 700 g. There is a tape 50, 100, 150 mm wide.

Views and reviews

The manufacturer produces several products that are designed to work with different surfaces. Before buying it is recommended to study the product description and customer reviews.

"EKoplita"

EcoPlite is produced from volcanic rocks, excluding blast waste and slag. Such products are used on complex acoustic objects (listening rooms, recording studios, cinemas with several halls).

Based on the location of the object, you should determine the appropriate density.

- Products with a density of 60 kg / m3 are suitable for working with walls and ceilings.

- For surfaces with a profile it is recommended to use a material whose density is 80 kg / m3.

- For the floating screed product is available with a maximum density of 110 kg / m3.

The plates are not subjected to the process of decay, are not prone to burning and act as an antiseptic.

Buyers report that the material copes well with the tasks assigned to it, it does not start rodents, insects. EcoPlite can be used as a heat insulating material.

"Shumoizol"

The material is used as a sound insulation strip to install a floating floor. It can also be used as an elastic substrate under the laminate. The product is heat resistant, which persists for two hours after the ambient temperature rises to 85 degrees. Flexibility is maintained at temperature conditions up to -25 degrees.

Consumers using this material report that it is flexible, which is convenient when laying.

Installation of products is easy, so you can reduce time resources. When using MaxForte products, there is a significant reduction in noise of various types.

EKOAkustik

"Eco Acoustics" is made of polyester, in which there are no adhesive ingredients. To ensure that the material has the necessary form, the fusing technology is applied. The material is different environmental qualities, what attracts most buyers. The composition contains substances that do not emit harmful components.

Products do not shrink over time and retain their shape over the entire life cycle.

Users confirm the properties declared by the manufacturer. People who have decided to equip their homes with this material, note that "ECOAcoustics" does not sink, does not have unpleasant odors and has an attractive price.

"ECOPanel"

Products are sold in the form of cloths with a multi-layer frame, in which there is a quartz filler. The panels reflect and scatter sound waves, and mineral particles provide a high degree of frictional loss.

Most users choose this material to work with the surface of the floor, walls, ceilings. Products suitable for creating sound insulation walls. Sound engineers often purchase panels of this brand, noting the high performance characteristics of the product.

"Standard"

Laying the material on the surface reduces the noise level by five times. This indicator is considered the minimum. "Standard" is used to work with floors, ceilings and walls.

Users note a significant reduction in shock and airborne noise, easy installation and affordable cost of goods.

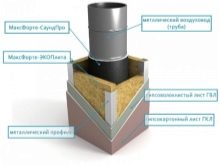

Soundpro

MaxForte SoundPRO is a delicate material for sound insulation of various surfaces. Products are distinguished by easy installation and a high degree of noise reduction.

Since the products are characterized by increased flexibility and elasticity, it can be used for sound insulation work of any diameter.

Many users appreciated the quality of the product. Buyers like the high quality of the product, the absence of unpleasant smell. The product has no harmful effects on the human body and copes well with the tasks.

How to choose?

Improving the sound insulation of a dwelling is a difficult task, which will require appropriate knowledge and skills. First of all, you need to make a competent choice of products, after which you can begin to work in an apartment or house.

Many people choose thin material for decoration. Reducing thickness is a normal desire, but a quality sound insulation scheme should have a minimum thickness of 4 cm. The thicker the design, the better the sound insulation characteristics.

To eliminate household noise, a material whose thickness is 4–5 cm is suitable. Thicker products should be purchased if the noises are strong or neighbors use a stereo system.

Before buying noise insulation for walls, floor or ceiling, you will need to decide on what noise you need to work. There are two types of noise:

- air;

- drums;

- structural.

To protect against airborne noise, products with a fibrous structure, low water absorption, resistance to burning, high strength and sound absorption should be purchased.

The remaining noise can eliminate materials with a low level of elasticity.

Experts recommend using three rules to create high-quality soundproofing in your room:

- First required determine the source of noise. Based on this parameter, the choice of noise insulation material is made. To do this, examine all surfaces and check the noise level. Often in the elimination of problems with noise helps partial sound insulation of the room. To identify the source, you need to attach the ear to the surface and compare the noise level. The insulation must start from the noisiest place, after which the effect can be compared. If the noise level has gone down insufficiently, it will be necessary to lay the material on the second loudest fencing.

- Specify the type of noise. This parameter allows you to make the right choice of material for sound insulation and system design. If loud conversations of neighbors, music and other voice sounds are heard in the apartment, protection from airborne noise will be required. It spreads through the fence that separates the apartment (floor, walls, ceiling).

