Waterproofing walls inside and outside: types and features

Obligatory stage of any construction work is waterproofing the walls. The absence of a layer that protects against excessive moisture leads to mold and mildew, which can cause many serious illnesses.

In addition, the violation of waterproofing technology affects the technical condition of the building and significantly reduces its service life.

What it is?

To protect the structure from the destructive action of moisture, it is necessary to take care of effective waterproofing of the walls, since water, penetrating into the material, destroys its structure.At the same time, it doesn’t matter what the construction is erected from - concrete, brick or wood - they all need hydro protection.

Probably, many faced with the appearance in the house or apartment of an unpleasant smell of mold and dampness, especially often this unpleasant phenomenon occurs in the basement and basement floors. This results from the fact that moisture gets into the room in several ways:

- from groundwater;

- during the spring thaw of snow and high water;

- from rain and other precipitation.

Moisture may have internal sources.: if the thermal insulation of the house is not of sufficient quality, then the temperature on the walls on the cold days can drop sharply, which often leads to the loss of dew inside the living room. In addition, individual rooms of a private house due to their functional purpose have an increased level of humidity, these include a bathroom, shower rooms, pools, baths and kitchens.

Consider why waterproofing is necessary.

- That the building stood as long as possible. Everyone knows that strong walls are dry walls. Under the influence of moisture, even the most resistant materials become brittle and begin to crumble and crack.A house devoid of waterproofing rather quickly loses its strength of retaining elements and gradually becomes unsuitable for comfortable and safe living.

- To make it warmer in winter. The connection here is the most direct - the raw walls freeze in the first place, since the accumulated moisture freezes quite quickly. Thus, the dwelling becomes not protection from the cold, but exactly the opposite, a kind of “ice igloo”. The owners of the house rush to insulate the walls and spend additional funds for heating, but, as a rule, this does not have the desired effect.

- To protect the house from pests. Dampness is known to be the best breeding ground for mold and mildew, the appearance of which leads to serious allergic and bronchopulmonary diseases in adults and children.

Obviously, waterproofing is needed not only to make the house better and stronger. This is one of the most important stages of work, neglect of which is fraught with the most serious consequences.

Waterproofing is needed for the treatment of the main elements of the building.

- The outer walls of the skeleton frame - from the constant impact of natural factors, the walls are gradually destroyed,a favorable environment for reproduction of pathogenic microorganisms is formed, and in addition, moisture begins to descend down the walls and destroy the foundation and pillars of the building.

- Basement - The walls of the basement are the most susceptible to destruction, as they are under tremendous pressure: the weight of the building, the proximity of the groundwater and the constant impact of wet soil. All this necessitates the protection of basements and plinths.

Standards and standards

Waterproofing materials, as well as work on their installation should be carried out in accordance with current regulations and standards that were adopted during Soviet times, but still have not lost their relevance.

In particular, the requirements for waterproofing compositions are regulated by the SNiP 3.04.01-87, as well as the BCH 35-95 and others.

Purpose

Depending on the purpose there are several types of waterproofing.

- Sealing. Such a coating creates conditions under which any possibility of atmospheric or capillary moisture on the walls is completely excluded. Such a waterproofing device is widely used between the foundation and walls.

- Heat-insulating. This is a comprehensive insulation that not only saves buildings and structures from moisture ingress from the outside, but also reliably holds heat inside the room, contributing to the formation of a healthy and favorable microclimate. Such sealants are used for the treatment of roofs and walls.

- Anti-corrosive. The composition is used for processing metal elements of building structures. The use of anti-corrosion coatings is governed by official building codes and regulations, and for metal structures of special importance it is considered mandatory to comply with GOST standards and SNiPs adopted in the territory of the Russian Federation.

- Anti-filtration. Such coatings are widely used to protect structures that are located below the ground level. This type of waterproofing is the most difficult from the point of view of structure, it has a lot of different options and modifications.

Most often, the arrangement of the building includes several waterproofing options, for each individual case materials and technologies are used, selected taking into account the assigned functions and operating conditions.

Technology

Before any homeowner at the stage of preparing waterproofing works, the question of how to carry out work, outside or inside, comes to the fore.

