TechnoNIKOL: what materials and systems does the company produce and where are they used?

Corporation "TehnoNIKOL" is today one of the leaders among European manufacturers of waterproofing materials. It has been on the market for more than 25 years, and every year its capacities are increasing and the range increases.

About the manufacturer

The company "TechnoNIKOL" was founded in 1992. Own production of roll-roofing materials was opened at the Vyborg ruberoid plant in 1994. To increase the production of products and saturation of the sales market, newest plants for the production of waterproofing products are launched.

And by the end of 1999, the company has five manufacturing facilities and 35 sales offices in various regions of Russia.Opened sales office in Kiev.

The range of products for the construction market is expanding. TekhnoNIKOL buys the first foreign enterprise Gargzdu Mida (Lithuania) with the aim of capturing the growing demand for sloping roofing and starts producing shingles under the Shinglas brand. Under the brand name "Techno", a batch of stone wool insulation material is produced.

A production for the production of mastic has been formed, which makes it possible to realize a complete supply of heat and waterproofing materials for objects under construction. Trade networks are actively expanding - in 2003, the 50th product marketing organization opened.

TekhnoNIKOL Corporation is becoming the largest European manufacturer of waterproofing materials, among the top five. In 2004, Luxard composite tile appeared in the product range, which was first produced in Russia. In the same year, a scientific center was opened, where newest materials are created and tested. One of the largest factories in Ryazan is launched in cooperation with the Spanish company Chova for the production of Shinglas tiles.

A representative office is opened in Poland, Warsaw.In all CIS countries there are branches of the corporation. In 2005, TekhnoNIKOL ranked first in Europe in the number of roofing membranes. In Ryazan, in 2006, production of basalt insulation begins, thanks to which the Corporation has become one of the center manufacturers for thermal insulation. The composition of the Corporation is growing due to the entry of the huge enterprise in the Far East of the Bazalit-DV plant and the TechnoNIKOL-Sibir plant built in the Republic of Tatarstan in the Zainsk plant of the TECHNO plant and in the city of Yurga, Kemerovo region.

In the period from 2006 to 2008, TekhnoNIKOL Corporation successfully implements investment programs and is one of the three trade union leaders in Russia on thermal insulation materials. By 2010, the Corporation is the largest manufacturer and supplier of thermal, hydro- and sound insulation. It consists of 35 enterprises that are located in Russia, Belarus, Lithuania, the Czech Republic. It has its own trading network of 141 branches and trade missions in thirty-three countries.

The expansion of the product range was due to the purchase of a large factory of building materials in the Italian Italian Membrane, which, in turn, increased the export of building materials to different countries.

In the Forbes publication in 1914, TekhnoNIKOL ranks 81st among the TOP-200 large official enterprises of Russia and became the first among enterprises-performers that are not associated with the extraction of natural resources.

In recent years, TekhnoNIKOL Corporation increases the productivity of the production of extruded polystyrene foam, polyisocyanurate foam (PIR), stone wool and other thermal insulation materials and increases exports to more than 90 countries around the world. New manufactures of the Techno Plant in Rostov-on-Don and the TekhnoNIKOL Far East plant in Khabarovsk are being created.

Expanding production volumes in Yurga at the TekhnoNIKOL-Sibir plant and drawing into fresh aspirations. A plant for the production of drainage devices and a concrete production plant in Voskresensk are starting up in Ryazan.

The company is constantly investing training in the construction industry, such training centers are opened in Kazan, Yekaterinburg. Concern's activities are aimed at replacing imported products. In 2017, its own complete construction “House of TechnoNICOL” was presented. More than two hundred contracting enterprises in the country agree to build high-quality housing with the best price-quality ratio.

The Corporation guarantees its partners twenty-four hours after delivery to a private or public building.

Roll waterproofing

Waterproofing systems "TehnoNIKOL" are produced for everyday solutions in difficult directions, which are associated with waterproofing construction sites from the foundation to the roof. Materials are used without the use of special equipment and you can not attract certified builders. A single material directly performs its solution to the problem.

Waterproofing materials for the foundation are characterized by excellent heat resistance and first-class flexibility at low temperatures, which are used to protect the foundations and to form obstacles from the bearing wall and the foundation.

