How to make waterproofing basement?

One of the main characteristics of a good basement is its high-quality protection against precipitation and groundwater. If all the norms and requirements for construction and decoration are met, then it will turn out durable, safe and dry. However, even the best outdoor waterproofing eventually loses its properties.

As a result, it is necessary to waterproof the basement from the inside.

Special features

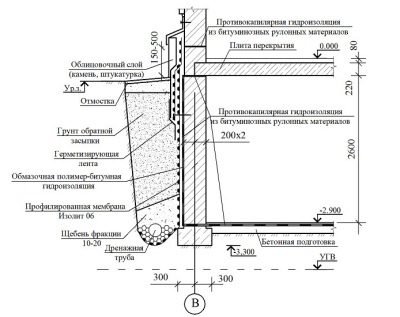

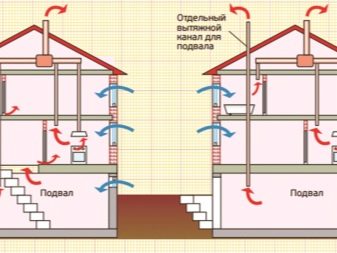

It should be borne in mind that waterproofing only from the inside of the basement is ineffective. For good protection from groundwater and precipitation, it is necessary to apply a complex of waterproofing measures, which is carried out at the basement construction stage.For example, a clay water castle is being constructed under the floor and a blind area or drainage is being made with external waterproofing.

The problem of groundwater often occurs when neglecting the arrangement of the drainage system, which removes melt water. If not, then even a high-quality internal waterproofing basement will not allow to keep it dry.

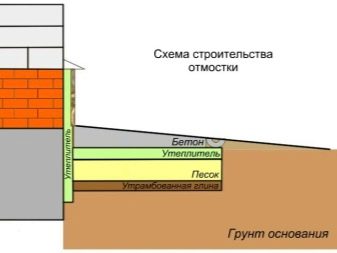

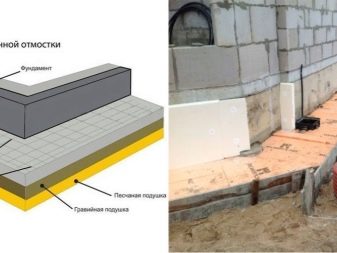

Partly with the problem of excessive moisture in the basement helps to cope the correct blind area around the building. It does not allow precipitation to penetrate to the foundation. Moreover, the depth of the blind area should be from 30 centimeters, width - more than the width of the foundation. A cushion of clay, crushed stone and sand, which is poured with concrete and decorated from above, necessarily lies on its bottom.

Only after the drainage, external waterproofing and blind area are completely ready, the internal waterproofing will be able to show a good result. Of course, there are cases when, for example, the basement has already been built for a long time, but it has become much wetter. Then, before the internal waterproofing should first check the condition of the external and, if necessary, update it.

Basements, which were built in zones with shallow groundwater levels, are especially in need of high-quality protection. However, it happens that the aquifer simply changes its level and you have to apply urgent measures. Without proper waterproofing of the basement from the inside in this case, a fungus, mold, corrosion can appear, products will deteriorate or the foundation will collapse. If the basement is in the house, impaired waterproofing can lead to a distortion of the microclimate even in residential premises.

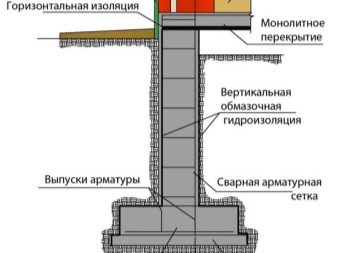

The internal waterproofing of the basement from groundwater should be carried out comprehensively to protect the walls, ceiling and floor as best as possible. At the same time, the junctions of the surfaces (between the walls and the ceiling, walls and the floor, the joints of the walls between each other), the joints of the blocks in the foundation, the joints of the brickwork, the construction sites of the communications, cracks or faults from the structure shrinkage should be carefully protected.

A plaster for waterproofing the foundation is best to produce bitumen mastic. Such a simple action will significantly reduce the cost of repair.

