The subtleties of the process of wall insulation

Winter can bring pleasant emotions. But only in the case when you can enter the house and enjoy its warmth. To do this without extra heating costs, you need to take care in advance about the thermal insulation of housing.

Special features

Wall insulation is significantly different from the work of retaining heat floor or ceiling. Much less often resort to the use of bulk materials. We have to take measures to ensure that the bulk substance does not clog under its own weight. The thickness of the structure is critical. It should not take up much space in the room. No less significant is the severity of the insulation block: if it is very massive, it will be necessary to strengthen the foundation, which will lead to its appreciation. All this means that decisive importance belongs to the right choice of insulation blocks and systems.

Materials

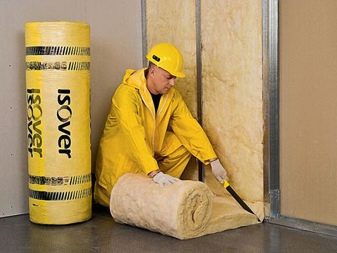

A growing number of people are now using mineral water. "Isoverom". It guarantees an optimal microclimate in a residential area, regardless of the heat or cold outside. Its main technological characteristics are as follows:

- thermal conductivity is 0.041 W xm hK;

- effective suppression of noise coming from outside;

- average density is 13 kg per 1 cu. m;

- absolute protection from fire;

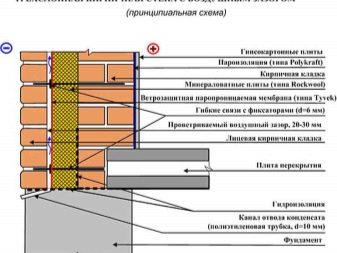

- reliable protection against condensate (provided that a gap is left for moisture extraction of at least 20 mm);

- minimum stable operation time is 50 years;

- perfect sanitary and environmental safety.

If the wall can not carry a significant load, it is quite practical and convenient to insulate it with Izover. Such a solution makes it possible to guarantee complete protection from the cold, whatever structural material is used. If the outside air temperature reaches extreme positive or negative values, the insulation will retain its basic qualities. But do not take "Izover" as a universal solution.Like any mineral wool, it can have a devastating effect on the human body and animals.

Under this brand material is supplied with various characteristics. It:

- lightweight construction;

- general construction soft plates and mats;

- mineral insulation under the pitched roof.

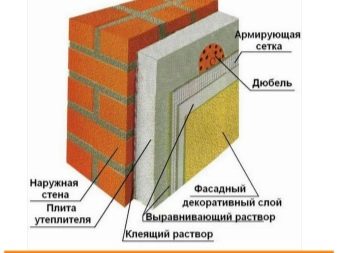

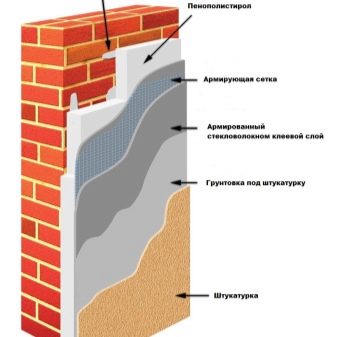

Installation of insulation for the cinder block house is strictly required. When it comes to cold housing, there is little joy. The construction of cinder block a considerable part of the masters and amateur builders are trying to warm the foam. It passes a little heat and is quite durable mechanically, although it has a low density. What is very useful, there is no need to spend money and time on the installation of a waterproofing membrane.

Polyfoam differs in good antiseptic properties. Buying it is not difficult for people with any income level. But there is a serious limitation: the likelihood of fire. Initially, you will have to apply a primer to ensure the most powerful adhesion to the substrate.

