Waterproofing: varieties and scope

During the construction of the house, many questions arise, but the issue of protecting the new building from moisture, which rises from the soil, as well as from precipitation, which are not uncommon throughout our country, is particularly relevant. There is a way out - this is a waterproofing construction.

What it is?

Waterproofing a house is used to prevent moisture from entering concrete structures. In most country houses, the walls, the roof, the basement and the basement need protection, directly in the house or apartment itself - bathrooms, bathrooms, in a word, those rooms where flooding is possible.

In addition, the house may contain insulation or other materials that need protection against any penetration of moisture in the form of precipitation or condensate. Generally, to ensure the water resistance of materials is necessary in all places where there is a possibility of negative impact on the material by washing or condensate water. For these purposes, various types of waterproofing are used, which differ in the place of use, materials and purpose.

In recent years, the market has been developing rapidly, offering new and innovative solutions, while the old-fashioned ways continue to operate - for example, laid ruberoid. The group of waterproofing works includes a wide range of materials that provide, in addition to protection from water, also sound insulation and preservation of temperature.

Special features

Hygroscopicity is the main operational property of waterproofing, which means that when in contact with water, the material does not lose its structure and does not change its properties.

Hygroscopicity determines the waterproofing as such, but you should take into account other properties that determine the effectiveness of each individual material. Most of these characteristics include the absorption and retention of moisture, water retention, hydro and vapor insulation.As for the latter, this is an indicator of the degree of sealing that each individual type of waterproofing demonstrates, for example, whether a particular material can protect the roof from leaking during heavy rain or whether it will withstand ground water pressure.

The possibility of external influence on the rooms is also taken into account, for example, the accumulation of liquid volume in one place, since due to the increased water pressure the tightness may be reduced. Certain types of insulation are able to absorb moisture and retain it inside their structure until complete evaporation.

Technical requirements

According to SNiP (building codes and regulations) The list of manipulations on the device of waterproofing includes preparing the base, laying or fixing the material, ensuring the tightness of the joints. Sometimes additional protection against mechanical damage is also created, although in the combined materials often metallized shells solve similar problems.

It is important to calculate the material consumption before the start of work.

When choosing waterproofing in the form of panel sheets, the consumption is considered according to the area of the coating at the rate of 0.8-1 cm thickness. A room of 30 m² will require 10–15 meters of roll insulation.

The volume of bulk mixtures will depend on the characteristics of these mixtures and their fractions, the same applies to the individual types of structures covered with paint and varnish mixtures.

The roof and the foundation are considered the most difficult parts of the house in terms of contact with moisture and water. It is for this reason that foundation protection is created during the initial stages of construction. This protection is provided, as a rule, bitumen coatings, and the joints between them, as well as individual structures, are sealed with mastic resins.

In order to avoid mechanical rupture of the canvas, the foundation is strengthened with the help of reinforced grids and special sealants.

Often, waterproofing is installed with thermal insulation, and therefore forms a multifunctional protective threshold.

The durability of the building is directly related to the waterproofing of the walls and roof.

The following types of protection are most commonly used for pitched roofs:

- Waterproof film, giving one hundred percent fluid retention. They are mounted on the inner and outer sides with two gaps that provide ventilation.

- Vapor proof materials diffuse type to effectively remove moisture to the outside. They are placed on pre-prepared flooring or insulation in the presence of a ventilation gap.

- Having waterproofing properties scotch tapes and ribbons, special adhesives.

When working with a flat roof, simple polymer insulators in rolls that have waterproofing properties are most often used. Besides, often use various mastics, drainage, primers, drainage membranes.

Facades, walls and ceilings are usually trimmed with membranes and films that have not only water-repellent, but also windproof and windproof characteristics that can remove excess moisture and excess steam from the insulation.

As a rule, protective materials are placed on a solid insulation or flooring, while providing mandatory ventilation above the membrane. When installing use tape, tape and glue.

Device

If it is planned to install a stove in the house, the chimney on the roof, which completes the chimney, will also require mandatory waterproofing. Working with this design is considered one of the most difficult. It is also worth considering that the durability of the chimney will directly depend on good waterproofing and protection.

When installing the furnace, a prerequisite is proper insulation of the roof from the inside, which guarantees the absence of leaks at the junction points. In most cases, leaks occur due to poor roof sealing. When the insulation is well done, it will not be possible for water to leak into the room. under the most adverse weather conditions.

Special waterproofing materials will provide the best performance insulation system, as well as prevent the occurrence of condensation. In addition, excess moisture can lead to accumulation of smoke in the room, as well as excessive pressure and reduced heat transfer.

When installing waterproofing pay close attention to the technical characteristics and properties of different types of materials. The most important aspect will be the temperature of combustion of fuel in the furnace, which determines the choice of heat-resistant sealant.

