Waterproofing joints: types of materials and sealing technology

During the construction of buildings, special attention should be paid to suture insulation. The level of protection of the interior against leakage depends on the quality of the sealing of the seams. Therefore, you should take this process very responsibly, choosing the right waterproofing materials and observing all the nuances of technology during operation.

Necessary materials

The seam is a slit in the building structure. In the process of sealing it is filled with a special material.

Creating a seam waterproofing is a painstaking and responsible process, so only proven and high-quality building materials are used for it. Most often used for this:

- Ground mixes.They contain quartz sand, cement and various special chemical components.

- Waterproofing materials. During construction work, minor shortcomings are often ignored, which can lead to negative consequences: the appearance of mold, dampness on the ceiling and walls inside the building. To eliminate them, waterproofing materials are used.

- Very often, special hydraulic seals are used to eliminate and prevent leaks.

- An excellent option for seam sealing are waterproofing cords. In contact with moisture, they tend to swell, thereby filling the space and eliminate any leakage. However, it should be noted that this material is suitable only for small seams.

- Waterproofing keys are often used to optimally protect the building from moisture. They also perfectly compensate for the mobility of the structure.

- Special sealants.

In addition to the above, it should be noted the modern material of the new generation - the hydraulic key.

For the production of this type of waterproofing used special tires and the latest technology.High-strength and waterproof gidroshponki are made in various shapes and different sizes, which allows you to choose the appropriate option for any seams.

Waterproofing seams can be carried out between the plates in panel houses, underground structures, ceilings, in places of junction, etc.

Types of stitches

There are several types of stitches:

- sedimentary;

- shrinkage;

- anti-seismic;

- temperature.

Each of them has its own purpose and plays an important role in the overall structure of the building:

To prevent the appearance of various cracks in the concrete during the construction of buildings create shrink seams.

In regions with frequent seismic activity, antiseismic seams are used in the construction of various structures.

To avoid deformation of the structure, sedimentary seams are used. They are evenly distributed throughout the building structure, including the foundation.

Temperature joints are on the building structure, bypassing the foundation.

Ways to protect

Before proceeding with waterproofing, it is necessary to choose the appropriate method. It is important to consider some criteria:

- it is important to determine the depth and width of the seam;

- take into account possible loads on it;

- take into account the peculiarities of building construction and its subsequent operation.

Suture waterproofing can be carried out in the process of construction, during operation, as well as during repair work. In the process of building structures, certain types of seam sealing work are carried out:

- a special membrane is formed at the site of the seam;

- hydroshpals are carefully fixed;

- the seam is filled with sealant;

- A special elastic tape is fixed on the construction to improve the quality of sealing.

During the operation of the building, as well as during the repair, certain works are planned to improve the quality of seam insulation and prevent depressurization.

The seams are filled with special sealants or similar materials with high elasticity. Filling of seams is carried out also by means of acrylic or polyurethane pitches. For this, an injection method of waterproofing is used. Then elastic tapes and hydraulic splines are carefully attached at the joints.

Choosing the right sealant

Sealants and mastics used for suture waterproofing must meet certain requirements and comply with GOST. There are few such requirements, but when choosing a material you should pay attention to them:

- excellent adhesive properties;

- resistance to humidity, temperature extremes, various precipitation;

- environmental Safety;

- resistance to fire.

In addition to these requirements, you should pay attention to the elasticity and flexibility of the material.

The indicator of elasticity is very important to ensure long-term operation of the structure. Sealants are divided into low modulus and high modulus compositions. Low modulus sealants, after complete curing, are rubber.

The flexibility indicator indicates how elastic the material is at low air temperatures. This criterion is important in the construction of various structures in the northern regions.

In addition, waterproofing materials must maintain elasticity at different temperatures, high humidity, under the influence of sunlight.

Drawing

The technology of applying waterproofing is different depending on the type of seams.