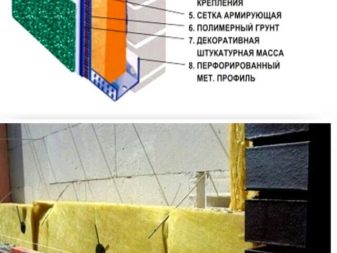

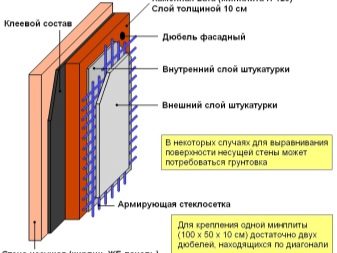

A prerequisite for success will be the installation of fiberglass reinforcing mesh. This grid is of two types: for internal and external amplification.To confuse such species is undesirable.

Has its features and insulation aerated concrete walls. Blocks of cellular concrete contain many gas bubbles (hence the name). They must be insulated in any case, regardless of production in the autoclave or without it. For aerated concrete, a whole range of heaters was invented, but more than other options, foam plastic and polyurethane foam are more popular variants. The second material is considered more reliable and modern. But its application without the help of a brigade with special equipment is impossible. Polyfoam and PPU are less durable, but the house owners themselves can use them.

Aerated concrete can be isolated from frost and simple mineral wool. But it is worth doing only as a last resort. The ability of wool to concentrate water vapor will negatively affect the properties of the blocks. To warm such houses will also have to inside. For this purpose, experts recommend the use of plaster mixes. Moreover, it is the inner work on warming that precedes the outer, and not vice versa.

In many cases, builders use stone wool. This material has really earned its reputation.It is obtained from basalt, metamorphic rocks, marl. Typically, construction firms acquire the basalt option for the most demanding projects. But it is equally important to take into account the level of acidity. The less pronounced the alkalinity of the cotton wool insulation, the harder it will last, the longer it will last.

To increase the resistance to water, phenol-formaldehyde resins and other additives are added to stone wool. Therefore, it is important to find out what the exact chemical composition of the mixture, so as not to encounter sudden toxic effects. Although the stone wool itself will not catch fire even when heated to 1000 degrees, its binders will evaporate at 200. Therefore, in the event of a fire or other emergency, the entire insulation will have to be removed and replaced with a new one.

The advantage of such insulation is also the fact that all the excess moisture leaves the rooms or working rooms, not lingering in the insulation. As for the negative aspects, then we need to remember about the abundant dusting and inevitably high price of products. Buying material, you should pay attention to the conditions of its storage. You can not buy cotton wool outside the factory packaging and without shrink film.Packing is recommended to check that there is no leakage. It is unacceptable to store material on the street without a canopy or awning. When stored in cardboard boxes, technological requirements prohibit placing them where there is at least insignificant dampness.

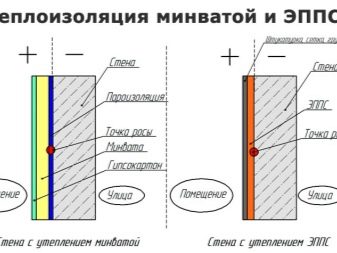

Scheme

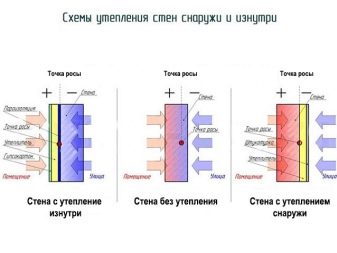

Warming of the concrete wall of the house from the inside is practiced in those cases when it is impossible to perform external work. Concrete creates many difficulties and problems in the winter, and in apartments it is almost always warmed inside. The services of industrial climbers or lifting equipment are very expensive. In addition, the housing inspection is almost never considered by the project of selective thermal protection of a single apartment. Doing work without coordination means to face a wave of fines or deprivation of housing for arbitrariness.

The easiest way to keep warm in a concrete house with plaster. But not always it gives a decent effect. In the coldest regions or even the corner of the house, the microclimate will not return to normal. The first actions in any case are exposing the constructional surface and antiseptic treatment.Then you have to wait for the complete drying of the substrate. Warm plaster do in three stages:

- sprayed;

- primer coat;

- nakryvka (outer decorative coating).

