Features of injection waterproofing

Often, we all encounter cases when a water leak is observed from some place of the building structure. And the usual ways to eliminate this problem is not possible. However, in the modern world there are new technologies that solve such problems quickly, very efficiently and at an affordable price. One of these technologies is injection waterproofing. She has features of use for different buildings and conditions.

Injection waterproofing is an excellent method of protecting buildings from moisture. It even copes with pressure leaks in the structure. The principle of operation is based on the injection of waterproofing materials under strong pressure using special pumping equipment.

For long-term operation of the building requires a good hydroprotection of the foundation. Therefore, the construction of the foundation takes 20-30% of the estimate of the value of the structure. And that is why it is very important that the foundation be erected in compliance with all rules and regulations. And one of such norms is the high-quality waterproofing device of the foundation.

Application

Each building foundation is the main foundation. And the term of use of the building depends on the quality of the foundation. Therefore, at the beginning of construction should do waterproofing grounds. It will make the foundation resistant to corrosion and protect against rainwater and groundwater.

For reliable waterproofing of the concrete base must be monitored. Such supervision is not easy to organize, as it is not very visible behind the backfill and building materials. In this case, effective waterproofing provide waterproofing materials with a penetrating effect.

One of the troubles during construction is the capillary rise of groundwater.waters It occurs between the foundation and the wall, while the free space is quickly filled with water. Such water is often saturated with salts and acids, and during capillary lifting it moistens the structure to a height of 10 m. Good waterproofing of the base of the building will protect it from such misfortune.

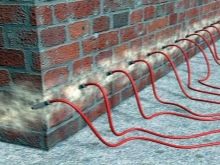

Injection can be carried out horizontal waterproofing for cold rooms. Restoration of brick walls will happen much faster.

What is the point?

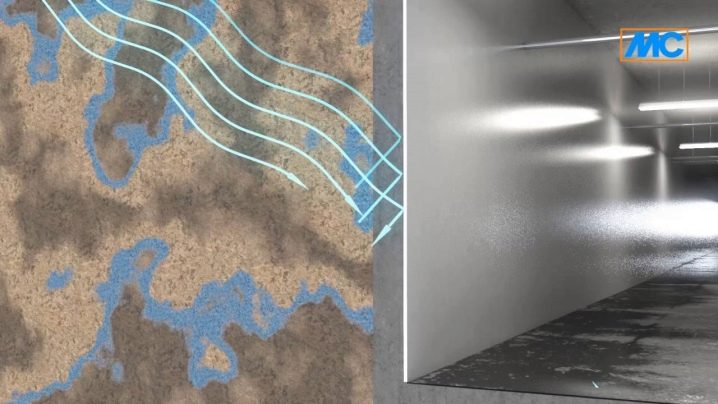

The essence of injection waterproofing is to create a membrane between the layer of moisture-saturated soil and the enclosing structure (wall or foundation). I.e, Hydrophobic gel is injected, which solidifies, clogging the pores in the wall and in the ground.

Moreover, such a membrane, depending on the type of injection substance, has a different level of rigidity. The gel plays the role of not only waterproofing, but also a reinforcing frame. And the technique itself functions no worse than the equipped external hydroprotection.

This technology is used in scheduled repairs of tunnels, underground parking and other objects.

Benefits

Injection waterproofing has special advantages over its counterparts.

- Saves time. Injection can be carried out both after completion and during construction.

- Saves finances. High-quality waterproofing is a very long time and does not require frequent repairs.

- Solves most leakage problems.

- The injected material can penetrate even the smallest pores and cavities.

- It has a high quality waterproofing membrane.

- It creates high-quality seamless waterproofing coating.

- Such waterproofing is safe for drinking water.

- The hardening time at a certain composition reaches a couple of seconds.

However, due to the difficult work on injection waterproofing, which thickens very quickly, it needs specialists. Therefore, this method is found in the list of services not every construction company.

disadvantages

The following disadvantages can be attributed to this method:

- Expensive materials and equipment.

- Specialists are needed for quality work.

However, these disadvantages are quickly offset by excellent quality and speed of work.

Materials

The basis for injection usually use the following compounds:

- Polyurethane polymer gels. Pretty cheap and have high efficiency.Polymer gel when interacting with water increases its volume by almost 20 times. This material provides high-quality blockage of cracks, leaving no space for moisture.