It is necessary to begin the process from the floor, and to complete it with work on the processing of floors.

Kinds

The internal waterproofing of the basement, depending on where the work goes, is divided into two types.

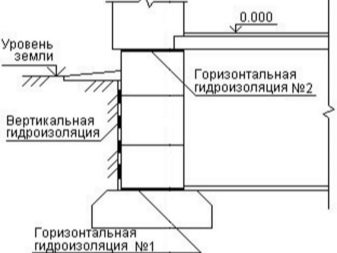

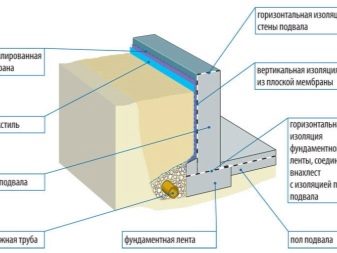

- Vertical waterproofing of walls is carried out, if the walls of the basement are located on the same level with groundwater, as well as in the absence of a drainage system. This type of waterproofing protects the places where cracks have formed, as well as the joints. It is best to use membrane, coating, injection, liquid glass or rubber, as well as polymeric compounds for vertical waterproofing.

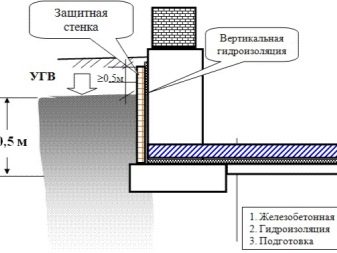

- Horizontal waterproofing of the floor is mandatory, as it is able to protect the basement from changes in the groundwater level or the amount of precipitation. It is also best produced if the basement base and groundwater are at the same level. Waterproofing the basement floor is also necessary in the case of clay soil through which water does not seep well.

It should be noted that horizontal waterproofing is additionally performed on the walls to a height of about 30 centimeters.

This helps to protect them in case groundwater rises, as well as from capillary leakage of moisture.For horizontal internal insulation using polymeric materials or roll method.

Types of insulation also emit depending on how much moisture is affected.

- Anti-pressure waterproofing is done in the event that the pressure of groundwater can reach 10 meters. There is no external waterproofing and drainage system. In this situation, the basement needs a solid and solid barrier to water. The principle of such a waterproofing is based on the use of water pressure, which presses the insulating material to the basement surface. It is desirable to do anti-pressure waterproofing even in the process of building a basement. For it most often used materials such as rolled seals, membranes, rubber. This type is the most difficult. The most important thing in it is to strengthen the walls and the floor as best you can. To do this, you will have to raise the floor level and make the walls thicker, which will slightly reduce the basement area.

- Anti-capillary the waterproofing serves as protection against an overabundance of moisture and dampness. It is best to use penetrating materials for such waterproofing. They are applied in several layers from the inside.Such compounds penetrate the cement to a depth of 0.25 meters. Additional advantages of such waterproofing are that the composition of materials for it is non-toxic and anti-bacterial. They are suitable for basements in which products will be stored. They also increase the frost resistance of concrete by blocking moisture in its outer layers. With such insulation, even in the most severe frosts, there will be no frost on the walls.

- Free-flow waterproofing will help in the event that the basement is temporarily flooded. For example, during seasonal floods, as well as heavy rainfall. Best of all, bitumen mastic will be suitable for this type of waterproofing, it is the simplest and most budgetary option. There are also more modern methods using liquid glass. However, we must bear in mind that this type of waterproofing is not suitable for all basements.

Basement insulation can be accomplished using a variety of materials. Today there are a large number of them. Often there are not only the flow of groundwater, but also the flow of communications. Choosing materials, it should be borne in mind that penetrating waterproofing can help from thawed, groundwater, as well as capillary flow.But if a communal accident occurred, it is better to use mastic or coating emulsions.

Depending on the materials used waterproofing is also divided into different types.

Roll

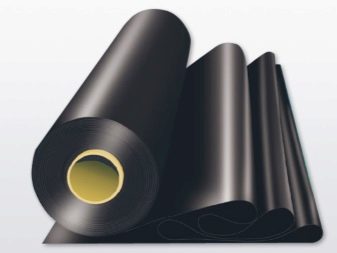

This isolation will allow you to reliably protect the basement from the inside from seepage of groundwater. It is used for waterproofing the floor. For the roll insulation method, bitumen based material is used. It is glued to the surface, and the overlap is required.

