Thermal insulation plates: how to choose?

Today, the range of thermal insulation materials allows you to choose the best product to customers with any budget. Especially popular in recent times, insulation in the form of plates. They are easy to install, keep in shape and serve for many years, without causing any problems. The article will discuss how to choose the right heat-insulating plates.

Special features

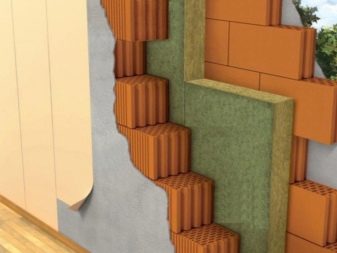

It is necessary to approach selection of the heat-insulating materials very responsibly, since it depends on them how comfortable and warm it will be in your house. Today, specialty stores sell high-quality coatings that are used to insulate a variety of bases.This may be the ceiling, and the walls, and even the floor. In addition, many manufacturers produce practical plates designed for the outer part of the wall floors.

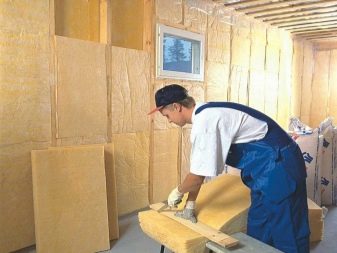

According to the masters, laying insulation in the form of plates is much more convenient. To do this, you do not need to use special expensive equipment, such as, for example, in the case of polyurethane foam. With all the work it is possible to cope independently, without resorting to professionals.

It is worth noting that Tiled insulation, like its other modifications, does not tolerate contact with water and dampness. Some materials do not absorb excess moisture, but under its regular influence they still lose useful properties. That is why such coatings simply need high-quality waterproofing. Not unnecessary installation and reliable vapor barrier. For example, in the case of the arrangement of roofing without such a "pie" just can not do.

Most modern heaters are durable, durable and non-flammable. Of course, there are cheaper options, but they are considered quite fragile. It is necessary to work with such plates as carefully as possible so as not to damage them.

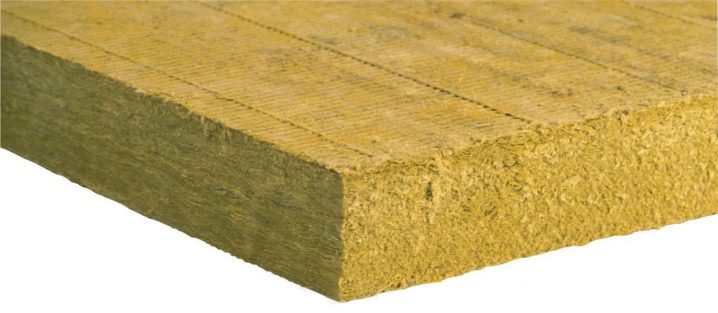

Tiled insulation materials have different thickness.This parameter affects the positive qualities of the coating. So, the thicker the sheets are, the warmer they are.

With the use of high-quality tile heaters can significantly save on heating the home. Many homeowners claim that with such an addition, the house becomes very comfortable and cozy. Often, after reliable insulation, people refused to buy additional heaters.

The range of thermal insulation materials today is great. However, it should be borne in mind that the market is full of dangerous and toxic coatings that have a negative impact on the health of households. That is why experts advise much attention to be paid to the environmental friendliness of the canvases.

Regulatory requirements

In a large assortment of insulation boards, you can “get lost”. When making a purchase, it is necessary to rely not only on the direct producer who issued the material, but also on the regulatory requirements that the purchased product must meet.

Insulating materials must meet the following requirements:

- they must be characterized by the lowest possible level of thermal conductivity, otherwise there will not be much point in installing them;

- similar materials should also have a low degree of vapor permeability;

- insulation should not be flammable, otherwise its use will be simply unsafe;

- high-quality heat-insulating material must be resistant to rotting and decomposition;

- thermal insulation materials must also have soundproofing properties (to varying degrees);

- they should not be afraid of temperature extremes and contact with aggressive chemicals;

- similar components should be as durable and wear resistant;

- insulation should be environmentally friendly (at present, not all materials meet this requirement, so they should be chosen very carefully);

- high-quality plates with thermal insulation properties should not be afraid of contact with solvents.

Today, assessing the heat-insulating materials of different types, we can distinguish plates belonging to different classes. In this case, the standard is the indicator of thermal conductivity of air at 0.025 W / (M / 0C).

If the plate has a value as close as possible to the specified parameter, then there is no doubt about its purchase.

The average figure for thermal insulation materials used in private construction ranges from 0.021 to 0.029 W / (M / 0C).

As for the technical characteristics, they are also different for different heaters. For example, the thickness of mineral wool slabs starts from 5 cm and can reach 12 cm, while this parameter for polystyrene cloths varies from 20 to 200 mm.

When buying insulation boards, you must ask the seller for a quality certificate. This document should cover all information relating to the product. Tiled insulation should be made in accordance with GOST. If you refuse to provide the document, then it is better to refrain from purchasing such materials.

