What is smearing waterproofing and where is it used?

The construction of many objects involves the use of concrete to obtain strong and durable structures. But these substances are not universal and can be destroyed by moisture. This phenomenon is due to the porous structure of the substance.

Solve this problem by applying various waterproofing materials. There are several ways to protect such materials, the environment of which should be distinguished waterproofing waterproofing. You can get acquainted with such products on specialized sites, where experts will help you choose the best product option for you.

Special features

Many structural elements of residential buildings or industrial buildings need to be protected from moisture.The main material for solving such problems is a waterproofing coating. It is a liquid formulation that is applied to various surfaces. Products are made on the basis of special substances that, after solidification, can form not only a uniform, but also a sealed protective layer.

Most types of coating waterproofing are available in the form of liquids of different consistency and thickness.

All technical parameters are controlled according to special GOST. This ensures high quality, reliability and versatility of the material.

The scope of application of waterproofing is quite wide, since with the help of these substances it is possible to protect various materials. Today, coating materials are used in several sectors of the national economy:

- Building. This is the main industry where waterproofing materials are found. With their help, various elements of buildings are protected, which allows them to minimize the effects of moisture. In living conditions, coating solutions are increasingly used for waterproofing walls of buildings or cellars.It is also used to handle piles or other building supports. But still the classic use of coating waterproofing is to protect foundations and roofs. Please note that this approach can be found in both domestic and industrial construction.

- Metal surface treatment. In most cases bitumen-based substances are used for such works. Obmazochnaya waterproofing well protects the outer surfaces of car bodies, pipes (water, gas or oil pipelines) and other structures made of sheet steel or similar metals.

Advantages and disadvantages

Abrasive waterproofing is a widespread and affordable product. The popularity of its use is due to several advantages of this substance:

- Versatility. Products of this type can be applied on various types of surfaces. Liquid solutions easily cover not only concrete, stone, brick, but also metal bases.

- Minimal preparation of the grounds. Before applying the surface should only be cleaned of dust or, if necessary, repair the damage to the structure itself.Some mastics can be applied even on unprepared bases.

- High quality protection. Liquids penetrate well into the structure of a solid material. At the same time they form an airtight layer, which is not so easy to damage. To improve these characteristics, sometimes bases are applied to the bases in several layers. This ensures reliable operation of the system over several years without the need for restoration or repair.

- Easy installation. Even an unprepared specialist will be able to cover the roof or foundation with the help of coating waterproofing. The process takes relatively little time, which gives a significant advantage over other methods.

- Low cost. The availability of the product on the market makes it very popular. It should be noted a good ratio of price and quality, which other coating materials do not have.

- Plasticity and durability. Roof coating substances can easily withstand various external climatic factors. The plastic structure of the material also contributes to the preservation of the original properties of waterproofing.This is achieved due to the fact that substances easily expand or contract with changes in temperature. It should also be noted that some types of coating substances can withstand exposure to aggressive substances. This allows them to be used to solve specific problems.

The use of coating waterproofing is not always a good solution. This is due to the fact that materials have several significant disadvantages:

- After applying the substance can withstand only small fluctuations. If the structure shrinks, then the substance will lose strength and become unusable. Therefore, it is not recommended to use them in those places where there are strong deformations and vibrations.

- It is possible to apply waterproofing only on completely dry surfaces. If they cover the raw concrete, it will have almost no effect.

- Durability of waterproofing is quite low. Therefore, it is not able to withstand mechanical stress. The solution to this problem can only be the use of an additional protective layer.

- Cement-polymer mixtures are suitable only for work with concrete surfaces.

- Some types of waterproofing materials can be destroyed by various bacteria and microorganisms. If the foundation is protected directly, then care must also be taken to protect against the effects of the roots.

Types and characteristics

Obmazochnaya waterproofing is made from materials that do not pass moisture through its structure. Depending on the main component, such substances are divided into several types:

- Bituminous. Mastic of bitumen repels water very well and has a high adhesion to various types of bases. This is achieved by adding to the composition of rubber (artificial) and various sealants. The disadvantage of this substance is the minimum service life, as well as low resistance to frost. Therefore, it is additionally covered with a reinforcing concrete layer that minimizes the effects on the structure of the substance. Among all the varieties can be distinguished products of the company Ceresit.

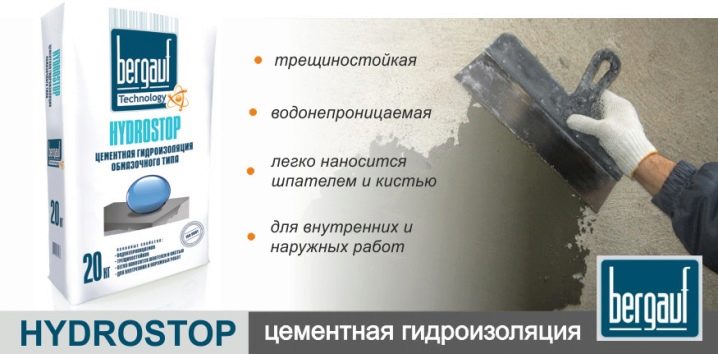

- Cement. Polymer mastic is made on a mineral basis with the addition of various types of cement. Among the positive aspects, you can also highlight the high adhesion to various materials.The only disadvantage is the high cost. But this lack is leveled by a small expense on 1 m2. The thickness of the screed should not exceed 3 mm.