Keep in mind that ordinary building sealants are not suitable for insulating furnace pipes.

SNiP determines the desired distance between the pipe and combustible materials. Waterproofing and vapor barrier cut crosswise in the place where they touch. Next, the edges are fixed using mounting brackets to the beams and piles that make up the overall structure. The insulation is fixed with frames around the entire perimeter of the roof: the waterproofing film is pressed against the crate and the counter grate, the vapor barrier is secured with the base for laying the material in the attic and attic. These actions will make it possible to isolate the pipe reliably.

The type of chimney waterproofing depends on several aspects, including the type of material from which the roof is made, although in general the set of rules is unchanged for all variants of roofing.

Actions during the installation of waterproofing pipes will be as follows:

- In order to roll moisture on the roof without falling into the joints between the pipe body and the roof elements, the pipe is coated with mastic or primed. Then fix the membrane, the edges of which are wrapped to the furnace structure and tightly compressed with metal strips.

- The upper and lower aprons are cut from metal and fastened around the chimney. Keep in mind that the bottom tie should reach the drain.

- In order to guarantee the discharge of water, the rolled roofing material is overlapped. The extreme sheet may be of different lengths - both shorter and longer, this will not affect the quality of waterproofing.

- All mounted elements are treated with mastic, paying special attention to the junction of materials. Large gaps filled with heat-resistant sealant.

- The main components of the roof are stacked on top, the joints are sealed. The apron of metal is fixed on top, after which the final sealing is performed.

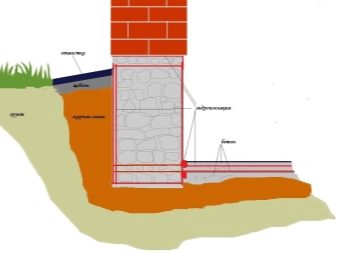

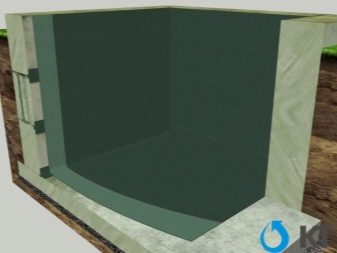

The presence of groundwater in the area and even high humidity in the basement will inevitably lead to the growth of mold and mildew, as well as the destruction of materials of construction. As a rule, this is due to improper installation of waterproofing or the complete lack thereof. It is best to produce this type of work at the stage of building a house., but sometimes you have to deal with them directly during the operation of the premises.

The most reasonable solution is to simultaneously conduct external and internal isolation., although this is done, unfortunately, not always.

Experts say that savings at this stage can turn into much greater losses later.

The most significant objects to which you should pay close attention:

- places of contacting communications with walls, ceiling and floor;

- the seams providing connections of different materials;

- structural damage, including cracks arising from the shrinkage of the building;

- connections between floor and walls, ceiling and walls.

Depending on where you plan to make the insulation, it can be vertical or horizontal type.

If there is no drainage system or the presence of groundwater, it is better to do vertical insulation. Very often, this type of work is combined with horizontal insulation, which eliminates moisture from entering the room to the maximum.

If the groundwater flows on the same level or if they can penetrate through the floor, it is necessary to make an internal waterproofing of the ceiling and the floor. The recommendation of specialists - always lay the floor waterproofing, as there is no preliminary information on where the water will be in the future. It is also difficult to predict what purpose the room will acquire in the future. Due to the abundance of precipitation, the ceiling can leak, so it is also better to isolate it.

Since moisture can have a different effect on each individual structural element of the basement, several types of insulation can be distinguished:

- Anti-capillary - serves as protection against excess moisture and excessive moisture.

- Anti-pressure - Matters when currents rise by 10 meters, as well as when there is no drainage system. It is carried out mainly due to proper pressure distribution, as a result - waterproofing is pressed against surfaces with proper force.

- Free-flow - is able to protect the premises from the possibility of flooding, and it does not matter if it is caused by a flood or an excess of precipitation. The simplest and most effective means is mastic based on bitumen.

The most popular and popular materials for insulation of the basement are considered to be:

- built-up;

- coating or painting, which contain acrylic, polymer-containing or bitumen-containing particles.

It is also necessary to considerthat in any case, the waterproofing elements will be under pressure from the volume of water, as a result, the insulating materials eventually lose their properties.

Below we consider the possible isolation options, taking into account the budget, the purpose of the premises and its features:

- pasting of materials with impregnation from bitumen;

- membrane waterproofing;

- penetrating insulation containing components penetrating into small gaps and pores of the material;

- the use of liquid rubber, bitumen and polymer-containing substances that provide the bond between the membrane and the surface at the molecular level;

- Injection as a kind of penetrating - as a rule, it is presented in the form of a gel;

- coating with cement in combination with a polymer, showing excellent adhesion;

- liquid glass - quickly hardens, covers the gap and blocking access for moisture, dust and other impurities.

