Extruded TekhnoNIKOL expanded polystyrene: types and advantages

Thermal insulation is an important attribute of each apartment building. It helps to create optimal living conditions. The main element of this system is the insulating material. On the modern market there are several types of these products, differing in the place of use and technical parameters. Therefore, it is important to select them correctly for solving certain tasks.

Features: advantages and disadvantages

Extruded polystyrene "Technonikol" is a kind of insulation, which are produced by the same company.It is obtained by extrusion, which involves foaming the polymer and forcing it through special holes. With this effect, the substance becomes porous.

It should be noted that the pore size inside the material is almost the same. This value ranges from 0.1 to 0.2 mm.

Expanded polystyrene of this brand can be used for insulating the facades of both industrial and household buildings. The high popularity of thermal insulation due to several of its advantages:

- High durability. The material is practically not destroyed by moisture and mold. Another feature can be considered resistance to compression. The substance is able to maintain the form for a long time.

- Easy installation. The material is fixed to the base with glue or special hardware. You can do this without even having experience working with such products.

- Long service life. Expanded polystyrene retains its original characteristics for many years, which allows you to create reliable and high-quality thermal insulation systems.

- Ecological purity. The material does not emit any odors and harmful substances.Still, the substance is artificial, so its safety for human health has not yet been fully studied.

- Wide range of operating temperatures. The heat insulator can be used in conditions from -75 to + 75 degrees.

- Minimum thermal conductivity.

The only drawback of polystyrene can be considered its low resistance to fire. This material is highly flammable and supports combustion. These figures are almost similar to those present in the foam. Also, when burning, the heat insulator emits toxic substances that are harmful to human health.

To minimize these drawbacks, the manufacturer adds various excipients to the product. With their help, the combustion quality is significantly reduced and the self-extinguishing characteristic of the material is improved.

Specifications

Expanded polystyrene plates are quite common. This product is characterized by several unique indicators:

- Coefficient of thermal conductivity. This value depends on the type of polystyrene foam. On average, it varies in the range of 0.032-0.036 W / mK.

- Vapor permeability This indicator is approximately equal to 0.01 mg / m h Pa.

- Density. The value may vary in the range of 26-35 kg / m.

- Moisture absorption. The material absorbs poorly water. This ratio does not exceed 0.2% of the volume that will be immersed in the liquid.

- The indicator of elasticity reaches 17 MPa.

- Strength characteristics are 0.35 MPa (bending).

- In order to deform the material by 10%, when compressing, a force of 200 to 400 kPa should be applied.

- The service period is up to 50 years.

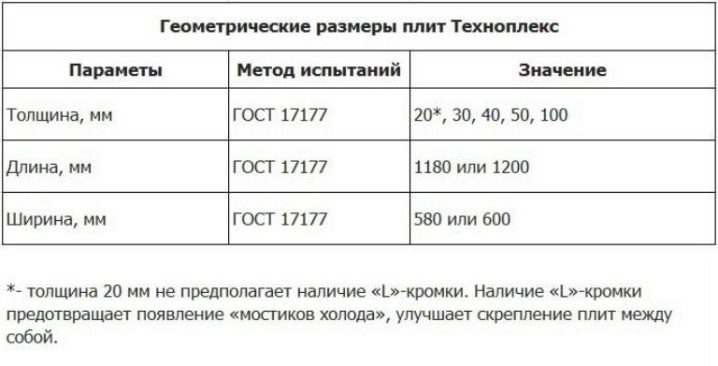

Let out expanded polystyrene in the form of plates which easily give in to cutting. Today there are many sizes on the market. The thermal insulation characteristics of the substance in most cases depend on the thickness. Standard indicators for this parameter are:

- 20 mm;

- 50 mm;

- 100 mm.

The thicker the leaf, the better it keeps the heat. As for the sizes of plates, there are also several standard values:

- 50x580x1180 mm;

- 1180x580x50 mm;

- 100x580x1180 mm;

- 1200x600x20 mm;

- 2380x600x50 mm.

It should also be noted products with a slope, in which the thickness varies depending on the side of the structure. A wide variety of dimensions allows you to fit the optimal type of products to solve specific problems.

Species

Extruded polystyrene foam "TechnoNIKOL" is very popular among builders. This has led to the emergence of many varieties of similar products, which differs in various indicators.

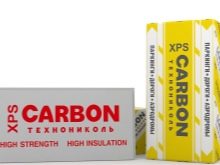

Today, among all this diversity, there are several brands of materials:

- "Carbon Prof". The highest quality product "Technoplex XPS" with minimal heat loss. The coefficient of thermal insulation is only 0,028 W / mK. Still should highlight the strength of the material. Often this extrusion product is used in the finishing of walls, roofs or foundations of commercial, warehouse or industrial buildings. Very often, wedge-shaped materials are installed on the roof to create the desired slope slope. This brand is also divided into several varieties with certain distinctive characteristics.

- "Carbon Solid". A distinctive feature of this product is a high coefficient of compressive strength, which reaches 500-1000 kPa. Therefore, this material is in demand in the construction of floors, landfills, roads or railways.

