Bituminous mastic: types and features of the material

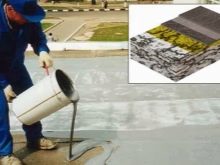

As a modern solution for sealing and filling cracks, bitumen mastic is often used - a material that has proved itself to be good and has a large field of use.

Over the past decades, the use of mastic asphalt screed has become a fundamental method of construction. Compared to traditional versions, using mastic asphalt screeds has the following advantages:

- reduced layer thickness;

- reduction of static voltage throughout the building;

- improved sound protection;

- significant time savings;

- no additional development of unwanted moisture in the building (short drying time).

What it is?

The appearance of cracks is the main mechanism of destruction that occurs when exposed to ambient temperature and humidity. Bitumen binder plays an important role in this mechanism of destruction. It has been found that the addition of mineral filler to bitumen has a significant effect on the life of the mastic.

The mixture should have a homogeneous consistency. - only then it creates a high-quality waterproofing layer without the formation of air bubbles, which reduce the protective properties of the material. The elasticity makes it comfortable during application to the surface.

The standard prohibits the inclusion of toxic substances that could be released into the atmosphere after using the composition. Heat resistance of bituminous material can not be less than 70 degrees. One of the main requirements for mastic is 100% waterproof.

After hardening, the material should not change the physico-chemical characteristics, but only maintain them throughout the entire operation period within the limits specified by the manufacturer on the packaging temperatures.

Application

The effectiveness of anti-corrosion coatings is related to its ability to resist moisture.Over time, this feature is lost and even minimal moisture penetration is sufficient for corrosion to appear on and under the steel surface. It will take at least two layers after the final drying of the first.

Ingredients used:

- for filling cracks;

- for shock and vibration absorption;

- for warehouses, granaries, surfacing of bridge decks, roads, footpaths and installations for bottling the CIS;

- as a wet protective material for underground tanks, basements;

- as a base lining for flooring such as linoleum, flexible PVC sheets, rubber and acid resistant tiles;

- as a flooring material for electroplating plants, chemical processing departments, washing sections and gutters;

- in fertilizer, viscose or water treatment plants and other chemical plants where continuous or frequent contact with diluted drains is expected.

It is used for filling and sealing joints, points, formed at the points of assembly of concrete, wooden structures and brickwork. It is also used for thin holes, adhesion of bitumen membranes,the surface of which is covered with quartz sand.

It is broken into small pieces and heated, and then applied with a tree or spatula to the surface. Acid-alkaline composition allows you to use it as a protective impermeable membrane.

Mastic asphalt is a type of surface consisting of suitable graded mineral and asphalt cement. When the material is heated, it is in liquid form, and in the process of cooling it gradually hardens.

Available to meet various industrial needs in accordance with the technical characteristics of the product. Bitumen mastic is a plastic compound that provides an effective seal between materials.

Different visual effects can be achieved depending on the type and size of coarse aggregate.

Flat roofs with asphalt as a waterproofing layer are common practice in the UK and France. It is harmless, waterproof and resistant to root growth, therefore the composition is suitable for use as a protective layer on flat surfaces.

Application on terraces as a waterproofing, to protect the premises located under them, often realized together with thermal insulation.

For balconies, the material can be left in its natural state or painted. Mastic coatings are easy to clean. They require little maintenance and can be used within three to four hours.

Species

Depending on the properties of the product, you can choose:

- heat resistant;

- intrinsically safe;

- hydrofluoric acid resistant;

- waterproofing;

- universal;

- cold application;

- adhesive;

- hot

- MBI;

- coating;

- frost-resistant;

- single component;

- two-component.

This is far from the only classification, since mastic can be divided by its constituent components:

- mineral;

- rubber;

- rubber;

- polymer;

- latex;

- oil;

- primer

The primer is made for the foundation, wood and other surfaces. Durable, impermeable and resistant to deformation mastic is made from high quality components.

There are various types of bitumen mastic, suitable for different purposes:

- for the floor;

- for bridge and road flooring;

- for waterproofing;

- with antistatic and electric discharge;

- black resin;

- for the protective coating of concrete slabs.

