Features of membranes "TechnoNIKOL"

The roof is the main component of the roof of any residential and industrial buildings. The warmth and comfort of the premises, as well as the degree of reliability of the building, depend on the well-chosen coating. For the formation of the roof structure, it is necessary to strictly follow the installation technology, and the specificity of the choice of materials to ensure reliability from premature moisture ingress into the structures of the laying layers.

Preferring insulating membranes of the industrial company "TekhnoNIKOL", do not have to regret about the big expenses.

Advantages and disadvantages

The company "TekhnoNIKOL" produces and supplies a huge range of heat-insulating, waterproofing materials, mastic, roofing materials, consisting of more than 10 items. It allows to establish a roof of the highest property. The entire list is of excellent quality and meets all construction requirements. The product is popular in the construction of the personal sector, industrial and urban buildings.

It helps to perform thermal insulation, sound insulation and waterproofing of various degrees of complexity of roof structures. Modern waterproofing material “Bikrost”, which has the highest reliability, elasticity, long operating life and excellent heat resistance, is perfect for waterproofing roofs.

TechnoNIKOL manufactures the following products, which have the appropriate quality certificates:

- roll materials;

- materials that protect against fire pipelines;

- insulation material for roofing and buildings that prevent the ingress of moisture;

- facing materials.

All presented products meet modern requirements for the protection and absorption of water.

Purpose

Production of the TekhnoNIKOL company possesses a huge range of action.

Roll materials

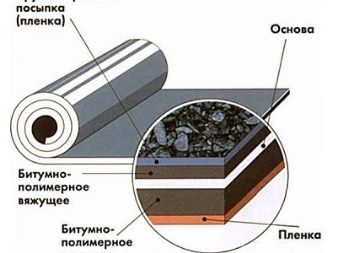

The presented type of roofing is used for waterproofing of transport structures, noise insulation of rooms, polymer membranes with absolute water resistance. And indeed, these products are from a number of bitumen-polymer materials, of the “Etalon”, “Business”, and “Premium” class roofing materials.

Polymeric membranes, which are used for thin roofing, have the highest quality and degree of reliability. It should be emphasized that the manufacture of polyvinyl chloride polymer membranes ensures long-term use of this material. It should be noted that the seams of this coating are sealed with hot air, which contributes to the best waterproofing criteria.

But also polymeric membranes have a number of advantages:

- UV resistance;

- opposition to various weather conditions;

- resistance to chemicals;

- resistance to microbes that can destroy and colonize in the seams of the structure.

Polymer-bitumen material is not subject to decay for a long time.And also the products have good air conductivity, which prevents the accumulation of condensate in the layers of the roof.

TPO-based membranes

Manufacturer TechnoNIKOL offers coatings based on thermoplastic polyolefins, which are the newest material. Polypropylene and ethylene-propylene rubber with different components are introduced into its composition, as a result of which the ability of resistance to fires increases, and the service life of the membrane increases. The entire product line is fire resistant, being a material that is safe during fires: polyvinyl chloride, which is a component, extinguishes the raw material for their production without supporting the spread of fire.

Waterproofing views of this flooring combine the characteristics of rubber and plastic.and, it is better combined with bitumen, unlike PVC-based membranes, are chemically neutral. All the described properties give the possibility of long-term use, simplify the repair process. Available in rolls from 1 to 2 meters wide, up to 2 mm thick, with a service life of up to 40 years.

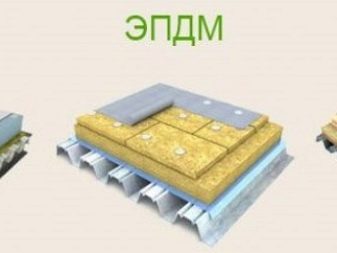

Membranes based on EPDM

Coatings on this base differ in elasticity coefficient, long service life, a huge range of temperature differences, reinforced and non-reinforced versions are offered.EPDM membrane - one of the first coatings of the company TekhnoNIKOL, has established itself in different weather conditions and has passed the test of time.

Additional details for work on difficult objects are attached to the kit - fasteners, sealants. To connect the boundaries of the polymer material, a self-adhesive tape, made from an EPDM polymer, is used, thanks to which a reliable, indivisible compound is released. They are issued in the form of rolls from 3 to 12 meters wide, up to 60 meters long, 1.14 mm thick, with a service life of more than 40 years.

Insulation of the building from the fire

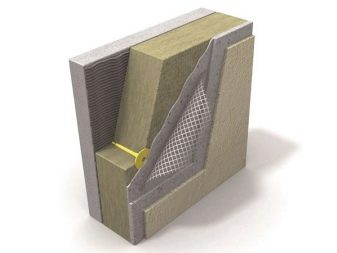

For this type of material, TekhnoNIKOL manufactures stone wool fire protection systems, extruded polystyrene foam and many variations of various products.