The range of rolled items has a lot of advantages:

- extensive product selection;

- environmentally friendly compounding components;

- the highest degree of product quality;

- satisfies current fire claims;

- multifunctional - can be used for the floor, roof, foundations of the house and inside;

- long warranty period;

- fully waterproof;

- quick installation;

- affordable price.

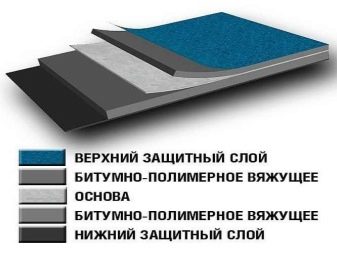

Rolled waterproofing "Tehnoelast" - built-up bitumen-polymer material. It is made by applying from two sides on a polyester fabric or on a glass bitumen-polymer fastening, consisting of bitumen, SBS (styrene-butadiene-styrene) polymer modifier and mineral filler. For the safety layer take coarse or fine-grained powders, polymer films.

"Tekhnoelast EKP" - roofing waterproofing material. It is used in the upper layer of roofing carpet in double-layer roofing. It is used together with the lining material "Tekhnoelast EPP". It is applied on roofs with a slope, on the planes giving compression or expansion.

"Technoelast EKP" keeps stability at temperature conditions - 30C, has a high heat resistance, protects from rain, snow, sunlight, is characterized by full water resistance, the service life is more than 25 years.

Tekhnoelast EKP is a multi-profile SBS-modifying material for roofing and waterproofing of premium class. The manufacturer gives an additional commitment and engineering assistance to the manufactured products.If construction requires a unique foundation and authority at the end stage, use this material.

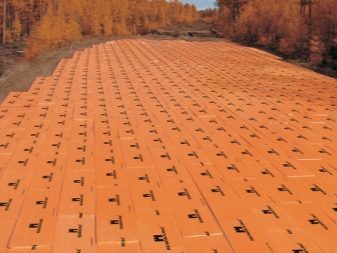

A characteristic feature of the material - on the lower side of the film "Technoelast" there is an indication image (the "TechnoNICOL" icon), thanks to it the dimensions of the profile lining are controlled.

The company's products are represented by various batches of products, which are distinguished by their specificity, produce 4 types of roofing material.

- Rubemast - the built-up roofing material, which is made in several layers, is taken as a basis for roofing paper, on which a viscous bitumen-polymer coating is applied on both sides. Due to the abundantly large bottom layer of bitumen, the material is characterized by excellent thermoplasticity; no gaps or dimples are created. And a protective layer is applied from above on both sides.

- Steklomast (glass rover) - it is different from rubemast where fiberglass is used instead of cardboard.

- Euroruberoid - self-adhesive roofing material. Apply completely different materials and components. Textile paper or synthetic fabrics are the basis. Bitumen-polymeric substances improve its parameters, which range from 2 to 5 kg per 1 sq. Km. meter basis.From above put a mineral crumb of different shades which protects from action of an ultraviolet and carries out decorative appointment. Warranty for euro ruberoid from 16 to 30 years.

- Tol - roofing material, which has a protective layer of mineral chips. Plain cardboard is the base for impregnating matter with slate or anthracite.

In addition to the listed ruberoids, liquid is also produced. It is called liquid rubber and is a bitumen mastic with polymer additions. It is used at the stage of construction of new roofs or with the maintenance of dilapidated roofs.

At the beginning of work, this roofing material is not heated and does not require any additives.

Types and classes

At the current stage, TekhnoNIKOL Corporation presents rolled materials of various classes.

Premium

The longest warranty from 25 to 35 years. It has a high level of elasticity and strength, and this is precisely what makes it possible to use materials of this class in various climatic conditions. Materials justify themselves when enhanced protection against the rise of groundwater is required. When using these materials, the manufacturer provides tangible engineering and informative assistance.

Materials - "Technoelast", "Technoelastmost", "Technoelast-Thermo".

Business

Warranty period from 20 to 25 years. The materials that belong to this class are durable and provide an opportunity to make an invincible, durable roof that provides “free breathing”. Used on many construction sites throughout Russia. Materials of this class improve construction work, it is easy to build with them. The technical assistance service will tell you how to design the roof correctly and what material to use.

Materials - "Uniflex", "Ecoflex".

