Izospan D: features and scope

Izospan is a modern material, which in recent years has become particularly popular due to its high performance. At its core, it is a film of polypropylene, while emit different options depending on the basic components in the structure of the coating. One of them is Izospan D.

Properties

The Gexa brand appeared on the Russian market in 2001. It offers users high-quality material Izospan D. Due to its high quality and durability, this material almost immediately conquered the market and became one of the largest European counterparts.At the same time, the domestic version is much cheaper than foreign ones, which means it is more accessible for the majority of our compatriots. That is why the brand is in high demand among the owners of country houses, and professional builders also unconditionally give preference to it.

At its core, Isospan is a special film materials, tapes and membranes, which are widely used to protect insulation and a variety of wooden structures from adverse weather conditions, such as rain and wind. The main sphere of use of Izospan is the external building structures, including the arrangement of the roof and the installation of a ventilated facade.

Izospan marked D was one of the most sought-after varieties.

From a technical point of view, this material is a polypropylene film consisting of two layers.

Its main purpose is the effective protection of buildings and other structures from the damaging effects of atmospheric moisture and vapor condensate. The first layer of the film is made of durable and very dense polypropylene canvas, and the second layer is the polypropylene film itself.

This structure causes a number of high performance coatings, namely:

- creates a fairly efficient and reliable barrier to moisture and condensate;

- shows resistance to any atmospheric influences (temperature drops, rain, snow, hail, as well as ultraviolet radiation);

- retains its physical and technical properties for a long time;

- It is characterized by increased tensile strength and punctures of different origin.

If we talk about the technical side, we can distinguish the following properties of Izospan D:

- the typical roll size of the vapor barrier Isospan D contains 70 square meters. m of material, the film length is 1.6x43.75 m, and the mass of the roll is 7.7 kg;

- coating density is 105 g / m²;

- ultimate tensile strength in longitudinal and cross section is at least 1068/890 N / 5 cm;

- the main component in the structure of the material is 100% polypropylene;

- The minimum resistance to vapor permeability is 7 square meters. m • h • Pa / mg;

- the water resistance of the hydro- and vapor barrier of Izospan D is at least 1000 mm of water. v .;

- The estimated operating temperature range is from -60 to + 80ºС.

Purpose

Paros and waterproofing film Izospan D is universal, it is widely used in various fields of repair and construction. The use of the material in the formation of the roofing cake, as well as during the installation of floors and floors, helps prevent premature rotting and destruction of building materials.

Izospan D can be used both as a steam and as a hydro insulator, since one of its layers effectively absorbs all the condensate, which then evaporates completely, without causing the slightest harm, and the second side of the film does not allow water to flow outside.

In the cold roof, Izospan D reliably covers and protects the attic space from moisture penetration, thereby contributing to an increase in the service life of the elements of the batten and attic floors, the Izospan D gasket allows maintaining the technical and physical properties of the insulation.

Another area of application is the creation of warm and practical floors on the concrete surface and the ground., protection of a log and floor coverings from soil moisture and destructive influence of ground waters. This function is especially relevant for monolithic concreting.The material is used to protect the structural elements of the building from the negative effects of moisture formed by condensation or evaporation.

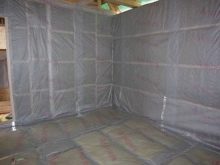

The membrane is also applied to the walls, and it not only performs a waterproofing function, but is also used as a heater. The coating contributes to the creation of a favorable microclimate in basements and in attics with high humidity, as well as the material is placed when arranging the basement.

And finally, Izospan D is commonly used for thermal insulation of baths, showers and pools.

Advantages and disadvantages

The wide popularity of Izospan D is due to its exceptionally high performance properties.

The advantages of the material include the following:

- durability - Coverage can last more than 50 years;

- heat resistance - the membrane has a wide operating temperature range, it withstands both frost in the winter season, and heat in the summer;

- weather resistance - Izospan D retains its physico-technical properties in adverse weather conditions;

- reliability - the top layer is covered using lamination technology, which causes the most effective hydro and vapor insulation of the film.

However, nothing perfect and perfect has yet been invented, which is why Izospan D is not without some flaws. These include low vapor permeability, which significantly limits the scope of application of the coating, allowing it to be used only on cold roofs. For warm roofs, other species of Izospan should be preferred, for example, Izospan AM.

Despite the fact that this insulation product is considered to be the reference and the most common among other building materials, there are also its analogues. They are characterized by similar technical parameters; nevertheless, all of them belong to first-generation counterparts, characterized by the old set of hydro- and vapor-insulating characteristics, while Izospan D is the second generation of effective insulation materials.

