Types of isospan and their use for vapor barrier and waterproofing

Izospan is a film-type insulation material. It ensures the preservation of the original qualities of thermal insulation and is used in various fields. Therefore, it is worthwhile to consider in detail its advantages and disadvantages, as well as learn how to properly mount the material on the walls, roof, foundation. This and much more will be discussed further.

Types and their properties

Thermal insulation retains heat in the house when it is cold, adds comfort in the heat, prevents the rooms from blowing. However, the insulating material itself needs to be protected from negative atmospheric phenomena. Such protection is provided by the polypropylene membrane - Izospan.

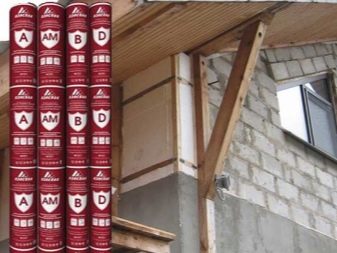

Such a sheet will successfully play the role of protection for thermal insulation. Despite its simplicity, this film material has differences: type A, type B, type C, type F, and others. Each type has differences in technical characteristics.

The film corresponds to construction GOST and has the following generalized qualities, which are confirmed by the manufacturer:

- thermal conductivity;

- density;

- water tightness;

- elasticity;

- resistance to adverse effects;

- resistance to ultraviolet radiation;

- environmental Safety;

- Fire safety.

The properties of Izospan correspond to the classification of products. Classification - this is the letter index, which manufacturers refer to the material produced. Sometimes on the sold samples you can see a combination of letter indices. Each new designation expands the application of the material. The performance of any Izospan high.

The material is widely distributed in the construction field. It is used for vapor insulation of both residential and industrial structures. The properties of Izospan correspond to sanitary and epidemiological norms.The material is supplied with certificates of compliance with fire safety and technical certificates.

In the production of Isospan used polypropylene. The base is melted down and then rolled to a certain thickness with special shafts. The material is obtained homogeneous structure, dense. The material is considered two-sided, and both surfaces of Isospan perform different functions.

If you put the steam insulator correctly, all the moisture will remain on the film, it will condense on it. Being on the film, the moisture evaporates, does not harm the structures.

Today Izospan received recognition as an effective insulation material for attic, garages, walls of private houses.

Material properties will protect the metal coating from corrosion, and wood from rotting. The material prevents the penetration of air flow, does not release heat to the outside. When choosing products, it is necessary to focus on the quality of the main modifications, each of which has its own characteristic features.

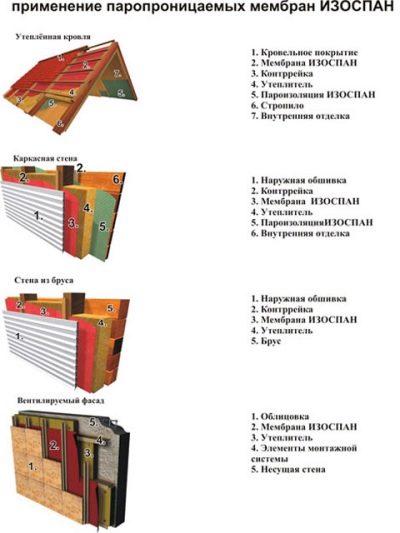

- Izospan A plays the role of an excellent waterproofing agent. Even this modification well protects the insulation from wind and water, thereby increasing its service life.Izospan A is suitable as an insulator of any premises, as it is resistant to mechanical stress, neutral to mold and fungi. The film is stretched longitudinally by 19 cm, and across by 14 cm. The material is used as an additional barrier, fixed to the outside of the insulation. For fixing the membrane used wooden slats and nails.

- Izospan B - a wonderful vapor barrier, which will eliminate the high humidity inside the room. The two-layer Izospan B can be used on roofs, internal and external walls, and attic ceilings. The material is stretched longitudinally by 13 cm, and across by 10.7 cm. In contrast to the previous modification, Izospan B is installed inside the heater, fixed overlapped, taking into account the presence of free space between the layers.

- Izospan C - two-layer, known as a good protection for the roof, frame walls, as well as concrete floor. The membrane is fixed on the insulation, overlap, wooden slats. For insulation, the floor is laid directly on the surface.

- Izospan D - very durable, known as roofing protection in terms of waterproofing. In addition to roofing, Izospan D covers concrete floors at the level of basement floors. The material is mounted in horizontal stripes, fixed with wooden slats.In addition to the main modifications, there are additional species of Izospan, the purpose of which is worth considering in more detail.