The entire proposed list of materials is produced based on the introduction of the latest technologies and meets all the stated requirements.

Pitched roof

In this direction, the company offers waterproofing materials, promising the highest reliability and long service life of products. And also the tile of various color schemes is presented.

Bitumens, mastics, primers

The company "TechnoNIKOL" is also mastic, successfully used in the repair of roofing structures, the installation of the roof. Presented mastic hot and cool types, bitumen emulsions and much more. The company also produces a huge selection of devices for the installation of flat roofs - aerators, various equipment for roofing.

Facing materials

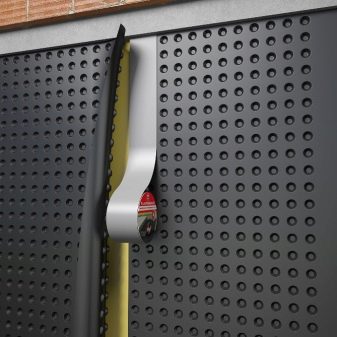

The tile for the design of the facade has a characteristic density, resistance to corrosion, an interesting color spectrum. The company "TekhnoNIKOL" produces a large range of materials to protect houses, urban and industrial buildings from moisture. Planter - the newest line in the development of the company. The Planter protective coating is used as a top layer for waterproofing the roofing surface, reliably protecting the roof from the effects of natural anomalies.

Planter - a protective synthetic material in the form of a roll, on the surface of which hollow spikes are extruded. It is created from cellophane of the highest density using extrusion technology. This is an automatic process, during which all technologies are strictly followed.The density of cellophane is achieved by a special formula, otherwise pressing is done without seams, thereby creating a holistic insulation.

The advantage of the diffusion material in retaining its own properties even at the lowest and highest temperatures, it has elastic resistance to chemicals, environmental friendliness, which allows the material to be used in the interior. It is used in the construction of residential buildings and industrial buildings.

The main advantages:

- enhanced damage protection;

- water drainage;

- replaces a layer of concrete before installing the slabs;

- is a draining base when laying tracks.

Laying this material on a wet surface provides air circulation due to hollow spikes.

Product Overview

Concern "TehnoNIKOL" has a huge range of products. Consider the most popular specimens.

Planter standard

"Standard" is a unique material, whose thickness is 0.55 cm. The super-diffusion membrane is used for the outer layer of the foundation, ensuring its protection against pressure, damage, promotes the discharge of water. Can serve as an initial layer under the foundation, can be used to isolate the walls in the basement.

Eco membrane

This membrane in a production of the TekhnoNIKOL company takes a prominent place and is not inferior in quality to Planter Etalon. The material is widely used in private construction. Eco membrane can replace bulk concrete cushion under the foundation.

Extra Products

It is used for the flooring of stylobates in high-rise buildings with complex structures, in the construction of roads, bridges, tunnels, parking lots, basements, it is notable for its increased strength and elasticity.

Planter geo

In terms of structure, this material consists of two layers created from profiled cellophane, with the addition of material that delays the penetration of water - geotextile, and has drainage protection. A cloth attached to the spikes increases the ability of the water to be removed, but at the same time delays foreign particles and soil deposits.

Planter Geo Extra

Geomembrane is used in drainage sewage to insulate pipes at a depth of 10 m. Provides protection for open tunnels, is used to install roofs on the roofs of huge objects, when organizing very large areas, roads and stadiums. It differs from previous products by the ability to endure imposing overloads, with an increased density.

Apart from the basic materials, the company manufactures and supplies all auxiliary elements for high-quality bonding and fastening of the main parts. Fixation is made in any position both vertically and horizontally.

- Dowels with washers are used for installation of cloths with a large area on a vertical surface. The washer is designed in the form of a special form, which allows you to moderately distribute the weight to one fastening unit. The elements are made by gluing the base, which allows you to firmly fix the canvas without the formation of "cold bridges".

- Planterband recommended for fastening joints and sealing seams, has an adhesive base, is made in the form of a tape. Development of laying membranes Planter has a fairly simple method, does not require special equipment and the use of hot methods.

- Nikoband - material designed to connect parts with overlapped edges. Consists of aluminum, adhesive base of bitumen. The adhesive layer is protected by an invisible film. When laying the membrane horizontally, Planter and Etalon are laid on the ground that has been cleared of stones and debris beforehand, the recommended height of the gravel bed is not more than 10 cm.

When folding webs, it is necessary to check the absence of folds and folds, the roll is laid down with spikes and covers the edges of the webs that need to be taped together on the base of aluminum.

