Penoizol: characteristics and disadvantages

In the construction of houses or their renovation often raises the question of effective wall insulation. For these purposes, produced a lot of materials, different in their technical characteristics, properties, performance and cost. Recently, penoizol or carbamide-formaldehyde foam has become increasingly popular in the domestic market.

It allows you to quickly and inexpensively insulate almost any building structure.

What it is?

Penoizoly is called the modified polyfoam. Its consistency is reminiscent of marshmallow. The material is a foam plastic with a cellular structure. Modified foam plastic is a modern heat insulator for warming building structures.

Often, the material is prepared directly on the construction site. Liquid mixture using specialized equipment fills the voids in the walls, ceilings, roofs and attic. Thanks to the manufacture of insulation at a construction site, money, time and energy are saved for the delivery of a conventional heat insulator and its handling. No additional space is required for the storage of thermal insulation products.

Composition

In the manufacture of penoizol inexpensive components are used, due to which the finished material has an affordable price.

For the production of this insulation is required:

- carbamide formaldehyde resin;

- foaming component;

- orthophosphoric acid;

- water.

Dosed parts of these components are laid in a special equipment (foam generator), to which the compressed air is supplied. Through the use of such a device, a foamy mass is formed, intended for embedding voids.

The modified foam has a white color and a jelly structure. With it, it is possible to quickly close up all the air spaces. Hardening of the applied foam occurs after 10 minutes. After 4 hours, the mass becomes solid, and after 3 days, it acquires "final" strength. 72 hours is enough for the final drying of the material.

Kinds

Thermal insulation of buildings produced by various types of penoizol. There are three types of them:

- Liquid. The type most often used by builders. Its popularity is due to ease of use. Such a heat insulator is prepared directly on the site with the help of specialized equipment. Material can be purchased in cylinders for a small amount of work. Liquid foam close up air gaps during the construction, reconstruction or repair of various structures.

- Sheet or in rolls. Such heat-insulating material is made by pouring liquid foam in the form. After the mass is solidified, it is cut into sheets with an optimal length, dried and mechanically cleaned. Some manufacturers offer foil sheet penoizol.Such materials can not be glued. They should be fixed with dowels, and covered with top facing.

- Baby Penoizol granules are obtained by crushing frozen penoizol into fractions whose size does not exceed 15 mm. Granular insulation has a minimum density (up to 8 kg / m2).

Different types of liquid foam can be used for different construction purposes.

Where is it used?

Penoizol is widely used in private and professional construction. It is used not only as a heat-insulating material, but also as a sound-insulating component.

It is used for insulation:

- exterior walls;

- facades;

- roofs;

- pipelines;

- vegetable storehouses.

The material is also intended to create sandwich panels. Granular penoizol has been used for thermal insulation of horizontal structures: floor surfaces, attics, and floor decks. Foil insulation can be used for insulating water pipes.

You should be aware that liquid foam has some restrictions on use. For example, it is not recommended for use in areas exposed to intense moisture.These include plinths, basements, foundations. The reason is simple: penoizol is able to withstand multiple cycles of freezing and thawing, but at the same time it loses its insulating properties.

Experts also do not advise the use of urea-formaldehyde foam for decorating the roofing pie. The fact is that the material quickly collapses under the influence of the sun's rays, because of which, very soon after installation, it can lose its heat and sound insulation qualities.

Special features

In terms of its technical parameters, Penoizol surpasses many modern heaters.

The main characteristics of the material:

- Excellent thermal conductivity. Indicators of this parameter range from 0.03 to 0.4 W / mK. To preserve heat and significant savings on heating, it will be sufficient to install 10 cm thick sheets of Penoizol on the walls.

- Good noise absorption (over 65%).

- Fire resistance Thermal insulation products based on carbamide-formaldehyde resins belong to the flammability class G-1, and to the flammability group B-2. This means that the material will not catch fire in the event of a fire and will not even melt.With prolonged exposure to the flame of fire, the insulation will evaporate, without emitting toxic substances.