Standard

The warranty period is from 10 to 15 years. Used for the construction of roofs of different slopes. Materials from this class perfectly fulfill their purpose - they protect housing from rain and snow. As a result of use, their durability and safety is confirmed. Extensive nomenclature in this class allows you to select the desired material. Safety and durability are consistent with widely available cost.

Materials - "Bipol", "Bikroelast", "Linokrom".

Economy

Warranty period of 7 years.With the help of materials of this class, you can make a high-quality, reliable roof. No need to use special technical equipment, but at the same time, the materials are quite durable. The roof covering from this class is easily and quickly mounted.

Materials - "Bikrost", euroroofing material.

Differences in composition

Rolled waterproofing consists of two layers of bitumen or bitumen-polymer composition, the base can be polyester, fiberglass or fiberglass. Materials are characterized by synthetic and biological strength, endowed with resistance to impulse.

According to the type of basis the rolled material is divided:

- on the main or baseless (the structure of the canvas);

- bitumen, polymeric, bitumen-polymeric (type of components of the coating composition);

- cardboard, polymer, fiberglass, combined (type of base);

- with fine-grained, coarse-grained, dust-like or scaly sanding, film or foil (the structure of the protective layer).

Marking

Overlaying roofing materials are made from oxidized modified bitumen on glass and polymer bases, which guarantees excellent strength and long service life.

Continuous monitoring of the process makes it possible to produce benign products required for marketing and in accordance with the standards and technical conditions used in our country.

Symbolic marking (mark) includes lettering.

Protective layers are designated:

- the letter "K" in the table specifications - coarse dressing;

- the letter "M" in the table specifications - fine-grained dressing;

- the letter "P" in the table specifications - protective film;

- the letter "B" - surface with ventilation channels;

- the letter "C" is a self-adhesive surface.

The basis is designated:

- the letter "E" - the basis of the polyester fabric;

- the letter "X" - the basis of fiberglass;

- the letter "T" - the basis of fiberglass.

The main types of roofing material.

- RCP - soft roofing material. Used for lower layers of roofing carpet.

- RPP - lining ruberoid, it is made of powdered dressing. It is applied to the lower layers of the roofing carpet.

- RKK - roofing material with coarse dressing.It is applied to the top layer of the roofing carpet, treated with a protective layer.

Application

In any category of rolled roofing materials there is, of course, its own professional leaders.

Technoelast Decor creates entertaining coverings of a large palette of colors, making this material a decoration tool. Good refractoriness allows to use Tekhnoelast Flame Stop on the construction site with an increased demand for fire resistance.

In business class, Ecoflex has a special need for use. The material allows you to make the assembly "breathable cover" without dismantling the old roof. It is resistant to high temperature conditions and will not lose its plasticity when it is cold minus 5? С.

"Uniflex K" is used for the top layer of roofing carpet.

"Uniflex P" is intended for the lower layer of the roof and waterproofing of the building.

The most popular materials in the standard class: "Bipol", "Linokrom." They are perfectly used to restore the existing and erection of a modern roof.Such a roof is able to protect the house in any weather and keep it from being wet.

The economy class has its own leader, Bikrost, which has many advantages. On the basis of fiberglass or bitumen with a profile backfiller, the dressing is applied on both sides and thanks to the protective application, the highest waterproofing technology is guaranteed.

"Technoelast EPP" designed for the installation of the lower layer of the roof, waterproofing the foundations of the building and the soil on the floor.

Roof

The company produces a wide range of roofing waterproofing materials, from which you can find the right solution for building a flat roof in any weather. Flat roofing system "TehnoNIKOL" is made on a solid and non-solid basis.

In addition to the listed roofing materials, in addition to the joint set of coatings, it is desirable to include a ridge aerator. The installation of this structure allows you to promptly remove excess moisture, which is often collected under the roofing layer, and thereby remove the swelling of the material.

At the roof device the roofing funnel is applied to a conclusion of rain streams. The funnel has leaf filtration.It is made of polypropylene, which provides durability and safety to weather conditions on the roof.

Soft roofing material has appeared recently and is used now quite often. The concern produces material adapted to weather phenomena in our climatic zones. To the roofing group belong materials where bitumen will be the basis.

Product categories "TechnoNIKOL":

- rolled mastic materials;

- flexible tiles;

- PVC membrane for roofing.

The built-up roof has the characteristic features that distinguish it from similar ones selling on trading floors.

