Polymer mastic: varieties, advantages and technical characteristics

Polymer mastics are multicomponent high-viscosity compositions based on various elastomers, latexes and other polymers, such as epoxy, polyurethane, polyacrylic, silicone. The main area of application is waterproofing construction and repair work.

Kinds

There are two main types of mastic:

- bituminous;

- polyurethane.

Polyurethane mastic in comparison with bitumen is a more multifunctional and improved material, the mixture is made on acrylic components.Unlike bitumen, it is not afraid of heating and high temperature conditions, does not lose its original shape and structure. It does not include toxic products of processing.

This material can act as an independent heater, because it has the ability to store and accumulate heat due to its structure.

Bituminous mastic is designed for cold curing.. Its composition contains petroleum products and is a black homogeneous mixture, rather thick and with a high level of density properties.

It is mainly used for sealing basements, basements and foundations. It is also used in rooms with high levels of humidity, such as bathrooms and toilets, basements and attics, swimming pools and many others.

Better not to be exposed to direct sunlight., because when heated goes into a liquid state and needs additional protection. Usually, a layer of earth is poured on its surface or made with masonry, and sometimes they simply use additional insulation.

Special features

Distinctive characteristics of polymeric mastic are:

- excellent adhesive ability;

- excellent chemical resistance even with prolonged contact with acids and alkalis;

- water resistance;

- high strength;

- excellent deformability - there are compounds that have a relative extensibility, even when stretched to 1000% and above; durability;

- wear resistance can reach 10 years and even more, including to ultraviolet radiation.

All these features attribute this material to one of the most unique, and polymer waterproofing based on them is among the most modern and progressive materials used in the protection of various buildings with a high dynamic load, and aggressive environments are not terrible.

Scopes of polyurethane mastic:

- waterproofing structures and structures with significant movements relative to each other, such as, for example, underground structures, where the base plate is not used;

- repair of soft roofs, including by applying to the old layers;

- lining of concrete and metal tanks and tanks, tunnels, wells and all kinds of pipes;

- as a corrosion-resistant coating for steel tanks, bridges, supports and other similar structures and structures;

- construction of pools and tanks for water, including firefighters, as well as tanks for the storage of petroleum products and other aggressive substances;

- the construction of baths and saunas, as well as showers and sports halls;

- during the construction of the roofs of parking lots, shopping centers and other similar structures, as well as underground floors of residential buildings, subways and tunnels.

Merits

The merits of polymer mastic whole mass. Let's name the most basic ones:

- do not exfoliate from the substrate and completely fill all possible niches, thereby ensuring the absence of voids;

- after being applied to the surface, the mastic penetrates into the cracks and voids of the waterproofing area, after which it hardens, thereby forming a material resembling rubber and having rigidity and strong adhesive properties;

- high maintainability - in case of partial damage it is quite easy to repair the damaged surface with its help;

- large temperature range from -50 to 1200 ° C;

- have high elasticity;

- good resistance to ultraviolet rays;

- very good atmospheric resistance;

- the operational period reaches an average of 15 years and even more, depending on external conditions;

- in most cases does not require additional finishing;

- is an excellent binder in itself.

Technology

When using this material, virtually no special tools, tools or equipment are required. Almost all the work with the use of this material is performed using a conventional roller and brushes.

If the working area is too large, then in such cases airless spraying apparatus is used.

Technology of applying polyurethane mastic

The whole technology can be reduced to three stages, as it is very simple.

- First preparatory stage. The entire surface must be cleaned of all kinds of debris and various contaminants, for example, traces of paint or oils. If necessary, additional work is carried out to remove dust and dry the surface. If there are significant cracks on the surface, it is better to seal them with a special elastic sealant, but not necessarily depending on the specific case.

- Now consider the main stage - applying mastic.It is carried out in two or more layers evenly over the entire surface. Each subsequent layer of mastic is applied after complete polymerization of the previous one, which is approximately from 6 to 20 hours, in each case is determined individually. It depends on factors such as temperature and humidity.

- Final stage. After the entire surface has been processed, it will be ready for operation after 24 hours.

