Brick furnace for the bath: design features

Although metal stoves for baths were invented quite a few years ago, most people still prefer the traditional brick. Such a choice is due to the fact that it is the “living” material that can create the most comfortable level of heat for the person and the optimum amount of steam, as well as give the room a cozy atmosphere.

Special features

The main advantage of brick furnaces for baths is a certain technology of vaporization, which is achieved due to the unique properties of bricks. The person in the room breathes easily, feels “soft” heat and enveloping steam, saturated but not burning.When the metal is heated, infrared radiation arises, burning out oxygen in the steam room and burning the skin. It is not surprising that brick-made heaters are preferred by people who take care of their health and choose comfort.

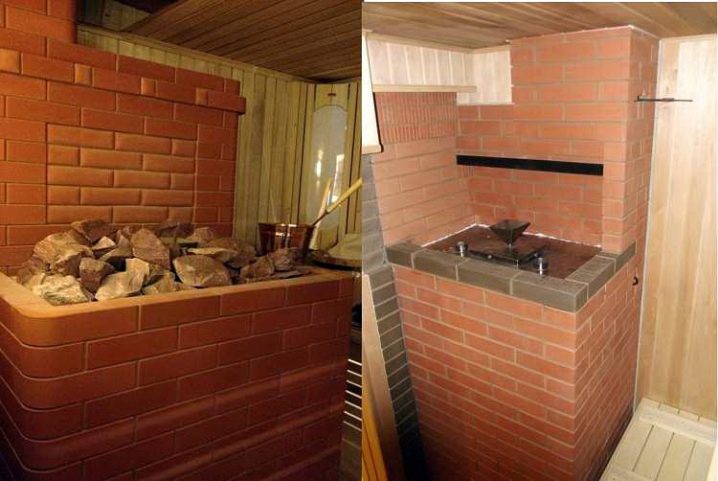

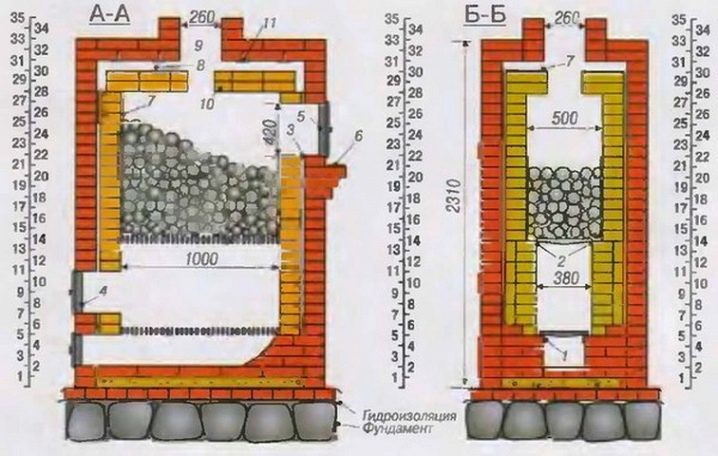

Brick construction comes in a variety of sizes and designs.and, therefore, can fit into any bathhouse, demonstrating the individuality of the owner. As a rule, furnaces are formed with a base of 3.5 by 4 bricks (89 by 102 centimeters), or 4 by 5 bricks (102 by 129 centimeters). Height without a pipe can be 168 or 210 centimeters. The most popular is the model with a tank for heating water.

Advantages and disadvantages

Preferring brick kilns, it must be remembered that they have both certain advantages and disadvantages. Among the advantages are the following:

- attractive appearance and ability to fit into any interior of the bath: both made of wood and brick;

- such a furnace will delight the owner for much longer than the iron one: unlike metal, brick is a material that will not be spoiled by small defects;

- no need for additional finishing work;

- emerging steam has a beneficial effect on human health;

- a heated brick will not release hazardous chemicals into the air;

- brick stove better maintains heat in the whole room of the bath;

- for kindling used fuel that is sold in any construction market, as well as the simplest raw materials that do not even have to buy: sticks, branches, newspapers, dry moss and others;

- in a room with a stove with a periodic effect, you can steam for 2-3 days and it will not cool down;

- if, after the bath procedures, simply do not close the door in the steam room, the stove itself will dry the bath;

- The chimney does not require monthly cleaning, unlike the metal firebox.

