Water repellent: what is it?

Environmental factors often adversely affect the quality and durability of building materials. In order to protect structures and foundations from destruction and to extend the service life of structures, there are a number of specialized products. Among which it is possible to allocate such means as a water repellent.

Special features

Not all methods of ensuring the protection of buildings from the effects of environmental phenomena are effective, especially when it comes to the impact of moisture on materials. ANDDescending from practical experience, builders agree that waterproofing should be carried out in a complex, combining various techniques. However, the use of such means as water repellents makes it possible to simultaneously solve several pressing problems. Such a possibility means due to the specific features inherent in the composition.

Among them are the following properties:

- impregnation such as water repellent can be used to process any raw material, for example, concrete, asphalt, brickwork, natural and artificial stone, slate, aerated concrete, wood, gypsum, tiles and others. But for each building material it is necessary to acquire a highly specialized composition designed specifically for a specific foundation;

- most of the protective equipment of this type, having deep penetrations into the material, does not block natural air circulation through the treated surface, like some polyurethane varnishes. This feature does not affect the level of vapor permeability, which eliminates the risk of the emergence and development of fungus and mold on raw materials;

- versatility water-repellent agent, as well as a wide range of products make it possible to use the tool not only for external application, but also as an additive for various kinds of compositions, for example, for preparing concrete, which increases the service life of the finished product and the whole structure;

- besides protection against moisture products improve some material properties - it concerns elasticity and resistance to negative temperatures.

Based on the above-mentioned features, it can be concluded that thanks to modern technologies, it became possible to use highly efficient means that have a beneficial effect on the quality of building materials, increasing some indicators, which, in turn, has a positive effect on the durability of structures.

The water repellent agent is an agent that contains various organic compounds. It has an astringent structure that is most often applied to the surface of the material. Due to the treatment with a water-repellent agent, a film is formed on the base, which prevents the penetration of liquid into the raw material.

The use of products is absolutely safe for human health and the environment. Water repellents for most materials are resistant to UV light and temperature fluctuations. In addition, this product has the following advantages:

- this impregnation minimizes the risk of destruction of the material;

- the composition has an effect that prevents the occurrence of corrosion of surfaces;

- the use of funds makes it possible to save on additional purchases of paint and varnish materials and primers;

- water repellent properties of water repellent persist over a long period of time;

- the appearance of the material after processing remains at the same level, in particular, it is important for natural materials, for example, wood and natural stone;

- resistance to precipitation is reinforced by resistance to the damaging effects of alkali and other acids that may be contained in water;

- the tool is able to penetrate into the porous structure of products to a depth of up to 35 mm, which increases the protective and strengthening function;

- the water-repellent agent has no restrictions in the field of application, therefore it can be used for exterior and interior works;

- the tool reduces the adhesion of ice to the base, which helps reduce the load on the walls of the structure;

- product life is about 15 years;

- the treatment with such a base prevents the accumulation of various contaminants on the materials;

- due to the presence of some components in the composition, it will not be possible to apply various graffiti on the surface, which spoil the appearance of buildings, in particular, facades.

In order to have a complete understanding of what constitutes a water-repellent agent, it is necessary to note its disadvantages. According to professional builders, the flaws of the products should include the full transparency of the film, if you use products for processing. Therefore, it is very difficult to distinguish a material coated with a protective compound from products for which such work has not been performed.

Taking into account a similar feature of the water repellent, many unscrupulous manufacturers sell unprotected products under the guise of the material with the presence of a water-repellent film.

However, you can eliminate the risk of fraud by checking the surface with a special device called the Karsten tube. This method determines the level of impermeability of a material by applying a certain pressure of liquid to the substrate.

Kinds

Water repellents can be divided into two groups such as:

- volumetric water repellents, which are introduced into the composition, in particular concrete even in the process of its production;

- the second group is represented by surface products, which penetrate into the structure of the finished product, during its application to the substrate. Such compositions are used for concrete products, natural stone, especially marble, for tiles and decorative finishes.

The chemical composition of water repellents are as follows:

- water based;

- silicone products.

Products, where the base is silicone, are more in demand due to the durability of the coating. The mixture of water-based also stands out advantages, among which it is worth noting a higher level of resistance to ultraviolet radiation. .

The compositions are used for shallow penetration into the base - about 10 mm. They are very simple and safe to use. Typically, water-based solutions are sold in a concentrated state, so before use they must be diluted with water, strictly following the instructions

Besides, It is possible to distinguish products based on an organic solvent, the level of penetration of such an agent into the composition reaches 35 mm, as well as water repellents that change the appearance of the base. The main advantage of such products is the ability of the composition to enhance the base color of the surface, as well as the creation of the "wet stone" effect. There are products that have properties that not only ennoble colors and shades, but also set their own color, because it already has coloring pigments in its composition. Such products are popular for use in the work with the plaster constructions made by hand.