During the installation of the geotextile fabric the connection takes place in two steps. Raising the textile layer, connect the polyethylene base with adhesive tape, repeating the connection of laying layers. In residential buildings, the canvas is spiked upwards, providing thermal and waterproofing, strengthening the connection with polymer-bitumen tape.

Specifications

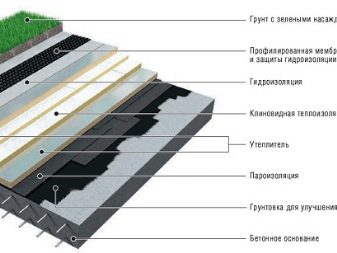

Covering the roof of various buildings is the main point in construction. The quality and the upcoming operation of the facility depends on the right work. The modern market offers a wide selection of roofing materials that meet all the criteria presented. Membrane coating allows seamless connection of its parts. The method is suitable for all types of roofing and provides waterproofing, which eliminates the need for good protection against water.

The TekhnoNIKOL company offers different types of PVC-based roofing membranes, which have been recognized in the market for quite a long time and are in demand due to their technical characteristics.These membranes enable the joining of roofing materials, ensuring the density of the coating.

It is used for flat roofs with a small slope. The PVC membrane replaced the previously required EDPM, being an elastic waterproofing material made from polyvinyl chloride. There is a high windproof fortress and hydro-windproof reliability. Such a roof will provide a reliable windproof and ventilating degree of protection.

The PVC membrane "TechnoNIKOL" is distinguished by a huge list of advantages, unlike other materials:

- does not require additional protection from water;

- the development ensuring lack of seams thanks to which it is possible to receive a complete surface

- resistance to microbes and chemicals, no need to prematurely protect the surface from mold and mildew;

- retains its characteristics when temperature drops;

- ease of installation, allowing work on the tallest buildings;

- the coating ensures a similar degree of protection at different angles of inclination and in the joints of the material;

- vapor-permeable membrane that ensures the preservation of a dry place in the roofing layers, where insulation can be used, ensuring its safety.

The introduction in the production of these membranes reinforcing mesh gives them the highest degree of strength and elasticity due to plasticizers and stabilizing substances. Installing this material is a fairly easy process, with the promised long-term use.

Types of PVC membranes

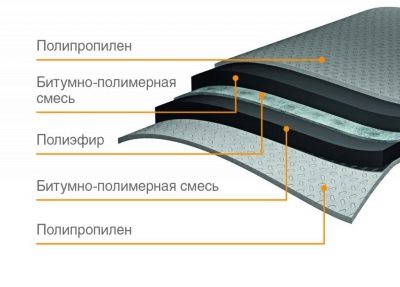

It should be mentioned that all coatings have a subsequent structure:

- textured PVC - has a protective effect;

- reinforcing mesh made of polyester;

- High quality polyvinyl chloride is also an integral part.

Consider the composition of the membrane.

- Soft top coat membrane is a flexible base based on PVC, able to withstand different external influences. Its composition does not support combustion and ensures the reliability of fire on subsequent layers, it contains the highest concentration of ultraviolet absorbers.

- Reinforcing layer is an average in which fibers and polymers intertwine, forming a dense mesh capable of withstanding external overloads.

- Extreme layerconsisting of polyvinyl chloride, protecting against the adverse effects of the contact surface.

PVC membranes differ in several types, consider the most popular.

- Ecoplast V-RP. The membrane is used as a waterproofing method for the roof. The surface of this product has an anti-slip embossing, making it safe to work during precipitation. Apart from this, it makes it possible to work on a roof that has a slope of more than 10%.

- Ecoplast V-GR. It has puncture resistance, as it has glass-reinforcement. It contains antifungal additives, is resistant to the action of the sun.

- Logicroof RP. The material reinforced with a polyethylene network, with protection against an ultraviolet, as a part of which fire-retarding agents and the stabilizing components. Inflated elasticity, which provides the ability to work at low temperatures.

- Logicroof V-SR. This material is used during the installation of the junction, with various designs, being not reinforced.

- Logicroof Artiks. It is used in regions with low temperatures, three layers have dimensional stability, there are flame retardants and a certain type of stabilizers in the material, which simplifies installation in the cool season.

- Logicroof. This material is used for waterproofing a flat roof thanks to plasticized partPVC, has resistance to ultraviolet radiation, you can work at unstable temperatures.