As for the seams and joints, they are necessarily melted with a blowtorch. In this method, the adhesive is bitumen mastic. As for the subsequent works, they are carried out as necessary in case of floods. If the water often rises, it is better to miss the floor with bitumen mastic in four layers.

If raising the water to the top is rare, then two passes with mastic are enough. After the mastic has dried, a concrete screed is made. As materials for roll insulation use roofing felt, linokrom, waterproofing.

Penetrating

It is required for high groundwater levels. This method is applicable to the inside of the basement walls.Composition for penetrating waterproofing is made from a mixture of cement, sand (preferably fine), as well as chemical components. Such a composition has viscous properties and penetrates to a depth of 100 millimeters. After that, it crystallizes.

This method allows you to protect against the rise of moisture in the capillaries, makes the basement frost-resistant, reduces corrosion of reinforcement. One of its advantages is that it can be used in areas where there is food.

Membrane

Waterproofing does not penetrate groundwater into the basement. The main advantages of this method are that the foundation is not overloaded, there is an adhesive layer, it is easy to work with it.

There are various types of membrane coatings.

- PVC Is fireproof material.

- TPO membrane manufactured on the basis of rubber and propylene. These membranes are used not only to waterproof the basement, but also to protect the toilet, kitchen, bathroom. The main disadvantage of this material is its high cost.

- EPDM membrane made of synthetic rubber. They are able to protect the basement even at low temperatures.

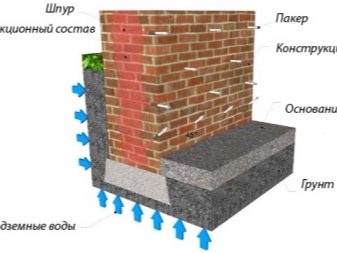

- Injection insulation is a very reliable method that can protect not only the surface, but also the entire structure of the basement. The main disadvantage of the method is the large labor input. The essence of this method of isolation is that a large number of holes are drilled, and then a special compound is pumped into them with the help of injectors.

Most often for this method using the following mixture:

- cement to increase strength;

- polyurethane allows for expansion to push out the liquid from the inside;

- epoxy need only in places of direct leakage;

- methyl acrylate well fill the cavity due to deep penetration.

Coating

Insulation is carried out using liquid rubber. This method is great for isolating the floor in the basement. Liquid rubber is made on the basis of bitumen, which is also added latex. Thus, this rubber forms a film with high strength on the surface. Due to its elasticity, the material is also suitable for insulating walls and ceilings.

The coating method isthat a special compound is applied to the cleaned surface that is responsible for the best setting, then the entire surface is coated with grease and cracks and joints are filled. This is followed by drying and plaster, which is necessary for a better pressing of the film and prevent the destruction of the surface under it.

For good protection, it is enough to apply the film with a layer of just two millimeters.

Liquid glass

Insulation is easy to apply and low material consumption. Waterproofing in this way is carried out using liquid glass, which is diluted with water before being applied to the surface. This composition fills the pores well, and when frozen, crystallizes. As a result, resistance to mold and fungi, structural strength, resistance to mechanical stress, moisture absorption does not occur. In addition, liquid glass can protect decorative coatings.

"Penetron"

Waterproofing is necessary if moisture is visible on the walls of the basement. Means "Penetron" is a dry mixture that must be diluted with water to a liquid state. After that, it is applied to the surface using a brush.Due to the penetration inside the walls to a depth of 200 millimeters, this mixture is able to prevent fluid infiltration. However, this tool misses steam.

Used to protect walls made of brick and stone. Surfaces treated with this material can withstand any pressure of the water layer. Also undoubted advantages are convenient application of the solution and its environmental friendliness. Moisturize the surface before applying.