Based on the technology of application, surface water repellents are classified as follows:

- impregnating agents;

- stains;

- paint and varnish compositions.

On the construction market there are various tools that are designed to work with a wet or dry basis. Water based products are applied only on a dry basis. The principle of action of water-repellent agent is based on the penetration into the raw material and freezing. This possibility is explained by the porous structure, which is typical for most materials, especially stones. The capillary fluid is released, however, the molecules can circulate freely.

For stones of various rocks, protective compositions based on silanes or silicone polymers are used. During the deposition, the liquid composition penetrates into the seams and pores of the raw material, while the solvent, most often in its role, isopropyl alcohol, evaporates, as a result, a film is formed on the substrate.

Scope of application

The main advantage of water repellents is a wide range of applications. Due to this, it is possible to protect virtually any surface with the compositions.

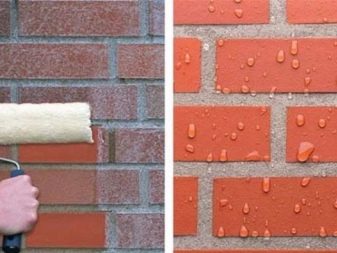

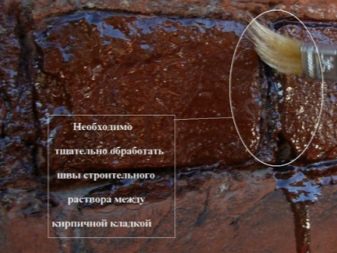

- Water repellents for brick. The brick quite often began to be used as a facing material for the facades of buildings. Brick cladding does not require additional decoration and finishing, but just such a surface has some drawback - the appearance of white bloom on the base. Such neoplasms are called salting, representing a bloom of mineral salts. Timely surface treatment with a water repellent will help eliminate the risk of plaque, as well as increase the strength and durability of the brickwork, while having a beneficial effect on the aesthetic component of the material.

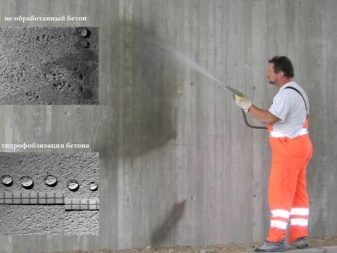

- Water repellent for concrete protects raw materials from moisture penetration. The composition can be used as an impregnation for the erected structure, and as an additive for the solution. Sometimes the protection of such surfaces is carried out in the complex.

- Protective compounds for slate positive effect on the quality of the roofing material, in addition, the material itself is notable for its impressive weight, and being saturated with moisture, it will create an additional load on the roof truss system. Therefore, asbestos cement slate must necessarily be treated with the composition by drawing on the sheets. In addition, thanks to the timely processing on the roof will not accumulate dirt, as well as grow moss.

- Moisture protection composition for artificial and natural stone It is necessary because even such strong rocks as granite absorb moisture. It is easy to be convinced of it, having paid attention to the stone bases of pools or fountains, on socles of buildings on which greens begin to sprout. Water repellent for granite will provide him with a reliable level of moisture resistance, as well as help to maintain the external attractiveness.Worktops or sinks made of artificial stone can sometimes be quite difficult to clean off plaque and efflorescence. Using a protective compound will help avoid such problems. Specialists engaged in the manufacture of products from natural and artificial stone, it is recommended before applying it is necessary to test the composition on the back side of the product to make sure that it does not affect the color of the raw material.

Among the main applications of water-repellent agent, it is also worth highlighting some more areas where the use of the composition is important, namely:

- concreting workshops, laboratories;

- treatment of drainpipes, septic tanks and wells;

- ensuring the protection of curbs, pavements and blind areas, made of tiles.

How to choose?

To choose the right means for impregnation of concrete, brick, wood and other materials, you should consider the following nuances:

- waterproofing facades of buildings should be carried out using tools made of silicone or silicon-based;

- Do not forget that for each material highly specialized formulations are recommended. Since, for example, in the composition of the mixture for wood, there are often additional components that counteract the development of fungus, mold and the process of rotting of raw materials;

- should carefully examine the composition of the water-repellent agent, focusing on the technical properties of the product. It is necessary to give preference to compositions that have the maximum level of penetration into the pores of the material, as well as a long service life;

- You should not save on the acquisition of protective mixtures, because as a result of poor-quality processing, after a few years, you will have to replace all the material that has become unusable from moisture, especially for external works.