Each method is more logical to apply in different cases depending on the specific situation, namely:

- existing drainage system along the entire perimeter of the foundation;

- groundwater flow;

- components of the foundation and reliability of the insulation of the existing structure;

- planned use of isolated space.

Before starting work, it is necessary to pump out water, if any. All internal surfaces must be thoroughly cleaned. The cracks are broken in order to be able to fill them thoroughly, then they must be cleaned and filled with mortar. After drying, the walls are primed to ensure better adhesion, problem areas are processed twice.

If the building is new, reinforcing elements are fastened to the dowels on the walls, on which the cement composition is subsequently applied.

When laying protection horizontally, remember that materials go on the walls not less than 30 cm.

Bitumen-containing emulsions as well as penetrating compounds can be applied on wet surfaces, in all other cases the walls must be dried beforehand.

If waterproofing is installed on its own, keep in mind that, as a rule, rooms with heating are not painted, because over time the paint will begin to move away. Mandatory descents and stairways are processed. In the basement it is also necessary to create ventilation, for which special holes are made.

When creating external insulation, first of all, the issue of protecting walls, ceiling and floor from moisture exposure outside is solved.

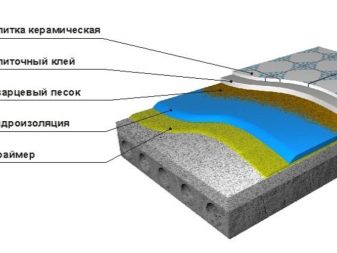

A budget option that is popular is laying a layer of clay on the bottom of the pit. On top of the stack roofing felt or roofing felt so that the layer thickness reaches 100 mm. In some cases, each layer is treated with mastic of bitumen.

Concrete is laid on the prepared layers. Sometimes an additional waterproofing is laid between the base plate and the layer to level the base. In this situation additional protection fits in so that the materials protrude 0.2-0.3 meters.

The process of laying waterproofing on walls is organized in a similar way. A prerequisite is the continuation of the horizontal layer on the wall at a distance of 15 cm. Next, the roofing felt is laid so that the exit is carried out at 20 cm.

If the waterproofing is made outside, it is very fitting that the clay be compacted, which has excellent insulating properties. With a large space, the roofing material is additionally protected with brickwork and fill the cavity with clay.

Subtleties of work

This type of work includes:

- Mandatory base training.

- Creating fencing and waterproofing cover.

- Strengthening joints and joints between waterproofing.

How to choose?

As a rule, penetrating mixtures are used to isolate the floor. They do an excellent job even with the floor in the basement, in which there are cracks.

Guaranteed good results will be given by rolled products with taped seamsSince the film creates a strong protection against moisture, however, it should be used before the start of work with capital structures. For insulation in the bathroom is applied in several layers of materials from a roll of bituminous or polymeric products.

Among other things The method of isolation by dyeing, namely multi-layer deposition of lacquer formulations, is widely popular.. When working with wood flooring, remember that it should not have cracks and seams. At the junction of the floors with the wall, it is also necessary to process the vertical surface of not less than 0.3 meters.

Walls of concrete basements in most cases are treated with coating compositions. If the soil contains a lot of water and there is no possibility to drain the drainage, this method may lose its effectiveness and even lead to the appearance of mold. As a way out of this situation can recommend the use of injection treatment methods.

As a rule, protection occurs as follows - the gels enter the walls through the pumps and exit to the outside in the form of a film. Remember that for efficiency it is necessary to take into account all the input data - the type of operation of the premises, the amount of water, and the possibility of a drainage installation.

Kinds

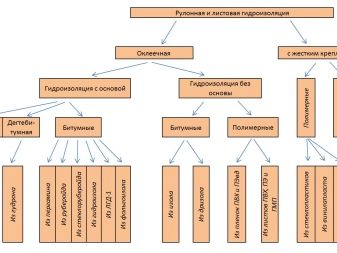

The classification of waterproofing compositions is based on the principle of their application to the surface:

- Painting. Could be hot and cold. It is applied to the base with a roller, brush or spray principle. This type creates a protective film up to 2 mm thick.

- Anti-filtration. It is used to isolate basements and underwater areas (for example, mines, tunnels), and also protects against leakage.