Kinds

Today in the construction market there are several popular varieties of tile insulation, each of which has its own distinctive characteristics, advantages and disadvantages. Let us consider in more detail what kind of insulation materials offered by modern manufacturers.

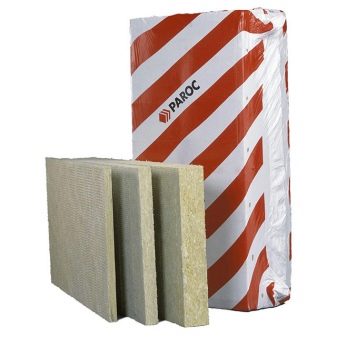

Minwat

One of the most popular and sought-after heaters today is mineral wool. It is also available in slabs and has excellent thermal performance. The following properties are typical for this environmentally safe and practical material:

- tiled mineral wool is not afraid of high temperatures, as well as their differences;

- even being in prolonged contact with high temperature values, the mineral wool does not begin to smolder and emit sharp chemical odors;

- this popular material can easily come into contact with aggressive chemicals without losing high quality;

- mineral wool in slabs is chosen by many consumers, since it is characterized by high vapor permeability (thanks to this property, it can be used in rooms with high humidity levels);

- the material is quite pliable and easily takes the form of the base on which it fits.

Of course, tiled mineral wool has its own weaknesses, which include:

- not the highest rates of strength;

- low hardness;

- large weight (plate mineral wool is a heavier material than, for example, polystyrene);

- high price.

But it should also be noted that it is necessary to work with mineral wool in protective clothing and glasses - irritation will often remain on the skin after contact with this material.

Basalt

Basalt (or stone) insulation materials are no less relevant and enjoy an enviable demand. They are used for wall and roof insulation. In addition, they can boast quite good soundproofing qualities, and this is one of the reasons why many homeowners choose them.

Basalt insulation also have many positive qualities.

- Basalt fiber-based material is seamlessly resistant to high temperatures.

- The service life of high-quality basalt insulation averages 50 years. During its operation, this material does not lose its positive qualities and does not require constant updating.

- It has excellent sound insulation qualities.

- Not afraid of temperature changes.

- Easily withstand impressive loads.

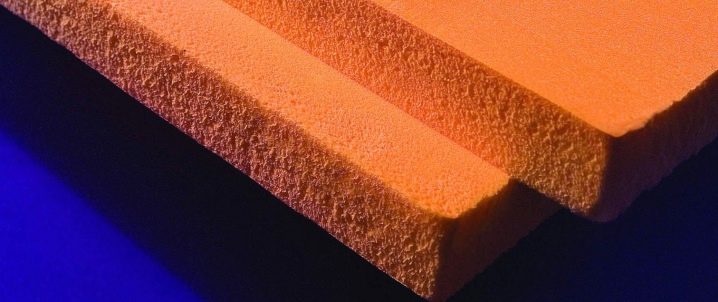

Polystyrene foam

No less popular today are polystyrene insulating materials.Such plates are much cheaper than mineral, so many consumers acquire them.

Polystyrene foam insulation is perfect for arranging private residential buildings, which makes them even more relevant in our time.

The popularity of these materials is due to their positive qualities.

- Polystyrene foam insulation is lightweight, so they are easy to install and transport.

- These materials are quite durable. For example, for a break - 80 kPa, and for compression - 130 kPa.

- Styrofoam is inexpensive and is found in many stores.

- Conveniently and easily fixed on different bases.

- This material is hygroscopic and resistant to moisture.

If you decide to warm the home with such affordable material, then you should know what disadvantages it has:

- expanded polystyrene is flammable;

- this material has mediocre soundproof qualities;

- does not tolerate contact with solvents;

- only its use for warming residential residential buildings is possible.

Perlitocement

In the construction of large industrial buildings often use practical and reliable perlitocement insulants.Such plates are made on the basis of such raw materials as perlite, which is mixed with cement and special asbestos pulp.

These materials have received their distribution due to the following positive qualities:

- perlite slabs are refractory materials that are not afraid of exposure to high temperatures;

- such materials are not afraid of mechanical damage;

- perlite tile insulation has excellent heat and sound insulation characteristics;

- they are not afraid of negative environmental factors;

- are environmentally friendly and safe for human health;

- are not toxic;

- not subject to mechanical damage;

- not afraid of aggressive chemicals.

A large number of defects in this heater is not observed. One has only to take into account the fact that it is not the most convenient in the matter of transportation because of its fragility.

In addition to perlite slabs, the construction of large industrial facilities uses equally strong slabs of cellular concrete. These materials are manufactured in lengths of 70-100 cm, width 50 cm and thickness of 6-12 cm. These coatings are in many respects similar in their parameters to perlite.

Fiberglass

Fiberglass insulation boards are produced from the recycled glass industry. Such materials are often used for wall insulation with irregularities and potholes. Such coatings are perfect for thermal insulation of ceilings, curtain walls and basements.

These materials have the following advantages:

- they are characterized by low thermal conductivity;

- are chemically resistant;

- do not differ in hygroscopicity;

- are environmentally friendly;

- elastic and compressible.

The disadvantage of fiberglass materials is their ability to absorb moisture. However, this feature does not affect the properties of fiberglass to retain heat.