Interpanel

Poor sealing of interpanel seams leads to negative consequences: there is mold on the walls of the room,damp, wet spots. To avoid these unpleasant moments, it is necessary to properly seal all seams. Suture waterproofing must be made from inside and outside the building. This process occurs in several stages:

- At the first stage, it is necessary to carefully remove the old insulating material and various construction debris from the seam.

- After the seam has been cleaned, it is necessary to apply a primer to the inner surface of the joint. Dry the primer coat thoroughly.

- Next, you should isolate the panel joints. To do this, you can use the foam or polyethylene foam gasket.

- Then over the installed special gasket you need to apply a layer of mastic or sealant. The waterproofing material must be applied in such a way that the interpanel joint does not act as a bulge.

After complete curing of the sealant, a special protective film should be stuck on the seam.

Deformation

The main purpose of the expansion joints is to compensate for the various loads on the structural elements of the structure. Such overloads occur under the influence of temperature extremes and seismic activity.Waterproofing of expansion joints should be carried out, strictly observing all the requirements and nuances of technology.

Greasing is carried out as follows:

- First you need to thoroughly dry the walls.

- Next, the expansion joint is filled with rubble. It is important to remember that the material must be dry. Crushed stone is filled up in several stages, gradually.

- Each layer of rubble is filled with bitumen. This is necessary for bitumen to fill all voids between fractions.

- Then the operation is repeated, and so on several times, until the expansion joint is completely filled.

Cracks

As a result of precipitation, vertical cracks often appear in the walls of various structures. First you need to identify and eliminate the cause of precipitation, and only after that you can begin to seal the cracks.

This is done as follows:

- slight damages on the surface of the walls slightly widen to make it easier to inject the mortar, while it is imperative to remove poorly adhering pieces of plaster;

- moisten the surface of the wall before applying the solution;

- the consistency of the composition of the waterproofing solution should be identical to the composition of the solution of plaster.

Ceilings

Suture waterproofing of the topcoat can be done in several ways. The best option is to use special impregnating compositions. Penetrating into the base of concrete, they are combined with salts, which are contained in the concrete composition. This forms crystalline compounds. These compounds grow, adhering to the base, and serve as an excellent protection against moisture penetration.

For suture waterproofing of the ceiling, in addition to penetrating compounds, you will need a special tape. The surface of the ceiling is thoroughly dried, cleaned of dirt and dust. Next, it is necessary to soak the joints and corner joints with the help of the impregnating compound. After that, the treated surface is thoroughly dried. A special tape is applied and carefully rolled using a roller. Then another layer of impregnating compound is applied over the tape. The surface is dried. Next, you need to process the entire surface of the ceiling with the help of the impregnating mixture. Two should be applied, in some cases three layers for more reliable insulation.

The choice of waterproofing method for each case should be carried out by an experienced specialist.

Injection protection

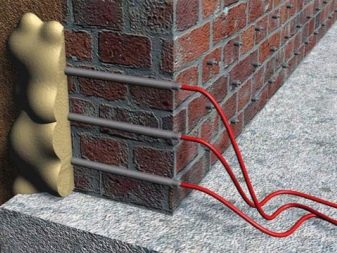

This method of waterproofing various joints is one of the newest and most effective technologies for protecting a building from moisture penetration. It is used to restore and protect structures in the most inaccessible places. This method allows you to perform a seam seal without opening the trim.

The essence of this technology lies in the injection of waterproofing solutions into the seams using a special injection pump. In this case, even minor cracks and seams are filled evenly due to the high pressure and a certain consistency of the solution. The polymerisation of the material takes place within a few minutes.

For suture waterproofing injection method uses special elastic acrylic and polyurethane resins.

In some cases, the use of epoxy resins is allowed. This material is most effective to restore the mechanical integrity of the building structure. Epoxy resins have excellent adhesion properties and allow you to seal up various damage to even the cold outer, though always warm, internal surfaces.But the connection, made with the help of such a material, turns out to be quite rigid, which does not always correspond to the operating conditions of the expansion joints.

More clearly the process of waterproofing injection method is presented in the following video.