- Anticorrosive. It is used to protect structures from chemically aggressive liquids, from aggressive environmental influences and from electrocorrosion, which is caused by stray currents (for example, in power transmission towers). According to the type of material, the anticorrosive waterproofing can be asphalt-containing, mineral-containing, plastic or metal; according to the method of application, it can be painting, plastering, pasting, solid-cast, impregnating, injecting, filling and mounting.According to the individual characteristics of the design, this type of insulation is divided into surface type, keyed, creating density and solving complex problems.

- Plastering. It can also be cold or hot and is applied in several layers. It is used for reinforced concrete structures.

- Pasty. It is created by gluing polyurea roll materials in several layers with the obligatory creation of protective screeds and walls. It is widespread, but in recent times it is increasingly being replaced with a painting or plastering one. Resistant to cracking, develops along the path of fiberglass and polymer films.

- Cast. It is considered the most reliable, created, as a rule, by spilling hot asphalt mastic on the base structure in several layers. Due to the high cost and complexity of execution applies only in a special case.

- Filling in. In this case, loose waterproofing materials are filled up in waterproof layers and cavities. By type of construction and purpose coincides with the cast, but has a greater thickness, as well as a complex thermal hydration purpose.

- Impregnating. With this type of porous materials such as concrete blocks, tuff, asbestos cement sheets are impregnated with an organic binder. This type is often used for prefabricated structures that are exposed to aggressive external influences.

- Injection. It is created by introducing a binder into the cracks and pores of the material or the adjacent soil. In this case, new polymeric substances are increasingly used.

- Mounted. It is made of special elements (self-adhesive profile tapes, metal sheets, mineral wool), which are fixed to the main structure by mounting. As a rule, it is used in especially difficult cases.

- Surface. It is created in such a way that the pressure of the water pressed the insulated supporting structure. At the moment, there are new designs, working "to break". In this type of sealing is of great importance. It is done to ensure that the seams do not diverge under the influence of water. In addition to waterproofing, the insulation must also be resistant to deformation and have adequate flexibility. In this category, the most widely used metal diaphragms, compensators, molded sealants.Polyurethane, bitumen-polymer sealants, fiberglass and glass plastic are also widely used.

- Penetrating. It is a dry mixture of cement and quartz sand of a special composition. The ions contained in the mixture, when diluted with water, fill the pores of the material being processed and crystallize, preventing water from entering.

- Sprayed. Insulation has found widespread use for protecting basements, roofs and rooms located underground. Sprayed in a cold way, forming a membrane after freezing. Durable, demonstrates a high degree of adhesion with any type of surface, is fireproof.

By the time of application waterproofing can be primary or secondary. Primary is carried out directly during the construction of the building. Secondary refers to the application of repair measures.

If for some reason the primary insulation ceased to solve its direct tasks, a secondary insulation is created: the old coating is removed, the surface is thoroughly cleaned, the new layer is applied.

Sometimes a new layer is applied directly to the old one, but experts do not recommend going this way.

Consider the types of waterproofing in more detail.

Coating

It is used from the outside of the building as protection against precipitation and groundwater, from the inside of buildings - for the treatment of basements and bathrooms. Often they cover the cracks in houses with a coating method..

Of the advantages can be noted cheap material. Disadvantages include material fragility: bitumen loses its elasticity at temperatures below zero degrees. Deformations lead to the appearance of ruptures, flaking over time. Bitumen does not serve for a long time - about 5-6 years.

Hot bitumen is a hazard and injuries can occur in production. Also requires surface preparation - cleaning it from dust and debris. Only fair weather is suitable for work, since the concrete to be processed should not be wet. The treated surface must be protected from any mechanical damage.. Restoration of the original layer of insulation can cost several times more expensive than the first layer. From all of the above, we can conclude that coating insulation is good in cases where leakage is unlikely. For example, when the groundwater level is low, this type of insulation is quite suitable for the foundation, coatings on the roofs are not used, as cracks are formed from frosts in the bitumen, and the ice crust damages its surface.

Currently on the market are bitumen-polymer and bitumen-rubber compounds that can be applied cold. Thus, they win in the method of application, but still they are also poorly resist deformation. The slightest mechanical impact or vibration will lead to breaks and cracks.

Pasty

This waterproofing is used as anti-pressure insulation outside. It can be laid both in a vertical position and horizontally. The most commonly used are roofing felt, roofing felt, rubber-bitumen, glassine.. New generation materials are durable, they are not susceptible to rotting and no mold is formed on them. Their undoubted advantages include the ability to lay them on a concrete, metal, wooden or slate base, they are economical, not exposed to the environment.

Of the minuses, you can list the following: you can not lay insulation on unevenness more than 2 mm, pasting requires special care,during the work the temperature should not fall below plus ten degrees. If the foundation is pasted over, it is necessary to create a clamping wall. The coating is easily torn, so it must be protected.

