Advantages and application of waterproofing Mapei

Mapei, which began operations in 1937, is one of the world leaders in the production and supply of various building materials to consumers. About 50 enterprises are located in different countries of the world. Among several thousand items of products of the Italian brand, waterproofing materials are of particular interest. In particular, the two-component composition Mapelastic and the liquid elastic quick-drying membrane Mapegum WPS deserve attention, which are used for waterproofing various indoor surfaces.

Properties and applications

- Waterproofing materials of this brand have proved to be excellent when finishing various kinds of structures, waterproofing pools, protection from moisture in residential and industrial buildings.

- This product can be used for interior decoration and exterior work on the moisture insulation of basements and foundations, for finishing bathrooms and showers, terraces, loggias and means of communication.

- The material can, if necessary, serve as protection for surfaces with structures such as plaster, gypsum plasterboard and tile ceramics.

- Mapei waterproofing is also widely used in the industrial sector, where it is used to treat concrete surfaces of various tanks, including drinking water., transport facilities, smoke pipes, tanks made of concrete and bricks.

- This waterproofing can serve to protect concrete that has cracked during shrinkage due to water infiltration, either under the influence of aggressive agents or in case of contact with salts and seawater.

Mapei coating waterproofing composites are characterized by high elasticity and adhesion to various surfaces, for example, with ceramics, masonry, marble and concrete. These qualities, combined with resistance to ultraviolet solar radiation, allow this waterproofing device to be operated even in regions with high density of industrial enterprises and significant air pollution.

Waterproofing of this brand is actively used in coastal areas, where there is a high concentration of various salts in the air.

The composition and purpose of Mapelastic

This composition is a two-component composition of solid ingredient A and the liquid component B. The first of these is a mixture of cement binder with fine-grained filler and special additives. The second component consists of water-dispersion synthetic polymers.

In finished form, the two-component composition of this brand should be a homogeneous mass, for which the components are mixed, and the solution is applied to the treated surfaces with a spatula.

The quality of synthetic polymer resins in the composite is such that the finished waterproofing retains its elasticity and water resistance even at a pressure of about 1.5 bar.

Apply this waterproofing composition on the treated surfaces should be such that the thickness of its layer does not exceed 2 mm. If you exceed this indicator, the elasticity of the material is significantly reduced. Works should be performed at air temperature above + 8 ° С.

It is not recommended to add water, cement or other components to the solution, and the finished layer after application should be protected from water ingress to it for 24 hours.

It is necessary to put a hydroinsulator of this brand on in advance prepared, cleared and strong surfaces without cracks and damages. The surface of the base must be moistened before work. If you plan to apply waterproofing to concrete, you should first verify the strength of its surface. It must be cleared of cement residue and dust must be mechanically or manually removed from it.

If the metal base is contaminated with lubricants or oil, then its cleaning is carried out by sandblasting or hydro-washing. In the presence of rust, it is removed with a card brush, sandpaper or a converter.

If we are talking about surfaces that have the ability to absorb water, then before starting work this base should be saturated with liquid.

In the process of preparing the working solution, the liquid component is placed in a container, to which the dry ingredient is then added. Mixing the composition is carried out with a mechanical stirrer at low revs.This is necessary in order to eliminate the saturation of the working mixture with air bubbles. The mixing of the composition continues until a homogeneous mass is obtained, and the powder should not be allowed to settle to the bottom of the working tank.

The finished solution should not contain lumps, and its structure should be completely homogeneous.

The application of the waterproofing compound Mapelastic is done manually or with a spray gun. Waterproofing in working condition is about 60 minutes, and all its subsequent layers are applied only after the final drying of the previous layers, and the thickness of each layer should not exceed 1 mm. With the manual application of this material, its consumption is 1.7 kg / m2, and with the mechanical spraying method - 2.2 kg / m2.