The original thin layer is a solution of 1 share of cement and 4 (5) shares of well-sifted sand. This solution must have a liquid consistency to stay on the surface. The layout is made with a hard trowel. Make an effort, trying to inject the solution deeper into the pores of the base. The total thickness of the first layer can reach 1 cm, it should be done evenly over the entire surface.

The primer layer is created using typical cement plasters of the appropriate category. But it is better at this stage to make a choice in favor of a material with low thermal conductivity. The primer is put in a layer from 5 to 6 cm, and it is created in three steps. Each subsequent processing is carried out only after drying the already applied material. Next you need to make the front cover (not thicker than 0.5 cm).

Covering solution - finishing putty, diluted with water to a liquid state. Work lead by rubbing this solution into the primer.When the treated surface dries, it is further improved by grouting and grinding. If such a solution is not effective enough, it will be necessary to veneer the concrete wall with foam.

As in the previous case, antiseptics can not do.

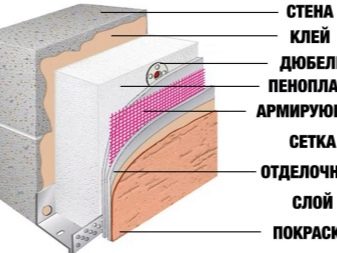

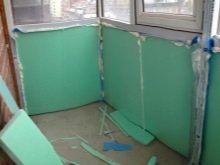

The dried disinfected wall is covered with a finishing liquid putty with a layer of 0.5-1 cm to level the surface. Then, in any case, put a waterproofing layer from 3 to 5 mm. The foam is glued with a specialized powder formulation, which is stirred in water for 90-120 minutes prior to the start of work, turning it into a thick uniform lump. Smear glue to the entire wall evenly, the sheets themselves are only enough in the center. Gluing produce with little pressure, the joints should be tight.

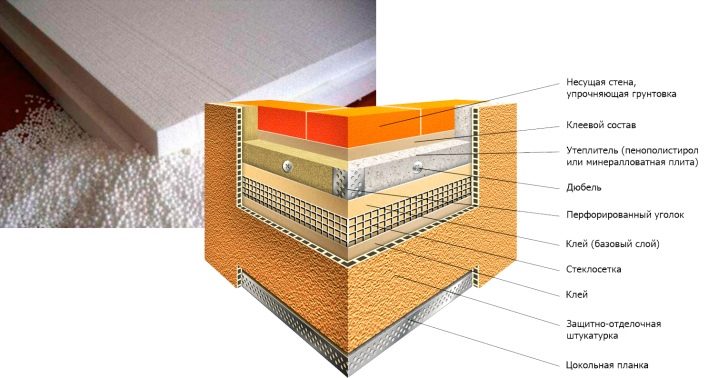

Seams after gluing sheets need to be covered with filler or foam. The final hardening of the adhesive, depending on its formulation and working conditions, occurs 48-96 hours after application. Reinforce attachment to the wall using plastic dowels. The final plastering of the foam is carried out on the polymer mesh. It should be embedded in the glue, cover the final plaster (necessarily rubbed and ground).

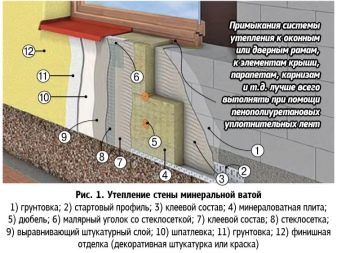

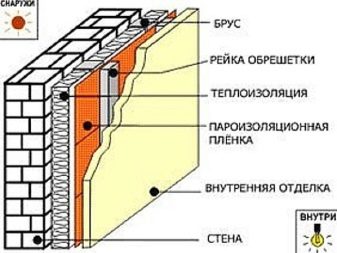

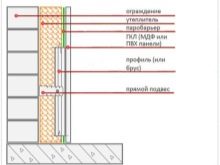

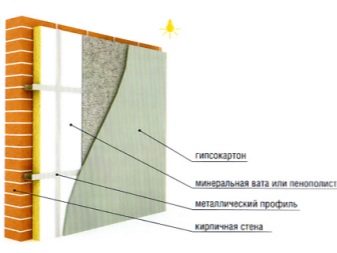

Technically attractive is the insulation of concrete with fibrous materials, including mineral wool. Under it will have to create a frame of wood impregnated with antiseptic preparations. Fastening the rails should be done vertically (from the top to the bottom points of the wall), the distance between the lines is approximately 0.6 m. You need to attach the material to the rails with anchors, drilling 3 holes in each wooden piece.

