Penetron penetrating waterproofing: scope of use

Over time during the operation of buildings and structures, their surfaces made of reinforced concrete are inevitably exposed to temperature fluctuations and precipitation. Even the highest quality concrete or brick will not be able to resist under the influence of water and gradually begins to collapse, which leads to a decrease in the safety margin of structures made of these materials. Given this circumstance, concrete and brick surfaces require thorough waterproofing. The most effective method of protecting concrete surfaces is considered the method of penetrating waterproofing or, as it is also called, “penetration”. About 70 years ago, the Danes became innovators of this technique, and only years later, adopting the experience of foreign experts, did such moisture-proof mixtures appear in Russia.

The composition of such a waterproofing product traditionally includes Portland cement and polymer or mineral components that are added in certain proportions.

Specifications

The first penetrating compound produced in Denmark was called Vandex. Later, the technology was mastered by a Canadian manufacturing company and began to produce a similar product called Xypex. Further, the invention was adopted by the Spaniards and began to produce a composition called Drizoro. A little later, penetrating waterproofing began to be made in America under the name Penetron– the brand name was chosen the same as the plant that produces this product. Professionals who specialize in waterproofing work, believe that American-made Penetron is the highest quality product, but if you compare any other of its counterparts, a product from America costs much more.

In our country, the use of "Penetron" began in 1984. On the territory of the Russian Federation there is the Penetron-Russia Group of Companies representing the American product on the Russian construction market in the segment of waterproofing products.In 2004, the first plant in Yekaterinburg, specializing in the production of dry mixtures of the Penetron brand, began its work. The plant is part of the Penetron-Russia Group of Companies, which, in addition to production and sales, also contributed to the creation of a unified quality standard for this product in Russia, thanks to which GOST R 56703-2015 was adopted from 04/04/2016 regulating the quality of waterproofing the mixture.

The penetrating waterproofing system of the Penetron brand implies the use of additional materials such as Penecrit, Peneplag, Penetron Admix, Penebar and Waterplug.

All these products are applicable when working with monolithic or precast concrete structures.

- Product "Penetron" produced as a dry mixture, which includes a certain brand of Portland cement, quartz in the fine fraction in the form of sand, as well as a patented chemical additive, the composition of which is not disclosed. Impregnation from "Penetron" is a material that has the ability to penetrate deep into the inner layers of the treated concrete surface to protect it from the capillary penetration of moisture.

- Product "Penecrit" - this is a dry mix for seam insulation of joints of concrete parts from moisture and water. The material is used to eliminate drip leaks and filter water through concrete microcracks.

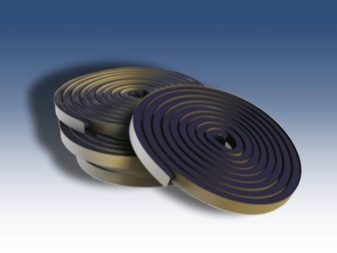

- Product "Penebar" - protects seams from joints, connecting surfaces of structures, I / O points of communication systems, as well as local points of interfaces and adjacent surfaces in building structures.

- Product "Penetron Admix" - a specialized additive, which is designed to be added to concrete mixes in order to enhance the strength of concrete to moisture and the effects of low temperatures.

- Product "Peneplag" - a unique material that can in the shortest possible time stop the spouting flow, even under a certain pressure of water. Work is permissible even in the aquatic environment.

- Product "Vaterplag" - similar in action to the "Peneplag" and is able to eliminate the flowing leakage under the pressure of water, but slightly inferior to it in the speed of action.

In view of the great popularity, the brand “Penetron” is actively being forged, giving a low-grade product for quality material.Therefore, the container for the finished mixture in Russia is supplied from America. Previously, Penetron mixes were packed in white buckets, but more recently, the color of the buckets has turned blue, and the sealed covers are orange. Tightness of the container allows to increase the shelf life of the product to 18 months from the date of its release, while the usual mixture, packaged in Kraft bags, have a shelf life of not more than 6 months.

Penetron, Waterplug and Penecrit waterproofing penetrating materials are packaged in multiples of 5, 10 and 25 kilograms, while Penetron Admix and Peneplug mixes are packed in multiples of 4, 8 and 25 kilograms. The most frequently requested packaging of the mixture is 25 kg.

Application area

The use technology for concrete of the product of the Penetron brand makes it possible to fill cracks existing on the surface with a depth of 30-40 centimeters and a width of up to 4 millimeters. If necessary, the material can be used by applying it on the surface in two layers.

