Rules for using liquid waterproofing

Most building materials, except plastics from polymer and natural stone, have insufficient water resistance. In order to protect these materials from moisture, various types of waterproofing protection are used. As such protection, sheets of roofing material, polyethylene, materials of bitumen are used, but their disadvantage is that they cannot penetrate into all the pores of the protected material.

Currently, widespread use of liquid waterproofing, which has the ability to completely fill all the surface pores of the material, as it has a liquid state of aggregation.Such waterproofing can significantly increase the service life of the protected material.

Liquid waterproofing is a relatively new type of protective material that has already proven itself from the best side. Fluid like rubber or polymer penetrates deep into the material being processed and turns it into a single monolith.

It does not require any heat treatment.

Special features

Among the main qualities of the material are the following:

- With this insulation, you can eliminate all the disadvantages of the treated surface, for example, potholes and cracks.

- Adhesion has high rates.

- A wide range of methods and methods of applying insulation allows you to choose the best solution, depending on the type and amount of work being done.

- The long service life of the insulation will allow you not to change it very often, this work is done for many years.

- The insulation coating is holistic and seamless.

- This coating perfectly repels moisture.

- Waterproofing well withstands all kinds of negative impacts, both natural and artificial nature.

- There is the possibility of using the material both indoors and outdoors.

- Waterproofing has no restrictions depending on climatic conditions.

- It is not an obstacle to normal air circulation.

- Liquid insulation is an environmentally friendly material.

Installation of such insulation in a wooden house should be carefully considered. The material can be used for outdoor construction of wood or metal, as well as for interior work.

You must first remove all interfering insulation design.

Kinds

There are several types of waterproofing layer of this type. Before choosing it is important to familiarize yourself with the characteristics of each of them:

- Liquid glass. This type of waterproofing is used in construction for a long time. To create it use the same materials as for the manufacture of ordinary glass, so he got this name. Such waterproofing penetrates into all cavities of the processed material, as a result a uniform layer of protection is obtained. This material is colorless and odorless, so it can be used both inside and outside the room.

- Liquid rubber. This type of liquid waterproofing is also called membrane. The main component is latex, thanks to this rubber has high water-repellent properties.It is used to protect walls, foundations, roofs. Such waterproofing is applied with a special sprayer and penetrates into all cavities of the protected material. When interacting with air, a moisture resistant membrane is formed.

- Polymer materials. The basis of the liquid waterproofing - polymer-sand-cement mixture, which is able to penetrate deep into the material being processed. Before applying this protection, the material is primed. Such protection in most cases is used for foundations, as it is not afraid of temperature changes and is resistant to the appearance of fungi and mold.

Liquid rubber

The material has the following advantages:

- This type of waterproofing reliably binds the surfaces of any materials, regardless of their structure and age.

- The substance can penetrate into all cavities of the processed material, filling them with them.

- It perfectly protects the surface of the material from corrosion.

- Rubber can not be deformed, as it has a high elasticity.

- Environmentally friendly material is completely non-toxic.

The disadvantage includes the following nuances:

- To work with liquid rubber can only be a professional, because when working using specialized equipment that can be dangerous.

- Such waterproofing is expensive, but it pays off its benefits. In addition, it is a durable material.

- It is necessary to additionally cover with special paint.

- The material does not have an attractive appearance.

Coating methods

There are the following methods of applying liquid rubber:

- With the help of special installations, two-component rubber is sprayed onto the surface to be treated.

- From high-pressure equipment, one-component rubber is sprayed.

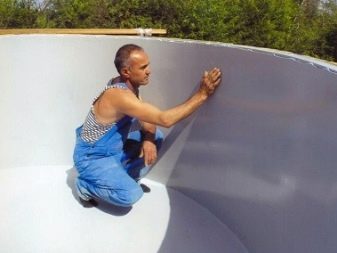

- Developed a special liquid rubber that can be applied manually.

Liquid rubber is able to meet all the requirements of companies engaged in waterproofing. It allows in a short time to carry out large volumes of work on the waterproofing of the surface.

For example, in 8 hours of work a builder can cover up to 1000 square meters of surface.

Two-contact equipment is used, with the help of which monolithic coating is achieved.The first layer is formed in about 10 seconds due to the evaporation of water, the second layer is applied to it. Due to this, such waterproofing has become very popular among builders.

When applied to a waterproofing brick, it must be dry and clean, otherwise condensation will form, which is unacceptable. Therefore, in most cases, a waterproofing layer is applied outside the building. For masonry brick mainly use the composition, which is applied by hand.

This composition has a not very attractive appearance, and therefore is rarely used in the construction of private houses. When working, the specialist must use personal protective equipment.. Builders also recommend putting on this layer another layer of additional protection, for example, from hail.

The service life of such waterproofing is more than 10 years.

Liquid glass

Such compounds are mixtures of a solution of potassium and sodium silicate. Liquid glass has the following advantages:

- It well maintains various mechanical influences.

