PVC membrane for roofing: choice of waterproofing film for the roof

One of the most important stages in the construction of buildings is the waterproofing of the roof and facades. Not only the quality of the roof, but also the general condition of the whole building depends on the installation technology used and the quality of the insulation materials. To date, the most reliable protection and the best tightness of the roof provide membrane materials.

What it is?

PVC membrane has gained great popularity in recent years, this is due to its high performance, as well as ease of installation.

The product was first introduced on the market more than four decades ago and almost instantly won the hearts of European users.In Western countries, over 80% of all roofs are fitted to the PVC membrane. Not so long ago, this material appeared in our country.

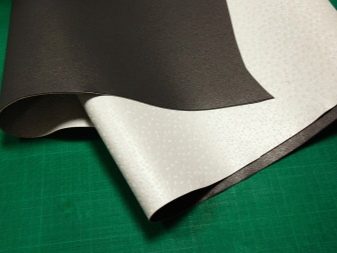

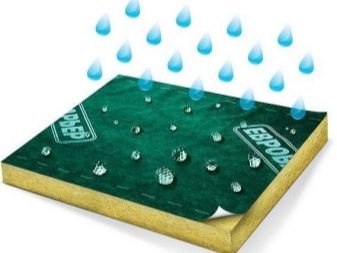

From a technical point of view, the membrane is a special waterproofing coating based on polyvinyl chloride.

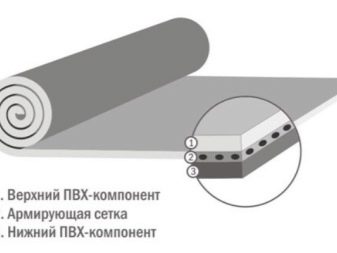

The membrane structure includes three components:

- the top layer is made of PVC - it determines the hygroscopicity and resistance of the coating to ultraviolet radiation and temperature fluctuations;

- mesh reinforcement of polyester filaments and fibers;

- the lower layer is of a much darker color - this is very important - in situations where any deformations (dents or tears) occur on the roof, then the damage place will be perfectly visible, which means it can be quickly performed repair work and eliminate roof leakage.

What is it for?

Membrane waterproofing suitable for the device as exploited and unexploited flat roofs. It is widely used in the construction of shopping centers, business complexes and industrial enterprises. In the private low-rise housing construction material is used quite rarely - this is due to its high cost. There are more often used sheet insulation materials.

The membrane is distinguished by high performance:

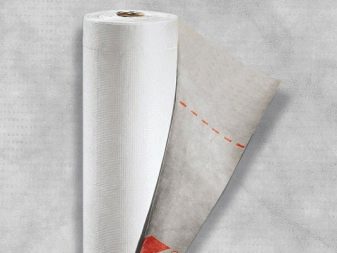

- the product has a low weight, therefore it does not exert much pressure on the bearing floors of the building and its foundation, the material thickness is 0.8-2 mm, and the weight is 1 square meter. m cover no more than 1.5 kg;

- the membrane is produced in rolls of the most different lengths and widths, thanks to which it is possible to choose the required volume of material so that the number of seams and joints is minimal;

- the installation of such a coating is quite simple, does not require professional skills and can be carried out without the involvement of paid specialists;

- the coating shows resistance to adverse factors of atmospheric phenomena, withstands t to –60 degrees;

- material is characterized by great strength, but it does not lose its elasticity;

- the membrane surface is vapor-permeable, which eliminates any formation of condensate and runoff of water along the wooden elements of the roof;

- it can be laid on surfaces of different types, even with irregularities, without requiring prior alignment;

- it is resistant to burning, does not ignite spontaneously and meets all necessary standards of fire resistance and fire safety;

- the membrane does not react with acid-base solutions;

- non-flammable membrane, made from environmentally friendly raw materials and in the process of use does not emit harmful and toxic substances;

- has a long service life - serves up to 50 years.

The lack of material is poor compatibility with foam and bituminous substances., as well as reduced resistance to certain types of reagents, for example, to solvents.

