Features of waterproofing with liquid glass

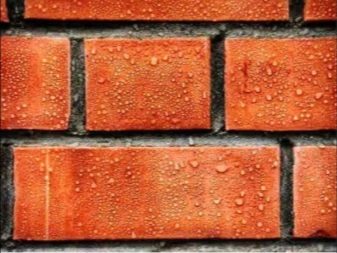

Silicate glue is attractive for consumers not only because of its relatively low cost, but also due to its high strength and moisture resistance. In addition, it is able to resist chemical and mechanical stress. Liquid glass can be used for waterproofing, for example, a bathroom, because it has mostly only positive reviews.

Properties

Before adopting liquid glass in the repair work, you need to know about its characteristics. Liquid glass (in other words, silicate glue) is an inorganic compound,whose chemical elements are potassium and sodium. As an exception, lithium silicate can be used in production. The characteristics of the prepared solution strongly depend on the constituents and proportions used.

According to many consumers, liquid glass based on potassium silicate has a higher degree of resistance to chemical and atmospheric effects. You should know that if a product treated with liquid glass interacts with a mineral substance, it is better to give preference to a solution based on sodium silicate - it will contribute to the instant hardening of the structure. When combined, these substances provoke the onset of a chemical reaction during which sodium aluminate is formed. This element catalyzes the beginning of the process of hardening the cement structure. In addition, the main advantage of liquid glass based on sodium is resistance to fire and protection from penetration of moisture, mold and fungus.

Material consumption

Before starting the waterproofing work, the silicate glue should be diluted with water, mixing intensively.It is necessary to use a proportion: to one part of water two parts of liquid glass. When using this mixture the approximate solution consumption is only 300 g per 1 sq. m. m

When working with liquid glass "Stekloizol", you can safely handle places with weathered plaster surface and uneven concrete bases - this will create a protective film from mold and mildew, will fix the existing layers.

Why choose liquid glass?

To date, manufacturers have developed a considerable amount of waterproofing compounds. They are necessary to combat the damaging effects of water on materials. Silicate adhesive has many advantages, for example, resistance to moisture, chemical inertness, fire, lack of toxic substances and low thermal conductivity. Due to this, such a substance became an integral assistant in construction work.

It is used to improve the waterproofing characteristics of the flooring, walls, floor basement and attic. They are treated with wood floor and ceiling, equip pools and protect the foundation of the foundation from groundwater.

It is worth mentioning that silicate glue is capable of adhering to many surfaces. It has an antiseptic effect and is resistant to the formation of corrosion.During operation gives minimal performance for wear. In the process of waterproofing liquid glass acts as an ingredient for an insulating composition, in its pure form it is not used.

Glass production is as follows: quartz sand is burned with soda and crushed. This procedure is necessary in order to obtain a composition that is able to dissolve in water.

Preparation of the solution

First of all, you need to mix all the dry ingredients. Mix thoroughly, you need to add silicate glue or its solution. Then mix again. After 3-5 minutes, the freshly prepared mixture should be similar to a homogeneous plastic mass. It is strictly forbidden to add liquid or additional additives to it.

Depending on the goals and recommendations on the packaging proportions may vary. But there is a ratio of universal waterproofing mortar: ten liters of cement mortar must be combined with one liter of silicate glue.

Silicate Glue Technology

The basis of the waterproofing work with silicate glue is to follow a specific algorithm of actions, which plays a huge role in obtaining high-quality work.

- The surfaces to be treated must be free from any dirt and dust. It is recommended to achieve a flat surface, since it will be extremely difficult to carry out this after waterproofing. The presence of small cracks is permissible, and with large gaps it is necessary to understand. To fill them, you have to spend a large amount of waterproofing material, which is not practical and will take a long time.

- Then all the necessary surfaces are coated with a mortar, and you need to achieve a perfectly even layer. The solution dries rather quickly. But it is recommended to leave it for a day for greater confidence that the entire surface during this period of time will dry and the layer will be fixed in place.

- There are cases when applied cement waterproofing. This process assumes that the material is added to the solution, and the insulating properties are manifested from the inside. To achieve the maximum effect of such waterproofing, it is necessary to mix all the ingredients in a quality manner - this will allow all the components to be in equal proportions of the entire composition.