Hot mastic is of the following types with a melting point:

- bituminous - 160-180 C;

- rubber-bitumen - 170-180 C;

- tar - 130-150 C;

- Gudrokamova - up to 70 C.

By brand, it is classified as follows:

- Mrb This is a rubber-bitumen material for roof repair, supplied by grades 65, 75, 90, 100. Plasticizers are present.

- MGTN. This is a waterproofing material with a solvent, bitumen and fillers in the composition. Used for wooden, reinforced concrete and concrete structures.

- MKTN. Treats cold roofing polymeric mastic. Used with equal success for basements, pipes and vehicles.

- KMG - hot bituminous material with polymer fillers in the composition. Used to repair any type of roof.

- VEBM - a water-based composition with a latex polymer without an organic solvent. It is used for the foundation and insulation of the roof. Also, the material is widely used in wet areas.

- MDG-G. This is a hot tar mastic with mineral filler.It is rarely used due to unpleasant smell. The main field is laboratories.

- MG-G 70 - hot Gudrokamov composition with a melting point of 70 C.

- MP 70 - mastic gudrokopolimernaya.

- MGH - cold bituminous waterproofing composition.

- DGM-1 - waterproofing road material.

The melting point is almost always indicated at the end of the abbreviation, and the presence of additives such as herbicides and antiseptics is indicated by capital letters G and A.

Composition

Mastic is made of bitumen and granular minerals. The exact chemical composition according to GOST depends on the type and scope of use. As a result, even waterproofing is made - a dense insulating material.

Various ingredients, such as mineral filler, petroleum products, resin, plasticizer, crumb rubber and additives, guarantee the special properties of the final product. Oil products can be used to isolate the oil and gas pipeline.

The composition consists of a material of bitumen binder and granular asphalt particles with a diameter of not more than 2 mm, and they constitute 50% of the total composition. Based on the weight of aggregates and crushed granular asphalt,the diameter of which does not exceed 2 mm, the binder component contains recirculation, while its amount is at least 15% by weight.

Due to the fact that the composition has a shear modulus of not more than 2 thousand MPa at -10 C and a frequency of 1 Hz, it can be reused. It has the same characteristics as the above composition. Can be used as a filler for road surfaces. It was found that it is possible to obtain a combination of finely ground granulated elements of asphalt and a bituminous binder, which has similar properties to the types of freshly prepared formulations.

Physical and mechanical properties are similar.

The material may contain the following oils:

- vegetable;

- soy;

- sunflower;

- rapeseed;

- corn;

- peanut;

- olive;

- coconut;

- Palm;

- palm kernel

The method of obtaining includes:

- providing a solid material containing regenerated granular particles that have a maximum diameter of not more than 2 mm and recycled bitumen;

- obtaining fresh bitumen and anti-aging agent (optional);

- mixing solid material with fresh bitumen to obtain a mixture containing regenerated granular particles and a binder consisting of a recycle component and a rejuvenating agent (optional);

- extraction of a mixture in which bitumen ranges from 15 to 75%.

The amount of agent can vary widely. Usually its size is from 0.5 to 5% based on the weight of the binder.

Manufacturing

The process of making sealants from bitumen rubber is as follows:

- From 4 to 11% of the treated bentonite clay is added to pure water in the mixer. When it is dispersed, it turns into a suspension, the viscosity of which ranges from 20 to 180 thousand centipoise at 77 C.

- This component and bitumen are mixed to form a soluble mixture, then additives are poured to increase stability.

- Non-asbestos fiber is needed to enhance the solubility and strength of the film. It also provides extra viscosity and texture.

- Pigment fillers are natural or calcined clay, mica, silica powder, slate powder, and coal ash.They are necessary to improve the strength of the film and its consistency.

- The elastomers in the composition create tensile strength.

The composition can be heated and dispensed directly in the mixer. Apply after cooling. The composition can be used to create waterproof surfaces, even under water. When the material is dosed, it is heated to a relatively high temperature, for example, from 160 to 200 C.

It is chosen so that under the prevailing conditions the water evaporates to form steam and, therefore, causes foaming of the bitumen component in the composition. While it is advisable to carry out the process at atmospheric pressure, the temperature preferably exceeds the standard boiling point of water. The composition is heated from 125 to 230 ° C., the preferred range is from 150 to 190 ° C. Then it is passed into the expansion chamber under pressure, which is in the range from 2 to 10 bar.