Specialists in this regard have a unanimous opinion that it is necessary to complexly waterproof a building: both on the external side and on the internal surfaces.

The main difficulty in carrying out external hydroprotection is that this type of work should be carried out at the stage of the beginning of the construction of buildings. If it has already been erected, then in order to fix the moisture-resistant coating it will be necessary to dig the foundation.

Optimally, if the building is surrounded by land, it will not be difficult to dig it out, but in recent years, asphalt or plank paths have been set up around the house, which must be dismantled before starting work, and at the end it is tiled or rolled up again.

In this case, waterproofing exterior walls can be quite expensive, then it is better to limit the internal work.

Materials

To date, the construction market offers a large selection of a wide variety of hydroprotective materials. Consider the most popular types of coatings.

Bituminous mastic

Bitumen is a by-product of the petrochemical industry. Mastic based on it is used for gluing rolled coatings, such as roofing felt or roofing felt. However, certain types of mastic can be used as an independent insulating material, which creates an effective seamless coating that completely retains moisture of all types.

Bituminous mastic in its structure contains active components-plasticizers and antiseptics, which improve the performance properties of the material.

Implement mastic in bars weighing up to 20 kg, wrapped in paper. Before use, the composition should be heated on an open fire, the melting point of the composition is quite high, so when working you must comply with safety regulations.

The advantages of bitumen mastic include good adhesion with all types of surfaces (brick, concrete or wood), as well as low cost. All this makes the composition of one of the most popular for many decades.

Polymer mastic

Polymer mastics are also used for waterproofing walls - these are coating compositions with special properties, they are applied to the inner surfaces of the walls with a brush or spatula.A distinctive feature of such mixtures is a high rate of hardening, it takes only a few hours to completely dry the composition.

This coating with high adhesion and exceptional strength, which causes a long period of use of such hydroprotection.

Roofing felt and ruberoid

Roofing material and roofing materials are materials that belong to rolled insulation variants made from construction paper impregnated with special bitumen compositions. The top layer of such coatings is a sprinkling of asbestos chips, sand and talc, this is important when installing the roofing pie.

Rolled materials are attached to the surface with the help of bitumen mastics in a hot way, as a result, a surface is formed that provides one hundred percent protection against the ingress of moisture from the outside. This method involves the arrangement of the walls outside.

Polyethylene film

Dense polyethylene film is truly indispensable when performing a wide variety of construction works. It is used for internal insulation work and is widely used in rooms with high humidity, such as basements and basements.

The advantages of the film are obvious - it has a low weight, is durable and completely waterproof, the thickness of the material reaches 3 mm. This covering material is easy to lay on surfaces of any type.

The composition has a low price and is affordable for most of our compatriots.

Polymer coating

Membrane materials are characterized by durability, their service life is 50 years. This material is resistant to oxidation, is not subject to rotting and corrosion.

Manufacturers produce a variety of materials based on complex polymer compounds that may have additional functions of vapor barrier and heat protection, the surface of the membranes can be self-adhesive and not.

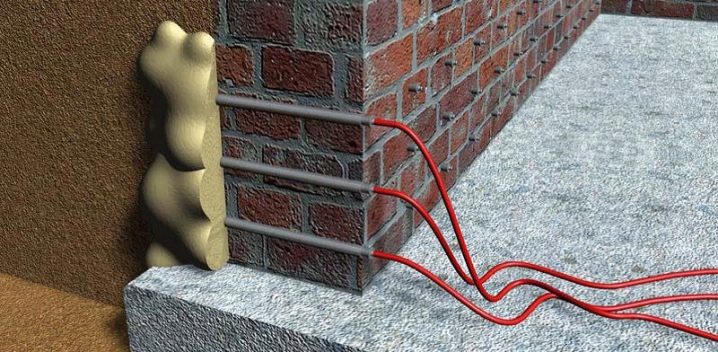

Injection waterproofing

Despite the intricate name, in practice, everything is much simpler - it is a simple priming. The liquid applied to the walls has the ability to penetrate deep inside and fill all the microcracks and pores. Penetrating compounds block all available capillary pores of the coating and form a high quality waterproofing layer.