- Acrylic Acid Gelsare called acrylate. Acrylate gels have almost the same density as water. This gel quickly hardens in the soil, concrete or brick, creating a very strong bond. Also, depending on the temperature and the ratio of substances in the gel, it is possible to regulate the time of solidification. Mixing with the soil, the gel becomes stronger, which ensures its protection against leaching and fixes it in cracks and crevices.

- Epoxy options. Such a composition hardens in contact with air, and moisture only prevents it from freezing. It is used for dry construction.

- Cement sand (microcement). This composition is able to completely fill all the internal spaces, thanks to this it improves the internal structure and creates hydroprotection.

The most commonly used injections are based on polymeric and acrylate gels. They harden on contact with water and have good penetrating power.

Support features

With the introduction of additional components into the gel, the following properties are achieved:

- fungus removal;

- fight against mold;

- improved chemical protection of the structure;

- reducing the risk of corrosion of reinforcement.

Process

The technology of injection waterproofing occurs in the following steps:

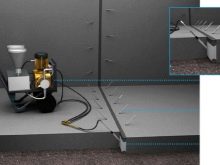

- First, we study the surface, where and in what places we want to apply the injection.

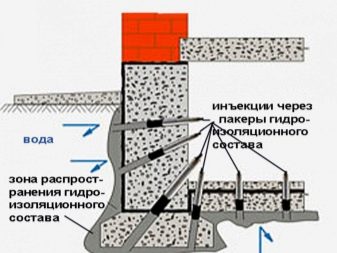

- Then along the wall with a pitch of 0.25–0.5 m, we drill small (20 mm in diameter) through holes.

- Further, holes along the crack are drilled along the crack.

- In the next step, metal or polymer tubes (fittings) are introduced into the holes, to the other end of which valves are fixed.

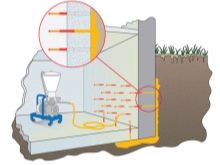

- To the ends of the valves connect the tank with injection solution. By increasing the pressure in the tank, the solution is transported through a tube outside the wall.

- When the solution hardens, the tubes are removed from the wall and the outer surface is treated with moisture resistant plaster.

This technology can provide only companies with special equipment. Such equipment is not cheap. Therefore, for high-quality injection waterproofing is better to contact such companies.

It is also worth mentioning that such work is not recommended at a temperature of 5 degrees Celsius and below. This is due to the fact that the solution hardens more slowly and becomes less quality at this temperature.

Injection waterproofing sites

Waterproofing works are carried out using the method of injection waterproofing during the construction and repair of the following buildings:

- metro, railway and road tunnels;

- basements of residential buildings;

- swimming pools, water parks and water tanks;

- plumbing and sewage.

Many works are carried out according to this method due to the fast process and long service life.

Waterproofing indoors

As a rule, waterproofing of walls or foundations occurs from the outside of the room. But sometimes it is inappropriate. For example, there is no way to dig a foundation. Then waterproofing work is carried out in the basement.

The most common methods of waterproofing indoors:

- injectable;

- impregnating;

- obmazochny;

- painting.

The injection method is the most common, and with its help the best efficiency and quality is achieved.To do this, use acrylic blends and gels. The resulting hydroprotection withstands strong water pressure.

Reviews

According to most experts, injection waterproofing should be applied using a special technology.

- First, holes are drilled for it at a distance of 0.5 m from each other with a diameter of 1 or 2 cm. A puncher is already required here.

- Also, the holes must be through for high-quality waterproofing. And for the repair of small cracks and crevices, blind holes.

- The holes are pre-moistened with water if hydro-reactive injection is used.

- Then you should inject the injection into the drilled holes.

- If desired, work can be done to protect against fungi or mold.

- At the end you need to cover the work surface with plaster. After drying, you get high-quality hydroprotection for many years.

Conclusion

Injection waterproofing has a special breadth for use in construction and repair work. Thanks to its use, high-quality and very fast waterproofing of seams occurs, anti-capillary protection of the foundation and walls, as well as repair of cracks by the pressure flow. Work can be carried out with a dry and wet structure.

Such work and materials for it are not cheap, therefore, the scope is limited mainly by large buildings.

However, due to its quality, speed and reputation, it is often used for the necessary protection against water and moisture from large buildings, as well as when other methods are impossible or more expensive.

The outlined features of the procedure for conducting injection isolation will be useful for performing specialized work on protection against pressure water and precipitation. And before embarking on such work, you should consider all the positive and negative points that may arise during injection waterproofing of the structure. The main thing is that such hydroprotection contributes to the quality of your structure for many years.

Instructions for waterproofing using injection PenePurFom see in the video below.