Okleechnaya waterproofing: technical characteristics and installation technology

Water can destroy many building materials in a very short time. Therefore, it is important to protect some elements of structures from its direct impact. The best solution is to use waterproofing materials. They cover directly the roofs or foundations of buildings, where there is a significant and permanent accumulation of moisture. Today more and more often for such purposes they use waterproofing waterproofing.

What it is?

Pasting waterproofing is a multi-layer coating of special materials that are fixed to the base with the help of various adhesive compositions.Technically similar products are rolled materials.

The device of such products assumes the presence of several components.

- Glue base. This layer is not mandatory, but it occurs quite often. Its location directly on the frame can significantly simplify the mounting procedure.

- Substrate. It is made of various polymeric materials, cardboard and so on. It is a link and is used as a frame for applying a protective layer.

- Waterproofing layer. It is located on top and allows you to better protect the surface of the structure. It is made of various types of bitumen or other similar materials.

In order to achieve quality results, roll materials are applied in several layers.

This allows you to completely close the gap and prevent water from entering the protective structures. They can be applied on concrete and other types of surfaces that need additional protection. It should be noted that the structure of the waterproofing cake may also include many additional layers, such as vapor barrier or insulation.

Benefits

Waterproofing materials of this group are very popular among the population. This is due to several positive characteristics of similar products.

- Low cost. Almost everyone can afford waterproofing. Moreover, these substances are present in all hardware stores.

- Relative safety It is made according to all standards of GOST and SNiP. It does not release harmful substances into the air and practically does not affect the human body.

- Speed and ease of installation. Roll products are fairly easy to cover both vertical and horizontal surfaces. Their use can speed up the work several times. All operations for finishing waterproofing waterproofing is easy to implement, even without a certain experience. It does not use any complex auxiliary mechanisms.

- Material Easily withstands strong water pressures. This value depends only on the number of layers and the type of protective substance. There are also frost-resistant products that can be operated in extreme conditions.

Wall waterproofing is not always the best solution. This is due to the presence of several drawbacks of products.

- Installation of almost all types of insulation involves heating the substance with a gas burner. This, in turn, requires compliance with safety regulations, as bituminous products burn very well.

- Finishing of rolled materials is carried out only on almost perfectly smooth surfaces. If the roof or foundation has significant and sharp drops, then they will have to be further removed using screeds or other approaches.

- It is impossible to paste over with isolation surfaces of a difficult form. Therefore, if there are pipe or vent duct exits on the roof, then they will additionally need to be treated with other waterproofing materials. The best application is a flat roof.

- Some types of waterproofing have a relatively short service life. They are not able to withstand long temperature changes, which will lead to the appearance of microcracks. The solution to the problem can be a constant analysis of the state of the protective layer and timely repair.

- Low mechanical strength. Insulation is easily damaged with sharp objects.This is the reason for the perfect alignment of the bases in order to minimize such effects.

Kinds

Waterproofing materials are very common in both domestic and industrial construction. High demand for these products has led to the emergence of many varieties of protective substances. Depending on the structure of the product, it is divided into several types.

- Sheet. Waterproofing of this type is available in sheets of various sizes. Similar products are used to cover concrete foundations and other bases with relatively standard dimensions.

- Roll. Materials are universal and are used almost everywhere. Rolls may have a width of 1 to 2-3 m depending on the manufacturer. The length of this product is not regulated by standards, so it varies in a very wide range.

- Tiled. Such products are used relatively rarely. But if you choose it correctly, you can get relatively good results.

Conditionally pasting waterproofing is also divided into vertical and horizontal.This classification is quite inaccurate, since many substances are universal and can be operated in different planes.

Depending on the method of application, waterproofing is classified as adhesive and self-adhesive. Some types of products can be classified as glued materials.

- Ruberoid Bituminous substances, which are based on paperboard. The cheapest and easiest type of insulation.

- Gidroizol. The product consists of fiberglass or asbestos base on mastic of oxidized bitumen. Let out coverings with scattering or a bilateral polymeric protective layer.

- Stekloizol. This waterproofing is very similar in structure to the previous type. As a protective component, a layer of stekloizol with several types of polymers is introduced into it.

- Isolate This material does not use a substrate, it consists only of bitumen and various types of rubber. It is used for waterproofing underground structures.

Among self-adhesive waterproofing should be divided into several types of products.

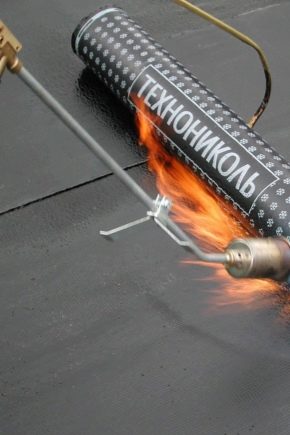

- TechnoNIKOL. The basis is the bitumen-polymer component, which is protected by a special polymer and adhesive layer.Apply membranes in the arrangement of warm floors.