However, there are some disadvantages:

- the furnace structure itself is quite large, you will need to either initially build a large bath, or you will have to sacrifice some square meters;

- if during the assembly process mistakes are made, then the furnace will become poor in keeping the temperature, and the room will cool down quickly;

- brick is a rather expensive material;

- professional stove-house services are also distinguished by high cost;

- because of the large weight of the furnace, a solid foundation is required, the depth of which should be below the freezing point of the soil, and the foundation for the furnace should not be tied to the foundation for the very structure of the sauna house;

- the construction of the heater is a long-term and time-consuming task;

- to completely melt a bath with a brick oven, it will take a long time, up to 6 hours.

Kinds

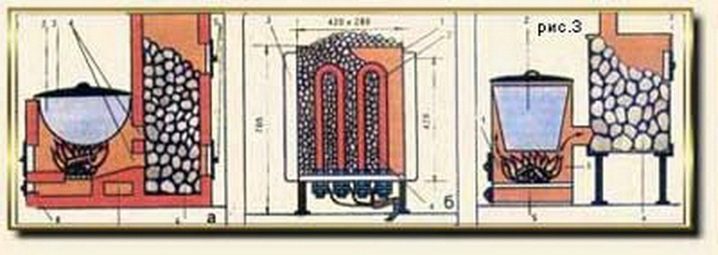

There are 4 main variations of sauna stoves:

- "In white";

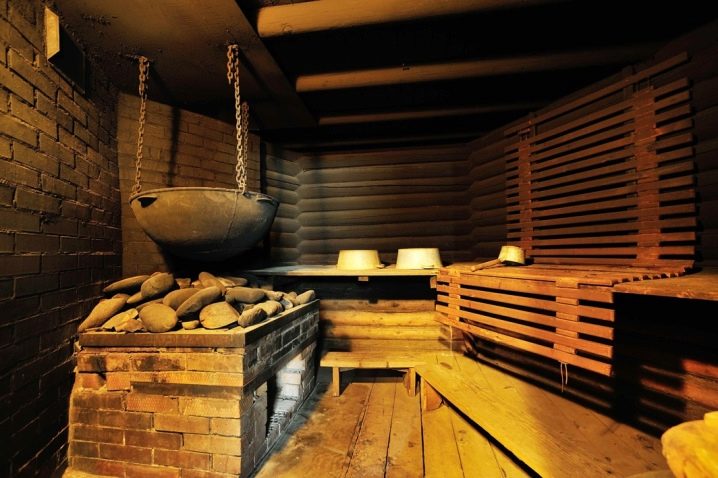

- “In black”;

- "In gray";

- with stove.

Stoves that are fired "in the black" do not have a chimney, and for many decades already used in villages throughout the country. All the fumes and smoke go through the steam room itself - naturally through cracks and roof gaps. Of course, this is how the best steam and aroma appear in them, and it becomes very pleasant to wash, but at the same time you have to wait until all the firewood is burned through. When choosing a “black” oven, it is recommended to treat the internal walls of the bath with a special solution that can prevent the occurrence of soot residues. Sauna "in black" have a very high efficiency, and therefore when using them you can save on fuel.

Further, the furnaces follow the difficulty, which are fueled "in gray." They have a chimney, but because the bath warms up much faster. However, you still have to wait until all the fuel is burned, as soot is deposited on the stones. The walls do not get dirty with soot, but when liquid is supplied to the stones, a small amount of soot microparticles appears together with the steam from the furnace. This design can be direct-flow and with channels. In the first case, the stones located above the firebox are on fire, and the gases go out into the air through a pipe, and in the second - through two valves.

Furnaces "in white" heat the room for up to 12 hours, but do not pollute the stones, therefore, are considered the most environmentally friendly. The process proceeds as follows: the overlapping metal plate is heated from the fuel, and from it - the stones that will keep heat for several hours. This method of heating is the most expensive - consumes a large amount of wood and other materials. Previously, the box in which the stones were put was made from ordinary black iron, and now from heat-resistant stainless steel. Traditionally, in “white” baths there are two separate spaces: a waiting room and a steam room directly.To warm both rooms, one side of the oven goes to the waiting room.

