Elastic waterproofing: technical characteristics and application

Waterproofing in construction and repair is a system that protects structures from moisture. Many waterproofing materials also do not pass alkalis, acids and other chemically active liquids. High-quality insulation increases the service life of the object. There are many types: butyl rubber, in the form of a cord, film, liquid rubber.

Requirements for waterproofing materials

The choice of material with waterproofing properties depends on what external factors will affect the structure. In general, these materials put forward a number of requirements:

- water resistance is the most important parameter;

- water resistance - the ability to maintain properties even under the conditions of prolonged exposure to water;

- biological resistance to microorganisms - bacteria and fungi;

- vapor permeability - the ability to pass steam (thanks to it, the air exchange is established, which contributes to biological stability);

- resistance to mechanical stress and damage;

- chemical protection;

- resistance to temperature drops in a wide range (from frost to heat).

Features elastic options

For some construction purposes, it is important that the composition of the hydro insolant is elastic. About such options and will be discussed in this article. For waterproofing of complex surfaces, the most effective are liquid and coating agents. They are resistant to many negative environmental factors and can be applied even on surfaces prone to chipping and cracking.

Elastic waterproofing offer many brands. Usually they have several components in the mixture:

- river sand of fine fraction;

- a special type of cement;

- plasticizers;

- polymers.

Construction stores offer a wide range of insulating products. Single component formulations include dispersion polymers that need to be mixed with water.The set of two-component compositions, in addition to polymers, includes polyacrylic elasticizers. When mixed, a pasty mass is obtained, and it turns into a flexible film after drying. There are also ready-made mastics on sale, which do not need to be additionally prepared before use.

One-component and two-component mixtures are used for structures of complex shape, which are in places of temperature jumps. And also elastic mixes are ideal for joints and hard-to-reach places. In many cases they successfully replace film hydrosolation.

Benefits

Flexible insulation perfectly protects surfaces with small chips, scratches, crevices. From a technical point of view, she has many positive characteristics:

- The high level of adhesion allows it to be used for concrete, brick, wood and metal.

- Environmental Safety. The composition does not exude hazardous emissions, suitable for work outdoors and inside it.

- Long service life. The film does not crack, does not form cracks.

- Easy to use mastic with Kohler.Bright shade allows you to see the uneven application and correct this defect. However, it is not recommended to apply tinting compositions for outdoor work: under the action of the sun, the color quickly fades.

- If necessary, a quick repair of the insulating coating is possible - it is enough to apply another layer on the damaged fragment.

- Vapor permeability The mixture can be applied even on wet surfaces, as it passes water vapor through itself. Application in the conditions of any climate is possible.

- Due to its plasticity, the material withstands deformation, vibration, and surface shrinkage.

- Efficiency is achieved due to the fact that the mixture must be applied in a thin layer. It uses tools such as brushes or rollers.

Spheres of application

Elastic insulating compounds are used at different stages and types of construction work:

- for protection from groundwater underground parts of buildings;

- for isolation from moisture coming from the room;

- in order to waterproof ceramic tiles in pools, bathrooms, balconies and terraces;

- for horizontal insulation of floors and other structures adjacent to the ground;

- for reasons of corrosion protection of metal structures;

- to protect the roof of garages, tanks and containers.

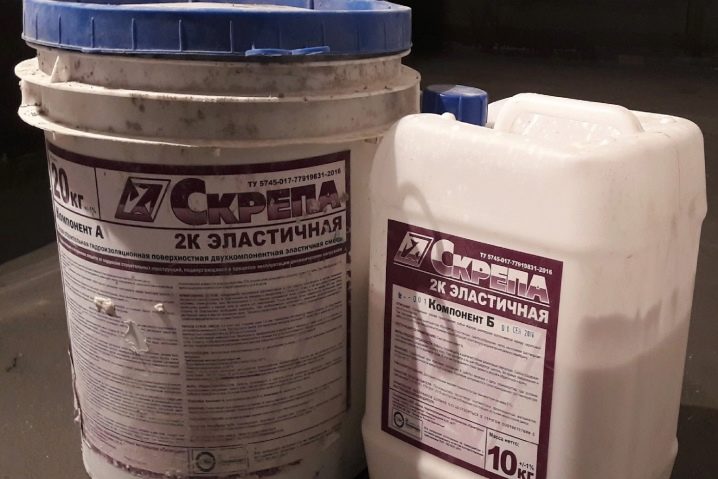

Two-component elastic mix "Clap 2K"

One of the most common on the market waterproofing mixtures - "Clapa 2K" - has a lot of advantages. It consists of 2 components (A and B):

- Component A is a dry mixture of quartz sand, portland cement and chemical additives.