- Tehnoelast. The structure of the substance resembles the previous type of products. But it is recommended to use it for floor screeds.

- Membrane Giscolene 120 Peel & Stick. Make waterproofing synthetic rubber. Butyl is used as a self-adhesive layer. Substance very well interferes with moisture penetration. It is often used in the arrangement of roofs.

Material selection

A variety of rolled film coatings is quite wide. All of them have unique characteristics and can be used in various conditions.

When choosing such substances should consider several factors.

- The operating conditions of the coating. This is especially important for foundations that are susceptible to groundwater.

- Technical parameters of waterproofing materials. Today, Italian-made products are especially popular (hydro-insol, etc.).

If you plan to cover the foundations (vertical surfaces), then it is desirable to use special materials that are complemented with abrasive powder. This structure allows you to protect the structure with a high level of pressure water.

Horizontal bases are coated with various protective materials based on polymers. It is important to analyze the strength of the web and the conditions in which it will be used. If the product will be subject to constant mechanical loads, preference should be given to glass fiber reinforced products.

Installation details

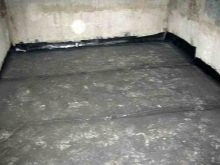

Pasting waterproofing can be used to cover floors, walls, foundations or flat roofs. The procedure begins with several preparatory steps.

- Initially align the base. This can be done with a cement screed. It is important to obtain a surface with a minimum number of height differences. If it is a roof, then it is desirable to provide a slope of the surface to the places of water collection (if such are assumed). In the presence of seams should be sealed with special mastics or solutions.

- Primer. Finishing surfaces with special compounds allows you to increase the adhesion of the insulation to the base. It is important to allow the primer to dry completely before starting the rest of the work.

- Finishing base obmazochnoy waterproofing. The similar stage is used very often for the bases or external facades which need reliable protection. For roofs, it is increasingly used to form a heat-insulating layer, which is hidden under a reinforcing screed.

Please note that all operations should be carried out only on a clean and dry surface. Therefore, before applying the substances you need to remove the dust, then let the frame dry completely.

Applying waterproofing waterproofing can be done in several ways.

- Cold. Fixing paintings is performed with glue, which is applied to the inner surface of the rolled web. This technology involves the use of special mechanisms that allow you to apply the composition automatically. The process of pasting is quite simple. Glue is applied to the inner surface of the material, which corrodes its structure, turning it into liquid bitumen. After that, the substance is rolled using rollers to the prepared base.

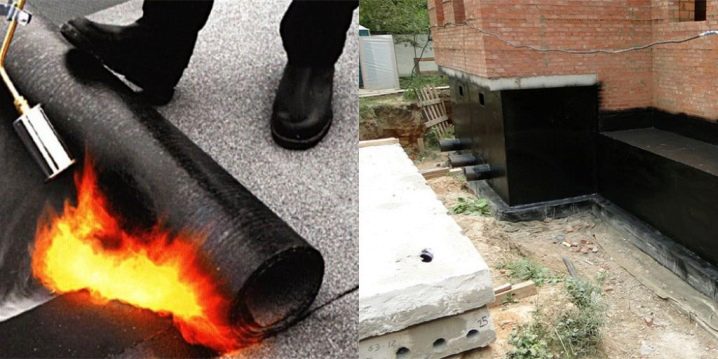

- Hot. Today, more and more often they use this technology. With its help it is possible to put tapes both on vertical, and on horizontal surfaces. Initially, the roll is set in a certain position.Then, using a gas burner, they begin to heat up its lower layer until it becomes semi-liquid. When the material is heated, it is rolled by rollers, carefully pressing it to the base.

Tips and tricks

Installation of waterproofing is a relatively simple operation. But in order to achieve quality results, you should follow a few simple tips.

- All joints should be organized with an overlap. Apply materials to a distance in the range from 15 to 30 cm, depending on the type of insulation.

- Installation of substances is desirable to carry out in several layers. In this case, all the lower joints should overlap the rolls on top. Thus, the risk of water ingress under the structure is minimized.

- Try to use the insulation very carefully, as it is quite easy to damage.

- Pay attention to how the roll is twisted. Sometimes the inside is on top. Therefore, the simultaneous unwinding and installation of them is impossible. In this case, it is better to cut the insulation into pieces of a certain size, and then roll everything in the direction you want.

Pasting waterproofing is a universal way to get a reliable protective system that will ensure the durability and reliability of any structure. But this can be achieved only if its installation was carried out with exact observance of technology.

About what is waterproofing waterproofing, see the following video.