Thermal insulation of the walls of the house: what is it and what materials will be needed?

When building houses, people care about their durability and external beauty, trying to make the most of the available space. But the problem is that in the Russian climate this is not enough. Be sure to need to provide enhanced thermal protection, even if the construction is carried out in relatively warm terrain.

Features and Description

Thermal insulation of the walls of a house is a combination of materials and technical solutions that prevent heat from leaking out through the walls. To solve this problem requires:

- reflect infrared rays into the interior of the house;

- block, if possible, the release of heat;

- complicate the convection leakage as much as possible;

- guarantee the safety of the main structures;

- achieve a stable waterproofing insulation layer (even waterproof is better protected additionally).

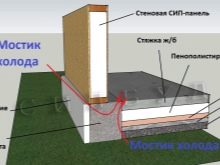

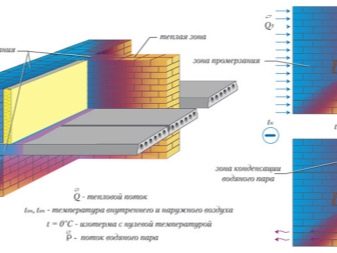

Such a definition in reality, unfortunately, has to be corrected. After all, the creation of an impermeable to thermal energy shell around the house in practice is either very difficult and expensive, or completely unrealizable for technical reasons. Big problems are brought by the so-called cold bridges that break the solidity of thermal protection and reduce its effectiveness. There are only two ways to solve this problem radically - the use of foam glass or gunning from the border with the basement to the ridge. But both schemes have significant drawbacks that must be taken into account.

In addition to cold bridges, you will have to pay attention to:

- blowing of materials and structures;

- their interaction with moisture;

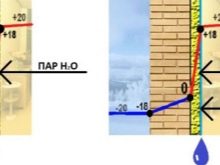

- the need for vapor barrier or vapor-permeable sheath;

- fastening strength and its nuances;

- sunlight intensity;

- average annual and maximum height of snow cover.

Raw Material Review

Great importance in the insulation of home walls is the accuracy of the choice of the base material.So, organic means of thermal protection are represented primarily by foam of heterogeneous density. They have a specific weight of 10 to 100 kg per 1 cu. This allows you to choose the optimal scheme for the load on the foundation and thermal properties. But there is a serious drawback: poor resistance to fire, so there is a need for structural protection of fireproof materials.

Other organic heat insulation products are:

- waste products of forest waste and rejected wood;

- peat based slabs;

- agricultural waste (construction of straw, reeds, and so on).

Heat-resistant protection in such ways is quite possible. But it is necessary to put up with poor resistance to water, to destructive biological agents. Therefore, in modern construction, such blocks as insulation are used less and less. Mineral materials are much more in demand:

- stone wool;

- fiberglass;

- blocks of perlite and vermiculite;

- cellular concrete and a number of other products.

Mineral wool boards do, processing the melt of mountain stones or metallurgical wastes to the state of vitreous fiber.The specific mass of the products obtained varies from 35 to 350 kg per 1 cu. But with a remarkable level of heat retention, mineral wool is not strong enough and easily deteriorates by water. Only the most modern varieties of it have the necessary degree of protection.

By tradition, some people use for wall insulation. expanded clay. But such a decision can hardly be called optimal. Even the lightest grade of expanded clay has a significant load on the base. And it will have to be used a lot, because three times more heat (with the same layer) will go out than through the most efficient insulants. And finally, the layer of expanded clay gets wet easily and dries very poorly. Not surprisingly, the film of various types is becoming increasingly widespread. It helps to increase the waterproofing of the inner part of the walls, especially manifests itself polyethylene.

In some cases, for thermal protection of walls is used polyurethane foam. The reliability of such a coating is appreciated by builders. But you will definitely have to wear protective gear for its application. Foam insulation permits steam and inhibits water flow.Allowed its use for closing gaps when installing a plastic window in the wall.

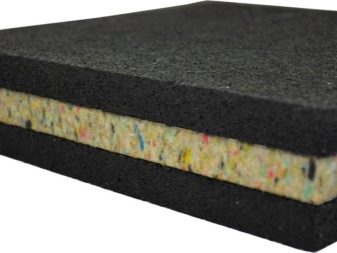

Monolithic sheet insulation is easier to install than foam, and usually does not require specialized equipment.