You can also heat the water. It is most advantageous to pass it into the expansion chamber at ambient temperature, that is, in the range from 4 to 25 C. The amount that enters the chamber will be suitable if the foaming of the bitumen binder material is reached and the remaining amount of liquid is not too high. Accordingly, the amount of water should be in the range from 1 to 10%.

The composition of foamed mastic is combined with coarse aggregates by means of injection nozzles. With the help of them, the composition is divided into small drops, intensively mixed with large components. Foamed bituminous binder material may break. Because of the speed with which it combines with coarse aggregates, it is advisable to use intensive mixing. The composition usually has a half-life of 2 seconds, sometimes 4. The expansion coefficient in the chamber is 3, sometimes 4, but usually not more than 10.

The composition with a particle size of ≥ 2 mm must be heated to a temperature in the range from 100 to 180 C - this will allow it to be easily mixed. Moreover, the aggregates will be dry, so no additional water will be present in the foamed bitumen binder material.

The composition can be combined with other components having a particle size of 2 mm or less.

Special features

Bituminous mastic is a toxic material when wet. But after it dries, it will not have dangerous properties.

Micronized polyvinyl chloride (PVC) is used as a soft filler. The binder consists of styrene-butadiene-modified bitumen. Increased adhesion between PVC particles allows to obtain a composition consisting of coarse and micronized particles, limestone dust and a polymeric binder.

Cold mastic is a modified bitumen mixture with elastomeric additives, special resins, organic solvents and inert materials. It is applied at ambient temperature and has good adhesion to a porous, as well as a smooth surface. Perfectly covers the usual deformations that occur due to temperature changes. The material is highly resistant to acids and basic solvents and is not exposed to salts.

Bitumen mastic is a homogeneous solution that has the ability to independently fill cracks. It absorbs shock and vibration.

Various ingredients, depending on the use of bitumen mastic, are prepared in a mechanical mixer until a homogeneous mass is obtained.If color decorative flooring is required, it may have a tint that will give the composition a pleasant decorative color.

Suitable for application to the following surfaces:

- concrete;

- tree;

- a rock;

- brick;

- drywall

Among the advantages:

- excellent adhesion;

- dries quickly;

- remains flexible at low and high temperatures (from -20 to + 80 C).

Specifications

Characteristic features of bitumen mastic are the following properties:

- frost resistance;

- resistance to salt water (salt) and chemicals;

- suitable for use on complex geometric surfaces;

- availability of coatings of a wide color range;

- increased strength, abrasion resistance and heat resistance;

- availability of fire safety certificate;

- water resistance;

- is environmentally friendly - does not contain impurities that are harmful to people and the environment;

- resistance to fungi and microorganisms;

- viscoelastic and shear resistant;

- provides good adhesion;

- Resistant to limited fuel and oil.

In addition, the material has the following physico-mechanical characteristics (at 20 C):

- can withstand a concentrated load without deformation from 20 to 40 kg / cm 2;

- has a relative tensile strength in bending from 0.04 to 0.07;

- line expansion coefficients for the temperature range from 20 to 30 С are 30-35 × 10-6;

- water saturation - less than 0.2 wt.% within 24 hours;

- density is 2.7 kg / m3.

Manufacturers Overview

The product can be scattered with a rake in the form of a loose mixture, and then compressed by heavy mechanically rotating rollers weighing from 5 to 1.0 tonnes. The presence of an excess of binder in the composition makes it more or less ductile, and under heavy or even moderate loads shows a slight displacement.

Enjoys demand in today's market Duraboard HD. This product is a high-density compound that provides the same high level of uniformity as Duraboard LD, but has increased compressive strength and a higher modulus of rupture. Such indicators are achieved due to the inclusion of clay additives in the production process.

High strength makes the Duraboard HD suitable for use in situations where special stability is needed under pressure from weight, for example, if a refractory brick is used or to cover large unsupported spans.The material is supplied in the form of a sheet of standard thickness from 2 to 100 mm.

Insulation HD 100 also has a high density, but has a high compressive strength.