The main disadvantage of the material is its price, which is much higher than, for example, the cost of a polymer-bitumen roof.

However, this disadvantage can be challenged. The same bituminous coating fails after 4-5 years, and the membrane will serve more than half a century, without requiring replacement.

Specifications

Many have heard about the modern waterproofing coating, but few understand the principle of the work of membrane sealants. PVC membrane is quite dense, but at the same time very flexible multi-component film with a complex structure. Despite the good plasticity and purely visual brittleness, this material has a high degree of mechanical strength and a large stock of service in the most demanding working conditions.

To give greater elasticity and flexibility to the material PVC plasticizedand then two layers of PVC with a reinforcing mesh are interconnected. It is the mesh that gives the coating additional strength and resists material shrinkage over a long period of use.

The total weight fraction of plasticizers in the structure of the material reaches 50%.

The upper layer of the membrane contains special components that protect the material from adverse environmental factors, of which ultraviolet is considered the most dangerous. It is opposed by a layer of absorbents that form a barrier on the surface and prevent the rays from penetrating inside the insulation and destroying the material.

PVC membrane is produced in two forms: 1.2 mm and 1.5 mm thick.

There is no fundamental difference in the technical characteristics of these species:

- roll length corresponds to 20 m, and its width - 2.05 m;

- tensile strength is 150;

- water absorption coefficient is 0 - this membrane does not absorb moisture at all;

- fire resistance class - G1 / G2.

PVC membrane sheets are welded to each other overlapping with heated air.This technology forms a strong seam and ensures the integrity of the coating, as well as enhances the waterproofing properties.Thanks to this method of work on the arrangement of the roof can be carried out in all weather conditions, and the installation of waterproofing occurs in accelerated time.

Unlike film materials, the membrane allows steam to pass through, which contributes to the timely removal of condensate from the base layer of insulation.

Thus, it is possible to assert with confidence that the structure and physical and technical parameters of the PVC membrane provide the highest quality protection of the roof itself and the under-roof structures.

Types of material

Depending on the functionality of the coating, there are several types of PVC membranes.

Vapor barrier membrane

This type of coating is a special polymer-based film that is commonly used to effectively protect the roofing pie from the warm, moist air rushing up from the living quarters.

Such a membrane is made of different types of polyethylene with varying density indices.

The membrane structure includes antioxidants, as well as additional components that enhance the physical and technical properties of the coating required for operation.

The thickness of the vapor barrier is in the range of 0.5 to 3 mm.

The material is suitable for both the internal equipment of the roof, and in the external arrangement of the roof. It is characterized by vapor resistance, withstands temperature fluctuations, resists sunlight, does not lose its properties at low temperatures.

Among the drawbacks, low resistance to mechanical damage can be noted - in other words, this material can be cut or pierced.

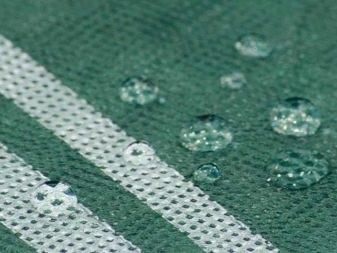

Breathing membrane

It is a non-woven fabric made from synthetic fibers. It is widely used to create a hydroprotective layer. And besides, the wind-protective surface saves from all sorts of precipitation. In this case, the coating passes moisture vapors well, thereby preventing the accumulation of condensate and the destruction of wooden rafters and attic floors. Vapor permeability is one-sided - it is caused by the presence of small holes on the surface of the coating.

Breathable membrane can be mounted directly on the insulation. For its arrangement the installation of the batten is not required, which significantly saves time and effort spent on waterproofing works.

Such membranes are widely used in the conversion of unheated attic rooms into residential penthouses.

The disadvantages of the coating are related to its price - the cost of breathing membranes is much higher than any other waterproofing material. therefore, not everyone can afford the protection of this level.