Installation Tips

Regardless of on what surfaces and for what purpose Izospan is mounted, there are a few general rules for installing vapor barrier coatings.

- The manufacturers of the membranes found that their working range allows you to successfully withstand temperatures up to -60 degrees. However, experts recommend laying vapor barrier materials at temperatures not lower than +25 degrees. In this case, the instruction allows the installation of the canvas both inside and outside the building.

- Heat-insulating material is attached to the facade with a construction stapler, at the same time the strips of coating are fixed with an overlap, the size of which should not be less than 15 cm. The seams and joints must be fixed with double-sided tape.

- During the installation work it is necessary to pay special attention to the fact that there were no coating defects on the surface and violation of the integrity of the material, areas of excessive tension is also better to avoid.

- To achieve greater durability and reliability Izospan D is fixed to the wall with the help of wooden bars, at the same time the slats should be fixed in increments of 30 cm, this is necessary for arranging the ventilation gap, which improves the removal of condensate to the outside. If work is carried out on a ventilated facade, then a three-layer hydro and vapor barrier system should be installed; for this, a layer of insulation is placed between two layers of Izospan.

These are the general principles of working with the product, however, when working with surfaces of different types, there are some peculiarities and nuances. It is necessary to dwell on them in more detail.

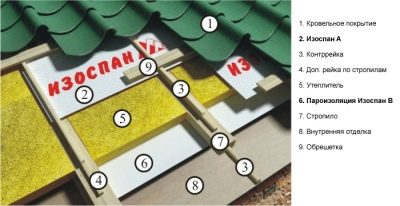

Installation of not warmed cattle roof

The cold pitched roof is insulated in such a way that the panels are located horizontally and strictly along the line of the rafters of the walls.

Directly installation of the film begins at the lower edge of the mansard roof, the material is overlapped, and between the horizontal and vertical joints it should be at least 15 cm.

Fix the insulating material on the rafters of the walls should be using the kontreek of wooden bars. After that, they are laid solid flooring, made of boards. At the finishing stage, it will only be necessary to glue the joints of the webs with a building tape., and you can use any option, since the brand and the manufacturer are not of fundamental importance.

Construction of a flat roof

When installing a vapor barrier coating on a flat roof, a roll is rolled over the surface of the base, and the overlap should be at least 15–20 cm.As in the first case, the joints should be insulated using construction tape.

Experts recommend using a tape of the same series (Izospan SL), since they belong to the same type of materials and are most suitable for each other in terms of adhesion.

However, the use of tape and other manufacturers. The film on top is covered with a layer of insulation or a special roofing coating, which in its functionality corresponds to the insulating material.

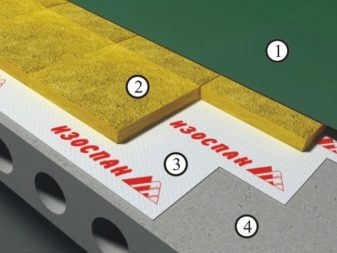

Arrangement of a concrete floor

If the material is laid on the floor with a concrete base, as in the previous cases, it is necessary to observe an overlap of at least 20 cm. To minimize the likelihood of irregularities in the future, cement screed should be applied to the surface of the coating. Such vapor and waterproofing is made with the mandatory installation of membrane material on the walls of about 10-15 cm.

It should be borne in mind that Izospan D protects the concrete floor only from the bottom, which is why the material can be laid completely by any side. To increase the efficiency of such work is best done using a construction stapler and special construction rails.

Izospan D refers to the roll-type materials, so any installation is not complete without joints, which are formed due to restrictions on the size of the canvas. For their maximum isolation and adhesion among themselves use building tape and other types of adhesive tapes.

At installation any types of the gluing materials can be used. However, experts recommend to give preference to brands that are produced by the same company.

According to consumer reviews, the best adhesive tapes that most effectively fix the edges of the membrane are considered to be the following:

- tape SL - it is a connecting material with a double sticky surface. Due to this structure, the tape can bond between two parts of hydro and vapor insulation, and at the same time achieve complete sealing of the seams. Maximum adhesion is formed on clean surfaces in conditions of positive air temperatures;

- scotch FL Termo - this is another connecting tape, however, which has its own structural features. This tape has a metallized layer, which contributes to an increase in tensile strength and wear resistance.By the way, this material can be used not only to seal the seams, but also to repair the web with minor violations of the integrity of the coating;

- ML Proff tape - it is an adhesive tape with one sticky side, however, the adhesion indicators of the adhesive composition are quite high, so this tape is used on the most difficult compounds, for example, at the junction of the membrane to surfaces with increased porosity - to the structural elements of concrete and brick.

On the use of films IZOSPAN, see the following video.