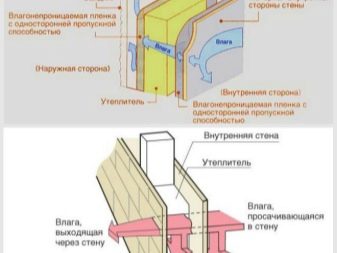

Modern manufacturers have learned to make sheets that can work in a wide range of temperatures and maintain elasticity. With the help of the same structures, it will be easy to provide heat protection for pipes and other communications entering the house. Heat insulation membrane There are two main types: the first one holds back the penetration of water vapor from inside the room, and the second one allows the steam that forms inside the wall to leave freely. The key value when choosing the second type of materials should be given to their vapor permeability, that is, the number of outgoing vapors per unit of time. Flexible multilayer insulation is used either to insulate pipes or to reflect heat rays inside the outer foil sheath.

Specifications

High-quality thermal insulation almost always performs at the same time the role of sound insulation. The choice of such a solution is justified, because it is required to minimize construction costs and reduce the total thickness of the walls.Reliable sound suppression is impossible to implement, if you do not take into account the differences in air noise (moving in air) and percussion (transmitted during vibration of structures). The walls must fully isolate people from airborne noise. Exterior walls at the same time have unequal level of protection, which is not standardized.

The standard values of noise protection are only minimal guidelines, they should not be smaller in any case. In practice, it is recommended to completely exceed these figures by 5-7 dB, then the situation will become comfortable. For external walls, the absorption of airborne noise is recommended to be from 55 dB, and near railways, airports, federal highways - at least 60 dB. Sound absorption is ensured by porous or fibrous heavy materials; most often for this purpose apply mineral wool, sand. Relatively recently, a polymer-based membrane with a spongy structure having a thickness of not more than 0.5 cm has been used.

In most cases, the noise absorber is placed between the materials reflecting the sound. But sometimes practiced two-layer, four-layer or five-layer coating.

To minimize the penetration of sound inside, it is necessary to break the bridges of the acoustic transmission with the help of special mounts. Be sure to use acoustic mounts, which are represented by many species. Only experts will be able to choose the right option.

Manufacturers Rating

Comparison of the properties of individual materials is logical to complement the comparison of the level of specific manufacturers. Basalt wool brand "Tizol" it is mounted very easily, the size of sheets makes 100х50 cm. But it is necessary to consider that the sheet can be scattered because of non-uniform density in different places, also in it defects can appear. During the season, the wool drops by 15-20 mm. Buy "Tizol" can be in any specialty store.

Competing firm "Rokvol" can offer basalt cotton wool with a density of 37 kg per 1 cu. m. Here also everything is fine with the installation with frame openings of 59 cm. One package allows you to cover about 6 m2 of the wall. Finding the company's products is easy in many outlets. Tara is very reliable, even rough handling (within moderate limits) will not damage the material; Lifetime will delight homeowners.

Techno Rocklight also belongs to the number of easily installed materials.There are four key sizes, allowing you to choose the optimal view in a particular case. But the shortened fibers easily fall apart, because the work is permissible to carry on only with gloves and when wearing a respirator. Buy "Rocklight" in certain regions of the Russian Federation will not work. The container is not reliable enough, in the process of loading bales can fall apart.

Mineral wool firm "Izover" sold in rolls and slabs. Technologists have managed to overcome their traditional barb and increase strength. Such goods are sold in all specialized stores. Cutting and styling are pretty simple. But there are also problems - unpleasant odors, the need to use protective devices, insufficient information content of the inscriptions on the packaging.

Products Knauf It has a wide range of options and effectively dampens sound. The composition of the mineral wool of the German concern lacks toxic phenol-formaldehyde and many other components. Material crumbling is excluded, the blocks are very light.

You can put the plate at a convenient angle. As for the problems, again you need to use protection.

How to choose?

Having dealt with the brands, it is worthwhile to once again study the characteristics of specific species. Experts recommend to anticipate the study of reviews to determine the appropriate type of insulation material. It is extremely rare now that bulk fillers are used, mainly rolls and plates are used. Additionally, a distinction is introduced on the fibrous, liquid and cellular formats. Using the second type without special equipment can be difficult.