Silicate glue application area

The main requirements for a benign waterproofing is to ensure a strong isolation of moisture from the surface and to withstand high dynamic and hydrostatic loads. It must be remembered that when waterproofing the surface, it is necessary to obtain plastic and thin layers, the solution to be coated must fill the pores and all possible cracks. The material used as a waterproofing material must be resistant to the occurrence of mold and mildew, and have high rates of adhesion.

Waterproofing with silicate glue on concrete surfaces is necessary for interior and exterior decoration. Upon completion of surface treatment, the product loses its ability to penetrate moisture - it can be operated even under water.

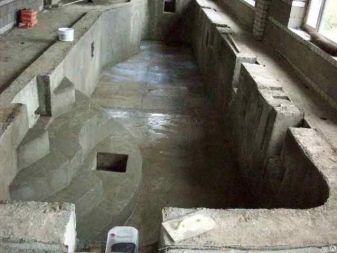

Without any exaggeration, the pool is an object with high processing requirements and subsequent maintenance. It must cope with a huge load from the effects of water, because in a short period of time it can destroy the building material, and subsequently - the entire structure of the pool. Waterproofing work in the pool is done from the inside and outside.Inside the base, as a rule, silicate glue protects against destruction and leakage, and outside it protects against the harmful effects of groundwater. By correctly selecting the composition, it is possible to significantly increase the life of the pool.

Insulation with a silicate adhesive basement or attic is similar to the procedure for fixing the soil on a concrete structure. Both procedures have high rates of insulation of the concrete structure from the harmful effects of water and can be used for exterior and interior decoration. Waterproofing does not take much time, and the service life of the insulating function of liquid glass is very long.

The chemical elements contained in the liquid glass make it possible to penetrate even the smallest pore and crack of the product, protecting it from the action of moisture. Despite the fact that during processing with liquid glass, the product gets waterproofing properties, it does not lose vapor permeability, since the adhesive has a single crystal structure. At the same time, the waterproof layer allows the application of another waterproofing solution, for example, bitumen and mastic.

If you plan to build a house on a soft and flimsy soil, which can subside after two years, it is recommended to add silicate glue to the cement mixture and apply the “injection” method - it is introduced into the upper layer of soil.

Paint brushes, rollers or spray guns perfectly cope with a uniform coating. Upon completion of the application of the first layer, you must give it time to dry. Usually it does not take more than thirty minutes under normal conditions: the permissible humidity and temperature should not be below 20 degrees. After that, it is recommended to immediately start applying the second layer. It is necessary to cover the surface as evenly as possible, avoiding the formation of gaps.

Then you should proceed to the protective layer. To do this, prepare a cement mortar used for plaster walls. It is necessary to add silicate glue to the prepared solution and mix thoroughly. It should be remembered that the solution, to which silicate glue was added as an additive, is not diluted again, since the glue may lose its protective properties. Apply the solution with a spatula in a very thin layer.

Subsequent work with a concrete surface (installation of waterproofing works) can only be done the next day. Finishing waterproofing work with warming using basalt wool or foam sheets.

To perform interior finishing work, silicate glue is added to the diluted cement mixture in the ratio of 8-10 liters of cement mixture per 1 liter of silicate glue.

For waterproofing work outside the room, you must purchase a cement mixture with sand and liquid glass. The multifunctional mixture for exterior decoration consists of 1.5 kg of cement, 1.5 kg of sand and 4 liters of liquid glass. Water is recommended to add no more than one-fourth of the total mass of the mixture. With all the proportions, you can get a strong insulation that will protect not only from moisture, but also from fire.

Often, liquid glass is used as an adhesive to join various construction materials, for example, during repair work with paper, cardboard, wood and porcelain products.

Waterproofing finishing of a well takes place in two simple steps.The first step is the application of liquid glass to the entire surface of the walls of the well, the second step is the application of the diluted cement mixture, which includes cement, sand and silicate glue.

Waterproofing walls with silicate glue is used extremely rarely due to the fact that water gets into the side surfaces in exceptional cases. But if you wish, you can do this finishing work by purchasing the required amount of liquid glass.

The use of silicate floor glue as a waterproofing is perfect if it is necessary to fill all small cracks and gaps.

Contrary to the wide range of silicate glue produced, there are no differences in its components. As a result, the purchase of material of a certain brand is the personal preferences of the consumer. Do not be mistaken that the higher the cost of the material, the better it is - by and large, all made mixtures for waterproofing works have the same characteristics.

For how to apply liquid glass, see the next video.