The use of penetrating waterproofing is advisable to apply in the following cases:

- to insulate the walls, floor and ceiling in rooms with a high level of humidity - showers and bathrooms, sanitary blocks for various purposes;

- during finishing works of the inner surfaces of the basement and the basement of the building;

- for waterproofing foundations built for large water tanks - for example, for a pool;

- to protect the concrete foundation from the destructive action of a moist environment;

- for the protection of concrete structures that are under the constant influence of fresh or sea water - the port, pier, pier, breakwaters;

- for waterproofing structures located underground with close adherence to groundwater sources — underground vegetable stores, car parks, subways, transport tunnels, and similar structures;

- to protect the supporting structures located above the water - bridge arches.

The life of such a penetrating waterproofing is on average from 70 to 100 years, which corresponds to the life cycle of any concrete structure. For comparison, a coating type sealant can last a maximum of 25 years. Material brand "Penetron" does not require special application when applying - the work can be done on wet surfaces. Penetrating waterproofing protects the concrete structure from the effects of sea or fresh water, steam, acid, alkali, carbonate and sulfate components, as well as resists the effects of nitrates and chlorides.

In addition, the product stops the growth and reproduction of fungus, algae and various microorganisms.

Advantages and disadvantages

Deep penetration waterproofing materials of the Penetron brand have such The main advantages that are not available to other types of surface waterproofing.

- The material is suitable for application from any side of the structure - from the outside or from the inside.

- The method of applying the insulating material allows uniform coverage of the entire treated area without chips and cracks.

- The age of the concrete structure does not affect the quality of the final results of waterproofing. The material adheres equally well to freshly prepared surfaces and to concrete, which has already been in operation for some time.

- The working waterproofing layer does not require the application of any additional protective layers of other materials on top of it.

- The waterproofing protection of deep penetration is able to withstand sudden temperature changes in the plus and minus ranges, and is also resistant to chemical and mechanical effects.

- The material is quite easy to apply by hand or with a sprayer, while it is safe for humans and the surrounding ecological environment.

- As a part of building structures, reinforced concrete is often used, deep waterproofing extends the service life of the metal frame at least three times.

- Penetrating waterproofing can be applied to the plaster, made of cement-sand mixture. But finishing and painting after applying the insulation material of the “Penetron” brand is best done after at least 28 days.

Feedback on the use of penetrating waterproofing brand "Penetron" is generally positive.

However, there is a list of surfaces, the application for which this product is impractical:

- foam concrete and gas concrete surfaces;

- expanded clay materials;

- foam magnesite and gas magnesite materials;

- foam-gypsum, gypsum and gas-gypsum surfaces;

- schungizbeton and shale concrete materials;

- polystyrene foam concrete products;

- asbestos cement materials.

The use of penetrating waterproofing for these materials is effective, but due to their porosity, the mixture consumption will be unreasonably high.

For such cases, it is more economical to use a type of sealant.In addition to these surfaces, experts do not recommend to apply materials of deep penetration on surfaces that are subject to vibration loads - in this case, the waterproofing layer will crack and will not perform the protective function assigned to it. For example, bridges or road viaducts are subject to such influence.

Surface preparation

Before you start applying waterproofing penetrating mixture on concrete surfaces, Experts recommend that the preparatory work.

- For the outflow of excess moisture will require the construction of a small ditch, where it will drain and drain from the working surface.

- To carry out work on the creation of the so-called hydraulic seal, which will close the joints, cracks and other problem areas that exist on the treated surface.

- Identify those surface areas where moisture can practically or theoretically pass.

- Crumbling and crumbling surfaces will require stripping and plastering with a cement-sand mixture. Defects in the form of destruction and spalling need to be repaired by using a construction mixture, which will not shrink later.

- In the process of eliminating defects in the integrity of the coating, sealing of cracks and chips is best left in the rough state for better adhesion with waterproofing material.

- The surface to be treated is necessarily cleaned of all biological microorganisms — mold, fungus, moss, algae, and marine mollusks are to be removed. This cleaning is carried out using antiseptics.

- Accumulated salt deposits on the working surface must also be removed by applying a hydrochloric acid agent for this purpose. Salts protruding on the surface impair the adhesive and working properties of Penetron.

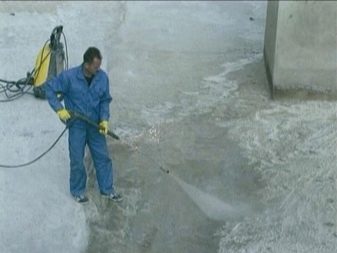

- The concrete surface is cleaned of dirt, dust, and oil stains - this should be done before a clean porous layer of concrete appears.

