Floor waterproofing under a coupler: types and technology of laying

Building a house and repairing an apartment is an expensive and responsible event, the result of which should delight residents for many years. Therefore, strict adherence to the sequence of work, construction rules and technologies, the quality of the materials used are necessary and necessary.

Features and Purpose

The destruction of the structural elements of the house occurs under the influence of various factors. One of the main destroyers is water, moisture, various liquids. High humidity in the house not only contributes to its destruction, but also threatens the health of residents: it causes asthma, bronchopulmonary, skin and other diseases.

For a safe life, the humidity should be in the range of 40-60%.

If the figures are higher than normal, then over time, the centers of mold and unpleasant odor form on the ceiling, walls and windows, and the furniture deteriorates. In order for the house to stand for a hundred years, the tenants were healthy, and good neighborly relations did not deteriorate due to the constant flooding of the lower floors, you need to protect it from the harmful effects of water and steam, creating a reliable waterproofing system.

One of the stages of home protection is high-quality waterproofing of the floor under the screed, the purpose of which is:

- Protection against emergency leakage of water due to technical faults plumbing and communications, the bay from the neighbors above in apartment buildings.

- Protection from water vapor and capillary moisture rising from the ground from the basement, which often have an acidic or alkaline environment, actively interact with the components of concrete, and within a few years the screed can become covered with small cracks and begin to break.

- Proper slow drying of the screed, its higher quality and durability.

Previously, they made insulation using rolled materials: roofing material, roofing material or, better, polyethylene. These materials are still the cheapest on the market, but they are not recommended for use due to their shortcomings.

Modern technologies are not standing still and offer the builders the most innovative and reliable compositions for hydro protection, different in composition, cost, and method of application. The choice becomes wider and more difficult.

For greater reliability, it is recommended to use several different types of waterproofing.

Kinds

With all the diversity there are several types of waterproofing of the floor under the screed. They differ in the method of application and the materials used.

Rolled

He fused or okleechny. The material, the canvas of which is rolled up. Previously, often used roofing material, glass asphalt - bituminous mixture on a paper basis, polyethylene. Today there is a huge variety of such films and coatings. They have a solid and durable fiberglass base, low cost, the greatest speed and ease of installation, creating a continuous waterproof film. The rolled materials include: roofing material, filizol, isoplast, waterproofing, glass fiber-based glass insulation.

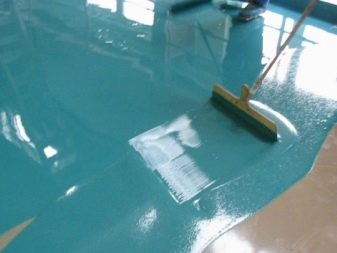

Liquid

Coating with hydrophobic mastics. Liquid coating mastic is made on the basis of bitumen, rubber, polymer, bitumen-polymer, polymer mixtures and solutions. Their cost is higher than that of the roll, but they do not need to be heated.Synthetic resins, which are part of the mastic, form on the surface a continuous seamless polymer or rubber coating. It penetrates into all hard-to-reach areas and perfectly isolates the screed from moisture.

There are also disadvantages: poor tolerance to constant vibrations and mechanical damage, does not like sudden temperature changes.

Plaster mixes

Low moisture absorbency coating. Plaster dry mix contains cement, sand and special components that prevent the penetration of moisture. Advantages of plastering waterproofing are: ease of application, safety, compatibility with other building materials, durability, the possibility of applying to surfaces of complex shape.

The disadvantages include: high cost and complexity, long drying.

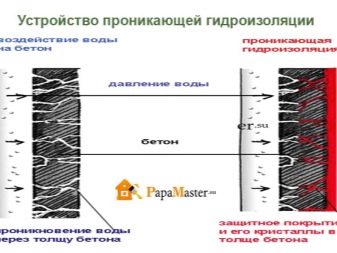

Penetrating formulations

They are impregnating. Relatively new technology. This rather costly screed protection method is renowned for its efficiency and water resistance. They use special penetrating solutions based on polymers and bitumen, which are applied to the surface of a rough base, impregnate concrete, fill all its microcracks and pores.