- Moisture resistance. The heat insulator absorbs moisture well and gives it back without losing its performance. Insulation is able to absorb up to 1/5 of moisture and evaporate it soon.

- Strength. Compression with linear deformation is 0.25–0.3 kg / cm2, and when stretched to 0.05–0.08 kg / cm2.

Penoizol can be operated with severe temperature fluctuations from -50 to +100 degrees, which allows its use in difficult climatic conditions.

Advantages and disadvantages

Liquid foam has numerous advantages that distinguish it from other types of heat insulators.

This material has the following advantages:

- Low thermal conductivity.

- Elasticity and elasticity. Thanks to these properties, the foam fills all the cracks and voids, eliminating the formation of cold air bridges.

- Resistant to mechanical stress. Under power loads, the frozen material is crushed, and after the pressure stops, it quickly returns to its original position.

- Resilience to sudden temperature changes and resistance to changes in humidity.

- Excellent vapor permeability. Due to this property, condensate will not accumulate on the warmed wall surfaces.

- Good adhesion. Foam quickly and securely engages with any of the grounds, so that it is convenient for it to warm buildings with a complex structure.

- Excellent protection against mold and mildew. You can not be afraid that insects will start in a heater or that rodents will spoil it.

- Favorable price. Raw materials for the manufacture of penoizol is inexpensive, which has a positive effect on the prices of the finished material. Having completed the installation of a heat insulator with your own hands, it is possible to save a significant amount on the insulation of the house.

- Durability. Properly installed insulation material can last more than 50 years without changing its performance.

- Eco-friendly. During operation, the heat insulator does not emit harmful substances. It is safe for health.

Despite the above advantages of liquid foam can not be called an ideal insulation. It has some drawbacks.Reviews of those who insulated their home with penoizol indicate the shrinkage of the material (approximately 5%). The disadvantages include the impossibility of preparing and applying the foam mass without specialized equipment.

It can be rented or bought, and this leads to additional financial costs.

The disadvantages of consumers also include a high percentage of moisture absorption, low tensile strength and the inability to work with foam at temperatures below +5 degrees. In addition, when installing the material there are risks of exposure to phenol-formaldehyde vapor hazardous to health. And still harmful penoizol or not it is worth to understand in more detail.

Harmful or not?

According to numerous reviews in the network, most consumers of liquid foam complain about its toxic smell during installation and drying. According to experts, such situations are observed when purchasing low-quality heat insulator. The fact is that some manufacturers use cheap urea resin with numerous impurities in order to save money.

High-quality heat insulator can emit an unpleasant smell only during installation. This is explained by the fact that during the polymerization the substance begins to release formaldehydes. However, their number is insignificant. In comparison, many modern paint and varnish products emit much more harmful substances, while the standards-made penoizol ceases to emit formaldehydes when it dries.

Comparing the pros and cons, we can conclude that it is better to abandon the cheap insulation from unfamiliar manufacturers. It is better to overpay and give preference to well-known brands that have managed to win the trust of consumers.

Manufacturers Overview

Penoizol is the trade name for carbamide foam plastic and this sign can only be used by NST ("New Building Technologies"). This material is produced abroad, in each country it has its own name:

- in the UK - flotophoto;

- in Germany - animotherm;

- in Canada, insulspray;

- in the Czech Republic - mofoterm.

The basis for the manufacture of liquid foam in Russia is produced by the companies CJSC Metadinea, OJSC Togliattiazot, OJSC Acron and others.

