Foil Penofol: characteristics and application

Professional builders and people who follow the changes in the market of finishing materials will be the first to know about new products. For those who encounter them for the first time, a number of questions may arise regarding their features and areas of application. One of these materials is foiled polyethylene foam, also known as penofol.

Material Features

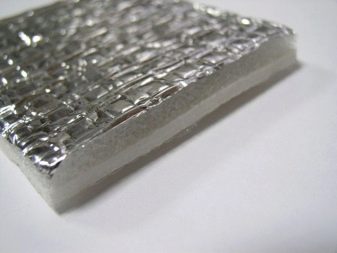

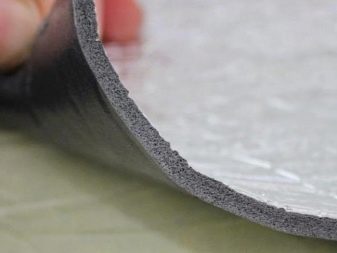

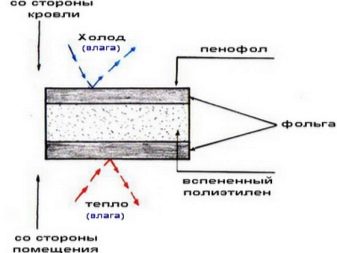

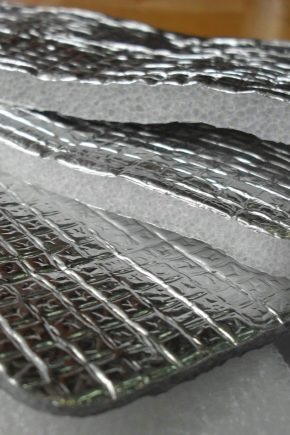

This foil construction material has a significant advantage over the others due to the double action: it prevents the penetration of moisture and retains heat with the help of an aluminum insert. Consisting of a foamed polyethylene layer coated with thin aluminum foil, penofol works on the principle of a thermos.

This material with high hydro and thermal insulation replaces the usual insulation and polyethylene, which were widely used in construction and repair.

Foamed polyethylene underlying penofol has a thickness of 0.2–1 cm and may have a different structure and density. A foil 20 microns thick is applied on such a base with the help of heat sealing, the purity of this foil must be at least 99.4%.

The main technical characteristics of the material are:

- water absorption in 0.3–0.7% of the total;

- heat reflection 95–97%;

- depending on the variety, the coefficient of thermal conductivity ranges from 0.31 to 0.51;

- The material retains its properties at temperatures ranging from -60 degrees to + 100.

Advantages and disadvantages

The main function of this multilayer material is to protect a particular structure or space from various environmental influences. This non-combustible building material has many advantages.

- Versatility. Penofol is used not only to preserve heat and protect against moisture. It has high vapor and sound insulation, allowing to reduce the use of a large number of different films.The product can be used both indoors and outdoors, as it is not at all afraid of moisture.

- Subtlety material. Penofol thickness is several times less than many similar insulants. When installing even in the smallest room, you can not worry about the reduction of living space.

- Wide selection. The material is marketed by a wide range of species. Therefore, it is easy to choose the one that is necessary for the current work and taking into account the specific conditions.

- Quality level The material is made using the most modern technology, which allows to reduce heat loss of up to 4%. In winter, in a room decorated with penofol, it will be warm, and in summer - cool.

- Easy installation. Material produced in rolls is light and plastic. This allows you to cope with the work even in the most difficult areas of a person who does not have experience in the construction industry. This building material, in contrast to the old heaters, does not need to construct a frame. It can be glued directly to the rough wall, and can be cut with ordinary scissors.

- Environmental friendliness. Unlike mineral wool, you can work with penofol even with bare hands, since it does not cause any irritation on the skin.This insulation can be safely used even for installation in kindergartens and schools.

- Practically does not burn. It can be described as flame-retardant.

- Without parasites. This insulation does not serve as food or home neither to rodents nor insects.