To do this, take a drill with a diameter of 0.8 cm. The rails themselves are held with screws on the concrete. The intervals between the slats are supposed to be laid with roofing felt. Above it is a cotton layer. Laying insulation is made in 2 or 3 levels, above it have an insulating vapor foil film. It is pressed to the rails on the building brackets. The insulating block on top is closed for decorative purposes:

- drywall;

- chipboard;

- plywood

In private construction is great popularity of brick houses. They are even more popular than concrete, because they are a little inferior to them in strength, they keep heat better and are more aesthetic. But the thermal qualities of the best grade of bricks are not enough to protect against Russian frosts. To prevent condensate from dripping from the inside of the wall, and no cold drafts go around the house, you can use:

- expanded clay;

- mineral wool;

- penoplex;

- Styrofoam;

- polystyrene foam;

- warming plaster;

- EPPS;

- cork;

- environmental cotton wool.

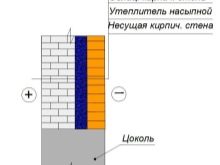

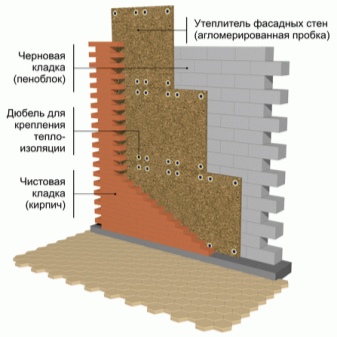

External insulation with polyurethane foam is carried out on a frame made of wood or metal. This material is also suitable for internal thermal protection. If the house is still planned to be built, it is possible to build an internal brickwork in the project. Such a step is no worse than special plates or rolls. First of all, they put the outer wall, lift it up to 150 cm and steel rods are successively introduced into the seams of the fifth or sixth rows. Immediately after this, tiles or sheets of thermal protection are being mounted, and an internal brick row is being laid.

When thermal insulation is achieved due to expanded clay, the outer inner walls, which are separated by a gap of about 0.15 m, are raised to 150 cm. From this point, the construction is carried out to the upper target line. If you plan to insulate the house from the outside, this work is first carried out with the foundation and plinth. The outer wall is thoroughly cleaned, only under this condition, finishing will be an effective measure.Extruded PPP or foam outside put, initially aligning the walls with plaster and priming them.

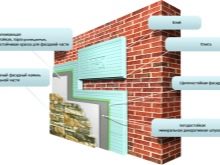

Placing insulation produced with glue or steel dowels. Installation is conducted from bottom to top in a staggered manner to increase the stability of the structure. If it is planned to create a ventilated facade, begin by attaching a vapor barrier, on top of which a frame is placed. In this frame put a wadded insulation, additionally overlapped with a hydrobarrier. All three insulating substances are attached with dowels.

The typical exterior finish in this case is siding.

Internal insulation foam or EPS on brick is not very practical. These materials are poisonous and easy to burn. Before the start of warming, antiseptic primers are applied, they effectively suppress fungal aggression. Waterproofing and overhang protection for silicate bricks should be more thorough and thoughtful.than for ordinary ceramic block. It is recommended to use concrete with expanded clay for masonry. Its thermal conductivity will immediately go down by 50%.

Putting claydite inside the walls will be most effective when choosing a large fraction (this will reduce the load on the foundation).