Purpose

The variety of materials in the Izospan line is wide. In addition to basic materials, you can find related products for sale, namely scotch tapes and adhesive tapes.

- If connective taped SL to fix the strips of hydro- and vapor-insulation among themselves, the best tightness of the connecting joints will be ensured. Installation with connecting tape is carried out at moderate temperature conditions, and the surfaces to be joined must be dry and clean.

- Ribbon FL it is possible and to connect cloths, and to close up small damages. This is a metallized tape with excellent durability. Wear and tear strength of this tape is also high.

- Unilateral scotch ML characterized by high quality adhesion. The material of the Proff modification has proved itself in particularly difficult cases, as it helps in connecting uneven surfaces, of various bases, for example, bricks with concrete, porous surfaces. Izospan ML allows gluing together plywood, wood and plaster surfaces.The material provides the best connection of pipes, windows to window openings.

- Izospan KL allows you to glue together two panels. Well seals material overlap points. Izospan KL is glued on the upper edge of the warmed panel, paper side up. It is pressed to the lower canvas with a slight movement of the hand at a certain distance from the edge. Then the paper side is removed from the tape and both edges are pressed against each other. Installation of the material is made on clean dry cloths at a positive ambient temperature. The basis of the adhesive layer is water-dispersion modified acrylic. Izospan KL does not include solvents.

Waterproofing is applied according to general instructions for the ceiling, walls, on the sub floor.

The work associated with laying the membrane is simple and does not require special skills.

- Regardless of the place of installation, the smooth surface of the film should always be turned to thermal insulation. Incorrectly laid canvases will not add to the effectiveness of the weatherization; Each type of product is accompanied by instructions. Its exact observance will not allow to make mistakes in work.

- Lay the material tightly to the surface with a small spade in the corners. Lay the canvas overlapping, the size of which should be about 15 cm. If the membrane is attached to wood components, you can use a furniture or construction stapler. Sealed seams with tape or tape.

- If a reflective film is mounted, then it should be installed with the metallized side inside the room. Laying must be done without overlap, butt. Glue the joints with duct tape.

- If you carry out the vapor barrier of the insulated roof, then lay the film on the bottom. Fold the appropriate canvas horizontally, tightly to the rafters, avoiding windage. As clamps of the film, wooden, treated with an antiseptic slats 4 x 5 cm wide are suitable. This crate will provide free evaporation of condensate.

The general view of the system will be as follows:

- interior trim;

- Izospan B, C;

- rafters;

- insulation;

- hydroprotective membrane;

- roofing.

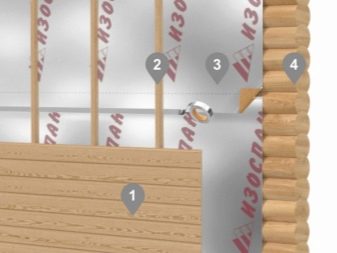

Vapor barrier of internal partitions of the house is needed if the interior floor frame.

In this case, Izospan V can be installed on either side of the wall.For works the stapler or special nails is used. Izospan needs to be laid horizontally, starting from the bottom. Izospan is fixed by slats, and on the other side of the wall you can mount Izospan A. General form:

- finish;

- rail;

- steam insulator;

- frame;

- insulation;

- moisture protection;

- rail;

- finish

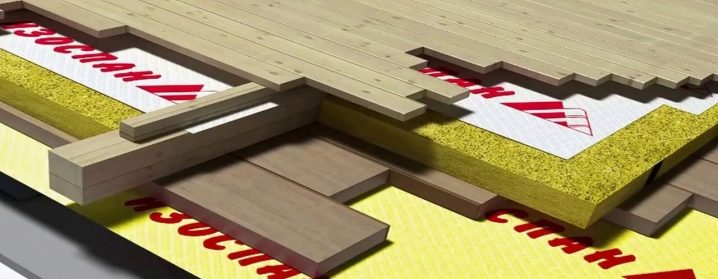

Izospan can be used as a paroizolyator of interfloor overlappings.

The material is laid on the rough base of the ceiling with the rough side down. If the membrane is spread on the genital lags, above the insulating layer, then a smooth surface should be laid up. Clearances are needed:

- Between a layer of insulation and a layer of vapor barrier.

- Between the flooring and vapor barrier.

- Between the ceiling trim and Izospan.

General form:

- ceiling trim;

- reiki;

- steam insulator;

- draft floor design;

- beams;

- insulation;

- steam insulator;

- reiki;

- floor finish.