Device

In general, a complex of waterproofing works to protect a foundation or brickwork against water consists in a number of the following actions:

- examine the structure along the perimeter and strengthen the blind area;

- identify sources of water in the basement;

- prepare the foundation for filling joints and cracks;

- waterproofing cracks and seams of the foundation;

- perform filtration waterproofing of the floor in the basement;

- provide good ventilation in the room;

- make drainage systems on the territory adjacent to the structure, for example, digging out grooves, installing drainage grids and the like.

The process of waterproofing begins with the fact that they carry out a hydrological survey of the soil at the site, establish how deep the groundwater is, and how much the soil freezes through.In that case, if groundwater flows below the level of the basement, then it is possible not to drain and lower their level. It is enough just to protect the walls and floor of the basement, and not too expensive materials.

Inspect the blind area should be around the perimeter of the building. The blind area must be at least 100 centimeters. The pavement is made of concrete, paving slabs, asphalt or natural stone.

Most importantly, the materials do not have cracks and do not let the water through.

If there is no blind area, it should be done. To do this, dig a trench around the perimeter of the house with a depth of 0.3 meters and a width of 1 meter. Put clay on the bottom of the trench with a layer of 0.1 meter and tamp it down. Pour river sand (about 5 centimeters) on top of the clay, and then rubble a little with a fraction of 10 millimeters. Next, the blind area is reinforced with a reinforcing mesh with cells of 10x10 millimeters.

As for the remaining trench depth (about 0.1 meters), it is necessary to fill it with a cement-sand mortar. And for him the best cement brand M300. After the blind area is ready, you should examine the basement room from the inside. The first thing to begin with is to inspect the floor for the presence of standing water on it. If it is, then it is siphoned off.After that, you need to find out how the groundwater penetrates into the basement and waterproofing it.

External waterproofing basement is best done at the construction stage, while the internal - at any convenient time. However, it is worth remembering that waterproofing only inside the basement is not always able to solve all the problems with excessive moisture in the room.

Scope of application

Waterproofing is applied not only to the basement, but also to the foundation of the house, garage, as well as other structures. Especially in waterproofing need brick buildings. And to protect building structures, buried under the ground and directly in contact with groundwater, apply anti-filtration waterproofing. Such structures include basements, tunnels, mines, pools, reservoirs, hydraulic structures.

To protect the above-ground structures from moisture, anti-corrosion waterproofing is used.

Most often, waterproofing is produced at the stage of construction, reconstruction or repair of the structure. The only exception is structural waterproofing.It lies in the fact that manufacturers of building materials add special additives (water-repellent) to the compositions. For example, concrete, which is already moisture resistant, can be even more waterproof.

How to choose?

The choice of waterproofing is a responsible and difficult event. This issue becomes especially acute in the spring, when thawed and groundwater flood the underground parking lots, basements, reduce the life of the foundation of houses. The biggest problem is the waterproofing of underground rooms.

Before proceeding to the choice of waterproofing method, it is necessary to decide whether waterproofing works will be carried out from the outside or from the inside.

External waterproofing is carried out at the stage of building the foundation. It can be plastering, painting or pasting. It should be borne in mind that such waterproofing is short-lived and temporary, as it is applied over the foundation. Even with good performance during the construction of the waterproofing will be carried out mechanical impact, and as a result of its integrity is broken.

Internal waterproofing is necessary in cases where the waterproofing was done poorly on the outside or the groundwater level rose. When the groundwater level rises, the pressure on the basement walls increases. The type of internal waterproofing is chosen based on the groundwater level and the amount of precipitation in the region. Of course, today is considered the best modern penetrating waterproofing. And it is suitable for any conditions of operation of the premises.

As for the choice of materials, their range is also huge. They are divided according to the principle of action and method of application. Such a variety of materials and types allows everyone to choose the ideal waterproofing option for a particular room.

For example, obmazochny traditional materials differ in low cost, and they proved the efficiency. However, they have serious drawbacks. One of them is that even with a weak pressure of water, they move away from the surface. As a result, they have to be replaced with new materials.

When choosing a waterproofing do not forget that it must be durable, wear-resistant, frost-resistant, fire-resistant and safe for humans.

How to do it yourself?