Concrete during the work must be dry, on a wet surface coating does not fall. Quality control is needed between welds and material overlap. The material is superimposed in several layers, which is difficult to do with uneven terrain and with a large number of corners. Regardless of the shortcomings of waterproofing waterproofing is popular both for the foundation and for the roof. Significantly better if combined with other types of protection..

Painting

This waterproofing is used for both internal and external works. With it, you can deal with the appearance of cracks in the walls, their destruction. Waterproofing of the room can be created using similar mastics. In particular, processing the walls and floor in the bathroom will save neighbors from possible flooding.

As a material used as an additive to bitumen mastic of asbestos, talc and synthetic resin.It forms a vapor-tight and abrasive-resistant coating, the use does not require special skills, but, unfortunately, the coating does not last long - it lasts for 5-6 years.

Sprayed

Mostly used for roofs, sometimes for basements - but this is not very correct. Spraying of liquid rubber does not withstand the pressure of water and simply comes off the surface. Rubber is used as a material.

Of the benefits it can be noted that the rubber fills the smallest cracks, the surface is subjected to high-speed processing. Of the minuses - the temperature during the work should not fall below five degrees Celsius. The resulting surface should not be subjected to mechanical stress. Windless weather is necessary for the work, since the wind makes it very difficult to spray the material. In the presence of complex relief work can be very expensive. For the work requires special qualifications and special equipment.

A necessary condition is also compliance with the rules of storage of materials, otherwise it threatens to lose all insulating properties. Liquid rubber is only suitable for use on exterior parts of structures.

Penetrating

The insulation blocks the capillary rise of water in the pores of the concrete.The material itself is a dry mixture of active chemical elements, sand and portland cement. Unlike other types of insulation, a wet surface is needed to apply penetrating, as the composition must enter into chemical interaction with water, after which crystals are formed in the surface of the concrete, which prevent the ingress of moisture. The composition can penetrate inside the surface by 10-25 cm.

This type of insulation is ideal for use in basements.. The foundation is also often treated in the same way as other concrete tanks (such as silos). The advantages include the ability to carry out work directly inside the basement without the need to dig up the foundation.

No need to expose the concrete to dry, because the more wet the surface is, the deeper the composition will penetrate into it.

Good quality materials provide penetration into the walls to a depth of about a meter. Protection manifests itself not only inside, but also outside - concrete will not let moisture through. If a crack appears in the wall, it will self-destruct by the appearance of new crystals in it. Service life is extremely long.The quality characteristics of the concrete itself are improved - frost resistance, vapor impermeability; No additional equipment is required for the work.

Processed concrete is not afraid of mechanical impact - drilling, twisting dowels. The material remains environmentally friendly and may well be in contact with drinking water. Some types of compositions are suitable for repairing leaks.

Among the minuses it makes sense to consider the following nuances: the compositions are suitable only for concrete surfaces, as well as for cement-based plaster, brick and stone will not be suitable for these purposes. For work required temperature not below plus five degrees. Before starting work, you must remove the old finish and plaster and degrease the surface. After which the concrete requires thorough wetting.

This type of waterproofing ideal for fresh concrete, the old one needs pre-cleaning and degreasing, which will require a sandblaster.

Injection protection

Suitable for insulation joints and seams, where the walls are adjacent to the ground. It increases the carrying capacity and strengthens the foundation of the brick, cuts off the capillary leakage of moisture from the soil.The materials used are rubber, gels, foams and resins, cement-containing injection materials. During the work there is no need to dig up the foundation. Works can be carried out not only on cement, but also on brick and stone surfaces.. The method demonstrates effectiveness in isolating various seams, suppresses capillary leakage in a brick, eliminates spouting leaks.

Of the drawbacks is to take into account the high cost of not only materials but also equipment. Before starting work, it is necessary to make a complete dismantling, and special skills are required for the work. You need to know the exact location of leaks.

The work itself is a sequence of certain manipulations in strict accordance with the instructions. Moreover, the decision to conduct this type of work can only be taken by a specialist.

Super diffusion and diffusion membrane

It is a vapor-permeable material, having reinforced fibers. It has found its use in pitched roofs and ventilated facades.

Membranes can be laid directly on the insulation. This type of work requires gaps for ventilation - between the membrane and the roof and between the material and insulation.Due to the high vapor permeability creates a favorable indoor climate, in addition, it does not require excessive attention, easy to install.

Among the disadvantages: in the case of pore clogging, the efficiency of the material decreases. Also installation is not carried out on products from euroslate and metal tiles.

Bentonite mats

So called mounted insulation. Mats are clay in granules, which is enclosed between layers of cardboard or geotextile. After installation, the cardboard decomposes, meanwhile, the clay component performs the function of protection between the surface of the foundation and sediments. Upon contact with water, bentonite becomes a gel. During installation, the mats are overlapped and the joints are blocked with bentonite granules.