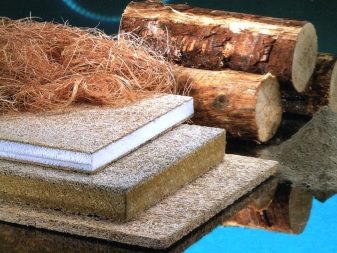

Woody

For the insulation of houses are also used wood-fiber or materials based on sawdust. Such coatings contain components such as chips, resins and antiseptics. From these components are obtained solid and durable sheets of particle board, which are often used for leveling floors and insulation of houses.

And also for the insulation of houses use compressed cork tree and dried cereal stems.

Scope of application

Modern insulation materials are used in various fields. See their list:

- heat-insulating plates are suitable for facades;

- floors;

- overlaps;

- basements;

- inside the attic (residential) space;

- loggias;

- roof structures;

- basement insulation.

Quality materials can be used for both interior and exterior dwellings.

Manufacturers

Currently on the market there are many eminent and advertised manufacturers that offer customers high-quality and reliable insulation materials. Let's get acquainted closer with the most demanded of them.

Isover

Isover is a popular brand that produces mineral wool of unsurpassed quality. In addition, the range of this manufacturer has both products for private and for industrial construction. The range of Isover pleases many consumers with its diversity.

Also, the brand offers a choice of buyers insulators designed specifically for the roof, as well as slabs of various dimensions. With the help of such materials you can save on utilities.

"TechnoNIKOL"

Today, Pir from TechnoNIKOL thermal insulation materials are very popular. This manufacturer is known in many countries, and its products are often chosen by masters (both beginners and experienced).

Plates from the Pir series are distinguished by excellent thermal conductivity characteristics, ability not to absorb moisture in their structure, non-susceptibility to burning and flame support. Besides, This heater does not rot and serves for many years.

Rockwool

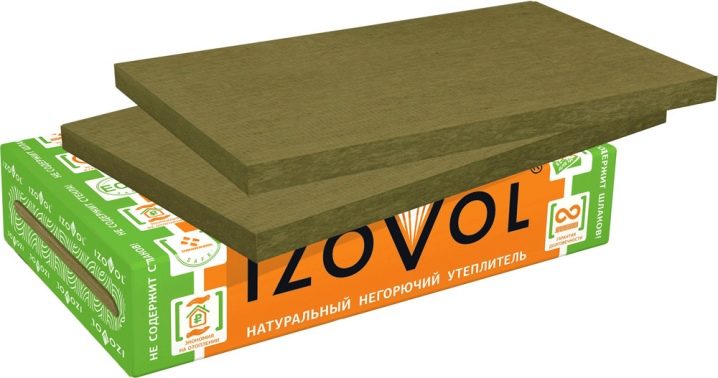

Rockwool is a world leader in the production of heat and sound insulation materials of the highest quality. Branded products are made of eco-friendly stone wool and are available for both private and larger construction. In addition, Rockwool raw materials are used for technical and marine insulation.

According to the manufacturer, its heat-insulating plates are able to adjust the microclimate in the living space, making it as comfortable and cozy as possible. Such useful materials can warm not only the walls, but also the floor, the ceiling, the attic, the balcony, the fireplace, the bath and the sauna.

Brand products are not afraid of temperature fluctuations, so it can safely be even close to a hot electric stove.

"Penoplex"

Penoplex is the largest Russian manufacturer of high-quality building and decorative materials. Currently, heat-insulating materials of this brand are leaders in the market.

The range of “Penoplex” is represented by durable products for both private and large construction. In addition, the company offers insulation not only for walls, floor and roof, but also for foundations, basements, basements, balconies, loggias, pipelines and septic tanks.

Tips and tricks

If you are looking for insulation for flooring, then you should refer to the materials of higher rigidity. Such products seamlessly withstand heavy loads and in no way will they suffer.

When transporting perlite insulation, it is recommended to use special sheets and fasten the packaging as tightly as possible. Otherwise, the material may be damaged as it is fragile.

If you are looking for the cheapest and most affordable material for home insulation, then you should pay attention to the foam. Such coatings have a low price, but it is worth consideringthat they easily ignite and emit acrid smoke / smell with toxic substances. Because of such nuances, foam plastic is not recommended to be used for insulation inside residential premises.

It is possible to proceed to the laying of heat-insulating plates only after careful preparation of the base - at first it is thoroughly cleaned of any contamination. In addition, all the "wet" work must be completed before the laying of insulation.

Buy heat-insulating plates only from well-known and large manufacturers. Otherwise, you risk acquiring low-quality or toxic material that will not only serve a short time, but also harm your health.

Select plates that are suitable sizes. To do this, measure the base that you are going to warm. So, the most common parameters are: width from 50 cm to 100 cm, length from 100 cm to 200 cm.

When buying insulation, it is recommended to familiarize yourself with the quality certificate. It should cover all information regarding the product. Ensure that there are no hazardous or toxic substances in the material. If any parameters confuse you, or the seller refuses to provide documents,it is better to look for another insulation.

You will learn more about insulation boards in the following video.