Entering into chemical interaction with concrete, penetrating solutions form a stable crystalline complex.by changing the properties of concrete, making it waterproof, less porous. Strength index increases by 20%. Acquires resistance to mechanical damage, chemical attack, increases the life of the floor.

In the case of further microdamages, the coating self-heals, producing special substances.

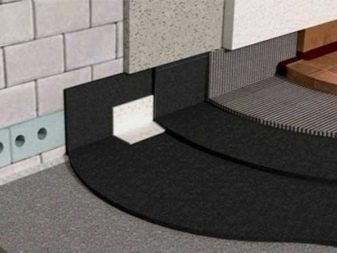

Cast protection

Rubber-bitumen, a mixture of foam, hot bitumen, pitch, asphalt concrete of varying degrees of viscosity are poured onto the substrate and get a fairly thick cast coating. The relatively high price is compensated by an absolutely durable and waterproof protection.

Filling method

The material for this method are concrete bitumens - dry bulk mixtures. When wetted, betonite turns into a gel, which has excellent waterproofing properties and perfectly retains heat.

Which one to choose?

A wide range allows you to choose one or combine several ways to protect against moisture, depending on the parameters of a particular room in an apartment or private house.The choice is influenced by the purpose of the room, the level of humidity, the thickness and characteristics of the floor covering, the wet screed is planned or semi-dry.

Mixes with antibacterial components work great in bathrooms. Huge areas are quickly covered with roll materials. In addition, it is necessary to take into account that any materials are not perfect and have disadvantages.

For example, film - not strong enough, it is recommended to choose them on the basis of fiberglass and fiberglass. The coating materials are subject to mechanical damage, the pasting materials require special conditions and the use of gas burners during installation, this is not allowed everywhere, and bitumen has a short service life.

Impregnating compounds are not applicable to gypsum and lime plaster. Ineffective for working with concrete with a low brand waterproof.

Foundation preparation

The base for the screed and waterproofing must be prepared.

This is done as follows:

- the rough base is leveled, the protrusions are cut off, the sharp parts are cleaned, the cavities are filled with putty;

- cracks, chips, irregularities are eliminated with the help of cement-sand mixture;

- it is necessary to remove all debris and dust, degrease oil stains, remove glue or paint stains;

- make a wet floor cleaning;

- in case of using ruberoid it is necessary to apply a bituminous primer. Primer primer needed and before coating with hydrophobic mastics;

- A damper tape is glued around the perimeter of the room.

- You can walk on the floor surface penetrating composition. Before impregnation, the surface of the base should be abundantly moistened;

- for the cast and backfilling method it is necessary to build a low formwork;

- wooden floors should be cleaned of debris and dust, repaired all the cracks and cracks, sanded or ottsiklevat, degrease, dry. Then soak in antiseptics and primed. Previously, wood was treated with linseed oil, tar. Now apply acrylic primer.

Technology

On the basis prepared in such a way we put or apply insulating material. The technology depends on the chosen method of protection, in wooden houses or new buildings have their own characteristics.

Roll canvases are fixed by fusing or pasting. In the first case, use a building dryer or a gas torch, and when pasting - fix the roll on the base. They unfold the stripes and lay them out along the length of the room, leave for one day to finish. The canvas should overlap with an approach of at least 10 cm. The length that overhangs the wall must be at least 15 cm wide; after pouring the finishing tie, the excess is cut to the floor level.

Roofing material is glued to the roughing screed using bitumen mastic, which is applied with a layer of 1.5-2 cm. Carefully glue the joints, pierce the bubbles with a knife, expel the air and re-glue this area. This method requires sufficient experience and permission to work with an open flame of the burner. It is usually laid in several layers so that the seams do not match.

Polymer seams are welded together in the flame of the burner. Welded heated with a building dryer and melted to a draft basis.

To do this, heat the bottom side of the roll and press it to the floor.

