Barbecue: Step by Step instructions

The design of the barbecue perfectly combines the best qualities of barbecue, grill and smoke chamber. There is a huge variety of its models. Many barbecues can be made independently by following the step-by-step instructions for making.

Features and Purpose

The basis of the barbecue design is a box inside which there is a coal tray, a grill for cooking products. High sides protect the heat from blowing, and it keeps the temperature, heating the sides themselves.

This kind of design allows not only to speed up the cooking process, but also ensures even roasting, also prevents overdrying and burning of food.

The undeniable advantage of a barbecue is its versatility. both with respect to the design, and with respect to the possibility of preparing various dishes and products. On it you can cook not only kebabs, wings and any kind of meat, but also more everyday everyday dishes from soup to baked fish. In addition, it is ideal for quick drying of mushrooms and fruits. Homemade grill in the country will certainly become an indispensable thing. To make it yourself, you must select the appropriate projects, drawings and follow the advice of experts.

Species

All models of barbecue is divided into two options.

- Mobile models can be folded, easily carried, they are small in size and light in weight;

- Stationary models - This is a barbecue stove, made of brick or stone. They have large dimensions, and almost all models require installation on a foundation.

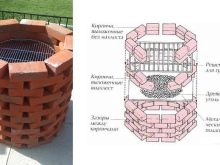

Mobile barbecues come from bricks laid out without the use of mortar. These street models are easy to assemble yourself, disassemble and reassemble. Designing in such structures is not very complicated. Stationary barbecues are usually brick or stone.The functionality of such a barbecue is limited only by its design.

The simplest model of mobile barbecue is disposable. Its design consists of a pallet for coal and a thin lattice. Since it is made of a thin type of tin, the pallet burns out after the first use. There is a large variety of folding models that fit into a small plastic case, which makes them easy to transport. Their design is very simple, consists of a roaster and a grate.

A more sophisticated model is a barbecue boiler. This original American version is made of chrome-nickel. In appearance it looks like a cauldron or a deep pan, is presented on three stable legs and is supplemented with a dome-shaped lid. Below is a rounded pan, which is suitable for plates and other auxiliary utensils. Thanks to this device and the presence of a lid, it can be easily used as an oven or a smokehouse.

Barbecue cart has a fixed or folding surface.

Hibachi is a round-shaped cast-iron model with stable legs and a height-adjustable grille.

Electric barbecue is convenient for use inside the house in the kitchen. Gas barbecue is a whole complex that contains the main functions of a barbecue and grill. Such models are more suitable for use in the catering industry. They are very massive, weighing about 60 kilograms, which relates them to a greater degree to stationary models.

Any model has many additional elements, which gives more comfort in use.

These include the following:

- built-in mechanical and automatic spit;

- open area of the firebox of increased size, due to which a variation of the garden fireplace is easily created;

- grill designed for frying products;

- place for the installation of the cauldron, which allows you to cook a large number of various culinary masterpieces in the fresh air;

- a separate barbecue area;

- construction for cooking kebabs;

- cooking and working surfaces;

- smoke chamber and not only.

Manufacturing materials

The basis for the barbecue are metal, natural stone, brick,foam concrete block and high quality concrete. The main requirements for the production of materials - it is their resistance to stress and high temperature. For the exterior of the barbecue oven there is a large selection of materials (natural stone, granite, shell rock). You can make your own barbecue construction from cinder block, blocks and foam blocks.

Original design looks from the usual barrel.

Where to place?

Proper placement of a barbecue is not only a matter of convenience and beauty, but first and foremost security.

The basic requirements for the location of the barbecue are the same for all models, namely:

- Smooth surface;

- there should not be flammable objects (buildings, plants, cars, etc.) in the vicinity;

- distance from the residential building at 5–15 meters;

- protection against rain under a canopy or roof;

- wind rose (the direction of smoke should be in the opposite direction from the residential building).

Do not forget that the strong heat from the barbecue can harm any vegetation, so do not need to have it surrounded by flower beds or garden beds.Suffer not only the appearance of the landscape, but also the harvest. It is also better to think in advance about the way to the barbecue from home and recreation area.

Dimensions

Requirements for all types of barbecue are standard.

- The minimum distance of the location of the brazier should be from 70 to 80 centimeters.

- The location of the plate is always 10 centimeters below the level of the roaster.

- Required storage of firewood and tongs.

The final height of the location of the brazier, cooking plate, surfaces of the cutting tables and additional shelves is calculated based on the growth and convenience for the owner.

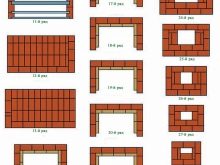

The simplest models of barbecue are equipped with a stove and worktop. They are under force and for self-erection. The dimensions of such a complex are 1210 mm in depth, 2240 mm in width and 1900 mm in height.