One of the leading manufacturers today is the company TechnoNicol, which has gained consumer confidence due to the high quality of the product supplied.

The quick-drying resinous Black-Stallion Mastic is used to repair roofing systems, as well as to install glares in the Millennium system. Coal tar in combination with a modified polymer provides excellent resistance to moisture, chemicals, ultraviolet radiation and aging, which guarantees unsurpassed durability. It is specially designed so that the roofs do not sag at normal temperatures, and unlike most other products of this type, this premium composition will be held on vertical surfaces.

Flexible elastic Garla-Flex is developed from special weatherproof thermoplastic rubber for sealing roofing compounds and other structures. Its excellent elongation properties provide flexibility due to which extreme structural movements are maintained, not allowing it to peel off when displaced.The modified SEBS mastic is UV and sag resistant and has outstanding durability.

Aluminum mastic is used on vertical and horizontal surfaces for asphalt roofing systems. It has double reinforcement, which provides excellent performance. When applied correctly, this multi-purpose compound has a bright silver color that reflects ultraviolet rays.

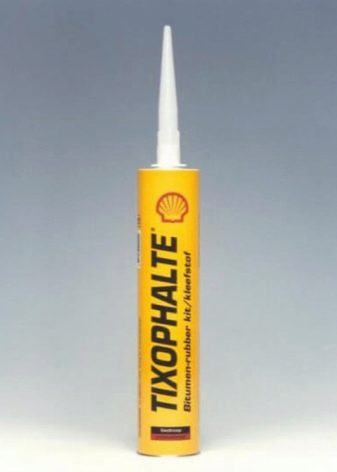

Shell Tixophalte is a ready-to-use bituminous product that can be applied cold as a filler, sealant or glue during a wide variety of jobs: from large-scale industrial production to household. Its waterproofing properties indicate its use: the composition can be used even under water.

Shell Tixophalte is a bitumen-based sealant that has been used in the construction industry for over 20 years. It is created from carefully selected components using modified rubber in the base. Thanks to its components, the sealant is easy to use and is able to provide long-term protection and waterproofing. Possesses excellent resistance to such negative factors as:

- shifts;

- wind effect;

- chemicals

The advantages of the composition:

- immediately ready for use;

- convenient for application;

- has excellent adhesion;

- easy to apply and does not come off most wet surfaces.

It can safely be used under water. The material is able to provide the necessary protection against rust, moisture and corrosion. Fully compliant with ISO11600 standard, which determines the physical properties of this type of sealant, including long shelf life.

Shell Tixophalte properties make it ideal for waterproofing cracks in wet conditions. Moreover, it is thixotropic. This means that the material can be applied to steep and even vertical slopes without runoff.

Anticorr is resistant to acids and alkalis when used as a protective impermeable membrane suitable for concrete, brick and steel.

When applied, the mastic should be broken into small pieces and heated. The surface on which it is applied is covered with a primer. You must use a straight blade or trowel. The surface should not be used within 24 hours after application.

It is not recommended to use it where there is an excessive amount of heat or solvents, as well as in the case of mineral oils and lubricants.

Specifications:

- softening temperature - 60-65 C;

- melting point - 160-170 ° C;

- loss of performance - below 160 ° C;

- bitumen content in mastic - from 13 to 18%;

- change in acid weight - ± 1%;

- hardness coefficient - from 4 to 12.

Flammable sealant contains flammable petroleum distillate. Keep it away from fire, sparks or other sources of ignition. Be sure to wear protective clothing, rubber gloves, a mask and goggles.

One-component bitumen sealant is used to quickly repair cracks and faults on roofs. It is suitable for sheet metal, aluminum, copper, brass, ceramics, concrete and roof tiles. It is resistant to ultraviolet radiation, as well as to various weather conditions.

Recommendations for use

What to dilute? Insulating material made of bitumen rubber is a one-component, durable solvent-based sealant. When cured, it forms a strong and flexible seal. It has excellent adhesion to concrete, masonry, asphalt and most building materials. Mastic material manufacturers modify non-asbestos fibers to make it thixotropic when applied to vertical areas.

