Features waterproofing "Kalmatron"

Waterproofing "Kalmatron" is an effective composition for the protection of various objects from the negative effects of the environment. The technical characteristics of the composition make it possible to call it a universal remedy, which has many advantages over similar materials, including foreign ones. One of the main advantages of the brand’s products is a harmonious combination of two basic categories: quality and cost.

Brand history

The manufacturer Kalmatron has been present on the construction materials market since 1992, since the introduction of waterproofing of penetrating effect in Khabarovsk.The company's business was successful: in 1997, a plant for the production of patented composition began operating in Novosibirsk, and in 1998, it began to produce Kalmatron-SPb products in St. Petersburg.

Nowadays, about a dozen enterprises operate in different cities, the priority activity is: release of protective and decorative materials on their own patents. Active research and production work continues on the introduction of new technologies and materials. The Kalmatron company repeatedly became the winner in the nomination “Promising construction product of the year”, which in itself speaks volumes.

Purpose

Branded compositions "Kalmatron" are used for waterproofing reinforced concrete structures and other building materials. The composition of products include cement, seeded quartz sand, various mineral additives.

The following products are included in the brand assortment:

- penetrating compounds "Kalmatron", "Kalmatron-Ekonom";

- compositions for repair work "Kalmatron-Shovny", "Kalmastop", "Gidrobeton-SRG-F1", "Gidrobeton-SRG-F2";

- plastic waterproofing "Kalmatron-Elastic";

- waterproofing additive in concrete "Kalmatron-D".

Kalmatron products have unique characteristics., perfectly resists mechanical impulses, well withstands hydrostatic pressure. It is used to eliminate various leaks, as well as an effective waterproofing universal action, suitable for almost all building materials. Waterproofing "Kalmatron" is a reliable barrier that protects concrete products and other porous building materials from the harmful effects of the environment. Such waterproofing has a powerful penetrating effect, allowing you to provide reliable protection for any objects.

With the help of “Kalmatron” compounds, it is possible to restore the protective properties of the structure, which need preventive repair.

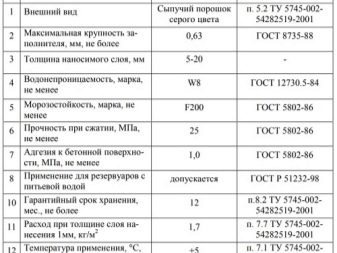

Products do not contain toxins, are not exposed to high temperatures, may be in contact with drinking water.

Advantages and disadvantages

Waterproofing of any object is a built technological structure, which has elements connected with each other.

Parameters that determine the successful application of Kalmatron products:

- the level of humidity of the object and the environment;

- the presence of aggressive media;

- the level of deformation of the treated coating.

The importance of the presence of joints and seams, which are always potentially problematic areas, through them the likelihood of moisture leakage.

Taking into account all factors when choosing a waterproofing material take into account:

- reliability factor;

- cost;

- ease of use.

Kalmatron products have a diffuse penetrating effect.They are able to function successfully in all types of waterproofing. The permeability of the treated surface composition depends on the porosity of the material. The maximum effect of compaction after treatment with the composition occurs on more porous surfaces.

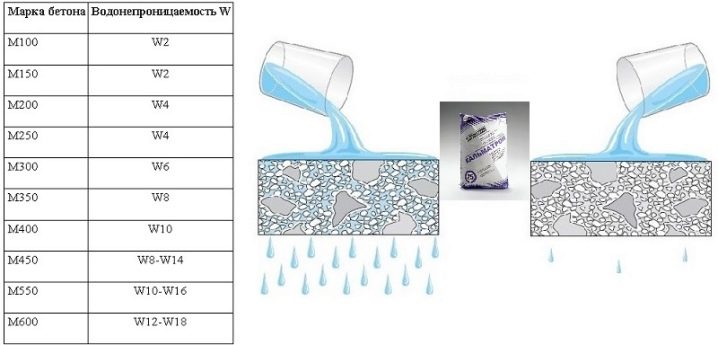

Laboratory experiments have shown that the permeability of concrete increases from brand W4 to W12, that is, with time clogging effect increases. The composition penetrates to a considerable depth of the concrete product (up to 10-15 cm), if the additive is applied to the concrete surface, it will be reliably protected for a long amount of time (experts say that this period can be up to fifty years).

The ability of Kalmatron products to penetrate deep into the concrete surface is one of the unique properties of these compounds.

Their advantages also include the following nuances:

- high quality;

- democratic price;

- lack of toxins;

- high adhesion;

- ease of use.

