What are the Rockwool 100 cylinders for?

Staying communications in the face of constant changes in environmental factors (decrease / increase in humidity and temperature) significantly reduces the service life of pipes. However, this problem can be solved, and this is done with the help of modern protective materials. The best of those on the market today are the wound cylinders of the Rockwool 100, produced by the same-name trademark founded in Denmark more than 100 years ago.

What it is?

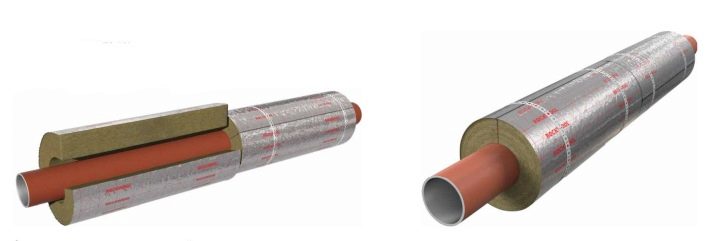

Rockwool 100 wound cylinders are hollow products made from rock wool. Their creation is based on the manufacture of so-called shells - the fibers of mineral wool are wound on a special shape in a circle.

Such manufacturing technology increases the strength of the insulation design, and also makes the material uniformly dense, with the same thermal conductivity throughout the body, durable.

Structurally, the cylinder is a pipe cut through on one side. The same cut, there is also on the inner wall on the opposite side, only it is small and shallow. This is done to make the product easier to put on the pipe. That is, you need to straighten the cylinder into two halves, like a book is opened, and put it on the tube, then bring the unbent ends together and fix.

Characteristic

The material from which the Rockwool 100 is being protected is not deformed. This fact suggests that throughout the entire life cycle, products from mineral wool will have an initial appearance. Wound cylinders withstand the temperature of the pipes encircling them up to 650 C. The inner diameter of the cylinders is 18–219 mm, and the thickness of the useful insulation layer is 20–100 mm and the length is 1 m.

Today, there are two types of woven insulation from Rockwool:

- standard, not having a protective coating of aluminum;

- foil-lined cylinders.

The latter version of products is more useful in application, since they protect pipes from many negative factors:

- effects of ultraviolet: despite the fact that the winding cylinders are almost invulnerable, it is still better to avoid constant exposure to sunlight;

- moisture exposure;

- exposure to any liquids and vapors;

- mechanical damage: of course, if a very large and heavy object acts on the pipeline, the section will be damaged, but a lighter object, such as a hand tool, will not cause harm.

In this case, the foil layer plays the role of a screen, which is designed to reflect heat but not let it go away (which is very important in the industry - for heating systems and process piping).

The aluminum-foil-laminated shell of the Rockwool trademark is also often used for insulating pipes in the ground (especially samples with dimensions of 25 x 114 and 76 x 25 x 1000 mm). These cylinders need extra protection. After all, the “bare” section of the mineral wool can be damaged by the movement of land masses. In addition, constant contact with a moist environment is not useful for an insulating product.

The foil layer is a kind of barrier that protects the heat insulator from the above-mentioned negative effects of environmental factors. Mineral-cotton products of this type (cylinders lined with aluminum foil) are denoted by two letters - Kf.

Rather rigid, but meanwhile the porous structure of basalt cotton wool differs in fine resistance to any kind of deformations. You can not worry about the fact that at any moment of operation there will be a shrinkage, the entire service life of the wound cylinders will retain the original characteristics, and due to the low thermal conductivity they will perfectly cope with the main function - protection of the pipeline from freezing and heat loss.

Main features and disadvantages

According to the manufacturer, the wound cylinders of 100 KF have the following properties:

- Chemical resistance Mineral wool is an inert material, therefore it does not react at all in contact with acids, oils, alkalis and solvents. This feature allows the use of insulating shells in combination with other insulators, even chemically active.

- Water resistant. Cylinders absorb a liquid of only 1% of their total volume.Filling with moisture occurs exclusively under the influence of external forces.

- Fireproof. The Rockwool barrier begins to melt at a temperature of 1000 C, without changing its insulating properties. For this reason, this shell can also serve as a protective layer for structures produced from combustible materials.

- Biostability

- Easy to install. The material is easily cut with a conventional penknife, and the installation does not take much time.

The quality of the product is also indicated by the place where it was first produced. The first plant was built in the country of Denmark. However, Rockwool products are famous not only for their advantages. The cost of heat-insulating cylinders of the Kf brand is significantly higher than for products of the same type from other manufacturers, and this is their obvious disadvantage. There is also the possibility of the formation of a cold bridge at the seams of basalt heaters.

Application area

Rockwool 100 cylinders are used for the following purposes:

- Insulation of the external pipeline for hot and cold water. The material does not allow the pipeline to freeze, so the water temperature during the movement does not drop.

- External protection of the heating system.The hydrobarrier provides an economical consumption of energy resources, saves heat.

- Insulation of the pipeline outside the premises. It prevents the formation of condensate inside the pipes, thereby improving the quality of the gas.

- Noise isolation pipes.

Rockwool 100 cylinders are sold in a package of 2 to 12 pieces, and the larger the insulation diameter and thickness of the basalt layer, the smaller the amount contained in the package. Products, as mentioned earlier, have a standard length of one meter. This allows you to quickly calculate the right amount of material.

The use of these products will minimize the likelihood of a fire hazard situation at enterprises using “hot” technological processes.

Installation

- Working with the Rockwool 100 cylinders is pretty straightforward. Thanks to a specially made notch on the inner plane of the product, the shell easily opens like a book, and it can easily be put on the pipe.

- Cylinders should fit snugly to each other, being fixed on the pipe with a special bandage or knitting wire.

- At least two bands must be installed on one cylinder.

- If foiled cylinders are used, longitudinal and transverse joints should be glued with self-adhesive aluminum tape.

- If necessary, for example, during the external laying of pipelines or in another case, a protective cover (casing) should be put on the cylinders.

- On vertical pipelines, in order to avoid cases of structural failure, every 3-4 m it is necessary to install unloading systems - support rings. Devices will prevent slipping of insulation and protective coating.

- When cylinders are used to prevent condensation in the pipeline, a vapor barrier must be installed with sealed seams.

For more information on installing Rockwool 100 cylinders, see below.