Liquid mastic based on bitumen is applied with a brush or roller in several layers. First, in one direction, with a thin brush, hard-to-reach places are carefully processed, for example, around a cluster of pipes, and the bottom of the wall is also smeared.Then in the perpendicular direction, after 3-4 hours, but not more than 6 hours, until the polymerization process began. So a multi-layer coating will become a single structure and get the most durable.

In the bathroom, the mandatory height of the wall plastering is 20-30 cm. This forms a seamless rubber, bitumen, polymer coating, a kind of bowl, which in case of an accident will not miss the water. In order for the mastic to stick evenly to the base and not peel off in the future, first apply a primer. It is usually purchased with the same brand as the mastic. After two days, the protection will completely dry out. This method is the most durable.

Plaster mixtures are sold dry in bags and diluted with water according to the instructions on the package. Put the first layer with the spatula, level, wait for drying, about 15 minutes. Then put the second layer, moving in the opposite direction. Such layers may be 3-4. This cake will dry for a long time - 2 weeks, and it is necessary to constantly moisturize it in the first days of drying. The result is a durable hard coating.

Penetrating waterproofing is used both separately and in combination with other methods of protection against moisture.It is recommended to impregnate and finishing screed on top. Preparatory work includes abundant moistening of the rough base. Impregnating composition based on bitumen or polymers is sold in the form of ready-made liquid solutions or dry mixes for dilution with water.

Apply the composition on a wet basis, wait for the time specified in the instructions, then re-moisturize, apply the impregnation again. Finished work must be closed with a film, then constantly moistened, so that all the chemical reactions necessary to create a needle-like crystalline structure, complete penetration into concrete, take place. It takes about 2 weeks to complete drying. This coating changes the physical properties of the screed; it is often used in combination with the coating method.

Cast insulation has a relatively high price and is considered the most reliable of the modern, performing noise and thermal insulation function. First you need to prime the base with hot bitumen, build a formwork around the perimeter of the room. Then pour the preheated composition over the floor surface, level it with a special scraper. After complete curing, apply the next layer, if necessary.

Filling protection also requires formwork. Dry loose mix - concrete is scattered on the floor surface, leveled, compacted.

Wooden floor requires protection from moisture and decay from the bottom, from the basement or the ground, and from above. If there is no basement, then a gravel-sand pillow should be poured, and then a heat insulator and a hydro insulator should be laid. In the basement, arrange high-quality ventilation, impregnate the draft boards with antiseptics, close with isoplast (roll method). For the floor, it is preferable to use waterproof varieties of wood, alder, larch or aspen.

The wooden floor can be protected from above by several methods:

- Painting. First, the boards are soaked with antiseptic, then primed, then simply painted in several layers with paint or varnish. The lacquer coating is short-lived - under the influence of temperature changes, it will collapse in a few years.

- Cast.

- Backfilling.

- Plastering.

- Pasted.

In the bathroom, the best solution would be laying tiles in combination with a waterproofing coating.

Common mistakes

To avoid major mistakes, it is necessary to pay close attention to them and not allow in the process of work.

These errors include:

- Improper floor preparation: debris and dust, oil or chemical stains that interfere with adhesion of insulation materials.

- Lack of soil primer.

- Small overlap of rolled strips and underglued areas of joints.

- Insufficient number of layers in multilayer application.

- Lack of moisture during the impregnation.

- Incomplete drying.

- Mechanical damage to the finished coating, such as metal fittings.

- Insufficient height of the wall insulation in the bathroom.

Professional Tips

If you have to carry out repairs or construction yourself, then the advice of experienced professionals will help to avoid the mistakes listed above.

The flaws in this work are fraught with serious consequences, up to the complete dismantling and alteration of the entire floor:

- You should not save on materials, in this case it is very important to purchase high quality insulation and the most modern.

- Be sure to strictly comply with the technology.

- Do not rush to apply finishing screed, wait until it is completely dry or hardened.

To learn how to waterproof the bathroom floor, see the following video.