Like any building material, Izospan has its pros and cons. Let us examine in more detail the technical advantages and disadvantages, as well as consumer reviews.

Advantages and disadvantages

The main advantages of the material:

- Lasting. Izospan is not torn at installation, has long service life.

- Reliable.When laying the material other materials will remain dry in the most negative conditions.

- Universal. It is possible to use the material on any types of structures when installing any insulation.

- Ecologically safe. The film does not emit harmful substances into the atmosphere.

- Practical.

- Fireproof.

- Convenient to install.

Izospan perfectly weathers the accumulating condensate, significantly improving the characteristics of the insulation. The walls remain dry, so fungi and mildew do not appear on them.

Of the minuses of Izospan, it is worth noting the need for mandatory processing of wooden structures with antiseptic agents.

There are other disadvantages:

- in case of violation of the insulation technology, condensate may form at the joints of the material;

- the vapor barrier rolls can not be mounted immediately, you need to keep them in a warm room;

- vapor barrier process is not possible if phenomena such as fog or rain are observed;

- during the installation of Izospan on the concrete surface of the basement, the latter is recommended to be heated with heat guns.

Consumer feedback on the material is generally positive.

- For example, users write about the qualities of Izospanthat work with it can be carried out simultaneously with the laying of the cake. The material allows you to save on the installation of crates. The condition of thermal insulation for two years is good. Loss of heat, wet spots are not observed.

- Another user notes characteristics of Isospan AS. Of the benefits of a high speed installation. The material also has disadvantages - it is thin, the web breaks during fixing to the frame. In addition, this type of material is difficult to determine the correct side of the installation, as both are smooth.

- By contrast, FB series option define easier. Users note the good roughness of the right reflective side. However, the material is expensive, since its width is non-standard. Investments justify themselves in further exploitation.

- Sides of Izospan B also easily identified. The smooth side of the material must be mounted to the heater. The vapor permeability of the material at a height, the cost is fully justified.

Features of use

The sides differ in appearance and touch: one is smooth and the other is rough. It is believed that Izospan should be laid smooth side to the insulation.The rough side of the film should touch the insulated vertical. Isospan roughness effectively absorb condensate. Without vapor barrier, condensate will always flow down to the floor structures. Condensate harms both wood and concrete. Consider some special types of vapor barrier Izospan more.

Vapor barrier series FB used in interfloor hardwood floors, for walls inside a steam room, saunas. At the heart of the FB series is kraft paper and metallized lavsan. Features structured Izospan allow you to effectively reflect thermal energy. It is not necessary to fix the FB series outside, as the material perfectly resists the temperature environment with dry steam to 140 degrees.

The strength characteristics of the material are excellent, it is environmentally safe.

The use of Izospan reduces the heat loss in the steam room. The same vapor barrier will prevent moisture inside the wall structure.

The sizes of a roll of Izospan FB:

- width - 1.2 m;

- length - 35 m.

The material can be used in the temperature range from -60 ... +140 degrees. Technical characteristics of the material correspond to GOST.The quality of the characteristics may be reduced by UV radiation.

Similar characteristics have materials series: FD, FS, FX. These are vapor-permeable membranes that prevent water vapor from escaping into the atmosphere. Waterproof materials, hydro-resistant, have an energy-saving effect. The materials are able to reflect infrared thermal radiation, protect floors from steam. The use of steam insulation helps to reduce the warm-up period of the room, provides significant savings on space heating.

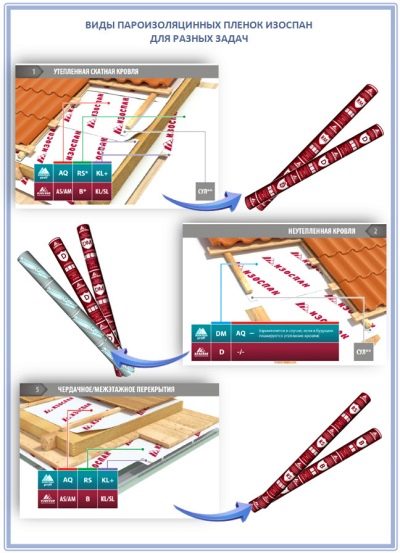

Izospan AS Series it is at the same time, waterproofing, vapor barrier, interchange protection. The membrane has three layers, protects insulation, elements of the roof, walls from gusts of wind, moisture from the external environment. Izospan of the AS series can be mounted on a heater without ventilating gap. As a result of the application of a series of spending on the crate between the insulation and Izospanom excluded.