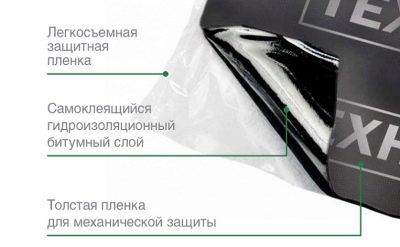

- Logicroof T-SL. The material is used in the construction of bridges, tunnels, foundation foundations, providing waterproofing of objects. It does not have a layer reinforced with a network, it is distinguished by the presence of a yellowish, distinguishing layer.

- Membrane LogicPOOL. This material has two layers, used for cladding, decoration, waterproofing in the arrangement of swimming pools. The basis of the membrane is a high-quality plasticized polyvinyl chloride, covered with a protective layer of acrylic.

Dimensions

Considering the produced polymeric membranes, it is necessary to consider the dimensions of the mounted surface. Depending on what area of overlap will have to be laid, whether it is a production or a private structure, thus the size choice of products is carried out.

The sizes of rolled membranes vary:

- 2x20 m;

- 40 m2;

- 1.5 x 50 m

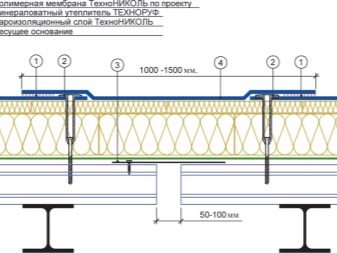

Laying technology

Installation can be done in several ways. It is recommended to perform the joint by thermal welding as a more efficient way to guarantee the density.The recommended width of the weld is not less than 2 and not more than 10 cm. Stages of work with the introduction of PVC membranes: to simplify the upcoming welding of the seams, we should painstakingly fix the sheets, providing an “air pocket”, perform welding on the joints of the sheets, followed by checking the quality of the work done.

Installation is recommended to create according to the annotations for the installation of PVC membrane. Consider the main points.

- We painstakingly clean the surface on which you plan to apply the material from dirt, dust, debris and parts that damage the surface.

- It is also necessary to clean the surface of the material being welded, while using a wet cloth, PVC cleaner from TechnoNICOL.

- Moderately spread the canvas, removing air at the points of contact.

- Putting each part of the membrane into a single structure.

- Hot air soldering design is applied, which allows installation to be done in a faster time.

- Try to secure the coating around the entire contour and at the junctions of the membranes. Apply a thin layer of adhesive for PVC membranes from "TechnoNIKOL".Its special structure allows, without difficulty, to make the installation, with the quality of bonding not lost, forming a transparent invisible seam.

To join the individual parts of the material on the surface of concrete, a consistency of glue and different compositions is used.

A special formula containing not only the adhesive base, it also has a rubberized structure that allows you to connect the concrete and the surface of the membrane due to structural penetration into the surface of the joined parts.

The adhesive solution is cool, allowing the bonding of materials of different composition, giving a strong base. But it is also possible to remove individual damage to the membrane to preserve the integrity of the cover, while ensuring absolute density, able to perform excellent waterproofing. When working with adhesive mixtures, it is recommended to take into account the temperature conditions.

Materials based on PVC are the most modern, the term of use of which can last up to forty years. You can use them to install and repair a variety of roofing.

They are mixed with almost all materials, whether metal or wood, with huge angles of inclination of the roof. Naturally, you can see the disadvantages of roofing:

- rather rapid loss of brightness of color, especially in sunny regions;

- incompatibility with solvents, extruded polystyrene foam, bitumen-containing materials, due to the release of volatile fractions harm to the environment;

- the inability to apply the adhesive method of installation.

During installation, you should consider all the nuances in preparation for installation:

- Material is recommended to be stored away from heating devices in the package, in the prone position;

- To obtain high-quality welding, you should use a measured voltage in the contact network.

For high-quality installation and installation it is recommended to use the following tools:

- automatic hair dryer;

- probe to check the seam;

- elements for fasteners;

- cleaner "TechnoNIKOL";

- slotted nozzles;

- stitching rollers.

The instruction, developed by TehnoNIKOL specialists, will ease the complexity of installation work:

- the size of the roof installed around the perimeter to the vertical surfaces of a profile covered with galvanized steel 0.7 mm wide should be determined by the size of the mounting area;

- we strengthen through passages with the same sheet in the size of the hole;

- installation of thermal insulation;

- webs of the membrane are laid with overlap of 60 cm using dotted rivets;

- inserting a hot dryer, we make a bonding of the weld.

After the connection is ready, it should be checked by testing with a probe to make sure that it does not leak into the seam, then treat the connection with an aqueous solution of PVC.

At observance of councils of the manufacturer the highest quality of a roofing surface and service life not less than 30 years is guaranteed. Using the products "TechnoNIKOL", purchase it only from decent sellers, making the installation only with the help of specialists.

In the next video you will find waterproofing the foundation with materials "TechnoNIKOL."