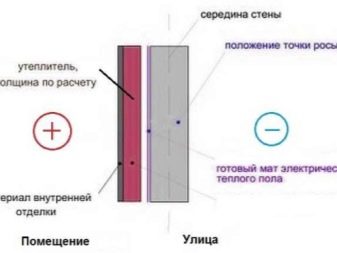

When it is impossible to insulate a brick wall outside or in the middle, materials with the least permeability to water vapor are taken for internal warming. Most often it is EPPS or penofol with an outer shell of foil. It is only important not to confuse which side these materials need to be mounted inside the room. If you have to use a material that permits a lot of vapor, you will need to block it with a water-vapor-impermeable film or a thin penofol shell.

In the case of the slightest difficulty, it is more correct to entrust brick wall insulation to professionals. There are also subtleties in the warming of the walls of a frame dwelling. Asphamine is widely used for waterproofing such buildings, insulants are taken only with foil to reduce steam leaving. Typical insulation solutions are polyurethane, foam and mineral wool.

Be sure to have to do the crate of the edged board with a moisture content of not more than 15%. The recommended cross-section of the batten fragments is 2.5x15 cm.

Warming blocks put in the gaps between the frame racks. Sprayed insulation is underestimated by homeowners in vain.They give excellent results in frame buildings, while they can be applied without the help of a professional team. Hardened polyurethane is required to be improved (remove excess fragments and sand the surface). Due to the exclusion of joints and seams, heat loss will be minimal.

In old houses, the walls inside often have many cavities or one large cavity. As a result, the owners and residents suffer from freezing rooms, nothing can be done with it. Cavities can also occur due to errors when laying insulation or due to its natural degradation over time. Eliminate such troubles can, if ensure the introduction of thermal insulation through the holes made in the outer wall.

Since such manipulations are responsible and in case of mistakes they can even lead to the destruction of the house as a whole, you should definitely turn to professionals.

In regions where there is a lot of precipitation, it is unacceptable to use, including for closing the voids, cavities mineral wool and basalt insulation. You can not use and expanded clay. Where better manifested itself in such harsh conditions according to the operating experience of polyurethane foam. To find out if there is a cavity in the walls of a cold room that can be “blown out” with a liquid or sprayed material, a standard plan will help. In the absence of a plan, with its inaccuracies or obvious mistakes, technological holes are made in the seams and the wall behind them is checked by the movements of the wire. More benign options - call professionals with a thermal imager or self-scanning structures with this device.

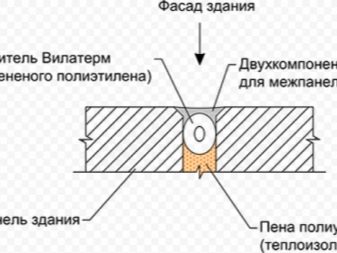

But the cold gets to the tenants of apartment buildings, in the bearing walls of which there are weak seams. The suture elements of panel structures for the most part provide an additional insulating layer on the outside, since it is inefficient to do this from the inside. In any case, before starting work, you should carefully study the technical regulations and building codes. If it is impossible to mount the insulation from the outside, its internal version should be overlapped by an inseparable, long serving vapor barrier.

The seams in panel houses are recommended to be insulated with elastic materials in order to compensate for possible thermal expansion.

Most often, experts take for these purposes:

- foam polyethylene "Vilaterm";

- polyurethane polyurethane foam "Macroflex" (or similar foamed polyurethanes);

- sealants that do not precipitate (for example, Sazilast 24).

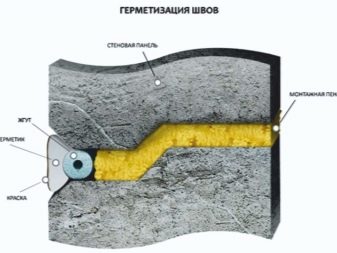

In houses that have been operated for a long time, the sequence of work consists of several stages:

- opening the old seam;

- dismantling the existing protection;

- rusts in case of urgent need;

- remove dust and dirt;

- filling space with foam;

- attaching to the fresh layer of its insulating tubes;

- foam additives in areas where it initially went unevenly;

- cutting the hardened foam;

- waterproofing.

Cross warming is suitable for frame buildings. Heat-saving mats impose so that the seams do not coincide with each other. Then the occurrence of wind-penetrated cracks is excluded. Frost bridges (wooden parts) are guaranteed to overlap. The fight against them will be successful if you add another 5 cm of insulation at problem points outside the 15 cm heat protection.