Prior to the expiration of this time, it is recommended not to produce any external effects on the treated surface.

Technology of applying bitumen mastic

The bituminous composition is applied with a roller or brush. If the consistency of the mixture is quite liquid, a spray may be used. The primer is applied in 1 layer, and if the surfaces are highly absorbent, then it is applied in 2 layers.

Polymer-bitumen mastic is used for insulation, and with the help of these compounds, you can create durable and very reliable protection of houses and buildings from moisture penetration. As a material for waterproofing, bituminous mastic is one of the most economical and reliable ways to seal various surfaces.

This material is most common in the field of construction and repair due to the fact that the use of this building material does not require any special skills, abilities and years of experience. This task is feasible for almost everyone who is engaged in construction or repair.

Today, bitumen-polymer waterproofing is a leader in the construction and repair sector of roofing and other structures where high tightness and durability is required.

The main distinguishing characteristics of bitumen mastic

According to its properties, bitumen is a solid organic resinous and highly soluble substance. Its density is 0.95-1.50 g / cm ³. It is a mixture of hydrocarbons and their derivatives. Oil derivatives are classified as natural bitumens, while synthetic compounds are considered to be components derived from the residual products of shale, coal and oil.

Bitumen curable fire retardant mastic for waterproofing is a highly elastic building material. It has a rather viscous and restorative characteristics, so it creates a waterproofing continuous membrane over the entire surface. In the market there is a large selection of bitumen mastics.

These compounds are produced mainly from petroleum-bitumen raw materials and may have different properties and composition, and therefore their purpose.

With the help of bitumen mastic, you can effectively solve a whole range of tasks, for example, waterproofing, anti-corrosion treatment, priming, bonding of rolled materials, and performing various repair and building roofing works.

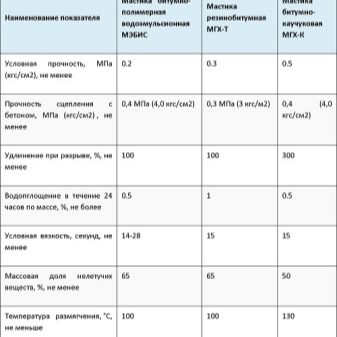

Bituminous mastics are classified according to the composition:

- Bituminous. Their main features are low price and relatively short lifetime.

- Rubber-bituminous. Excellent for applying a waterproofing layer or for fixing roll and other materials. Their elasticity is the highest, so they are very durable material and very resistant to external influences. The most popular area of application of these compositions is waterproofing and repair of roofing. They can be applied directly to the old layer of the roofing pie.

- Bitumen compositions with mineral fillers. With their help, you can create a very durable coating, so they are mainly used in the roofing work.Compounds with mineral fillers are less elastic than with bitumen-rubber, so, for example, in waterproofing the floor they are better not to use.

- Bitumen-polymer. Their composition may include various modifying additives, plasticizers, flame retardants, artificial rubber, steam formers and others. These compounds are the highest quality and durable, their price is the highest. These mastics are widely used in the repair of the roof and its device, as well as for insulation of building structures, foundations, pipelines, critical nodes, various joints, expansion joints and abutments.

- Petroleum bitumen or bitumen-emulsion. They are liquid formulations. Most often they are used as primers.

Bitumen Mastic Applications

According to the method of application are divided into compositions of two types:

- Cold formulations. Ready mixes concern to this type. Before use, they just need to stir very well, and you can immediately use it.

- Hot Formulations. Before applying these compounds must be heated to 160-180 ° C.

The main features of the use of bitumen-polymer mastics:

- no need to stick on a pre-heated layer of bitumen, the application is made by fusing, which allows to greatly improve the quality of waterproofing;

- bitumen-polymer mastic can be used at any time of the year;

- when working with these materials, there is no need to make special barriers to prevent shifts of the waterproofing layer;

- They are highly resistant to foaming, quite durable and light, quite resistant to corrosion, wear-resistant and have high water resistance.

To learn how to perform an urgent repair of the roof with liquid mastic, see the video below.