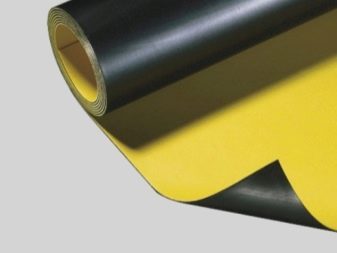

Polymer membrane

This is a relatively new material made from PVC with increased elasticity. The special structure of the components in the composition of the membrane determines its high quality and consistency of technical characteristics over a long period of use.

Laying the polymer membrane in a single layer provides the same waterproofing as several layers of other types of roll coatings.

Installation is carried out with the help of hot air, which stitches together well and causes hygroscopicity for several decades.

In addition, the material is resistant to ultraviolet, as well as chemical reagents, is not subject to decay and destruction. The disadvantage, as in the previous case, is associated with the high cost of the material itself, as well as the need to use professional equipment for installationpolymeric roofs.

Super diffusion membrane

By its organoleptic parameters, such a coating resembles skin. The material is made of 3-4 layers of polypropylene, so that the product acquires enhanced strength while maintaining the ability to stretch.

By the way, these technologies are often used when sewing outerwear. Such jackets and shoes do not allow a person to sweat and get wet, which means that they retain their dryness in all weather conditions.

Such a membrane consists of two layers - the bottom one helps to improve the diffuse characteristics of the coating, while the top one protects from the wind. moisture, dust and ultraviolet.

The advantage of the material in its ease of installation. It is attached directly to the insulation and does not need to install the frame above the rafters. All this reduces the cost of the arrangement of the roof and saves space for the arrangement of the attic.

However, it should be borne in mind that the scope of application of such a membrane is limited. Super diffusion membrane is not mounted simultaneously with metal tile and also with bitumen-based sheets - such coatings tend to be very hot, therefore they form too much condensate.In addition, its pores can become dirty, leading to a significant deterioration in vapor permeability.

Anti-condensate membrane

The material is made of polypropylene coated with a hygroscopic coating. This structure contributes to the absorption of steam and its further withdrawal beyond the boundaries of the roof structure. The membrane reliably holds the condensate that forms on the inside of the roof, thereby protecting it from rotting. The villi of the material are able to withstand the weight of the condensate, several times the weight of the coating itself.

Anti-condensate membranes are widely used in the construction of a sloping roof of metal tiles. Such coatings more than others, need high-quality waterproofing, as over time, cracks may appear on the metal surface, water gets into them and the coating begins to rust. This will not happen if an anti-condensate membrane is used: its absorbing layer absorbs well not only the condensate, but also the vapor itself.

Features of installation of such a coating require work only in dry weather, and the product should not be in direct contact with the insulation, and the installation itself should be carried out with small gaps.

The correct choice of the type of membranes is largely due to the climatic conditions of the region in which construction is underway, as well as the architectural features of the roof.

Manufacturers Overview

The range of the construction market today is filled with offers of membranes from different manufacturers. However, experts recommend to give preference to products of several brands, well-proven in recent years.

TechnoNicol

PVC membrane from TechnoNicol is an innovative product with extremely high waterproofing characteristics.

Products of this brand differ from their analogues by a number of advantages:

- resistance to climatic phenomena;

- high strength and elasticity - it can be laid in all weather conditions, and this waterproofing can be mounted even on a wet surface.

The structure of the TechnoNicol membranes is multi-component.

- the first layer is nothing else than an elastic base, which reliably covers the roof from adverse natural phenomena, it consists of active components that limit the damaging effects of elevated temperatures;

- the middle layer is a reinforcement, the structure of which includes interwoven polymer threads and fibers, they create anchorage with each other and form a fairly strong mesh, so that the waterproofing material can withstand the pressure of rain and snow layers;

- the bottom layer is a PVC plate, it is necessary to improve the adherence of waterproofing to the main roofing material.

The assortment list includes membranes from 1.2 to 2 mm thick.