Arrangement of bars of size 5x5 cm horizontally outside the frame will be the first step. The distance between each pair of bars should be 10 mm less than the width of the warming block. The block itself is put strictly on the contrary.Immediately after the installation of all insulating parts, it is supposed to close them with protection against moisture. It will cover the material from the wind and prevent it from falling out.

It is categorically not allowed even for corners tamping of thermal protection and forcing material in by force. After all, the basic properties of mineral wool are given by the air contained in it. Breaking the integrity of the insulator, you can not keep it inside. Because the house will be colder than expected tenants. The basement ceiling is insulated almost according to the described scheme.

How to choose?

Now you need to find out: which insulating material is better. There is no universal answer to this question. But some points are useful to keep in mind. Carrying out a full-fledged thermal calculation without special knowledge is not possible: ready-made online calculators hardly help or even mislead. When analyzing the properties of each coating, the following are analyzed sequentially:

- steam capacity;

- heat exchange efficiency;

- fire and chemical safety;

- the load created by the warming layer.

Stone walls are optimally combined with mineral wool and its analogues.Even weakened compared to the leading products on the market, thermal protection is justified by excellent cost and ease, as well as ease of installation. The mineral variant is soft and has an average thermal conductivity. More reliable is the cotton wool with the addition of basalt crumbs. But for this, manufacturers take extra money. Such material is especially good in areas closely adjacent to stoves and fireplaces.

Problems with cotton are due to its poor form holding ability. Accumulating moisture, the heater becomes heavy and sags. The way out is the increase in fastenings compared to the recommended placement. Warming wooden or frame buildings with wadded materials is not very practical. They are useful in cases where the walls need very little additional insulation. Styrene and substances based on it better preserve the form and are resistant to temperature jerks.

Excellent heat capacity allows to provide intensive heat protection of thin walls.

Among the foam it is recommended to choose products under the marking of SPB-S, denoting the addition of flame retardants. If they are not, it is better not to use such material at all.Penoplex is recommended for insulating joints to the roof. Penopleks worth using to sheathe the walls from the inside. There it will absorb quite a bit of space.

Preparatory work

If the wall is being insulated for one reason or another from the inside, preparation consists in:

- maximum surface drying;

- installation of vapor barrier;

- laying waterproofing.

Before applying the foam, it is better to mount the formwork. She will allow to keep a surface as much as possible and to make a layer especially reliable. The frame is covered (wrapped) with insulating material, otherwise it will turn into an entrance gate for frost. If a brick wall is trimmed, everything is removed from it (right up to the base). Similar to the approach to concrete. Vacuum dirt is removed, visible fungal lesions are easily removed by brushing the surface with sandpaper.

How to warm your own hands?

Step by step instructions for installing insulation of polystyrene is simple. This material is recommended for laying on wood, brick, fastening is the same. The dry method is used for limited periods.Wet method requires the introduction of the material in the wall grooves and its natural drying 48-72 hours. With severely adverse weather conditions, these periods increase noticeably.

Under expanded polystyrene only ideally smooth walls are suitable. This material is fragile. If you start to fit it to the surface with significant relief, the plates can crack. It is advisable to eliminate all differences greater than 3 mm. Low vapor permeability paint will have to be removed. For fixing you need to use a special glue. Be sure to apply primer.

Tips and tricks

If it is decided to use mineral wool, it is worth staying at the modification "Line Rock". It guarantees environmental cleanliness and excellent insulation from noise. When choosing different materials should immediately clarify:

- their total length and width;

- the possibility of cutting;

- desirable ways of joining.

It is necessary to wait after applying the primer for about 4 hours, even if the manufacturer promises faster drying. When asking for help from hired installers, you should carefully monitor how many dowels and glue they actually use.

Do not overpay for the "eminent" product. It is better to spend extra time getting to know the practical characteristics of dissimilar products and reviews about them.

How to insulate your house with foam plastic with your own hands, see the next video.