Izospan AM: instructions and specifications

The construction of virtually any residential building implies its additional heat and waterproofing of various surfaces. This problem can be solved with the help of various approaches and materials. Today, increasingly used for this roll film, which cover the roof structure. They do not allow the destruction of the tree and the insulator. This product differs in physical characteristics, which can be found on specialized sites.

Special features

Izospan AM is a special film material that is used in construction together with various heaters.Technically, this is a kind of membrane in whose structure there are micropores.

The main objective of this product is to protect the insulation from external negative factors, such as:

- wind;

- condensate;

- low temperatures;

- moisture.

It can have both one and two sides of the insulator. The film is made of polypropylene, which is unable to withstand direct sunlight for a long time.

Technically, Izospan can be operated in such conditions for no longer than 3 months. It is excluded by closing with various decorative elements.

It should be noted that the material has several distinctive technical characteristics.

- You can operate the material in the temperature range from -60 to +80 degrees. If they are disturbed, then the substance will eventually lose its physical characteristics and become unusable.

- High rates of stretching and strength. The load on the gap of this material does not reach the performance of 125/95 N / 5 cm and above. This is achieved by the introduction of special additives that strengthen the structure of the product.

- The density of a substance can reach 110 g / m².This is a relatively small weight, which practically does not affect the structural features of roofs and other surfaces.

- Form release rolls. The width of one reel varies from 1.4 to 1.6 m. In the roll itself there can be from 35 to 75 m² of material.

- Indicators of waterproofing reach 1550 g / m² / day.

Among the features can also be distinguished ability to stretch. This affects the durability of the service and resistance to external factors. It should be noted that such indicators may vary. It depends only on the party and production technology.

Advantages and disadvantages

The popularity of Izospan AM is due to its unique technical characteristics. The material has several positive features.

- Using membrane can reduce the cost of repairs. This is due to the fact that waterproofing qualitatively protects the house from moisture. Thus, inside the building an optimal microclimate will be maintained, which will not lead to the destruction of internal materials and structures.

- Availability in the market. Vapor barrier is an affordable material that can be easily purchased at hardware stores. In this case, you can also choose and similar products of this company.

- Environmental friendliness. Izospan is made from polymers that practically do not emit any harmful substances. Raw materials are completely safe for human health and can be used in various types of houses. It is advisable to ask when buying a quality certificate confirming this figure.

- Vapor permeability and resistance to moisture. The structure of the substance passes only vapors, but at the same time retains water. This allows you to maintain an optimal microclimate, without fear that the film will lose its properties over time. It is worth noting that it can be used on almost all types of surfaces, both inside and outside the house.

- Resistance to sunlight. The material can technically be used in such conditions, but it is not able to withstand long-term direct ultraviolet radiation. Therefore, it is better to additionally protect it in order to obtain a reliable and stable system.

- Durability. Polymers are practically indestructible when exposed to moisture, and are not popular with rodents or insects. Moreover, the membranes do not rot, which allows their use in various microclimatic conditions.

- High strength. This effect is achieved due to the presence of a special substrate in the membrane structure. In this case, the product is quite easy to cut with sharp objects, so it is important to protect it from such exposure.

The only disadvantage of the membranes can be considered only their relatively low resistance to ultraviolet. Although the manufacturer claims that the substance can be under the sun for up to 3 months, in practice this indicator often does not exceed 1–1.5 months. Another disadvantage is the relatively high price of such substances. This leads many to use alternatives.

Species

Izospan is a unique diffusion membrane that is used to solve various problems. Under this brand produce many types of materials that are divided into several types.

- Izospan A. The propylene membrane is capable of passing pairs. The manufacturer recommends using it indoors only, so it protects walls, ceilings or ventilated facades.

- Izospan AM. This three-layer material is intended for external protection of insulation.Often it is used in the formation of the roof or facades. Products should not be used as the main roofing, as it is not able to endure permanent loads for a long time. It has an optimal combination of price and quality. At the same time, the products are very popular and are used by many construction companies.

- Izospan AS. By its properties, this substance is almost the same as the previous one. It differs only in the increased level of vapor permeability, as well as the size of micropores.

- Izospan AQ Proff. This is one of the most durable vapor barrier membranes that can resist UV for 12 months.