- "Carbon Sand". One of the simplest products of this group. It is very often used as an intermediate insulating layers in the manufacture of sandwich panels, as well as truck bodies.

- Carbon Eco. The products are characterized by unique thermal insulation and strength parameters. The manufacturer to change the properties of the material adds a certain amount of carbon particles. This category of heat insulators includes special drainage varieties. In their structure there are many small drainage ditches. This contributes to better water drainage. Use materials as for arrangement of drains, and warming of the bases, roofs and other places.

- "Technoplex". Universal material of general purpose. In most cases, it is recommended to use it only indoors. Therefore, this heat insulator insulate the floors, walls and partitions.

- Carbon Fas. Products have a rough surface. This structure allows to increase the adhesion of the material and bases. Therefore, more and more often they are used for finishing facades, which are then planned to be covered with various types of plasters.

Purpose

Expanded polystyrene "TechnoNIIKOL" is used very often. Today with its help solve several main tasks:

- Wall insulation Often the heat insulator is mounted on the outer surfaces of balconies or loggias. Sometimes it can be found as the main insulation of the facades of small private houses.

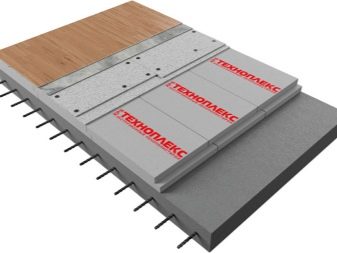

- Warming of floors. Such polymeric heat insulators are great for laying under the laminate and other similar coatings. This allows you to create optimal and comfortable conditions for moving people.

- Warming foundations. For such works, it is necessary to design a technological map, where all the basic calculations are carried out. But for such operations only special types of heat insulators are used that can withstand aggressive media.

- Thermal insulation of roofs. The polymers are used as intermediate layers, which are then coated with a layer of hydro insulators. The practicality of using products in this direction is due to the fact that the substance is able to withstand high loads, while retaining its original properties.

- Road construction. Very often, such materials warm the soils, which are planned location of runways, etc.

Expanded polystyrene is quite popular material, as it is used to solve both standard and specialized tasks.

Tips for choosing

When choosing such products should pay attention to several parameters:

- Specifications. It is important that the material corresponds to the place where it will be applied. For example, if the substance will yield to large loads, then pay attention to the strength. When the level of insulation is important, you should consider the coefficient of heat loss.

- Qualitative indicators. You can define them quite simply. To do this, just break off a small piece and analyze the surface of the gap. When the surface is relatively flat, and small fractions have the shape of polyhedra, this indicates high quality. If the structure is characterized by the presence of small balls, then polystyrene in its composition is close to the foam and is not of high quality.

Particular attention should also be paid to the materials with which it is planned to fix the heat insulator.The polymer is not able to withstand various chemical effects. Therefore, all substances to work with it should not contain such substances:

- bituminous glue;

- ethyl acetate;

- acetone and other organic solvents;

- coal tar.

Facade insulation technology

Extruded polystyrene foam has a high porosity and minimal strength. Its installation is a fairly simple operation that is easy to do with your own hands without experience.

Please note that this material can be laid not only on the facades, but also to install the floor.

Consider the technology of wall decoration in more detail. This process consists of several consecutive steps:

- Preparatory operations. Initially, the facade should be processed to get a solid foundation. Preparing walls involves removing dirt, removing gaps and leveling the surface. The last step is not always required. Minimize irregularities can be using different thickness of the adhesive, which will be located on the expanded polystyrene tile. After cleaning the facades are primed with special solutions.This treatment allows to increase the adhesion between the joined materials.

- Fixing plates Initially, you should attach the sheets to the wall and through them make the mounting holes for the dowels. It is important to accurately determine the location of the material along all planes. After that, glue is applied to the plate and applied to the wall. Please note that it is not advisable to use some types of glue immediately. Manufacturers recommend waiting a little time for the composition to be absorbed into the polymer structure. The procedure is completed with additional fastening of materials with the help of special dowels.

- Finish When the glue dries, a finish can be applied to the plates. In most cases, plaster is used here, but it is possible to form a substrate for clinker or another type of tile. All this must be considered depending on the recommendations of a particular manufacturer.

Production

Extruded polystyrene foam is obtained in several successive stages:

- Initially, suspension polystyrene is mixed with various additives. They are needed in order to change its physical characteristics. Often, manufacturers use flame retardants, clarifiers and dyes.When the composition is ready, it is loaded into an extruder.

- At this step, the raw material is amenable to pre-foaming. The structure of the material is saturated with a large amount of air.

- When processing is completed, a lot of sintering and molding. After that, the mixture is cooled. In most cases, the foam gets cold naturally. At this stage, the composition also further foamed.

- The procedure ends with the extrusion of the material, its stabilization and final surface treatment. At the very end, the substance is cut into plates and served on the packaging.

Extruded polystyrene foam is a unique heat insulator that allows you to quickly get the optimal level of thermal insulation with minimal cost.

On how to warm the floor using extruded polystyrene foam, see below.