The effectiveness of such waterproofing has led to its widespread use when working with monolithic and reinforced concrete products.

Gypsum wall putty

Another variant of penetrating insulation, in which the surfaces are filled with special gypsum mixtures. When dry, gypsum creates a surface with high adhesion, protects walls from mold, and in addition, reliably protects against any penetration of water.

The choice depending on the structure

When choosing waterproofing materials it is necessary to take into account the peculiarities of the structure.

For example, if work is done on a wooden surface, it is very important to completely replace the structural elements damaged by putrefactive processes, it is necessary to find the source of the formation of rot and eliminate it.

Best of all, waterproofing impregnations are suitable for such surfaces; they are applied only to dry and cleaned surfaces. The multiplicity of the applied layer depends on future conditions of use.

Concrete walls are more often treated with rolled materials, but the use of any other coating is allowed - the choice is completely dependent on the personal preferences of the owner of the house and his financial capabilities. Waterproofing options for concrete are many:

- penetrating insulation;

- adding special components to concrete;

- liquid waterproofing;

- coating compositions;

- fused or glued materials;

- special sealants.

Ways of doing

At arrangement of an internal waterproofing use several basic techniques of drawing.

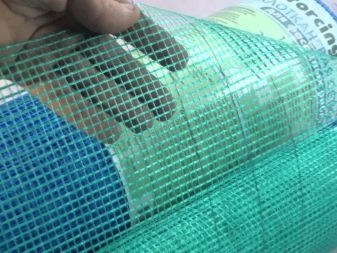

Coating

The method is to use mastic, which is applied to the surface with a brush after leveling.

The main condition for the effectiveness and quality of the coating is the absolute purity of the treated surface. Even before work begins, it is necessary to clean the working area, collect garbage and dust, get rid of all the holes and repair all cracks and chips.

Mastic needs to be smeared with one layer, while it is important to fluff the entire surface.

A reinforced mesh is attached on top, which is attached with a brush to the treated area of the coating, and a second layer of mastic is applied over the mesh.

After 3-4 hours, the final layer is applied, and if the first two layers were horizontal, then the finish layer is rolled vertically - that is, across.

The coating layer gives a good and effective, but short-lived waterproofing. As a rule, its service life does not exceed 3 years.

Pasty

This option is used only in the basement and basement floors; in this case, roofing material or roofing felt is used for waterproofing.

The surface must be previously sanded and cleaned in the same way as in the case of working with waterproofing of other types, if there are significant irregularities, then a concrete screed should be made.

The first layer is mastic, which is heated and hot applied to the walls with a spatula., then quickly, until the composition is dry, the roll material is taken and rolled down from top to bottom. If the mastic starts to harden directly under the roll, you should heat it with a gas burner, and only then put the roofing felt properly.

The future strength and reliability of the waterproofing layer largely depends on the adhesive ability of the mastic.

Penetrating

This option is rarely used by private traders, since it requires professional equipment and skills in working with materials. The penetrating insulation is a liquid rubber, which crystallizes in the pores of the concrete and creates a common whole with it. Such a material is applied by a construction spray; it penetrates rather deeply into the coating, displaces the water and air in the pores, filling all the existing voids.

Such isolation does not allow water to penetrate inside the building, but at the same time leaves the possibility of air circulation.

Waterproofing the walls outside also has its own characteristics; it is done in one of the last two ways, however, it requires some additional actions, namely: to protect the waterproofing layer from mechanical damage, it must be covered with insulation or foam on top, which will be sheathed with finishing materials later. Often this material is laid for painting.

Pro tips

Professionals advise in the arrangement of waterproofing of a dwelling house to use only proven materials of high quality, durability and reliability.

According to builders, it is best suited for internal waterproofing

- Elastopaz bitumen paste ("Elastopaz");

- Flex primer (Silpaz Flex);

- liquid waterproofing Master Flex ("Master Flex");

- abrasive mix Styrbit 2000 ("Stirbit 2000").

The waterproofing of the plaster-type Infiltron-100 and the Izofol film have proven themselves very well.

The process of waterproofing walls, see the following video.