Diffusion membrane, showed good water resistance and water resistance. The use of this film has a positive effect on increasing the service life of the entire structure.

The material is produced in rolls 1.6 m wide, 70 m long.The actions of UV radiation, as in the previous version, reduce the quality characteristics of the material. The original technical qualities correspond to GOST.

Similar performance has the AM series membrane. The material combines the characteristics of water resistance and vapor barrier.

The scope is quite wide:

- warm sloping roofs;

- frame type walls;

- walls with external insulation;

- ventilated facade;

- attic floor;

- internal verticals.

Separately for a ventilated facade can be used a series of film A with OZD. This vapor-permeable membrane protects the elements of the facade from wind, precipitation. The film will not allow the excretion of vapors from any type of insulation material. Film width 1.6 m, roll length 70 m.

Separately, the material of the RS series can be used as a roof insulator. The film is suitable for non-insulated structures. It will protect wooden elements from the effect of condensate, from penetrating atmospheric phenomena. As a vapor barrier suitable for flat roof structures.

Another type of film that is suitable for non-insulated roofs, Izospan RM. Three-layer material with reinforced polypropylene mesh.In addition to protecting roofing structures, it can be used to protect floor concrete floors. In this case, participates as a waterproofing layer.

Which to choose?

If the material is chosen as a vapor barrier for the roof, then such moments are taken into account as:

- temperature phenomena at the location of the building;

- the purpose of the roof (exploited, unexploited);

- roofing pie design.

The vapor barrier must first be completely hermetic. This quality is very important for similar materials. Self-adhesive tape or adhesive tape is not in vain recommended for sealing seams.

If a vapor barrier is chosen for a bath, it is desirable to minimize the risk of fire, therefore FD, FX, FL Termo, foil vapor barrier are the most suitable options for such structures.

It is important to note that the lower layer of the roofing pie must be non-flammable. The non-combustibility of the roof for the bath will be increased if the vapor barrier film is laid so that its edges extend beyond the insulation. Experts advise to glue the membrane to the wall and additionally fix the galvanized stripes.

Unlike ruberoid and glassine, Izospan - modern material of the new generation. Diffusion film has lower vapor permeability compared with the membrane considered in this article: it can be used for both hard and soft roofs.

Diffusion membranes are usually composed of several layers. The product combines polypropylene fabric and polyethylene laminate. The cost of this type of vapor barrier is quite high.

However, other analogs have advantages and disadvantages. For example, species such as roofing material and asphamine, have a low cost. However, today few people will use roofing felt for vapor barrier of the roof of a residential building. This is a household material. Glassine is also not used as the main hydro and vapor barrier.

The coefficient of application of bitumen membranes is also small. With the help of this material, concrete roofs are vaporised. This type is mounted by heating and subsequent gluing to the base. The main drawback of the material - a lot of weight.

Almost all of the above types of materials combines Izospan, which is represented on the market by the 14th species.Only the A class of Izospan combines several variants of films, for example, AS, AM, with different strength, density and ability to transmit steam.

RS series Izospana - a unique, versatile product that will completely replace all the materials in the aggregate. The material is indispensable in many construction areas, as it has high strength, does not harm the interior. Sealing reinforcing mesh of polypropylene will not allow the formation of harmful fungi and mold, as it creates an additional protective layer for the material and structures.

The length, thickness, weight, number of meters in a roll differs depending on the grade of the material. The division looks like this.

First grade

Izospan A

AS Series

AM Series

release:

- width, m - 1.6

- size, m² - 35, 70

Second class

Izospan B

release:

- width, m - 1.6

- size, m² - 35, 70

Izospan C

release:

- width, m - 1.6

- size, m² - 35, 70

Izospan D

release:

- width, m - 1.6

- size, m² - 35, 70

Izospan DM

release:

- width, m - 1.6

- size, m² - 70

Third class

Izospan FS

release:

- width, m - 1.2

- size, m² - 70

Fb

release:

- width, m - 1.2

- size, m² - 35

Fd

release:

- width, m - 1.2

- size, m² - 70

FX

- release:

- width, m - 1.2

- size, m² - 36

Indicators of different manufacturers generally coincide. We will talk more about the most famous suppliers of this building material and user reviews.