- A dry surface should be moistened with water so that the concrete is well saturated with moisture.

Penetrating waterproofing has a very good adhesion to surfaces made of concrete, and it also has a good adhesiveness during the insulation of masonry from ordinary bricks treated with cement-sand plaster. The composition works equally well when it processes the object from the outside and inside.However, in the process of arranging the moisture insulation of the cellar of silicate bricks, you may encounter the fact that the Penetron waterproofing compound does not adhere to smooth brick walls and literally rolls off of it without forming a protective layer.

The only way out of the situation is to apply Penetron not with a brush, but with a spatula, making several passes with material.

Mounting methods

Instructions for the use of waterproofing mixture "Penetron" reports that the consumption per 1 m2 of material is not more than five hundred grams. The material is quite economical - for processing it is enough to apply a thin layer. This application rate is relevant when machining flat masonry surfaces using bricks, and while insulating butt and seam joints. If you apply the solution to the surface of concrete, the primer 1 m2 will require from 800 to 1200 grams of the mixture. The thickness of one layer of the finished mixture on the treated surface is only 1-3 millimeters. If, for comparison, we take the consumption of material for mastic from bitumen, used during surface moisture insulation, it turns out that covering an area of 1 m2 will require from one to one and a half kilograms of product.And this is only in the case when the thickness of the layer is no more than 1 millimeter.

Before starting work, the powdered waterproofing compound “Penetron” needs to be diluted with water. - for this purpose take 400 ml of liquid and 1 kilogram of the composition. First, Penetron is poured into the container and only then water is added to the powder. It is necessary to mix the composition quickly and accurately to the consistency of thick cream, it is best to do this with a drill with a special nozzle. Use the drill only at low speeds so that the compound does not splash around you. Please note that at one time you need to prepare so much working material in order to have it applied to the work surface in 30 minutes. In the process, the ready-mixed mixture needs to be mixed regularly so that the whole mass retains the same working consistency.

Thickened composition can not continue to work - you need to prepare a fresh batch of material.

On a cleaned and moistened working surface, a mixture of waterproofing is applied in two layers using a wide brush with a pile of synthetic fibers. For processing large areas, it is more expedient to use a special solution pump with a spray.The first layer of material is spread over the wetted surface, and the second layer is applied immediately after the first one - it is not necessary to wait until the first layer dries. It is best if before the distribution of the second layer begins, the previous layer of material will be additionally well wetted. In the process of processing you need to ensure that the application of the material was uniform, without a single pass.

When applying the material in two layers, its consumption will increase and will be at least one kilogram per 1 m2. Experts recommend butt joints, cracks and various technological places of abutments of the structure to be specially designed for this purpose with the developed product Penekritom.

Working with the material brand "Penetron", you need to know some of the nuances. For example, to get good moisture insulation between a foundation of concrete and walls constructed of building materials with high porosity (bricks, wood, cellular concrete blocks), it is necessary to horizontally cover the entire surface of the foundation with “Penetron”, while not including walls. Waterproofing the surface of the foundation in this case will serve as a barrier that will prevent capillary from soaking the foundation with moisture from the walls.

When creating a penetrating insulation of surfaces made with the use of stone or brick masonry, before carrying out the work, it is necessary to cover these surfaces with a plaster mix of cement and sand, and then carry out the application of Penetron waterproofing.

It is best to plaster wall surfaces using masonry mesh, the cell of which should be 50x50 or 100x100 millimeters. The mesh is previously well fixed to the working surface, leaving a gap between it and the wall of at least 15 millimeters. A layer of plaster should be at least 40 millimeters - a thicker layer is allowed. A day after the end of the plastering work, the “Penetron” composition can be used for penetrating moisture insulation.

After completing the application of waterproofing, all surfaces with Penetron applied to them for three days should be protected from freezing temperatures and mechanical damaging effects. It is necessary to ensure that during these three days the entire layer of material is in a constantly moistened state - this is the only way to protect the hydro-protective layer from cracks during drying. For this purpose, the wetted surface is covered with polyethylene.

After the waterproofing works, the surfaces are allowed to dry out completely and only after 28-30 days after that it is possible to start painting or fixing the decorative finishing elements. This period is also much longer in duration - it all depends on what requirements for the moisture content of concrete will be for finishing decorative materials that are planned to be used for work. Until the application of finishing, the areas treated with Penetron are brushed with a metal brush or with a special device in the form of a water jet apparatus.

Video tutorial on applying waterproofing "Penetron" is waiting for you in the video below.