Accessories

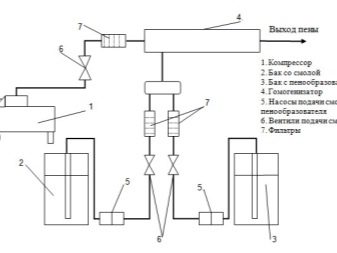

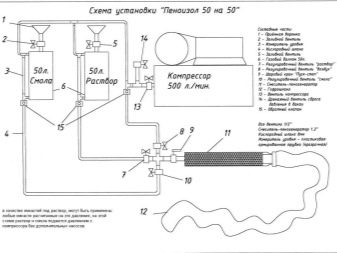

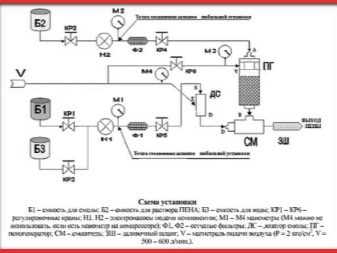

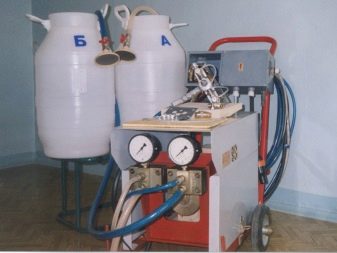

For the manufacture of penoizol directly on the construction site and its supply will require specialized equipment.It includes gas-liquid installations, the function of which is to mix the components that make up the material and to supply the finished foam to the forms or places of insulation. In addition to the units for mixing will need an air compressor and tanks for reagents.

The principle of operation of such an installation is simple: all containers with necessary components and a compressor are connected to a gas-liquid unit through hoses. After mixing the reagents, foam is formed. Next, it is fed into the mold or air gaps at the construction site.

Before you buy Penoizol, as well as purchase or rent all the necessary components for the insulation of the house, it is important to familiarize yourself with some of the recommendations.

How to choose?

When selecting equipment, consider a number of nuances.

- Two types of installations can be used for the installation of liquid foam: gas-liquid and pneumohydraulic equipment. The first, budget, it is advisable to use for insulating small objects, for example, a private house. Pneumatic equipment is large in size, performance and cost.It should be selected when large-scale work is needed.

- It is recommended to give preference to installations with a built-in compressor and receiver.

- Pay attention to what the plunger pump and its options are made of. Choose a pump made of stainless steel or plastic. It must have a speed control function.

- It is not necessary to buy an installation with a foam generator attached to the pump part.

It is strongly not recommended to purchase penoizol "blindly." Be sure to ask the seller to prepare the material and demonstrate its quality. Sample should:

- have a white color;

- do not decrease in volume immediately after exiting the installation sleeve;

- withstand hand presses after 15 minutes of freezing;

- not have large and heterogeneous pores;

- recover quickly after clicking.

If the cooked mass meets these requirements, you can safely buy it.

Tips and tricks

In order to reduce the costs associated with the thermal insulation of the building, it is possible not to purchase ready-made equipment, but to make the installation yourself at home. Such a device should have:

- gas-liquid unit;

- hoses for supplying reagents and foamed mass;

- plastic containers;

- compressor;

- cranes.

The scheme of self-assembly installation is shown in Fig. one.

Installers advise to work with penoizol according to this scheme:

- installation installation in accordance with the instructions;

- mixing in the barrel all the necessary components;

- preparation of the treated surface by dismantling of old facing materials (the base does not need alignment: a layer of liquid foam is able to hide all the bumps, protrusions and other flaws);

- installation of metal or wooden crates (wood construction must be treated with antiseptic compounds);

- installation of a log from wooden bars;

- drawing a uniform layer of penoizol or filling up of voids;

- cutting off excess material with a construction knife after it hardens;

- installation of reinforcing mesh after polymerization of insulation;

- facing work.

In order to install the heat insulator in a quality manner, it is best to contact certified installation organizations.

Masters are able to quickly insulate any structure and provide warranty for the work done.

Positive reviews

Thousands of domestic consumers have already taken advantage of Penoizol. All the people who installed this insulating material, noted that the room becomes much warmer. Because of this, energy consumption costs are reduced in the autumn-winter period. At the same time, a comfortable temperature and air humidity are established in the dwelling.

Consumers noted the quick installation of insulation, and its low cost compared to other types of insulation products. The use of penoizol is a great way to reduce the cost of construction or renovation work without losing their quality.

A comparison of the properties of penoizol and foam, see the following video.