- Easy transportation. The weight of one roll of penofol is so small that you can easily carry it in your hands all the way from the hardware store to the house. The material is difficult to deform or break.

- Radiation protection. It is almost the only insulating material that can reflect radiation exposure. This effect is achieved by aluminum foil and is necessary for some industrial facilities.

Unfortunately, with all its positive properties, penofol has some drawbacks. Due to the soft surface of the material, it is impossible to finish the plaster, as it just does not hold on it and is easy to break. The installation of such insulation with metal clips will violate its integrity and may reduce the heat and waterproofing characteristics. It is necessary either to purchase it on a self-adhesive basis, or to plant it on a special compound that is purchased separately.

Despite the high rate of heat preservation, the material is recommended to be used in conjunction with other heaters.

Kinds

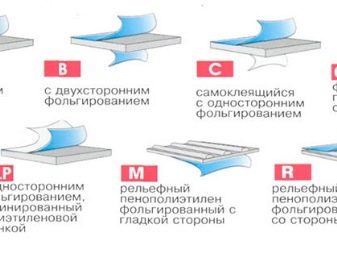

Flexible insulation is available on the market with various models, which are designated by the letter A, B, C, ALP, R, M, AIR and Super NET. The most popular are the first three types of penofol.

- The letter a tells the buyer that the foamed polyethylene is covered with foil on one side only. A-Penofol is recommended to be combined with other heaters.

- V-Penofol, unlike the first, double-sided and can be used without additional materials.

- Letter c written on self-adhesive product. Moisture resistant glue allows you to lay the material on the rough surface without additional materials and tools.

- ALP marking applied on penofol, which is often called "laminated." Since aluminum is coated with a polyethylene coating, it resembles a sheet of foil sealed in a transparent coating. Such material is used in non-aggressive environment and agricultural construction.

- R, M. The coating of the material is done on the one hand, but it is corrugated.

- AIR-Penofol mounted in the air vent structures and rooms.

- Super NET used for insulation of communication networks, as the "NET" from the English "network".

Also in the construction market can be found material called "Penofol 2000", which is much cheaper than the usual types. However, professionals do not recommend the use of this analogue, since according to its characteristics it is significantly inferior to any marking of standard material.

Dimensions

Rolls of such material may vary in size depending on the type.

- For all types of material, except ALP, thickness from 3 mm to 5 mm, as well as 8 mm and 10 mm is standard. Their width of 1200 mm remains unchanged, and the length varies from 15 m to 30 m in one roll.

- ALP-Penofol is produced in a thickness of 3 mm, a width of 580 mm and a roll length of 15 m.

Since this is a registered trademark, it is produced exclusively by LIT. But this insulation in the construction market can easily be replaced. Such materials as izolon, tepofol, magnoflex and porilex can be used both to preserve heat and prevent the penetration of moisture. Some materials may even be more economical than penofol, however, it surpasses all of the above in quality and quantity of properties.

The price of foamed insulation depends on the thickness of the material, marking and the length of the roll. Classic A-Penofol has a price of 160 rubles. per square meter, B-Penofol costs from 180 rubles. for the same footage. And self-adhesive heat insulators on the market in the price range of 230 rubles. per square meter and above.

Scope of application

Since the technical characteristics of the foamed heat insulator make it possible to achieve significant results, penofol is widely used for insulating various utilities and industrial premises. According to customer reviews, he also does an excellent job with tasks in ordinary houses and apartments.

With the help of foamed polyethylene, covered with foil, you can warm the following structures and structures:

- wall insulation inside and outside the room;

- creation of a warm floor, organization of warm loggias and ceilings;

- thermal insulation of various boilers, expansion tanks and refrigerators due to the thick foil layer;