Famous manufacturers and reviews

Positive feedback is received by the following manufacturers of vapor barrier films that can be installed from inside the premises:

- Ondutis;

- Izospan B;

- Izospan D;

- Delta Reflex;

- Delta Luxx;

- Tyvek AirGuardSD5;

- Tyvek AirGuard Reflective;

- Stroybond B;

- Isobond V.

Well-known manufacturers of hydro and vapor insulation, which are also characterized from the positive side and became widespread, as a temporary roof:

- Ondutis RV;

- Ondutis RS;

- Izospan D;

- Stroybond D;

- Isobond D.

A small rating of films that are used outside:

- Ondutis a100;

- Ondutis A120;

- Izospan A;

- Izospan AM;

- Izospan AS;

- Delta Vent N;

- Tyvek soft;

- Tyvek solid;

- Stroibond A.

It is widely believed that the properties of hydro-vapor barrier films are better than those of simple vapor barrier materials. Users note the durability of Italian reflective films.

Way of laying

- To lay any vapor barrier on any type of roof you need after laying insulation. It can be put under a professional flooring.

- Waterproofing can be laid in any direction.

- If the material is laid along the rafters, the overlap should turn out directly at the level of the rafters. At the same points of contact, the material must be carefully fixed.

- In places of contact with water pipes, which can pass through the roof, the membrane is wrapped down, wrapped around the pipes and carefully sealed with tape.

- Some types of materials require a mandatory air gap. To create this space is quite thin wooden slats. They are located at a distance of about 50 cm from each other.

Useful recommendations

The general rules for film installation imply strict compliance with the instructions for use. Technology laying on vertical and inclined surfaces should be made from top to bottom. Film strips should be laid horizontally. Lay the film with an overlap of at least 15 cm. For reliability, glue with adhesive tape. If the wall is finished with gypsum plasterboard, the film should be laid with a rough side to the plasterboard and a smooth side to the insulation.

- When laying the vapor barrier on the roof Izospan can be fixed directly on rafters.For fixing, suitable bars or thin clamping strips. Finishing: drywall, plywood, wall paneling, etc., mounted above the vapor barrier. If the bars were used for fixation, the finish can be mounted directly on them. A gap is formed between the film and the finish. Ventilation clearance provides better condensate drying.

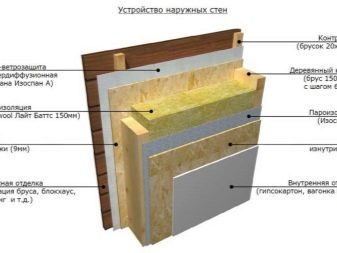

- If Izospan used for wall insulation indoorsfirst you need to fix the bars on the vertical. If the finishing plating is drywall, then a metal frame will do. After that the heater is installed: mineral wool or expanded polystyrene. On the bars reiki or stapler attached paroizolyator. The next step is the final finish.

- If the walls are insulated outside, the procedure should be reversed. First you need a crate of bars. Then a vapor barrier is attached to this structure. Next is the heat insulator, and on top of it - a waterproofing film. The final stage will be the installation of finishing.

- If a vapor barrier is used for the floorFirst, you need to lay waterproofing between the lags. Then the heater is mounted. On top of the insulation is mounted vapor barrier.For its fixing fit bars. Flooring boards are installed on top of the vapor barrier.

- When installing interfloor overlap The previous steps are almost the same. If necessary, the vapor barrier can also be installed on the ceiling from below. Ceiling trim is mounted on top of the vapor barrier.

- If during installation the steam insulator is damaged About any design elements, broken places must be repaired. For this you can use sticky tape or special glue. The material is very reliable in installation and more expensive than conventional plastic film. However, the quality characteristics of Izospan far exceed the quality of the film.

The following tips will help you do the job well.

- When laying any vapor barrier materials watch for the quality of the joints. If they are poorly glued, the ceiling usually becomes mistreated, and the efforts from the work done are practically reduced to zero.

- It is easiest to fill any hole in the membrane with a special tape for sizing not less than 10 cm wide. A narrower tape will simply peel off.

- Leave folds of material 2-3 cm wide around windows, other openings, especially if the building is new, built. Deformation stock in this case should be provided necessarily.

- If the vapor barrier membrane is laid around the roof windows, then it must be protected from the inside with a special finish.

- If the membrane needs to be fixed on the rough surface of the brickwork, wood, it is better to use adhesive compounds with acrylic or rubber base.

- Polyurethane based adhesive tapes are not recommended for use by specialists. It is believed that due to insufficient stickiness, they eventually depart from the base.

See the following video for the application of Izospan.