Mapegum WPS material

As mentioned above, Mapegum WPS is a liquid quick-drying waterproofing elastic membrane for protection against moisture of indoor surfaces and has the appearance of a light-gray paste. The product of this brand is a one-component, solvent-free solution that is ready for use. Its basis is a synthetic polymer resin with a water dispersion.

The thixotropic consistency of Mapegum WPS allows you to easily apply the product on the surface of horizontal, inclined and vertical geometry. Water from Mapegum WPS evaporates rather quickly, after which the composite turns into an elastic membrane, non-sticky and resistant to human weight during light pedestrian traffic.

The product serves as an excellent basis for the application of adhesive compositions used in the installation of tile ceramics, marble elements, natural and artificial stone. The degree of elasticity of Mapegum WPS makes it possible to withstand the deformations that are common in the compression / expansion of the base due to vibrations and temperature fluctuations.

The elasticity of Mapegum WPS allows it to be used as an anti-fracture membrane for bases subjected to a small, less than one millimeter, cracking.

Mapegum WPS is used for waterproofing floor and wall surfaces inside rooms that do not have constant contact with water or are not subjected to the capillary movement of moisture.

This elastic membrane, which is a compensator for the base deformations, can be applied to:

- drywall;

- gypsum plaster or cement mortar;

- foam concrete blocks;

- shipbuilding plywood;

- non-absorbable cement coating surfaces;

- anhydrite, wood and magnesite bases;

- already existing ceramic tiling and a coating of natural or artificial marble or stone after applying Mapeprim SP primer on them.

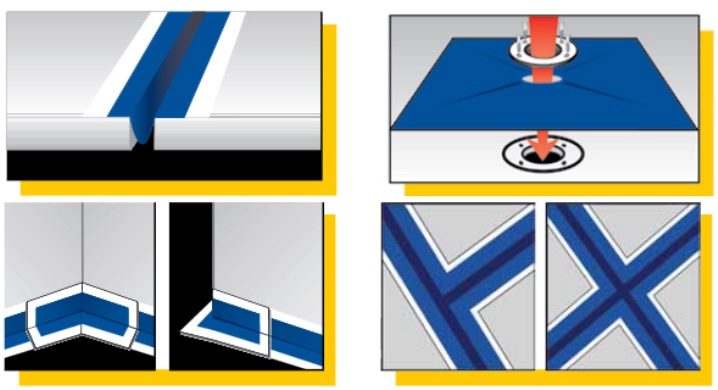

Mapei Mapeband tape: features

This type of waterproofing is used in conjunction with the above compositions of Mapegum WPS and Mapelastic. The purpose of this tape is to seal the seams, butt joints and all sorts of connections. when applied to the surface of waterproofing membranes elastic type. Like the membranes, this tape is durable and highly elastic, serves to prevent the occurrence of cracks and effectively protect complex and mobile abutments.

The waterproofing tape material Mapei Mapeband is a combination of high-strength polyester material nonwoven part with elastic tape. The recommended area of its application is the places of pipe outlets, base joints consisting of different materials, temperature and moving joints.

It can be used for waterproofing works.indoors for any purpose and architecture and outside buildings to protect their foundations, on balconies and terraces, for the treatment of foundations and the basement of buildings, ponds and water tanks, fountains and pools.

This tape is distinguished by high strength, elasticity, vapor impermeability, manifested in any temperature conditions. With the possibility of expansion and elongation, reaching 100%, this waterproofing is chemically resistant and is able to actively resist aggressive chemical compounds.

Mapei Mapeband tape is glued to the base, placing it in a layer of coating waterproofing. It is necessary to pre-cut this material to the required length, making an overlap of at least 70 mm in the process. The tape is superimposed on the freshly applied waterproofing composition and ironed with a spatula for more successful gluing and in order to remove air bubbles from the mass of waterproofing.

At the end of gluing, the tape itself and the entire surface to be treated should be covered with a waterproofing layer so that the waterproofing composite is applied to the tape on both sides.

For details on the properties and application of waterproofing Mapei, see the video.