- Component B - liquid base, which is a dispersion of styrene and special polymers.

If you mix 2 components, you get a thick substance that forms a waterproof membrane after drying. The purpose of this mixture: the secondary protection of materials (brick, masonry, cellular concrete) from corrosion.

Application is allowed on objects which will undergo dynamic loadings. The material is approved for use at water supply facilities.

Features of the mixture "Clap 2K":

- preservation of all properties, even if cracks up to 1.5 mm appeared on a hard foundation;

- excellent adhesion;

- high water tightness;

- exceptional durability and corrosion resistance.

Application Tips

Elastic waterproofing is not difficult, it can be done even by inexperienced craftsmen, but there are a number of nuances and consistency that need to be followed:

- It is necessary to clean the surface from dust and debris. Significant irregularities and indentations must be leveled with a special putty.

- It should be noted areas that are subjected to the maximum effect of water.

- Ground concrete and metal surfaces with a special construction primer (first read the recommendations for its selection on the packaging of waterproofing material).

- It is necessary to prepare the mixture, focusing on the instructions.

- Starting the application of the composition, make sure that a certain temperature is observed. This is a condition for the proper polymerization of mastic.

- In the joints of dissimilar surfaces (for example, the floor and walls, the exit of risers and pipes, a complex roof line), additional insulation with polypropylene building mesh or geotextile will be needed. The material is impregnated with a mixture and pressed in the first layer.

- In order to control the quality of work, you can add color to the second batch of mastic.It will help keep the processing uniform under control.

- When mastic hardens, you need to conduct a checkup. Seeing the empty (translucent) areas, you need to carefully process them and put a second layer on top.

- When the top layer has hardened and polymerized, it is time to finish the room.

Features of use of mastic "Clamp 2K"

This repair mixture can not be used at air temperatures below + 5 ° C. The ban also applies to wet weather with heavy rain and wind. The surface needs to be prepared as follows: clean it to a firm base, process it with bushade for best adhesion.

If the reinforcement has opened, the concrete around it must be removed by at least 0.1 cm. The reinforcement must be free of rust to degree 2 according to GOST. Immediately before applying the mixture, moisten the surface with water.

How to make a mixture?

To prepare the mixture, you can take only clean containers and water. Remember that the cooked portion should be consumed within half an hour. Recommended water temperature of about 20 ° C (this is important for the properties of future waterproofing).

The mixture and water are taken in the ratio of 0.165 kg of water per 1 kg of dry mix. Within 5 minutes it needs to be mixed with a drill at low revs or a construction mixer. It should be a pasty homogeneous thick mass.

When using you need to constantly stir it. Water can not be added to it.

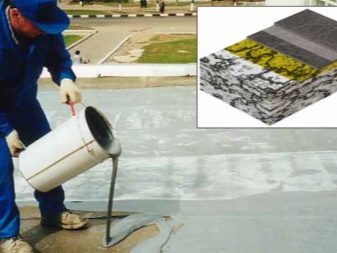

How to use the received material?

The mixture is applied on the basis of the method of wet gunning or manually. If you want to apply a second layer, the first is processed with a notched trowel. Between the application of layers should take 3-4 hours. Consumption is 1.8 kg of mixture per 1 m² of surface, if the layer thickness is about 1 mm. Surfaces that have already been treated should be protected from mechanical damage for 3 days. All this time they should be wet, for this they are sprayed with water or covered with a waterproof material (plastic film).

It is very important to observe precautionary measures: to put on rubber and cotton gloves, goggles, overalls, a respirator. If the mixture gets into your eyes, you must rinse them with water and seek medical attention.

Do it yourself or find a master?

Although surface treatment by waterproofing is available even for an inexperienced home craftsman, it is better to invite specialists for complex work. Such works include, for example, basement treatment, pool arrangement.

Wizards will accurately calculate the required amount of consumables, select the ideal protection option, perform waterproofing of an object according to technical standards.

In the next video, see the detailed description and scope of waterproofing CERESIT CR 65 and CERESIT CR 166.