In the fourth case - with a stove - stones and a tank with water, the placement of which can be changed, are heated by two cast-iron plates. One of them is located above the furnace, and the second - above the chimney. On three sides of the plate should be fenced with a brick screen, which will ensure the high temperature of the water. Such furnaces are usually built independently.

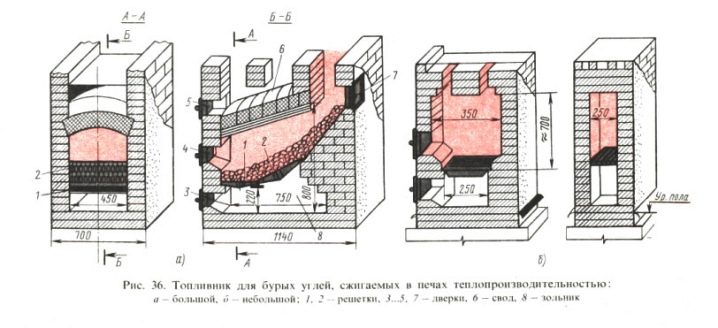

According to the type of fuel used emit furnace:

- wood

- melted by coal;

- natural gas;

- diesel fuel;

- wood chipboard briquettes;

- electricity.

By type of construction, they are divided into stoves:

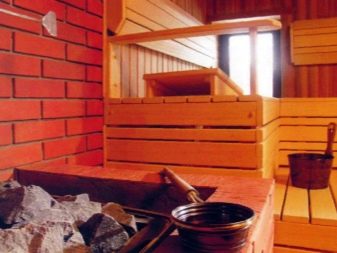

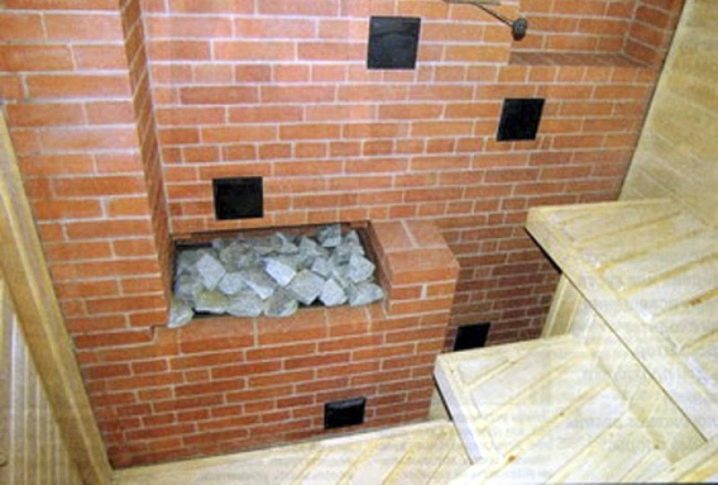

- with open stove (characteristic of the Finnish sauna);

- with closed stove;

- combined.

Kamenka in the first case is called flowing, and the furnace - periodic action. In the second case, the heater is direct-flow, and the furnace is of continuous operation.

Periodic stoves are usually chosen by large families.when many people go to wash, but the duration of the steam process is small. They have thick wallswhich for a long time store heat and provide the necessary period of functioning of the bath. Smoke passes through the stones before entering the chimney. The amount of stone backfill in such a heater is much larger than in constant-speed stoves.

Sauna stoves of continuous action have minimum wall thickness and volume of stones in an insulated metal box above the firebox. Their main advantage is the ability to use steam in the process of melting. Stoves with a closed heater are also safer. Heating is carried out inside the body through the wall, which is common to the heater and stove. Stones store heat much longer, and the air in the steam room at the same time has a stable optimal temperature. It will take about 4-5 hours to warm the air in such a bath.