- Izospan C. These materials are intended for internal use. With this film, heat insulating substances on floors or walls are protected.

- Izospan B. Very similar to the previous type of product, which is also not recommended for use on the street.

Application

Steam insulation membranes are now being used more and more. They have quality indicators of hydro and wind protection. This material is now used for insulation of various surfaces.

- Sloping roofs. It is worth noting that it is not recommended to cover flat surfaces with them, since this will lead to moisture accumulation and minimization of protective properties.

- Walls. The membrane can be used both for ordinary standard buildings of brick or aerated concrete, and for frame structures. It is undesirable to use material inside baths or saunas. This is due to the fact that the substance is not able to endure constantly high temperatures.

- Attic and interfloor overlappings. With the help of waterproofing films it is easy to ensure optimal steam exchange between several buildings.

Installation of such films is not complicated, which allows for its own hands. Before laying the membrane, you must first stock up with the following auxiliary tools:

- stapler and staples - their size is selected individually depending on the location of the membrane;

- scissors - You can also use a knife or other cutting tools. The main thing is that they can be well cut film;

- hammer and nails are used for nailing wooden slats, which will act as a framework for exterior materials.You can also use other types of hardware (for example, screws);

- roulette and building tape.

Installation work should begin only with the instruction of the manufacturer. This will allow you to understand the principles that will facilitate future operations.

When laying vapor barrier membranes should follow a few simple recommendations:

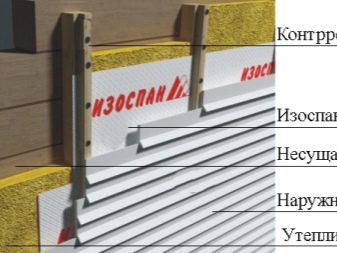

- Spread the film should be on top of the coating without pulling. If it is a roofing crate, even a slight sagging is allowed. Experts recommend placing the film with the red side inward to the insulation. The outer white layer is more durable and better resists external loads. Sometimes the colors may vary, so you should clarify the side directly in the instructions for the product.

- All sheets are overlapped to 15 cm. The joints between them need to be further isolated with a special tape. This will not allow water to penetrate into the gaps and will create more reliable moisture protection. If mounted on walls, the substance should be docked with an overlap of up to 10 cm.

- To the skeleton, the membrane is fixed with staples using a construction stapler. All operations should be carried out sequentially, controlling the tension and the location of the sheet relative to the base. If the design allows, then as an additional fasteners you can use wooden counter rails. They are located directly along the joints of the film.

- When the film is fixed, the battens of the batten are nailed to it. Heat insulation materials are placed in the cells formed between them. Do not use membranes without insulation, as this will practically not give any result. Between these substances, it is desirable to leave a small air gap, which accelerates the output of steam accumulated inside.

Useful tips

Izospan is an integral part of almost all modern roofs. It provides reliable and durable operation. The following simple tips should be observed when working with this substance:

- buying this product, be sure to study its technical characteristics. It often happens that the material does not correspond to the real conditions where it is planned to be mounted. In this case, you should look for analogues that can replace it;

- Be sure to take into account customer reviews.This will assess the quality of products;

- the film has a low strength, so it can be cut on almost any surface. Frequently experts carry out it directly on a heater. Important: carefully operate the membranes, as you can accidentally damage them, which will lead to accumulation of moisture inside;

- Do not use the film as the main roofing materials. Their main task is to protect the insulation, and not the entire roof structure;

- all operations should be carried out very carefully, especially if the roof is covered with a significant gradient;

- if the film is used in the formation of ventilated roofs, then it can be laid in 2 layers. It is worth noting that such a substance is often located below the insulation. On top of this material is placed waterproofing, which prevents water from entering the structure of thermal insulation;

- not recommended to close the lower edge of the canvas. Thus, you can create a natural outflow of moisture, which is located in the structure of insulation.

Izospan AM is a unique, very popular steam insulator capable of creating optimal microclimatic conditions inside the roofing pie.Before using it, you should always consult with experts who will help you choose the products of the desired quality and structure.

In order for this material to properly perform its functions, it should be laid with exact adherence to technology.

For details on mounting the membrane Izospan AM, see below.