- Due to such waterproofing, the base hardness increases.

- The use of such waterproofing allows you to speed up construction time.

- The cost of work decreases.

- Part of the solution penetrates the base.

- Even small cracks are filled with a mixture.

- Such glass excellently repels moisture, and also increases the refractoriness of the processed materials.

The most common uses for liquid glass are:

- It is used for waterproofing walls in residential areas.

- The substance is added to the solution in monolithic construction.

- With the help of liquid glass can strengthen the soil.

- The composition is used for the manufacture of screed walls, ceilings, floors.

- The material is used in the construction of pools, wells.

- The similar component is added to plaster mix for increase in durability.

- With it, the treated surfaces of bathrooms.

Recommendations for the use of liquid glass:

- When applying insulation, the air temperature should not be lower than 5 degrees.

- It is not recommended to apply a waterproofing layer on external surfaces if frosts are expected in the future.

- If the base is covered with frost, waterproofing is not acceptable.

- Processing of horizontal surfaces is not permissible in the presence of puddles.

Polymer materials

The advantages of this type of waterproofing:

- The elasticity of waterproofing has an optimum level.

- The material has a long service life - up to 50 years.

- The variety is suitable for both spot repair and large surface coating.

- This waterproofing can withstand almost all negative environmental factors.

- Waterproofing can be applied to any surface.

- Such waterproofing can be applied independently.

Disadvantages:

- does not withstand high temperatures;

- lack of environmental friendliness;

- relatively high price.

The coating is carried out according to the following technology:

- First there is a preparation, cleaning and alignment of the surface being treated.

- With the help of an airless pumping unit, waterproofing is applied to the surface to be treated. It is also possible to apply manually with a brush or roller.

Waterproofing coating should be carried out in two layers.

Use in construction

In the construction of private houses, this type of waterproofing is used in most cases to protect the foundations and roofs of various utility rooms. During the construction of the roof can be applied three basic methods:

- Bulk way to. In this case, bitumen-rubber, polymer or bitumen-polymer mastic is used as the base material. Both cold and hot pouring methods can be used. The shelf life of this coating is 20 years.

- Painting way to. In this case, enamels or paints, which are based on polymer bitumen, act as polymer waterproofing. This coating with brushes or rollers is applied to the treated surface. The service life of such a coating is not great and is about 5 years.

- Penetrating way to. It is applied in the event that the processed surface is porous. Waterproofing is carried out using a spray gun, polymers in the liquid state penetrate into the pores of the material.

Bulk method

By this method, insulation is applied on the floor or on a flat roof.

- carry out the dismantling of the old cover, collect all the garbage;

- make cleaning of the processed surface;

- ground the base with bitumen emulsion;

- wait until the solution seizes with the base;

- pour liquid waterproofing on the treated surface so that the layer was 2-3 mm;

- level the solution;

- they pause and allow the solution to freeze (usually it takes 2-3 hours);

- pour the second layer;

- Allow the solution to dry for 2 days.

Applying waterproofing by staining

This method is used if the area of the treated surface is small. This method of applying waterproofing does not require the use of special equipment.

It looks like the following algorithm of actions:

- carry out the preparation and cleaning of the base for the application of insulation (this procedure must be carried out very carefully);

- the base is processed with a bitumen emulsion;

- wait for the time until the solution dries (approximately 1 hour);

- Using a brush or roller, apply a basic waterproofing layer of 2-3 mm;

- level this layer;

- after a technical pause, an additional waterproofing layer is applied;

- wait until the waterproofing completely hardens.

Spray Insulation

This method is used for processing vertical planes, surfaces that are difficult to reach, or with a large amount of work. The application of waterproofing is carried out at high speed, but it is necessary to use special equipment and perform actions in a certain order:

- The base is being prepared and cleaned.

- The device for spraying is connected to tanks in which there is a liquid waterproofing with a hardener.

- The substance is sprayed in the required direction. There is a formation of a layer thickness of 2-3 mm.

- It is necessary to wait until the solution hardens (approximately 2-3 hours).

At construction of the bases the bulk waterproofing method is applied. In most cases, hot bitumen-polymer or cold epoxy-rubber mastic is used. Carry out the application of such waterproofing on the prepared surface to be treated in several layers. Sometimes produce reinforcement polymer insulation. A layer of mastic is applied at least 15 cm.

When using polymer insulation it is necessary to carry out a sufficiently long drying. (from 1 to 10 days at a temperature not lower than 18 degrees). Such waterproofing ensures reliable preservation of the surfaces being processed and does not require large expenditures of money and time.

When using liquid waterproofing in construction, regardless of its type, you must follow all the rules for its use, which are indicated in the instructions. This is extremely important.

Only in the event that all the rules and regulations are followed, you will receive a reliable waterproofing coating that is guaranteed to last the entire lifetime and protect the constructed structure.

How to repair the roof with liquid rubber, you can find out by watching the video below.