The basis of this roofing material will be fiberglass, bitumen dusted on both sides with the addition of special substances that complement the proprietary parameters. On top of the material is basalt dressing, thanks to which the roof takes on its unique shade. The color palette of basalt dressing is wide.

Inside, the material base is subjected to bitumen processing with polymers that are glued to the plane through fusion. Silicone-based film protects the outer layer.

The soft roof has such parameters thanks to which it is possible to apply it to a roofing flooring of various configuration:

- consistency at different temperatures;

- various shades of basalt dressing are embodied in the revitalization of local color;

- high waterproofing of the roof and all nodes;

- endurance to various involuntary influences;

- excellent noise isolation.

One of the clear advantages of the soft roof "TechnoNIKOL" over the various performers of the same material is that you do not need to use special devices during assembly. You can make any form of structures, such as hipped, dome-shaped roofs.

The polymer membrane is made in three ways: using plastic polyolefin, with the addition of synthetic rubber, based on a plasticizer.

Most popular is the membrane with the addition of a plasticizer, which gives the coating plasticity and strength to sub-zero temperatures.

Variety of soft roof types

For the manufacture of the roof are used such types as composite and flexible tiles, additional elements and lining materials, drainage and ventilation systems.

Luxard® “TechnoNIKOL” composite tile is a new-fashioned phenomenon in roof design. Unusual combination of high-tech forming aluminum + zinc with lumpsnatural sandstone. Using modern techniques and developments - this tile is one step ahead in construction. The specific coating does not allow to crumble sand granules.

Elite roofing material - this is what this tile looks like. Outside, it is covered with granules of natural stone, giving the impression of an ordinary tiled roof. Special application of glaze protects against the collapse of the granules. The structure of the tile makes it possible to device noise insulation, which helps to make attic rooms comfortable, without the noise of rain on the roof.

The aluzinc content in the tile coating makes it invulnerable to corrosion. Luxard® TekhnoNIKOL composite shingles are not afraid of various temperature and weather changes. Does not change color and is resistant to sunlight.

The following soft roofing material at TechnoNIKOL is Shinglas flexible shingles, a bituminous material consisting of rectangular shanks of medium shape, with figurative clippings on one side, overlapping each other on the roof, row by row. Perfect for flooring on any roofs - flat, uncomplicated, dome-shaped. Shinglas tiles are available in 15 batches and 75 different colors.

Hydrobar

Hydro splines "TekhnoNIKOL" - profiling strips used in waterproofing seams of concrete structures. Used to isolate underground, above-ground concrete structures. It is used in individual, urban, technical buildings and in the restoration of existing buildings.

It is necessary to use in tunnels under construction, underground structures, basins, canals, collectors. When building an individual house, they practice in basements, lower floors for isolation from groundwater.

Description

Hydro splines are made of plasticized polyvinyl chloride by hydro extrusion method, it is an elastic plastic strip with a length from 22 to 32 cm. It is used in concrete joints of structures - external, sliding, hidden, distorted. Still used when broken down into different segments of waterproofing films-membranes. PVC-P strips are assembled into the lumen and prevent the penetration of moisture, which destroys the concrete, and prevents the formation of mold and fungus. Create the right conditions for the room.

The rule of exposure to the hydrosles is incredibly primitive - the gaps in concrete are compacted with PVC tape, thanks to this moisture will not tread.

Industrial parameters of waterproofing keys are determined by the characteristics of the material, which is taken as a basis. Products made according to GOST and TU.

Purpose

Waterproofing pins - reliable material, resistant to physiological effects, is used in the construction of buildings in different climates, even in the Far North. This material is used when there is a large difference in temperature conditions, but it is necessary to put it into operation only when it is positive.

Hydro splines "TekhnoNIKOL" are divided into two categories - for waterproofing deformation and cold joints. By type of assembly - external and internal.

Concern produces nine varieties of keys. Any category differs by its parameters, area and method of use, but also by different symbolic signs by class.

Facade

Concern "TekhnoNIKOL" expands the range of as shingles, and the use of material from bitumen compounds.

The company produces 6 brick colorings for facades - sandy, terracotta, beige, burnt, marble, antique. The technique used in the enterprise for the manufacture of shingles, allows you to make spectacular, durable colors.