The simplest model of the oven-barbecue - it is assembled with the usual brickwork, which has a standard size. The height of such a furnace corresponds to 13 rows (about 702 mm each), specified on the basis of the thickness of the seam. The perimeter of the construction corresponds to the basis of 1810x900 mm. To build such a structure under the force even to an inexperienced builder.

The model of a barbecue stove with a hob will require basic skills of stove laying. The dimensions of this structure have the following standards: depth 1778 mm, width 434 mm and height 1900 mm.

When building such a barbecue, the Dutch masonry is used.

How to make yourself?

For self-erecting the simplest barbecue stove you will need materials such as:

- about a hundred bricks;

- Metal sheet;

- lattice.

The assembly of the structure and the lining are done in a specific sequence.

- On a flat, stable surface with a 1x1 meter perimeter, the first row is laid out. The shape of the future barbecue can be square, round or polygonal. The choice is limited to the desire of the designer;

- in the first row, the bricks are placed at a distance of about 5 centimeters from each other;

- the remaining rows of bricks are laid out in a staggered manner using the same technology;

- the number of rows is calculated from the desired height of the roaster;

- a sheet of metal is placed on the base obtained on which the coal will fall. On top of this, another 2-3 rows of bricks are being laid on the same principle;

- then the grilles and two finishing rows of bricks are installed.

This design is assembled without the use of mortar.that provides ease of assembly. It does not require special construction skills and takes a minimum of time.

Building a more solid construction requires laying the foundation, the size of which depends on the dimensions of the future barbecue plus 30 centimeters around the perimeter. They are calculated based on the size of the furnace and the availability of additional structures. Build a barbecue on your own is a snap if you follow the recommendations of experts.

There are three basement options.

- Finished concrete slab. A layer of a sand-gravel cushion about 5 cm thick, on which a reinforced concrete slab is placed, is laid on the bottom of the excavated excavation. The depth of such a pit is calculated based on the width of the slab plus a layer of pillow. This option will take little time, but has significant inconvenience due to the need for a crane for laying the plate, the cushion shrinkage can be uneven.

- A slab foundation is a more reliable option. Its peculiarity lies in the fact that the concrete slab is poured into the place directly in the pit.The technology is simple: a trench is dug about 35 cm deep, a layer of sand and gravel cushion is put in, a formwork is mounted, a reinforcement cage is made and concrete is poured.

- The most common and reliable option is a strip foundation. For the construction of a barbecue, it is placed not U-shaped, but along a closed loop. A ditch of about 50 cm in depth is pulled out for it, a layer of sand-gravel pad is made about 15–20 cm thick and a reinforced concrete foundation is poured.

The choice of a variant of the foundation is curled by the type of soil on which the construction will be. After choosing the construction site and the foundation, you can start building a barbecue. Folding a traditional type of barbecue is easy. This design does not require special skills.

The first step has been completed, the barbecue site has been selected, the foundation has been poured and it remains to wait until it is completely set (until approximately 3 weeks).

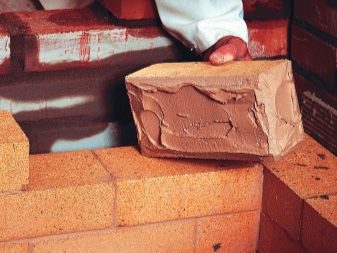

The second step begins with the preparation of building materials. For the construction of barbecue used two types of bricks: refractory and facing. The fire-resistant (chamotte or corpulent) brick is used for a laying of a fire chamber.Subsequent parts of the structure are laid with facing brick (it is possible to use other materials of both block and natural origin). Brick masonry requires less skill and is more affordable for self-built barbecue. Previously, shortly before laying, the entire brick is soaked in water.

The third step is erection. Before starting the laying work, the leveling of the foundation should be checked using a level. If errors are found, they are corrected when laying the first two rows using the thickness of the solution. The waterproofing layer is laid on the foundation without fail. As it is used ruberoid or other rolled materials. At construction the order scheme is used. It is calculated on the basis of a standard brick size 230x114x65 mm. When laying the firebox and furnace, clay solution is used, for further laying - ordinary mortar. Fireclay mortar is kneaded in advance from sand, red clay, water and cement.

When the erection of the furnace is completed, it is necessary to burn its internal surfaces.For this, charcoal or firewood is ignited in the firebox, bringing to the maximum temperature.

After heating the stove, it should be dried. The best option for it is a warm summer period, then it will take at least 5 days. If drying is carried out in cloudy autumn weather - no more than 20 days. In any case, it is worthwhile to take care of protecting the barbecue-oven from the rain and cover it. There is a final stage - it's glossing. The bricks are cleaned of residual mortar and painted so that the seams are emphasized. Now you can start operation.

