Tyvek Airguard SD5: features of hydro and vapor barrier membranes

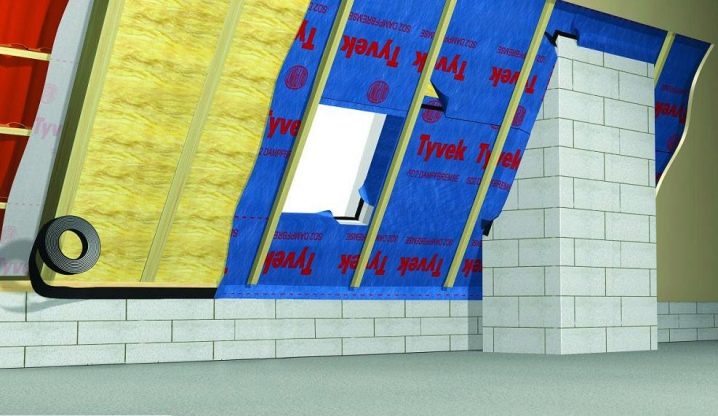

Warming roofs, attics and enclosing walls can significantly reduce heat loss, and, consequently, reduce heating costs. However, a layer of insulation can seriously suffer from condensation and moisture from the atmosphere. In the cold season, this leads to freezing of the heat-insulating material, and in the summer the heated wet layer of insulation can be damaged by mold or other microorganisms. The special waterproofing membrane will perfectly cope with the problem of excessive moisture of the insulating material of the roof or walls.

About the manufacturer

The American DuPont campaign opened in 1802. All this time, the company has specialized in waterproofing and insulating materials. Production has been constantly improved.Serious specialists and research workers have always been involved in the development of the next product line.

One of the latest and advanced developments of the company is the Tyvek Airguard SD5 hydro-vapor barrier membrane. Like many other DuPont products, it is manufactured at a factory in Luxembourg. High-performance modern equipment and environmentally friendly materials used in the production are a guarantee of product quality and safety.

Tyvek vapor barrier has gained recognition and popularity in many countries around the world. Relatively recently, this material has become possible to meet on the Russian market of building materials.

Features and benefits

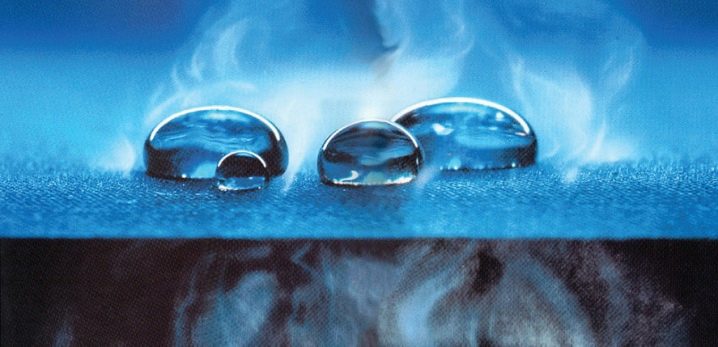

The membrane SD5 is widely and successfully used as a vapor barrier for insulation. Its properties allow to effectively remove condensate and moisture from the insulating material, thereby saving it from destruction and freezing. This allows not only to maintain high rates of thermal insulation, but also significantly extend its service life.

High vapor barrier properties are provided by the reinforced base membrane and special technological layer.

Consider the main advantages of AirGuard.

- The membrane material is capable of providing stable convection. This significantly reduces the heat loss of the room.

- The relatively small weight of the roll does not require complex transportation and the involvement of several craftsmen. Installation of the material can be done by one specialist.

- SD5 membranes are resistant to damage and mechanical stress.

- The vapor permeability of the AirGuard material ensures stable removal of moisture from the thermal insulation layer. Thus, the accumulation of condensate in the insulating material is practically excluded.

- The material of the membrane is not nostalgic, environmentally friendly and safe.

- AirGuard SD5 has a very long service life. He is over 50 years old.

- SD5 is able to eliminate the unpleasant effect of the "greenhouse", which can often manifest itself in polyethylene insulated lofts.

- Vapor and water insulation membrane AirGuard SD5 helps to maintain the optimum temperature and humidity inside the room. The degree of comfort conditions in the room are similar to the conditions in the building on the basis of a wooden log house.

- The SD5 film can significantly slow down the processes of dilapidation and destruction of the building and its structures.This is due to the fact that the building foundation is able to dry out well.

- The manufacturer is ready to confirm the quality of products with all necessary certificates.

Specifications

AirGuard SD5 has the following properties and characteristics:

- materials used in the manufacture of the membrane: polyolefin, polypropylene;

- roll weight: 8.5 kg;

- overall dimensions of the roll: 1.50 mx 50 m;

- material density: 108 g / m2;

- vapor permeability coefficient: 5 m;

- permissible operating temperature: from - 40 ° С to + 80 ° С.

Installation Features

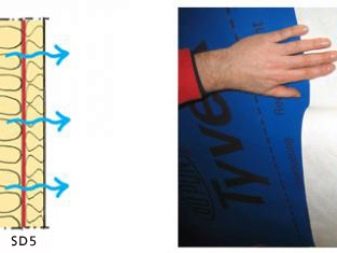

- The film Tyvek Airguard SD5 is rolled out along the entire length and fixed with staples to the rafters. The distance between the brackets is about 50 cm. The material can be placed both in parallel and perpendicular to the rafters.

- The material is fixed in such a way that the side with marking is turned inside the building or room.

- In places where membrane sheets form joints or overlaps, as well as adjacent to the elements of the building structure, it is necessary to carry out sizing with rubber-based building tape. When weathe the walls in the room, it is recommended to leave a gap of 3-4 cm between the vapor barrier film and the interior.

- For fastening of the material Airguard SD5 it is impossible to use brackets nails. Fixing the vapor barrier should be done with rails.

- If a rupture of the membrane was allowed, the damage site can be glued with construction tape or butyl rubber tape.

- Vapor barrier is not required for cold attics. If the house with a cold attic is heated in winter, the vapor barrier membrane is mounted in the ceiling of the last floor.

- If shortly before the installation of the vapor barrier, chemical treatment of wooden structures in the attic or indoors was carried out, then the installation of the membrane is permissible for at least 24 hours.

Make sure that the applied chemical layer is completely dry.

The waterproofing membrane of Tyvek Airguard SD5 has positive feedback from consumers and professional craftsmen. Buyers note the relatively affordable cost of this vapor barrier material in combination with high quality. Many buyers could make installation of a film independently, without resorting to the help of professionals.

Masters working with this material also note the convenience and ease of mounting the membrane. According to the observations of the developers, the film Airguard SD5 perfectly maintains storage in the open air, does not fade and is not deformed from the sun's rays.

10 tips on how to properly make a vapor barrier at home with your own hands, see the following video.