Unfortunately, this method of waterproofing has an extremely high cost and suitable for both vertical and horizontal surfaces. It can be laid near the foundation of the house on the ground, thereby blocking the entry of moisture. However, such work is best done directly during construction.

In concrete construction, experts recommend the use of specialized additives for concrete, increasing its quality characteristics.

From the above, the conclusion suggests itself: it is impossible to unambiguously answer which type of insulation is the best. Some types are more budgetary, some can boast a long service life or time of use. Therefore, it makes sense to rely primarily on personal needs.

If there is not too much money allocated for isolation, it makes sense to dwell on the painting type. When there is not too much time, it is better to choose the injection option, if you want to do it once and for centuries, it makes sense to choose an impregnating type of protection. Ultimately, they all solve the problem of waterproofing, but you must take into account the characteristics of each type.

Separately want to say about bitumen mastics of the well-known company "TehnoNIKOL". Most of the mastics of this brand are applied in a hot condition, their cost is low, but they require preliminary preparation of the temperature regime. With constant stirring, the composition is brought to a temperature of about 1000 degrees Celsius, after which a mastic is applied to a base previously cleaned and primed with a primer with a brush and waited for drying.

Product TechnoNICOL 41 freezes very quickly. It is mainly used when working with elements that come into contact with the ground.

TechnoNICOL 21 - It is a mastic cold applied. It is based on petroleum bitumen, artificial rubbers, minerals and solvents. Such mastic can be applied with a spatula or by pouring. Most often, it isolates piles and other elements that are in constant contact with the ground.

Please note that the layers must be at least one and a half millimeters.

Subtleties of work

When creating a waterproofing, you can do without materials produced at the factory, but this is possible only if the insulation is installed on the site in order to protect against groundwater. So, you can consistently pour rubble and sand. It is also quite possible to use plastic sheets made of polyethylene, ideally made of polyvinyl chloride. This is a fairly simple and budget option. In the case of a competent installation, this insulator will last for a long time, and if you install thermal insulation, it will even protect against condensation.

Despite the rapid growth of the industry, modern waterproofers have an acute problem of compatibility of the material with hydro protection. To solve this problem Experts recommend the maximum incorporation of waterproofing material into the surface structure. A well-known method called the “white bath” works according to the same principle. This type is used for communications located underground.

Today, the best qualities are demonstrated by membranes and polymers, since they can boast not only good waterproofness, but also additional protection conditions. Depending on the type, they have different properties, ranging from resistance to mechanical damage, resistance to fire, and even support for structural elements.

Tips and tricks

Before starting work it makes sense to take care of a thorough study of the material used and the sequence of actions when working with it. Carefully evaluate all the advantages and disadvantages, please note that some materials require plastering or tile cladding after application.

Also, carefully study the manufacturers of penetrating waterproofing.

"Penetron"

Known on the market for over fifty years. Its products include quartz sand and special chemical elements.Its cost is somewhat higher than the cost of analogues from competitors - for one kilogram of the mixture will have to pay about five dollars. The consumption of such a mixture is considered on the basis of the footage - one kilogram per 1 m².

This type is not cheap and has good reviews from customers, will last a long time, but pay attention to originality, otherwise you can buy a fake, much inferior in quality. Before buying, be sure to evaluate the reliability of the seller, read reviews about it.

Mixtures from "Penetron" are often used both in production and for household purposes. They do an excellent job with waterproofing pools, basements and other rooms.

"Crystallizol"

From the name, the principle of action of this substance is clear. When interacting with water and entering the structure of the concrete wall due to the presence of calcium salts, crystalline growth occurs, which, in turn, blocks the pores of the material and blocks access of moisture to them. The composition of this mixture includes quartz sand, cement and active substances, which the manufacturer does not disclose.

All mixtures have been compared with the original “Penetron” for a long time, and there is a simple explanation for this - for a long time this product has not had any worthy competitors.When reading the reviews, you will see that the experts speak well of Kristallisol, because it is not at all inferior to the well-known brand, and even surpasses it in some aspects. Repair and restoration of destroyed structures made of concrete is carried out using plastering insulation mixtures that Kristallizol has, but which Penetron does not have.. At the same time, "Kristallizol" is a mixture of domestic production, its price is much lower - about one dollar per kilogram.

"Kristallizol" is used both with constant exposure to moisture on the structure, and with temporary. This mixture demonstrates high performance when used in any water tanks, pools, bathrooms, as well as basements, even if they are located below the water table.