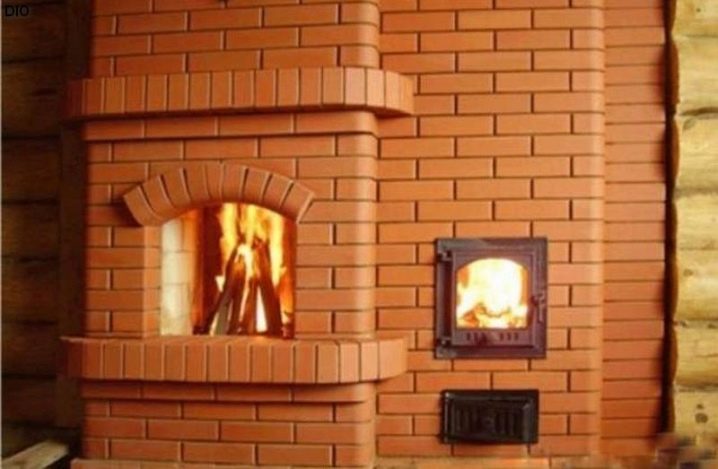

Separately, it is necessary to highlight such a variety as a stone fireplace stove for a bath. This design has an attractive design, but has low efficiency. If you install a valve made of refractory glass, you can protect yourself from flames and enjoy the rest in a warmed room.That is why fireplaces are often installed in the "waiting room". Modern technologies allow to design and mini-heaters. Such a design quickly warms the bath, but even after the fuel has completely burned down, the heating of the room remains. Its length and width are usually 2 bricks.

Design and style

There are various ways to design brick kilns.

- With the help of plaster, you can arrange embossed patterns, or simply create a neat smooth surface. Paint or decorative plaster is applied over the plaster.

- Painting is the easiest option. In this case, you only need to paint the oven with 1-2 layers of very resistant paint.

- If you need some kind of creative and effective solution, then you should turn to the facing of the portal of the furnace tile or stone in a sequential or chaotic manner. In the case when the fireplace is planned to be closed, glass cladding is selected, and the brick itself will serve as decoration. In general, the furnace can be faced with natural stone, majolica, unglazed terracotta, clinker tiles and porcelain stoneware.

Thinking over the color for the stove, it is recommended to rely on the interior design. For example, the loft style implies an artificially aged hand-molded brick.For a classic interior in soothing, light colors, as a rule, light yellow bricks are used. Thanks to modern materials it is possible to paint the stove in any light.

If there is a desire to arrange a log bath in the Russian country style, then the stove is best collected with your own hands. Usually it is revetted with tiles or simply plastered and painted white. It is also necessary to take care of the substrate, which can be glass-magnesite sheets or drywall.

Masonry patterns

If before building the heater did not happen, it is recommended not to be taken personally for drawing up a drawing, but to find a ready order and use it. Currently, various masonry schemes are used, the most complex of which are chosen by professionals, and simple ones by amateurs. In both cases, the result is satisfactory, and the furnace works effectively. In addition to traditional masonry methods, Kuznetsov’s bell-shaped sauna stoves are also distinguished. This design takes up much less space.

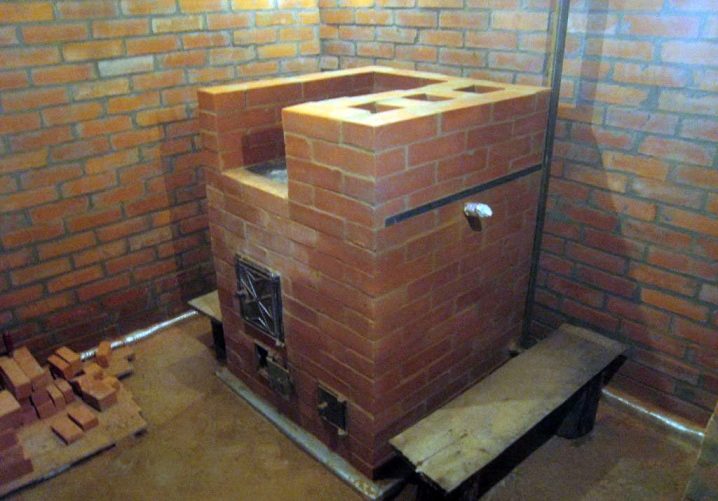

Initially, the stove is laid out on a dry one in order to draw a plan of order.It must be remembered that the standard schemes are not suitable for all rooms, so for each bath they need to be created individually, making the necessary changes to existing ones. As soon as there is a clear understanding of how each row is performed, it's time to start the main assembly.