Hauberk tiles are used for facing the front of the house. It is used in the decoration of various parts of the facade, can be used as a barrier.

Special features

Hauberk facade tile is made on the basis of material from fiberglass, SBS-modified bitumen and natural basalt sand, characterized by high endurance to different temperatures, heat resistance and long-term. The composition and characteristics of the tile are similar to roofing shingles, and therefore advantages are immediately visible, unlike other facade products:

- heat resistance to different climatic zones;

- infinite sphere in use (suitable for the construction of various structures);

- increased tenacity of basalt deposition to ultraviolet (original shade retains for a long time);

- ease of assembly (do not have to contact builders);

- tile impermeability;

- Hauberk tile looks natural, as applied natural basalt granules.

Advantages and disadvantages

The weight of manufactured products is the main advantage of this material ~ 12kg / m². The weight is much less than ordinary bricks, which is important for buyers who are ready to change the facade without using extra costs to strengthen the structure or foundation. The warranty period is set for ten years.

There are few minuses: it loses its operational properties at temperatures above +50 C, it does not tolerate the effects of aggressive chemical compounds.

Installation

Starting assembly with Hauberk facade tiles, Recommend pre-learn tips manufacturers:

- prepare the surface - level, clean, dry;

- it is not necessary to do installation work on rainy, foggy days, material, there are chances that it will swell up;

- on the non-exploited roof of an individual house, it is desirable to make a base of plywood, which is moisture resistant, in the end you get a strong and good frame, able to bear the mass of the entire roofing pie;

- It is recommended to assemble tiles using material from five or six batches in order to avoid differences in color;

- the material is stored in a warm place, if the installation is done in autumn or spring, when the temperature is close to zero or +5;

- opening the package, you need to bend it a little and shake it so that the tiles are easily separated from each other;

- the wooden crate must be disinfected with a special solution to protect it from fungus and moldyness;

- Attention should be paid to ventilation - an aerator is installed inside the roof;

- the tile is spread from bottom to top, laying is done from an arbitrary corner point;

- if the installation of a soft roof is overlapped, then the connections, moreover, are fixed with pins.

Sealants

Combat primers are used for priming the surface and improving industrial properties. Used to clean non-smooth structures that need waterproofing.

The most popular primer is the bitumen-polymer "TechnoNICOL 01". It is used in the construction of inexpensive roofs, base waterproofing, concrete structures, closed layers under the ground - tunnels.

There are various types of sealants that are used in different areas: roofing, road, insulating, universal.

The first are used at the very beginning in surface preparation for waterproofing works. The mixture perfectly aligns the base and firmly glues the rolled, sheet products. The latter are used to strengthen the foundations of the track, they combine friable substances, they prevent the untimely disintegration of the structure.

To protect the pipeline, various coating materials are used, which are fixed by insulating sealants.They are firmly connected to the treated side, the compound receives another insulating layer, thanks to it the strength of the metal from rust increases.

Universal sealants are used in the primer of various planes, to them belongs "TechnoNIKOL №1". It is used in the waterproofing of buildings of various types, often with him make a flat roof.

This material in the usual composition is applied immediately, no need to add any other substances. Basic extractants do not release toxic substances and are safe to work without respirators.

The material is environmentally friendly, it is much higher than other analogues, which are offered by other manufacturers. It guarantees a strong connection of waterproofing with concrete, reinforced concrete, sand-cement structures.

"Sealant number 31"

Increases adhesion in the waterproofing material to the base, irregularities are filled and at the same time strengthened. Connecting sand grains, surface crumbs, minor cracks.

"Sealant number 33"

Emulsion-water bitumen mastic, modified by latex and polymer modifier, does not have an organic solvent.It is used in the construction of mastic roofing, in waterproofing protection of engineering structures, which are buried in the ground and in contact with water - foundations, basements, piles. And also used in waterproofing of the bathroom, the floor of the pool, basement.

It is applied manually - with a brush or roller, but it is possible with the help of the mechanized installation RX - 28.

"Sealant number 42"

The single-component material is of heated use and composes with petroleum bitumen modified with unnatural rubber and high-tech additives. It is characterized by a large working temperature zone, high plasticity, no shrinkage, a short time for hardening.

It is used to seal improper joints in the concrete, asphalt concrete pavement of the airfield, road, sanitation of cracks in the concrete and asphalt concrete pavement.