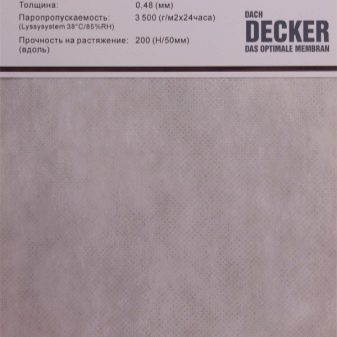

Decker

The membrane is a German manufacturer with a world name, it is commonly used to insulate cold attics. The product is a three-layer material made using the technology of molecular compound components. Due to this innovative approach, the membrane acquires increased strength and improved diffuse properties.

"Tefond Plus"

The products offered by this manufacturer is a dense membrane with a cellular structure, on which insulating seams and special locks are placed. Such material is widely used in roofing, as it guarantees maximum protection of the roof.The material for half a century retains its performance characteristics, does not collapse under the influence of moisture and chemical reagents.

"Tefond Plus" produces a membrane that is particularly resistant to rupture, surface damage during installation is absolutely excluded. A pleasant bonus is considered the moment that the product in parallel performs the drainage function, removes water into specially equipped wells.

Logicroof

This membrane consists of three film layers, includes a variety of stabilizers, plasticizers and flame retardant additives, which significantly increase the fire resistance class and reduce the likelihood of fire in an open flame. The material is treated with a special compound that protects the coating from UV rays.

This structure led to high strength, durability of the membrane and its resistance to external atmospheric influences. The membranes of this brand are used in all types of premises, even in power plants.

"Stroyplastpolymer"

Another domestic manufacturer of soft PVC membranes.

He received great fame as a manufacturer of the material "Krovlelon", which is conventionally divided into 2 subspecies:

- strong two-layer film with a reinforced coating;

- two-layer non-reinforced waterproofing coating.

Another well-known product of this brand is the Plastfoil membrane, the structure of which includes a polyester fiber fabric, plasticizers and PVC of darker tones. This coating is placed on the roofs, which are subject to increased requirements of flammability and fire safety.

Many consumers prefer products of the Swiss company Sika, which has established the release of a multilayer membrane that exhibits special resistance to UV radiation.

Not less in demand is the production of the manufacturer from the Netherlands Icopal, which offers membranes that exhibit high performance in absolutely any climatic conditions.

How to develop a design?

The range of materials for waterproofing is characterized by a large variety of coatings with different technical and physical properties, design, level of strength and other parameters. That is why, even at the planning stage of work, it is important to correctly identify key points that need to be taken into account when choosing the right coverage.

When buying a PVC membrane for roof waterproofing, special attention should be paid to these points:

- the composition of the components - the film must necessarily be impregnated with flame retardants, they protect the coating from exposure to UV rays and high temperatures, protects against fire;

- durability - high-quality material retains its functional features for at least 30 years, if the lifetime is lower, most likely, you have a low-grade fake;

- installation method - some membranes are built-up, they are optimal for flat roofs, this factor also deserves attention;

- cost - PVC membranes are distinguished by a rather high cost, if you have a product in front of you, the price of which is lower than the market average, this means that you are offered a fake product with low consumer characteristics.

At the design stage of preparation for installation, it is necessary to take into account a number of factors:

- the distance between the wooden rafters should not exceed 1.2 m;

- there should be a gap of about 4 cm between the insulation and the waterproofing layer;

- the membrane is spread from the eaves to the ridge;

- film coatings are not recommended to strongly tighten, it is allowed the depth of sagging of 2 cm.

The film is laid overlapping, its size depends on the angle of the roof:

- if the slope is approximately equal to 30 degrees - then the overlap is 15-20 cm;

- at an angle of less than 30 degrees, the webs are stacked on each other with an overlap of 25 cm;

- if the angle is more than 30 degrees, then the overlap should correspond to 30 cm.

How to lay?

The following tools and materials will be needed for the installation of the PVC membrane:

- adhesive solution;

- self-tapping screws;

- building roulette;

- large durable scissors;

- screwdriver;

- wire brush (preferably copper);

- welding equipment;

- wax chalk;

- cleaner;

- silicone or teflon roller;

- pick thread.