Order always begins with the foundation of the furnace, the so-called zero row. At this level, stacking is performed solid, but a half-round is usually left at the side so that additional traction is created and the chimney shaft is cleaned. At the next level, the dressing is performed - this means that the row is shifted by 30-50% to make the structure sustainable. If halves or quarters of a brick are required, it is recommended to use a grinder with a diamond disc. It must be remembered that such elements cannot be located in chimneys, the mines of which are always assembled from solid bricks, but only inside the structure.

At the third level, a flap usually appears, and the installation of the ash pan begins. The fourth row indicates the appearance of the door for sampling soot. At the sixth stage, as a rule, the mine is divided by a jumper into two parts,one of which will become a slab mine. On the twelfth row, one of the mines will be laid, and only one main one will remain. Usually at the twenty-fifth and twenty-sixth stage the laying of the main structure ends, and further the laying of the chimney takes place.

Drawings and projects

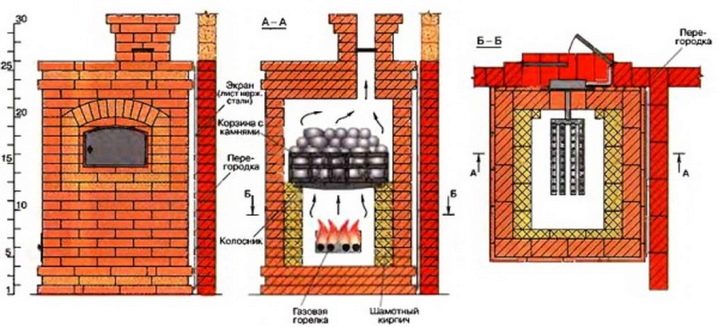

The project of a sauna stove differs from traditional projects: it has a special space for heating stones, which allows to heat the steam room at high speed. There are two main constructions of such a stove: grate and grateless.

In the fire grate, firewood is placed on a small grate or a grate. This device also serves as the bottom of the firebox, and through it is supplied primary air for ignition. Through the holes in the grate, the ash goes down, so there is a place for a new portion of fuel. The best material for this element of the furnace accessories is cast iron, since it is more resistant than steel. Such furnaces have high efficiency, high burning rate, and they are very easy to maintain.

There are one-piece grate, which can not be disassembled, and composing, consisting of several parts. In the first case, when purchasing a part, it is necessary to focus on the available area of the firebox, and in the second case, you will be able to assemble an element of the required size yourself. Steel grate produce chain or pipe. Steel are tiled, basket, beamed and movable.

The grateless furnace has also the name of the hearth. Firewood is placed on the under-deaf floor, on which it is also possible to cook and bake, and air is supplied through the firebox door. In such furnaces, “upper combustion of fuel” occurs, when the front spreads from the upper layers of the bookmark to the lower ones as it burns, which is considered to be a more ecological method. For such furnaces only wood materials are used: firewood and briquettes.

Some masters collect ovens "by eye"since they consider that both the assembly of the brick kiln and the iron lining are so simple that preliminary calculations are not needed for them. However, it is better to carry out preliminary calculations. Both the thermal regime and the amount of steam in the room depend on the correct design. Otherwise, it may happen that the air heats up very quickly and the stones stay cold.

The parameters are calculated based on the size of the room: length, height and width. The capacity of the furnace is also calculated depending on the volume of the steam room: 1 kilowatt of energy is required for each cubic meter.

How to do it yourself?

In order to independently lay down a standard furnace, first of all it is necessary to choose a suitable brick. The material must be very durable, capable of withstanding high temperatures and possessing refractory properties. The best option is considered to be a pale yellow brick based on refractory fireclay clay. It should be borne in mind that it is an expensive material, so when building a homemade furnace it is supplemented with solid red brick. For example, for fragments subjected to the strongest heating, fireclay bricks are used, and in order to enclose external walls, smoke stops and decorative elements - red hollow mark M from 75 to 150.