Waterproofing, at first glance, is not an easy process, but you can do it yourself. It is best to waterproof the basement during repairs or, for example, insulation, following a number of recommendations.

- Determine the level of groundwater. This moment is very important, though not as simple as it may seem at first glance.

- Inspect the premises. This task is to thoroughly examine every centimeter of space. And not only the walls, but also the floor and the ceiling.

- Identify water leaks. Attention should attract all suspicious places, that is, areas with cracks, loose fitting seams between blocks, loose surfaces, wet spots with mold, etc.

- Mark the places where cracks appeared. And this applies even to the smallest cracks.

- If necessary, pump out the water. If there is water in the basement, then it must be either pumped out, or wait until it comes off. No type of waterproofing can be carried out in water.

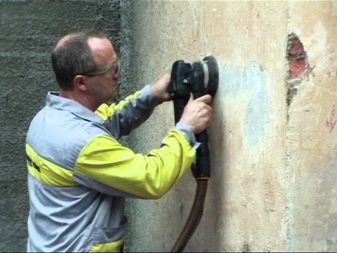

- Clean the surface of dirt dust lining. And this concerns not only the walls, but also the floor, and the ceiling, and even floors.If there is a need, you can even open the coupler. As a result, only masonry materials should be visible, for example, concrete or brick. This stage is very important, because due to skipping it, the consumption of materials may increase, and the quality of waterproofing will be much worse.

- Widen cracks. Be sure to expand all the cracks, including the most minor. Then clean them from dust. It also affects the quality of the insulation.

- Treat with primer surface. Obligatory stage of waterproofing, which should not be missed, is a primer. It makes the walls stronger, while increasing the adhesion of the surface with the solution. Moreover, the problem areas on the walls should be treated with a primer twice. After applying the composition must wait for it to dry.

- Choose a waterproofing material and type of protection. To choose what and how to waterproof the basement is necessary solely on the basis of the desired result and financial possibilities. For self-insulation it is best to opt for the most simple and clear waterproofing technology.

- Run isolation. The process of waterproofing is carried out according to the instructions.It is advisable to comply with all recommendations that correspond to a particular type of insulation and selected materials.

- Dry the room thoroughly. Dry the basement preferably after any waterproofing. However, this point is especially important when the insulation is done in a wet environment.

- Equip ventilation. For proper ventilation of the basement, it is necessary to make a airlock in its ceiling, and to install a pipe outside which will be an air duct. This design works as a hood. Moreover, the outer pipe is best closed with a cap and a fine mesh to protect the basement from rodents and ingress of precipitation.

Tips and tricks

- If the building is new and there is a possibility of subsidence, before waterproofing it is necessary to apply reinforcing fabric, geotextile or soft mesh on the walls. It is best to fix them with dowels or apply to a wet solution. If the waterproofing is applied in two layers, then the reinforcement fabric should be laid between its layers.

- Isolation of a dirt floor can be carried out after falling asleep by rubble and cementing. There is no such waterproofing material that can be applied to clean soil, and it will protect it from moisture.

- When horizontal waterproofing wall should be covered with insulating material for at least 30 centimeters.

- Only penetrating waterproofing is applied to damp walls, as well as bitumen emulsions. Before other types of waterproofing walls must be dried.

- In the event that the basement is planned to be heated, its walls should not be covered with oil paint, otherwise it will peel off.

- When waterproofing do not forget about the stairs leading to the basement, they also need to be processed.

- Paint waterproofing is suitable only for basements, which are located above the groundwater level. Moreover, it should be applied with a layer of no more than 6 millimeters. Such a thin layer is not able to withstand a large amount of water.

- For basements that are on the same level with groundwater, it is better to choose an epoxy or bitumen mixture, in which it is desirable to add polymers.

- It is best to choose epoxy-tar mastic as a frost-resistant insulation material.

- Roll waterproofing is best laid in several layers: either vertically or horizontally.

- Liquid waterproofing is applied in several layers, but with a break of two hours.

- Proper ventilation ensures dry basement.

- If fungi or molds form on the basement walls, they must be treated with an antiseptic solution before waterproofing.

What to do to prevent errors in waterproofing, and how to fix the existing ones, see the next video.