- Polymer. The composition of this product includes only synthetic components and plasticizers. After hardening, the coating does not pass water, and also does not sustain combustion. Some types of polymer blends are recommended to be applied with a layer thickness of only 1 mm.

Please note that some manufacturers use resin and organic additives instead of polymers to improve the waterproofing performance. The quality characteristics of the products have brands Bergauf, ATIS and many others.

Today also use acrylic painting solutions. Their structure allows you to apply them with sprayers. The materials are distinguished by high quality hydro and vapor insulation.

Drawing

Obmazochnaya waterproofing is an important element of almost any modern construction. But in order to obtain a high-quality and durable coating, it is necessary to properly apply the mixture on the surface. Please note that the principle of treatment of concrete foundations with bitumen or cement products is completely analogous. However, it does not depend on whether the mixture is applied to the floor or walls.

Surface preparation

The quality of the waterproofing coating depends on the condition of the surface on which it is applied. Therefore, it is important to pay special attention to the preparation of the foundation. There are many parameters that are recommended to pay attention. therefore When preparing the surface, several principles should be followed:

- The foundation or roof must be strong and without significant damage. If there are small irregularities on the surface, then the base needs to be evened out. For such purposes, use different types of screeds, which further strengthen the frame. Please note that you also need to seal cracks and other damage, as they cannot be filled with a solution. Some experts also recommend rubbing concrete surfaces, if they have a significant amount of bubbles and small sinks. Their presence will not allow to evenly cover the base and get a sealed protective layer.

- The application of the mixtures is performed after cutting the corners. They should form a smooth transition in the form of a chamfer with a radius of up to 5 cm. In this way, the quality of the coating increases, which will reliably protect the roof structure.

- If the design of the foundation or roof has vertical and horizontal transitions, then these places also need to be smoothed. This is done with the help of special fillets, which must be installed along all corners.

- Before applying protective mixtures, it is advisable to thoroughly clean all surfaces from dust and other debris. If this is not done, the solutions will cover the dynamic elements that will not hold water.

- The base should be covered only after thoroughly drying. Do not apply products to fresh screeds or concrete after rain. Some manufacturers of waterproofing recommend applying their mixture at a moisture level of concrete in the range from 4 to 8%. These values can be determined using various approaches that can be found on specialized sites.

Technology works

Before you start painting materials waterproofing, they need to be further protected with special primers. This process involves following a few simple guidelines:

- It is desirable to apply primer mixes only in one layer. It is desirable to evenly distribute the composition on the concrete.

- If there are junction points on the structure, then they should be covered in 2 layers in order to obtain a more reliable impregnation.

The technology of applying a primer is simple and involves the use of a conventional roller or brush. It all depends on the device covered surface and its area.

Today, almost all types of waterproofing are sold in liquid form. Therefore, they are immediately ready for application. But cement mortars are very often sold dry. When preparing them you should follow a few simple rules:

- For mixing use recommended water with a temperature in the range from 15 to 20 degrees.

- After preparation, the solution should be homogeneous. If it contains lumps, they should be removed as much as possible. To avoid this, dry mixes should be poured into the water, and not vice versa.

- It is desirable to insist prepared mixtures before applying for about 4–5 minutes.

- The solution after cooking can be used only for a limited amount of time. Therefore, experts recommend to prepare only a small amount so that you can have time to put all the products.

The very same waterproofing is applied quite simply using the same roller or brush. The process itself resembles the usual painting.But as the base serves a concrete roof or side surface of the foundation.

When applying should be guided by a few simple rules:

- The base is painted in two layers in order to obtain more reliable protection of materials.

- Apply the next layer preferably after the previously painted surface is completely dry.

The algorithm for applying a waterproofing coating can be described in such sequential steps:

- Primer of the basis and drawing the first layer. To do this, using a roller, the mixture is evenly distributed over the entire surface. If painting is carried out in hard to reach places, you need to use a brush.

- In this step, the surface is reinforced. This step is not mandatory, but it is being used more and more often. For such purposes, use special polymer mesh, which are pressed into the applied mastic.

- Applying a second layer of waterproofing. It uses the previously described technology.

- The formation of a protective coating. To extend the life of the waterproofing layer it must be covered with various substances. Today, polystyrene foam or profiled membranes are used for such purposes.The first type of material also acts as a good insulation.

Such a device waterproofing system is not mandatory, since it all depends on the specific conditions.

Tips and tricks

Arrangement of waterproofing protection is not a difficult operation. But in its formation should be guided by simple tips:

- Apply the mixture only in a continuous layer. The coating should not be interrupted, since the indicators of protection of the structure depend on it.

- If there are joints, it is desirable to close them with special reinforcing tapes.

- Be sure to let the previous layer dry mastic. If this is not observed, then you can get several independent layers, between which there will be pinholes.

- Buy only high quality mixes based on their technical parameters. For example, bitumen solutions can be applied to surfaces that are above the groundwater level. The solution to this problem can be polymeric materials. After solidification, they form a durable film capable of withstanding a water load of up to 70 kg / m2 with a layer thickness of only 2 mm.

Abrasive waterproofing is a group of substancesdiffering in physical and chemical properties. Using it, you should strictly adhere to the application technology specified by the manufacturer. Only by doing so, you can get high-quality protection of concrete surfaces, which as a result will serve a long time.

Below you can see a video tutorial on the use of obmazochnoy waterproofing.