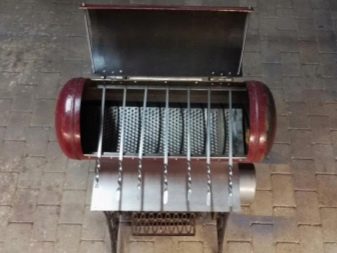

There are unusual options for self-production of metal barbecue. It should be immediately noted that their design is limited by the desire, ability and imagination of the manufacturer. One such option is a barbecue from a gas bottle. This is a very economical and affordable option, but it requires experience with a welding machine and grinder.

From an old empty gas bottle it turns out 120 cm long barbecue. If desired, it can be reduced by cutting off unnecessary centimeters and welding it over the cut. Such a barbecue, even the simplest of one gas cylinder, is weighty, therefore it is unsuitable for transportation, but due to the design of the legs it can be made both stationary and portable.

The main advantage of this design is simplicity and speed of production, since it will take no more than 2 hours. Due to the thickness of the cylinder walls, this option is characterized by increased wear resistance. The design is able to withstand high temperatures.

Regarding the rationality of manufacturing such a barbecue, there are disputes about the safety of the products cooked in it, since gas residues could remain on the walls of the gas cylinder. Therefore, it is worth thinking about safety immediately and before using the structure it is necessary to thoroughly wash and heat it several times. After this treatment, the barbecue is suitable for safe cooking of food. Before starting work with a gas cylinder, make sure that it is empty.

To remove the remaining gas from the cylinder, it is put upside down and the valve is unscrewed to the end. This trick is very effective, since the density of the gas is greater than the density of air, so it will come out faster. To test the gas output, it is necessary to lather its neck.

If the gas goes out, then bubbles will form, to finally certify in the vacuum of the cylinder, it will be filled with water.

Step-by-step description of the instructions for reworking a gas cylinder in a barbecue.

- A standard fifty-liter bottle is taken, and there is a production seam on it, along which a cut is made. For this purpose, the Bulgarian and edging wheel for metal. The side walls, meaning the bottom and the top of the balloon, remain intact, otherwise it will harm the brazier. As a result of the cut, the balloon was divided into two parts: one of them was the basis for the barbecue, the other was the cover.

- With the help of welding loops are fixed, initially fixed on rivets made of aluminum.

- Handles from heat-resistant metal fasten to a cover of a barbecue.

- Metal corners of 32x32 mm are welded along the perimeter of the hole in the balloon, which will serve as a support for the skewer. The same is done with the inside of the lid. Corners prevent deformation on cuts.

- Barbecue legs are welded. If it is stationary, the legs are fixed with concrete for greater stability. If it is thought out as portable, then wheels or small pins can be attached to the legs to drown in the ground.

- Small holes are drilled through the bottom of the hull to ensure thrust.

- Finishing of seams and cleaning of internal surfaces of walls.

Operating rules

Any thing requires proper and timely care. To avoid unpleasant consequences, you should follow the rules of operation.

It should be timely to clean all the details of the design, namely:

- the grill, doors and subsequent parts of the furnace should be cleaned of dirt and soot every time after its use, waiting for the furnace to cool down completely;

- the furnace tube must be cleaned from soot at least 2 times a year;

- release the hearth of burnt coal and food debris after each use;

- you need to check the furnace for the presence of accumulated water or snow in the absence of the tip in the chimney or canopy over the pipe.

Experts recommend to strictly follow these safety rules:

- mandatory constant monitoring of the intensity of the flame;

- no flammable things near the stove.

In the case of the use of means of ignition it is worth remembering that:

- it is allowed to use only starters, strictly following their instructions for use;

- the use of gasoline, kerosene and other lubricants is strictly prohibited;

- cover the barbecue with a lid at least 15 minutes after ignition to avoid ignition of the accumulated combustible gas;

- in no case can one impregnate firewood with such means, only spray for ignition.

In the cold season, barbecues at the beginning of use must be dried for 20 minutes over low heat. This will prevent premature wear and the appearance of cracks in the design of the furnace from a sharp temperature drop.

Examples of finished structures

- At construction of a barbecue the order scheme is used. It is based on a standard brick size 230x114x65 mm.

- Mobile barbecue made of brick, laid out without using the solution, it is easy to assemble yourself and, if necessary, disassemble and assemble again. This design is suitable for corner models.

- One of the unusual models of barbecue, made from a gas bottle, looks unusual and stylish. This design is limited to the desire, ability and imagination of the manufacturer. Any gazebo will become more functional with this design.

For information on how to make a Finnish outdoor barbecue oven with your own hands, see the next video.