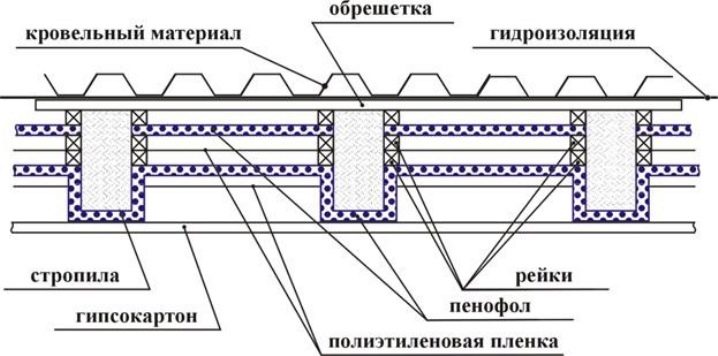

- for installation from inside the roof during roofing;

- thermal and water insulation during the construction of saunas and baths;

- protection of ventilation systems, air ducts and other engineering communications.

In addition to the above, various heated and open warehouses and hangars are insulated with penofol, they isolate vans and wagons. The material is placed under the battery so that it shields the outgoing heat.

Installation Tips

To Penofol revealed all its useful properties, it must be properly mounted. For each type of finish has its own nuances of installation. For example, for the insulation and insulation of internal walls, the sequence of works is one, and for external walls - another.

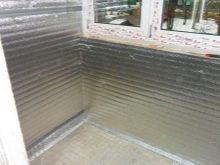

Internal work

To insulate the walls from the inside, first of all, it is necessary to build a wooden rack frame. This design will save a small space (about 20 mm) before and after the insulation, which will help to show the technical characteristics of the foam insulator. Foil penofol with a thickness of up to 5 mm is most often used indoors, but if necessary, more expensive material with a thickness of up to 10 mm can be glued.

The frame rails are mounted in increments that exceed the width of the roll of penofol by a few millimeters in order to easily stack it into the resulting strips. However, the pitch should be no more than 1000 mm.

After mounting the frame, it is very important to check all wiring and communications. If necessary, they can be isolated additionally, making sure that the metal of the foil of the penofol does not come into direct contact with the wire.

If there is no need for additional insulation, then you can immediately proceed to fixing the material on the frame with the help of a construction stapler. Do not stack foamed polyethylene overlap, as this can lead to the formation of steam and condensate flowing along the connecting seams.

After the insulation is laid, it is necessary to mount the second frame, leaving a layer of free space of 20 mm. Sheathing such a frame can be drywall, which is subsequently painted or covered with wallpaper with glue. Each roll also shows a small instruction manual for installation and operation, which is also recommended to be studied. To insulate the floor inside the room, penofol can be mounted directly on the subfloor under the screed, which allows you to lay on top any surface you like.

Exterior design

Warming of external walls and communications is carried out using penofola, which is planted on a special glue.Beginners should use a more expensive type of self-adhesive insulation, which is easier to work with than with ordinary types. Installation begins with the preparatory work: the surface of the walls must be cleaned, the concrete slightly sanded, and the wood treated with antiseptics. Installation is best done in dry warm weather.

As with internal insulation, installation of penofol from the outside begins with the construction of a wooden frame. It is possible to fix the slats to the draft wall with ordinary screws, and the joints of the laid material should be glued with a special aluminum tape for greater waterproofing.

You should not use ordinary nails or staples, as this will violate the integrity of the insulating material and allow moisture to get on the draft wall, despite the insulator laid.

When laying the roll material you should not forget about the airspace that needs to be left behind the penofol and in front of it. If in the process of work the material was cut in the wrong place, it is easy to fix using the scotch tape that held the seams. For higher rates of heat conservation, penofol can be placed in two or three layers.

The next stage is mounted on the outer frame, on which are mounted various finishing materials. Most often on the warmed surface mount a siding or a professional flooring. Warming open balcony or loggia is carried out according to a similar algorithm with the only difference that in such cases penofol mounted overlap.

Summarizing, we can say that the appearance on the market of such a material has significantly simplified the solution of many problems. With a thickness of only 5-10 mm, it has unique indicators of heat, hydro, steam and noise insulation. Of course, the choice of insulation depends on the specific situation and personal preferences of the buyer, but the presence of a large list of advantages today makes Penofol one of the leaders in the market of building materials.

How to fix penofol to the wall, see the video below.