It is very important to pay attention to whether a specific heater is suitable only for internal or external wall treatment. When choosing, it is also worthwhile to find out how large the thermal conductivity coefficient is - the smaller it is, the greater the amount of heat left in the house. If you want to achieve a long service life of the coating, preference is given to materials that minimally absorb water. The same circumstance directly affects the resistance to the appearance of the fungus. The next important parameter is flame resistance; even when heated to 1000 degrees, individual materials do not lose their original structure.

Even if the insulation meets these requirements, it is useful to find out how well it is:

- resists deforming efforts;

- stops steam;

- can withstand the effects of rodents and microorganisms.

For the internal insulation of the walls of the house it is difficult to find something more perfect than expanded polystyrene. Plates made of it are always thin and do not reduce the available space. The exclusion of moisture absorption helps to bring the dew point out and reduce the freezing of walls. What is equally important, in many cases, it is possible to do without vapor barrier.

But when it is planned to insulate the walls from the outside, it is better to use polyurethane foam.

Polyurethane foam is mainly sprayed onto the surface to be protected, creating a monolithic canvas that does not have a single joint and area where heat would flow away. Excellent adhesion makes it possible to use this material on any surface. Among organic insulants in the first place are mineral wool products. Economical version of them is always equipped with a foil layer. Do not put financial considerations in the first place, then the result will be poor quality in any case.

Process technology

The use of mineral wool for thermal insulation is justified in the situation when the insulation outside is not possible.The first step is naturally to clean the surface of dirt. It is especially important to get rid of traces of mold and treat the areas affected by it with antiseptic mixtures. The slightest recesses and cracks should be sealed with cement formulations. An effective method of dealing with shallow (up to 30 mm) holes is the use of foam.

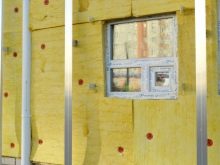

If their depth is greater, it is necessary to supplement the foam with tow. It is necessary to apply antiseptics and primers carefully, each layer must dry before applying the next layer. To maximize the efficiency of work, you need to level the surface, providing a particularly tight pressure on the structure or frameless insulation. On the surface of brick, foam or aerated concrete put plaster, and on top of it is a layer of liquid waterproofing. Frames are formed from wooden or steel profiles.

The distance separating the vertical supports, is somewhat smaller than the width of the rolls of insulation. Then the junction will be very reliable. The gap to the wall structures is made in such a way that the stove fits there and a few tens of millimeters of air gap remains.This is achieved through the use of point adhesive mixtures.

Plates are preferable to rolls because they roll less; the use of horizontal bars helps to cope with this problem.

Installation of vapor barriers is made with the upper parts of the structures, while working move horizontally. The main fastening method is double sided tape. A vapor barrier can be attached to wooden substrates using a furniture stapler. It is recommended to do an overlap of at least 100 mm, while making sure to overlap on the corners, floor and ceilings. Mounting tape and construction tape are ideal for sealing joints.

The approach of the film to the surface means the need to fill such areas with liquid sealants. A slatted counter lattice is placed above the “cake”, its assembly width is from 1.5 to 2.5 cm. Thanks to the counter lattice, it is possible to make a full ventilating gap. On top of it is placed the front decorative shell. In order to refuse the use of vapor barrier, a foil is mounted on the inside, which should be rotated deep into the room.

Otherwise, work is underway when using rolled blocks. On the surface of the staples are arranged in the form of the letter "P", they allow you to install profiles of metal. The typical vertical distance is 0.6 m, and the horizontal distance may be somewhat less. When measuring the required amount of mineral wool, we must not forget about the tolerance of 0.1 m. The lugs of the clips will block the movement of the insulation vertically. When they are pressed, put profiles and attach GCR.

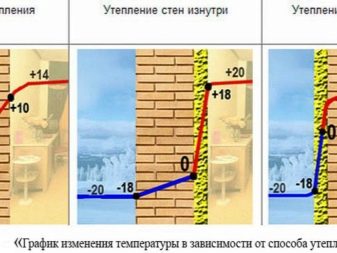

According to professionals, the insulation inside is much worse than outdoor insulation of residential premises. This is the most effective option in practice, in addition, it does not select a useful place and avoids the occurrence of condensate. Another important advantage of this solution is the prevention of cold bridges. External insulation from frost is carried out using a wet or dry technique. Wet option involves the application of an insulating layer directly on the wall and the subsequent finishing on it.