- If disturbance comes from the sound of steps on the upper floors. or the noise from falling things is shock noise.The sounds made by the elevator, air conditioning, pumping station - this is structural noise. The fight against sounds of this type is made in the zone of their formation. Such sounds are distributed in a vibrational way, so they penetrate the room from all sides. Therefore, you will need to carry out sound insulation of the room from the inside. The material is laid on all surfaces: floor, walls, ceiling.

MaxForte offers products that can be laid on the floor, walls and ceiling. For each type of surface there is its own collection, which has all the necessary qualities.

Installation Tips

Installation of the sound-proof material MaxForte differs in ease and speed. To facilitate the styling process, you should study the recommendations of experts on the example of working with products "Standard".

Laying products should be carried out only after a detailed inspection of the surface. To determine the presence of voids in the walls, you will need to resort to tapping. All cracks and other defects should be repaired with gypsum-type plaster or cement-sand mortar. Voids need to be filled with cement-sand mortar.Also required to inspect the joints. Gaps are not allowed.

Material laying consists of the following actions:

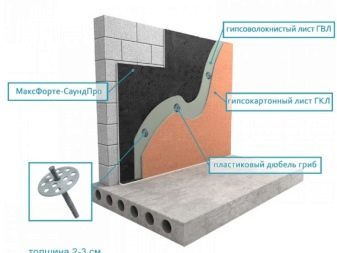

- After preparing the base, proceed with the installation. The soft side of the roll should rest against the surface to be insulated.

- The surface of the roll is fixed with a plastic fungus. Clamps should have a length of 70 mm. For each canvas will require three fungi.

- Rolls are overlapped, 4–5 cm wide.

- Formed joints must be connected with a mounting tape with reinforcement.

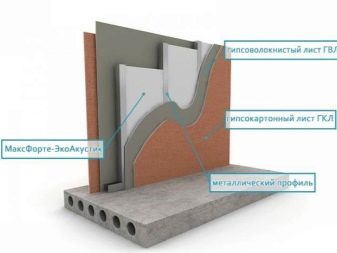

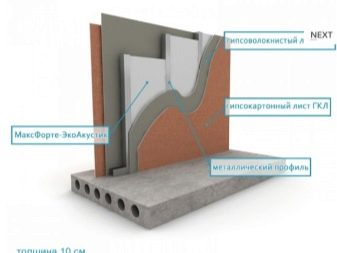

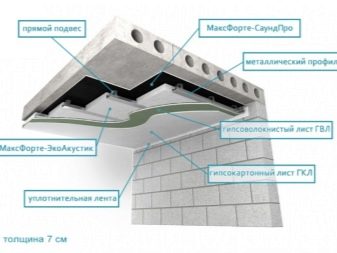

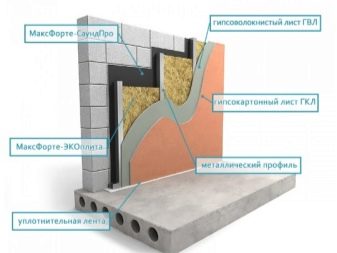

- Then you can begin to fasten the guides through soundproofing. Details are fixed to the wall. As a profile material, you can use a metal frame.

- Make sure that the parts do not firmly adhere to the surface and base.

- Under the guide profile is the substrate of the damping tape.

In order for the soundproofing material to perform its tasks, the installation of the skin should be done according to the rules. Installation consists of the following steps:

- A gypsum fiber sheet with a thickness of 10 mm is required. The installation step of 600 mm should be observed.

- The seams that are present between the webs will need to be treated with silicone sealant. Make sure the seams do not match. They should spread at a distance of half the width of one web.

- Joints are treated with putty.

- During the installation of sound insulation, you will need to ensure that the paneling does not come into contact with the walls, the surface of the ceiling and the floor. This rule applies to profile guides.

- When the skin is installed, the joints will need to be treated with non-drying type silicone sealant. Alternatively, polyurethane or acrylic sealants can be used. For this purpose it is not possible to use mounting foam.

Experts recommend combining the material "Standard" with "ECOplitoy."

The work also needs to follow the sequence of actions:

- It is necessary to attach a product from the “Standard” collection to the rough base, after which you can proceed to the installation of a metal profile.

- In the intervals between the metal profile will be located "ECOPlita."

- Then is the flooring gypsum sheet, which is covered by GCR.

- Stitches will also need to be filled.

These rules will help to correctly carry out the installation of products, as well as to avoid common mistakes.

Soundproofing wall materials "MaxForte" shown in the following video.