The easiest way to lay a PVC membrane is carried out in a specific order.

First you need to clear the base: remove all existing garbage, disassemble parts (antennas, stairs or signs). Then the surface of the roof should be leveled, dry all wet areas, repair the damaged fragments. If necessary, you must dismantle the old coating, if its integrity is seriously compromised.

Next, a drainage layer is equipped - for this purpose, it is advisable to use geotextiles, and also to additionally insulate all this construction with basalt wool or polystyrene foam.

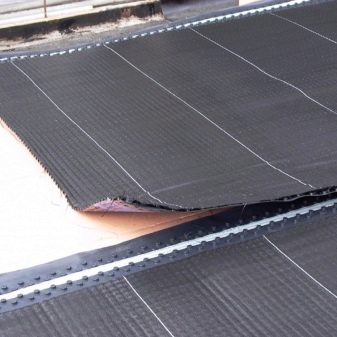

In accordance with the design scheme, direct installation of the PVC membrane begins next. To this end, the material unfolds on the coating, and with the help of special fasteners is fixed around the perimeter.

The layers are mounted overlapped by 15-35 cm, depending on the angle of inclination of the roof, and then the materials are connected to each other.

Traditionally, hot air welding is used for gluing the membrane., it requires a welding machine and professional equipment for roofing of high thermoplasticity. Welding is carried out at 400-650 degrees, the impact of such a high temperature leads to almost instant gluing of the plates together, as a result of which they form a single layer. In hard-to-reach areas where the possibility of welding is limited, a thermogun with thermoglue rods should be used.

A method of applying a PVC membrane using glue is much less commonly used; this method is rather uneconomical, since it does not provide the required degree of fixation of the material on a common surface.

As the adhesive solution is used such a mixture, the strength of which must necessarily be lower than the adhesion strength of the base layers of the membrane to each other. As a rule, glue is smeared not over the whole area, but only around the perimeter, as well as in the places where the sheets fit to the engineering communications.

This method is used in cases where all other fastener options are excluded.

On a flat roof often use a ballast method of applying waterproofing. It involves fixing the membrane with special fasteners with further coating with special ballast, which is used as gravel backfill, concrete blocks or paving slabs. The weight of the ballast should be at least 50 kg / m2 of coating.

The main factor that must be taken into account when deciding on the installation of a PVC membrane using a ballast method is the ability of the floors and the main structural supports to withstand such a high load.

Laying waterproofing should not lead to subsidence of the structure and its deformation.

Useful tips from the pros

PVC membrane is a relatively new product that requires certain knowledge, skills and experience in construction and decoration.That is why it is not recommended to engage in the arrangement of waterproofing of this type on its own - this will lead to the deterioration of expensive material and large losses of time and effort.

If you prefer the membrane, it will be optimal to seek the help of professionals who have not only experience with such a coating, but also all the necessary professional tools.

Here it is necessary to take into account the fact that in the Russian market PVC membrane became known relatively recently. Therefore, there are not so many professionals who are able to really carry out its high-quality installation in our country.

When selecting employees, particular attention should be paid to the following points:

- experience in this area;

- the opportunity to look at previously completed orders;

- customer reviews.

Immediately make a reservation that the cost of such services should not be cheap - the prices for services directly indicate the professionalism and competence of contractors. It is in the range of $ 5-15 per square meter. m and largely depends on the season, type of roof, material parameters and timing of the work.

Professional installers for 1 day can lay up to 1 thousand m2 of the roof.

What material to choose is up to you. But remember, waterproofing is very important in the arrangement of the roof. Incorrectly selected material and violation of the technology of installation during installation work can lead to an increase in the level of humidity in the attic space and provoke damage to the insulation. And this, in turn, violates the microclimate in the house and reduces the life of the wooden elements of the roof structure.

That is why give preference to the most modern high-tech material, they will allow you to forget about repairing the roof for many decades.

How to install a PVC membrane on the roof, see the next video.