Disadvantages buyers and experts in their reviews almost do not note.

Product Overview

Consider the most popular types of brand products.

- Kalmatron-D realizes the task of imparting water resistance to concrete at the very early stages of the preparation of the mortar. Being an additive to concrete, it significantly improves the performance characteristics of the structure (up to 30%), prolongs the number of frost-resistance cycles (up to 50), and increases water resistance to 4 steps. As the repair mix "Kalmatron-D" favorably differs from many analogues both in price and quality. Concrete that has been treated by Kalmatron-D is resistant to acids, alkalis, and phosphates.

- Colmatex - finishing coating penetrating action. Contributes to the increase of waterproofing and strength of reinforced concrete elements.Favorably differs from analogs in that the reinforced concrete structure treated with this substance quickly gains strength, is not afraid of the negative influence of the environment. It is used on surfaces where there are small cracks (up to 1 mm without opening), and also up to 3 mm (with opening). The layer is applied up to 2 mm thick.

- Kalmatron Econom - plaster protective composition. It is used to eliminate cracks with a width of opening from 3 to 10 cm. It has all the positive characteristics characteristic of the basic composition "Kalmatron". The material can be used offline.

- "Hydraulic Concrete SRG-1" (SRG-2) is used in all types of work, applicable to concrete, brick, stone. Before starting, it is recommended to treat the area with a protective compound “Kalmatron-D”. Concrete reinforcement provides a good sealing surface, reinforcing it, isolating joints and seam joints. Used on any objects. The structure contains special substances that interact with concrete molecules, forming inorganic compounds. They are reliable "shield" from moisture penetration.

- Kalmatron-Elastic - a two-component composition, based on high-quality cement, as well as mineral additives, which impart plasticity to the liquid material. Differs in high efficiency, it is admissible to apply it in any construction works, including at construction of pools and tanks for drinking water.

The principle of operation and technical characteristics

The principle of operation of the Kalmatron waterproofing is that it generates the creation of complex crystals that “block” microscopic cracks and cavities in the concrete mass. Thus, they reliably prevent the penetration of moisture into the structure of the coating. The crystals are so tightly “implanted” in the concrete that they become an integral part of it and have a positive effect on the increase in its density.

Specifications:

- setting after setting the solution after 10 minutes;

- in a month, the strength reaches 29 MPa - 2.4 tons per 1 m3 of concrete;

- gas resistance increases from 0.8 to 2.5 MPa;

- raises brand of concrete on frost resistance up to 34%;

- structural strength after processing increases by an average of 28%;

- consumption rate per 1 m2 - 3.3 kg (layer thickness - 2 mm).

The waterproofing structures are actively used on such objects:

- moles, breakwaters and docks;

- dams and cooling towers;

- sewer economy;

- dams;

- pumping stations;

- underground structures;

- pig-breeding complexes and poultry farms;

- housing sector;

- storage facilities;

- mine.

Instructions for use

Before starting waterproofing work, you should:

- remove the remnants of old paint and plaster from the working surface;

- using a punch to remove the remnants of old concrete;

- to embroider the places where there are cracks and chips;

- cut metal nodes a couple centimeters deeper than the concrete surface.

In the process, five percent hydrochloric acid is often used, which is an effective means for surface preparation. When working it is necessary to ensure that the surface of the concrete is rough, smoothing it is not recommended.

After completing the preparatory work on the concrete, a film may form, which must be removed with a metal brush.

On fresh concrete (from 1 to 3 days) can be applied "Kalmatron". To prepare the working solution, you can use ordinary or process water.The preparation of the mixture occurs mainly by machine, the mass must be homogeneous. The mixture "Kalmatron" can be applied to the concrete surface by hand (trowel) and mechanically (using a spray gun). Acceptable coating in several layers.

After processing and setting the layer, the first eight hours should be wetted with water. Such an operation is recommended to be repeated for three days. Quality work is the one when it turns out a smooth coating with no signs of flaking. The drying time of concrete with the use of "Kalmatron" is about four weeks.

When working with concrete mass, it is recommended to carefully monitor the execution of works according to the instructions, the density of the composition should be uniform, the quality of the future product directly depends on it. The additive "Kalmatron" is added to the mixer with the already prepared cement mixture. Stir the concrete with the addition of 10 to 15 minutes.

During work with the additive "Kalmatron" it is recommended to use:

- protective clothing;

- glasses;

- gloves;

- respirator.

Kalmatron may not be safe for children, it should be stored in specially protected places.

You can learn how to waterproof the basement and foundation by looking at the video below.