The total thickness of the insulation block reaches 150 mm. Mineral wool "put" on the glue or umbrella hardware. The base is recommended to reinforce.After this, a facial finish is performed, which also has a protective function. A similar solution is recommended for brick and aerated concrete buildings. Prefabricated houses before laying minvaty covered with hard flooring of oriented plates.

It is unacceptable to install mineral wool during rain and at high humidity. Theoretically, it can dry, but it will take a very long time to wait. Insulation outside is always overlapped by a moisture barrier film. A metal apron is placed on the slopes, which reliably protects from contact with precipitation, and from wind and rain. Around the glass all gaps must be closed with foam; it is desirable to take care of its protection from moisture.

It is impossible to limit ourselves to the insulation of one wall, it is very important to provide for the thermal protection of the roof. Through the ceiling, the building leaves up to 1/5 of the total heat.

Since most pitched roofs are equipped with highly flammable materials, only non-combustible insulation material should be used. In addition, he must freely pass water vapor and not absorb the water itself. For a flat roof, the insulating layer should be set as strong and stable as possible.otherwise, it will not withstand the load created.

How to prepare?

Calculations of insulating elements is extremely important. If you hold them badly or not at all, you can run into serious problems. So, weak insulation will not allow to maintain a comfortable temperature in the premises of the house. In addition, it will move the dew point to the inside of the wall. Condensation causes infection by mold and other putrefactive organisms. Too powerful insulation solves this problem, but it is unjustified economically, since an increase in the thickness of the layer only slightly increases the practical qualities.

It is necessary to take into account thermal resistance, which is normalized for different regions and key settlements. Competent calculation allows you to build the thinnest possible (as far as possible) wall and not worsen the consumer qualities of the house. The standard formula for the calculations looks like αyt = (R0tp / r-0.16-δ / λ) · λyt. To the left of the equal sign is the required thickness of insulation. On the right, after the normalized resistance, go:

- wall thickness;

- coefficient of heat loss through their carrier part;

- indicator of heat loss through insulation;

- material uniformity index for heat flow.

The thermal characteristics of air-spaced “cakes” may not be taken into account for the exterior cladding and the most ventilated pause. The choice of a suitable width of a single roll or plate is due to considerations of convenience when working.

At the same time, we must not forget that the fewer joints are made, the higher the reliability of the mounted structure will be.

How to make yourself?

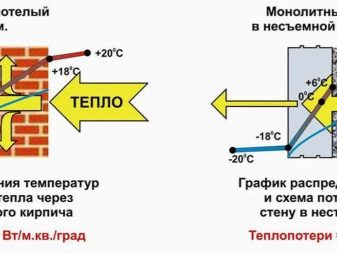

It is quite simple to install the wall insulation yourself. But there are a number of nuances that are often overlooked by amateur craftsmen. So, during the cold period of the year, it is worthwhile to slightly cover the exhaust ventilation ducts and completely block them during a long absence. Since up to 80% of all losses through the walls occur in heat rays, reflective heat insulators are preferable to ordinary ones. In already operated homes, it is often necessary to do internal insulation, which requires additional installation of a vapor barrier.

Thermal insulation of walls gives a positive result only if the thermal protection of the basement is prepared in advance according to all the rules. ATThe ventilated facade is created by attaching the insulation layer to the dowels or using a frame with exterior finish in any convenient way. If the wall is made of brick, you can resort to well-laying. The inability to ventilate it means that it will be necessary to apply solutions resistant to moisture. Heat-insulating plaster plays only a supporting role, in addition to it, it is necessary to make a substrate of a grid coated with a primer.

Useful tips from the pros

Do not ignore the advantages of plastering insulated walls. Yes, it is more laborious and dirty than finishing dry blocks, but allows you to combine finishing and additional heat savings. The water vapor permeability of the wall cake should gradually increase from the inside to the outside; any other layer ratio is fundamentally wrong. Vermiculite is extremely expensive, but it is easy to get around this difficulty - you only need to use it not autonomously, but as part of warm plaster. Such a solution, due to its excellent vapor permeability, can be used almost everywhere.

On the intricacies of choosing insulation for the walls of the house, see the video below.