"Lakhta"

It is also a mixture of domestic production. Presented by a wide range of mixtures of various purposes. By the principle of action, this mixture is absolutely identical to “Crystallizol” and “Penetrin” - when in contact with water, the pores of concrete are blocked by crystals of the active substance.When applied, the mixture is diluted and applied solely on a well-moistened and pre-prepared surface.

Regarding the price category, "Lakhta" stands between the above-mentioned "Crystallizol" and "Penetrol." To date, the cost is about three dollars per kilogram of the mixture. However, the properties of this product is not inferior to competitors.

"Element"

Another quite popular brand. The manufacturing city of this mixture is Stavropol. The products of this company are represented quite widely: it includes not only a dry mixture for penetrating insulation, but also elastic waterproofing and liquid rubber.

Of undoubted advantages, it is possible to note the low cost - the price on the market will be about one and a half dollars. Penetration isolation It has found wide application in the consumer’s everyday life - it is used for work on balconies, basements, bathrooms, and industrial needs - for waterproofing tunnels and even hydraulic structures, as well as in places where structures need to be permanently isolated from the harmful effects of moisture in the form of precipitation, wastewater or groundwater.

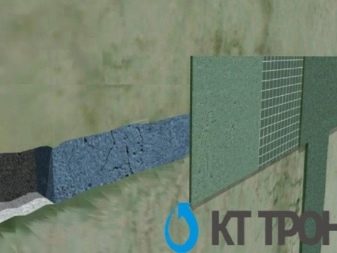

CT "Tron"

It is also the brainchild of the Russian market. This company produces the following forms of insulation:

- penetrating action;

- to protect seams and seams;

- special additives that improve the quality characteristics of concrete - for example, its frost resistance, water resistance, vapor resistance;

- waterproof types of plaster that can even the surface of the walls;

- many mixtures with the ability to instantly eliminate a strong leak.

The product line of the company CT "Tron" is able to solve a variety of tasks. On average, the cost of isolation penetrating action will be about 3.5 dollars. Mixes of this manufacturer are widely used for swimming pools, basements, various industrial facilities. Experts estimate the quality of the products presented quite high.

Speaking of waterproofing, it is impossible not to say a few words about the vapor barrier. Today, vapor barrier materials are becoming more and more popular. As you know, water has several aggregative states and can fall not only as precipitation, but also penetrates the room in the form of steam.According to the inexorable laws of physics, vapor-saturated air exerts high pressure on the walls of the room, trying to break free. Among other things, insulation of mineral wool when in contact with the steam lose their insulating properties, which contributes to the freezing of the room. The task of modern vapor barrier substances is to protect insulators from destruction.

In most cases, the vapor barrier is laid in a couple of layers on top of the insulation and below it. Materials are divided into several categories, each of which solves its unique task.

Type A - non-absorbent and windproof membrane that protects the insulation from the effects of external moisture. It is laid between the roof and insulation. The material is made according to the technology of spunbon and is widely used for work with ventilated facades.

The main task of this type of protection is to let steam inward freely, and then to prevent the ingress of water droplets. The material has no lamination and therefore it finds its application in roofs at an angle of at least 35 degreesto allow water to slide over them. When droplets accumulate in one place, they form small puddles and seep inside.

To protect the roofing insulation, a ventilation gap is necessarily created by creating a double sheathing.

AM type is a multi-layer vapor-proof membrane that protects the external elements of the roof and insulation from external influences. It is laid between the roof and insulation. This type is represented by two subspecies: three-layer insulation - a spunbond with a film in the center, or a two-layer one - in the form of a spandbond and a film.

The film is the basic difference between type A and type AM. Steam easily passes through it, but for water it is impenetrable. Due to the presence of lamination, the material exhibits enhanced moisture-proof properties and, as a result, can be used on flat roofs, forming protection from wind, snow and rain.

These membranes are placed directly on the insulation and do not require a gap for ventilation, so there is no need for crates.

Type B used as protection indoors. It is a barrier between insulation and vapors, as a result, retains its insulating properties. It has found its application in the installation of walls, floors, floors. When working on the roof used only for roofing in the form of a slope.

In the absence of insulation or with a flat roof, other types of vapor barrier are used, because Type B does not have adequate waterproofing density. It has a two-component structure - spunbond and waterproofing film. Spandbond prevents possible drops in the presence of morning condensate, as moisture passes into the material and then disappears during the day. Fits on the side of a smooth with respect to the heater.

Type C waterproofing possesses the strengthened density. The main difference from the previous type is the greater thickness of the spandbond layer, as well as the film layer. It has found its application in the same cases as the previous form, but when there is a need for a more dense material, as well as in roofs without insulation to protect wooden structures from moisture. It is often used in basements and basements without heating for protection if laying of parquet or laminate is planned.. Always put a rough side to the room.