Choosing a brick, you should follow a few simple rules:

- When struck with a pick or hammer on a high-quality brick, a sonorous and clear sound will be heard;

- The brick must meet the standard parameters: 250 by 120 by 65 millimeters;

- The quality material has no pronounced damage and defects, with the exception of filiform cracks and grooves;

- If the brick has a “mica” film, this indicates marriage.

To build a brick oven, you need to have knowledge of the masonry of the blocks and the observance of a single order. First of all, the waterproofing layer at the base of reinforced concrete is equipped in order to cool the foundation. At the same stage, the stove is formed for storing inventory. Then begins the preparation of clay and sand to connect the elements, because the cement in this situation is not suitable. Clay is carefully pre-cleaned of stones and impurities and soaked for several days. It is recommended to take samples obtained at a depth of 150 centimeters below the surface of the earth. Career or river sand is carefully screened for pebbles or pieces of pebbles. After that, the clay must be stirred, diluted with clean water without musty odor and combined with sand prepared in the same way.

When using high-fat clay, it is recommended to dilute it with sand in proportions of 1: 2.To check whether the mixture is correct, you need to use a wooden stick. She plunges into the solution, and if the resulting layer has a thickness of 2 millimeters, then you can get to work. Experts also recommend to give preference to the clay underlying the selected brick, that is, either red or chamotte.

At the next stage it will be necessary to lay out brick blocks. As a rule, this requires ordering, a square, pliers, a broom with a shovel and emery wheel. Each brick is preliminarily placed in water so that all air bubbles escape from the pores and the solution is prevented from dehydrating. Fireclay bricks are not recommended to be immersed in liquid for a long time, just a few seconds is enough to remove dust. Masonry begins with a corner. The first row is laid on a dry foundation, without applying a sand-clay mixture.

At some point, the installation of a water tank, slabs, and, if necessary, grate, as well as fixing the doors. Regardless of the masonry method, the key parts remain the same: a refractory brick firebox, a chimney, a water tank and an ash pan consisting of a cast-iron plate, a firebox and a sub furnace. The drying of the sauna stove takes 4-5 days with the windows open in the room.After this period, it can be started to drown with small slivers 1 time per day, for a maximum of 10-15 minutes. While the condensate continues to protrude to the surface, the furnace is not yet ready for full operation. If desired, a finishing can be done after this, for example, revetted with tiles.

Tips

Constructing a stone stove, you need to take into account the following rules:

- At least 50 centimeters should be left between the coating of the furnace and the combustible structures;

- between the brick chimney and the wooden parts of the bath should remain more than 1 decimeter;

- a gap will appear between the smoke channel and the roof, which must be covered with a metal plate, for example, made of galvanized steel;

- the floor in front of the base of the furnace is also covered with a metal plate about 10 millimeters thick, it will prevent sparks and coal from getting onto the combustible surface;

- the weight of the furnace with the pipe, but without the foundation should not exceed 750 kilograms;

- Before laying, the entire brick is neatly sorted, items of the same thickness are picked up in order to get even seams - the best samples go for smoke channels and fireboxes;

- the stove is recommended to be erected near the wall, which is opposite to the shelves in the steam room.

Beautiful examples in the interior

Decorative spectacular decoration options beautiful and stylish stoves.

- A massive full-wall stove will be a bright accent of the steam room. It can be decorated with inlays of tiles, decorated with stone and original brickwork. The rest of the interior details, including the pots with buckets, are made of light wood. Brooms are an organic accessory.

- If there is a desire to design a bath in the high-tech style, it is necessary to use a laconic small heater, perhaps a mini, and shiny metal sheets in the interior. The latter can also protect the wooden walls.

- The right choice of stones will not only improve the quality of steam, but also decorate the interior. Experts recommend to give preference to river pebbles, basalt, porphyrite, who are not afraid of high temperatures.

- The sauna in the shape of a barrel with an open stove looks very original. In such a room, wooden walls are protected by metal plates.

- The fire chamber of the massive furnace can settle down in the next room - a waiting room.Large size and red brick will ensure respect for the rustic style.

- A neat compact stove can be decorated with a carved metal bucket with stones. The decorative element will correspond to the protection of the wall, decorated under a stone.

Review of the brick furnace for the bath, see the following video.