"Sealant number 45"

Butyl rubber, consisting of butyl rubber, basic extractant, modified additions and fillings. Listed as a substance that is used in cold curing. It is characterized by a large working temperature zone, high plasticity, resistance to sunlight, a short time for drying.

It is used to fill the interpanel seam and different borders in the prefabricated building structure, insulation of the inner and outer plane of the concrete and reinforced concrete structures.

Heaters

Thermal insulation materials of the company "TehnoNIKOL" offer the following:

- expanded polystyrene, which is obtained by the extrusion process;

- basalt cotton wool.

Responses to Concern's insulation materials are generally positive.

The advantages include good noise insulation, sheet quality (smooth, uniform), environmental friendliness, moisture resistance, non-inflammability. The disadvantages are the crumbling of the material, if left in the open in the rain, it is easily deformed, while working with insulation, the skin is scratched (special clothing is required).

Species

Mineral wool insulators are resistant to weathering and the process of decay. Solid insulation does not shrink.

Types of polystyrene foam:

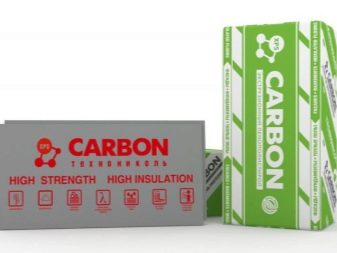

- Carbon Eco Drain - insulation with drainage workings;

- Carbon Eco - plates for individual houses, low-rise construction;

- Carbon Eco SP - a heater with special characteristics for arrangement of the base;

- Carbon Eco Fas - the material is used for the installation of the lower floors, plastered surfaces of the facade.

Varieties of basalt wool:

- "Heatball" - long mats based on stone wool;

- "Rocklight" - basalt slabs with resin, low in phenol (used in the insulation of individual households);

- "Tehnoblok" - material with low content of phenol (neither moisture nor flame disturbs, is used for walls - siding, frame);

- "Technocaustic" - moisture resistant non-flammable material, designed for sound insulation.

Specifications

Insulators "TechnoNIKOL" have the following technical characteristics:

- lowest thermal conductivity;

- fire resistance;

- immutability to deformation;

- steam conductivity;

- impermeability;

- noise absorption;

- strength to the fungus, mold;

- ease of finishing and assembly.

"Technoplex" or "Penoplex"?

To date, the most common heaters are "Technoplex" and "Penoplex." We will see which one is different from the other, what is the difference, which is better.

"Penoplex"

Extruded polystyrene foam is called tiled insulation. It is produced by extrusion method - the basis is the combination of foam particles in special chambers at high temperature and pressure.Using this process, they achieve a homogeneous composition of heat-insulating materials consisting of a huge number of small cells saturated with freon with CO². The result is a material with excellent heat-shielding parameters.

"Technoplex"

Produced differently. The main raw material will be polystyrene foam particles to which graphite nanogranules are added during the extrusion process. The result is a product that resembles self-adhesive foil sealing insulation.

"Technoplex" and "Penoplex" - tile insulation materials, environmental and belong to non-combustible material. In fact, they are not diluted in liquids and in the ground.

Here is a table for comparative characteristics.

Options | "Penoplex" | "Technoplex" |

Length, m | 1,18 -1,20 | 1,20 – 2,4 |

Width, m | 0,58 – 0,6 | 0,6 |

Thickness m | 0,02 – 0,1 | 0,02 – 0,1 |

Compressive strength, kPa | 150 – 250 | 200 – 500 |

Heat conductivity, W / mK | 0,032 | 0,03 |

Density, kg / m³ | 26 – 35 | 25 – 47 |

Temperature condition,? WITH | -70 ÷ +75 | -50 ÷ +75 |

Water absorption,% | 0,2 | 0,4 |

Heat conductivity at 25? C, W / (m * k) | 0,032 | 0,030 |

Vapor permeability, mg / m * hour * Pa | 0,018 – 0,02 | 0,02 |

"Penoplex" more durable to a static fracture and makes the most powerful mode. Both materials are almost identical in parameters.

Where are they used?

"Technoplex" and "Penoplex" are used in private construction and further insulation work - on the balcony, basement.

Penoplex is also purchased for road works, roof insulation, exterior and interior wall insulation.

About TehnoNIKOL and its products, see the following video.