Type D - fabric from polypropylene with the laminating covering from one of the parties. Very resistant to mechanical stress. It is used between screeds and floor insulation as a waterproofing layer.. This type is used for floors and wall elements in basements with high levels of humidity. It is also often used as a temporary roof during work.

For a more convenient laying of protective and paroizoliruyuschih materials experts advise the use of adhesive tape.. She glued both horizontal and vertical surfaces, connect the vapor barrier materials.

"Izospan"

Often used tape "Izospan" a variety of types:

- "Izospan KL" - double-sided tape, the basis of which is spandbond. She is recommended to glue type A sheets, the glue is a polymer that does not need a solvent. Service life reaches up to fifty years. Also often used double "Izospana", which is called "Isobond."

- "Izospan KL +" - the special tape having the basis from nonwoven material and the strengthened glue basis. For greater strength, reinforce the base. Glues individual membranes, creating a reliable vapor barrier surface.It demonstrates high temperature strength and excellent vapor barrier properties. It combines polypropylene and polyethylene films, as well as various materials in structure. Bonds with overlap any type of surface - A, AM, B, C, D.

- "Izospan ML proff" - adhesive tape with one-sided coating, has silk in its basis, as well as special reinforcing components that increase its quality characteristics. Perfectly connects all places of adjacent vapor barrier to the bases of concrete, gypsum, plaster, as well as at the joints of pipes and bases, or in places where there is a need for reinforced vapor barrier. It copes well with both internal and external work, copes with razym temperature conditions.

A wide range of materials is available on the market to provide vapor barrier. It can be:

- Standard film. Struggles with condensation on the roof or insulation.

- Film with additional foiling. It has a reflectivity and enhanced protection from steam. It also has the ability to return to the premises of the heat, which is widely used in saunas, baths, bathrooms.

- Membrane films control excessive moisture output. The peak characteristic is determined by the permeability of the membranes.

Pay close attention to the beginning of the work. First of all, it is necessary to identify areas requiring increased attention, especially for areas in which there is a constant contact with warm, moist air. In most cases, these zones are the boundary between warm and cold air masses - roofs, penthouses, basements.

It is also worth noting that the vapor barrier can be both in sheets and in rolls.

When installing roll insulation with your own hands, follow these steps:

- it is necessary to roll the roll upwards;

- material is fixed with wooden slats or galvanized profiles in a horizontal position;

- the ventilation hole is located between the inside trim and steam protection;

- Be sure to monitor the quality of fasteners.

Before installing sheet metal vapor barrier material, it is necessary to first mount the frame into which the sheets will be inserted. Fastening is carried out with the help of screws.At the joints, processing is carried out with a film or using "Izospan".

In case of need to form a reliable framework, experts recommend creating a cratethat is of particular importance in the subsequent sheathing or warming.

During installation, pay special attention to the mounting features of the vapor barrier, the strength of which is ensured by using nails or screws. Regardless of the place of installation, it relies on a set of the same rules.

The easiest way to consider the sequence of steps on a specific example of isolating the attic:

- the trim covering the first floor ceiling;

- insulated floor;

- insulation;

- wood flooring.

In addition, it is necessary to treat the floor with a means of fungus. In order to preserve the vapor barrier in the room, it is necessary to provide a covering with a continuous layer, avoiding the appearance of gaps as much as possible. The canvas is best fastened with staples construction stapler. Laying sheets of vapor barrier is overlapped, then with the help of scotch tape are glued in places where they fit to the door and window openings. Better to avoid film tension.because it may be damaged due to temperature fluctuations. Mount with a margin of a couple of centimeters.

When installing a vapor barrier ceiling panels laid overlap with the panels of the walls. To ensure reliable insulation against moisture, vapor barrier layers are laid both outside and inside.. It should be noted that external insulation is carried out in three stages: first, the vapor barrier layer, then heat insulation, and the vapor barrier again closes the layer. Thus, the service life of wooden floors is prolonged and the appearance of condensate is blocked.

If it is necessary to install a vapor barrier for reinforced concrete structures, experts unanimously come to the conclusion that it is necessary to provide isolation of such elements with special care. Due to temperature fluctuations, condensate is created, which subsequently will inevitably lead to the formation of mold. If the construction is being built from a timber, it is completely possible to refuse vapor barrier. Natural wood self-absorbs moisture and prevents condensation.

However, not all regions of our country have the opportunity to enjoy the warm season for a long time.We must not forget that the vapor barrier serves to preserve heat in the house, protects walls and ceilings from negative impacts both from the inside and the outside, and also contributes to efficient energy saving, which leads to a longer service life at home and the lack of need for repairs.

More information about the types of waterproofing, as well as tips on the application you will find in the following video.