Sealant hardens when solvent is released.This happens within 24-48 hours, but the time depends on the relative humidity. The compaction depth of 10 mm usually dries within 14-21 days at a temperature of 23 C and a relative humidity of 50%.

Before diluting or diluting the mastic, it is necessary to leave the balloon in the sun for several hours. It should be warm outside or indoors. It is necessary to add the required amount of solvent to the sealant only when it acquires a plastic consistency. For mixing use a stick. If the manufacturer indicated in the instructions on the label other requirements, then you should follow these recommendations.

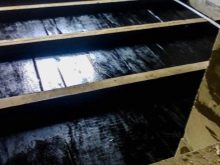

How to apply?

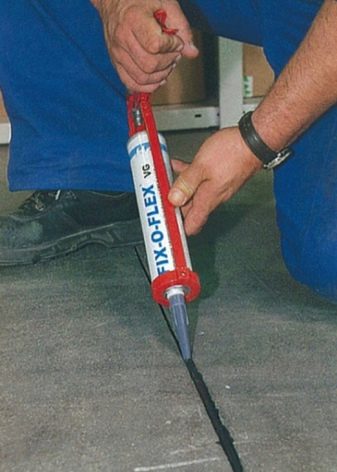

It is best to wait for dry weather to get good adhesion and immediately get the desired result. The surface must be dry and free from dirt, oil and rust. The composition is applied with a spatula or grease pump for cracks. After 2-3 days it is possible to re-fill the surface.

To protect bitumen mastic from ultraviolet solar radiation and rapid aging, the surface that is exposed to the sun is painted using ALUPASTE aluminum lacquer.

Tools should be cleaned immediately after application.. Mastic should be stored in closed rooms (from + 5 to + 35 C), away from direct sunlight, as well as from sources of heat and fire. In a closed container in the above situations, this product remains unchanged for an unlimited time.

Concrete and ordinary brickwork with a cement plastered surface are the main building elements in the construction of floors, foundations, tanks and sumps. They may be affected by a corrosive environment, spills of acids and alkalis, and other chemicals produced in modern chemical industry. Mastic is used as an interlayer coating.

The surface must be free from dirt, dust and loose materials. Any oil and grease contamination is completely removed. Before applying, the surface is additionally dried, masking tape is applied on the adjacent sides of the joints to obtain a neat coating.

Under normal conditions, primer is not required. However, for very dry and porous surfaces, it is recommended to apply a single layer of solvent-based primer.

As the product dissolves, it is recommended to mix the contents of the bucket using a paddle mixer for several minutes before application. Sealant is used from the bottom of the joint. To achieve full contact with the surface, a spatula is used with which the composition is pressed. The tool is moistened with a cleaning solvent to prevent the sealant from sticking to the surface and ensure a smooth and neat finish.

Useful tips

Bituminous mastic has good resistance to weak diluted acids, alkaline salts and other aggregates. It is not recommended to use it against strong, oxidizing solvents, oils and fats.

The composition is applied with a recommended thickness of one or two layers to achieve the desired result. To maintain the desired rate using a wooden or aluminum rail. Bitumen mastic is broken into small pieces and put in a saucepan. When heated, keep the material in motion to avoid burning.

It heats up until it reaches a uniform consistency, and then is applied to the surface with a wooden float, which helps to achieve a uniform smooth surface.

If the product is kept away from direct sunlight and heat dissipation, the shelf life will be unlimited. Mastic can be supplied in powder form. The size of this package is 40 kg.

In order to comply with the safety requirements, the molten composition should be thoroughly handled and skin contact should be avoided. It is advisable to wear protective clothing while using the material. However, all recommendations or suggestions do not guarantee complete safety, as the conditions of use are not controllable. In case of contact with eyes, rinse with plenty of water and consult a doctor.

Tiecoat can be used on various substrates, such as asphalt-containing, bitumen-containing substrates or modified bitumen, asbestos roof tiles or roof panels made from urethane foam. Tiecoat can be applied with a conventional brush, roller, airless spray and other improvised means.

The bituminous primer can be applied on various surfaces: steel, wood, cement. The primer is widely used on concrete as a primer - here it is recommended to use additional acid-resistant brick or tile cladding.

Review of bitumen mastic "TechnoMast 21", see below.