Method of use

Most often, after finishing the finish, small fragments of material remain. Such residues should be used to test the moisture-proof composition, it is worth buying the minimum package of the product and processing the product. After the material is completely dry, you can evaluate the appearance, as well as check the hydrophobicity of the material with the applied treatment.

It is quite simple to test the protective properties - it is necessary to pour water on the material abundantly, while liquid droplets should roll off the base. If the experiment was carried out successfully, you can safely purchase the necessary amount of water-repellent agent and start working.

For the treatment of the base, it is necessary to prepare personal protective equipment for the skin and eyes. Processing the composition of surfaces located indoors should be performed with good ventilation. According to the recommendations of specialists, it is possible to carry out the application of a water repellent in the temperature range from -20ºС to + 30ºС. But based on consumer feedback, outdoor work should still be carried out at a temperature of + 10 ° C, subject to minimum humidity and the absence of strong wind gusts.

Application technology is as follows:

- the working surface is cleared;

- the composition is uniformly applied using a spray gun, roller or brush on the material in several layers based on the recommendations indicated on the package;

- it is necessary to ensure that the composition does not flow, there is no large time intervals between the application of layers;

- moisture protection properties material acquires after 24 hours. At this time, the surface must be protected from contact with water.

When processing the protective composition of large-sized bases, it would be better to divide the working area into several sections and carry out work alternately.Hydrophobic additive for concrete, which is introduced directly into the solution itself, is added based on the calculation of the volume of the working mixture and the specified values on the packaging.

Manufacturers and reviews

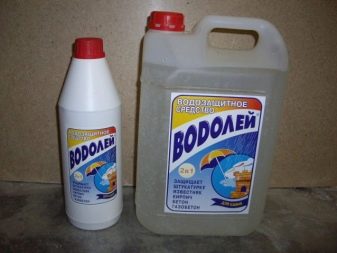

The first criterion when choosing products will be the scope of application, as well as the manufacturer of the composition. On the market of building products there are several trademarks of water repellents.

- Aquasil - This is a concentrated composition for concrete and bricks. According to consumer reviews, products are fire resistant, and the treatment with the composition provides tangible hardening of the monolith design. The tool can be used for surface application to concrete, as well as an additive to the solution

- "Spectrum 123" - it is an emulsion for concrete, which has a protective effect not only on the material itself, but also on the armature and other concrete products in the structure. The technology of applying the composition requires thorough cleaning of the working surface; work should be performed only at a positive temperature. The effect of hydrophobization on the basis of visible already after 20 hours after application.

- "Tiprom-U" - This is a composition that is similar in its properties to the production of Akvasol.It is notable for its good dirt-repellent properties. However, products are not recommended for use on surfaces that have frequent contact with water. In addition, the products found on sale are “Tiprom M” and “Tiprom K Lux”, used for works with paving slabs.

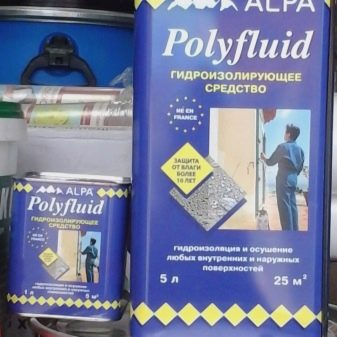

- Alpa polyfluid - It is a water repellent, deeply prijyayuschim in the pores of the material. It includes synthetic resins and antifreeze. According to consumer reviews, the composition has proven itself as a means for treating surfaces with existing defects. The cost of French products is much higher than domestic counterparts.

In addition, the Neogard, Armokril-A, GKZh-11, Penta, and Kristallizol products should be allocated in the product line for protecting surfaces.

Tips and tricks

An important point, providing high-quality application and protection of surfaces when using water-repellent agents, is to clean the bases not only from accumulated dirt and dust, but also from salt deposits, if any. This work can be done using special concentrates based on a mixture of acids.

There are products with enhanced water-repellent properties, which include organic solvents. Such a solution may have a rather peculiar odor; therefore, the use of the mixture is recommended exclusively for external use.

It is worth considering that water repellents can not be applied to polymer bases, because they do not have good adhesion with each other.

The degree of penetration of the composition depends on the level of surface porosity. The higher it is, the deeper the composition goes into the structure, which means that the level of material protection increases. The durability of the water-repellent coating is related to the frequency of mechanical impact on the material. Frequent surface treatments and washing will shorten the life of the protective base.

How to make a waterproofing, see the next video.