Features of the use of film for waterproofing

No private house now can be built without the use of waterproofing of various types. It is laid in order for the building to stand for more than a dozen years, and it would not have to be repaired every 3 years. This is especially true for wooden houses.

In the process of building a house, the walls, the foundation and the roof constantly need protection from groundwater, precipitation and the accompanying humidity.This article will explain what waterproofing materials are and how to use them properly.

Material Requirements

The roof of the future building should be strong and reliable. Only in the presence of these two conditions, it will last for many years and will not require repair. This can be achieved with the help of proper and high-quality waterproofing materials. For the most part, it is a film material to which there are a number of requirements on the modern construction market:

- elasticity;

- resistance to mechanical damage;

- immunity of high and low temperatures (especially in conditions of abrupt change of weather conditions and differences in the thermometer indicators outside and inside the dwelling);

- moisture resistance

Practical need

Steam insulation film is needed to ensure that the walls, floors and roof of the building are protected from precipitation and humidity. In addition, it extends the life of the wooden house (it does not matter if it is manually chopped log house or cylindrical logs) and protects the insulation from getting wet.

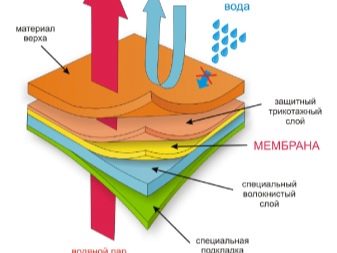

This material is combined with vapor barrier to remove moisture and steam from the walls and ceiling of a modern house. At the same time, the waterproofing material is fundamentally and functionally different from the vapor barrier: they perform completely different tasks.

PVC butyl rubber waterproofing film can be elastomeric or membrane. Its thickness is always selected individually. The device is suitable for many construction purposes.

Types of waterproofing film

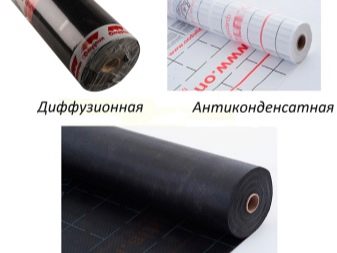

In modern construction uses several different types of material for waterproofing, among which:

- diffusion;

- pseudodiffusion;

- super diffusion;

- antioxidant:

- standard.

It is necessary to understand in advance how they differ.

Diffusion waterproofing is a material with a complex structure, the raw material for which is polypropylene. It copes well with the task of draining the liquid to the outside, while it is vapor-and moisture-proof. This material is very plastic and perfectly stretches, which will create additional convenience at the time of its application to the surface.

A feature of the use of such a film can be considered that between the insulator and the surface to be protected there should be a small air cushion (if you ignore this condition, the pores of the film will be closed and vapor permeability will not be as such).

If you approach the matter correctly, a roll of 100 by 100 cm in size will let in a little less than a liter of moisture, which is enough for proper steam exchange.

Pseudodiffusion film is used very rarely. This is due to the fact that its moisture permeability is about 300-400 grams per period (24 hours), which is not enough even for natural ventilation.

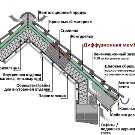

Superdiffusive waterproofing material, unlike diffusion and pseudodiffusion, is practically without drawbacks. It is applied to the surface or sheets of insulation. For such a film does not need to leave an air gap. At the time of installation, the outer side of the film is turned to a layer of finish, and the inner side - to a heater or wall.

The film with antioxidant properties has one very interesting feature: it contains hydrophobic spraying and an adsorbent. With their help, steam cannot penetrate through the material and is pushed out (beyond the roof). This material perfectly holds accumulated condensate that forms on the inner metal parts of the tile or profile sheet. Antioxidant waterproofing is applied in the gap between the finish and insulation.

Standard waterproofing is made of polyethylene, with which it is possible to provide at least a small but ample protection from water vapor and moisture. Polyethylene is used everywhere: in swimming pools, baths, saunas and bathrooms. Most often, polyethylene waterproofing is used at the time of installation of a floor heating system.

Choose a suitable waterproofing

It has been known since ancient times that water negatively affects any capital construction: it accumulates in the foundation, masonry, basements and roof, destroying them. Modern construction practice involves the use of polymeric and bitumen materials to protect the building and economic buildings from moisture.

Before you make the final choice of waterproofing, it is worth figuring out what advantages and disadvantages each type of material has.

First of all, keep in mind that the requirements for the film, which will protect the roofing layer, are completely different from the requirements for waterproofing the foundation or walls. This is understandable in a simple example - a very durable and waterproof material is needed for the foundation.After the film is laid on the foundation, a concrete coupler is placed on top to protect the material from mechanical damage.

On the roof, the situation is slightly different. There will need insulation that can withstand the negative effects of UV rays and "breathe" (that is, the material must have pores). So, at the time of the choice of material, you need to consider the type of roof and its insulation. The material for the ceiling can be used to protect structures made of reinforced concrete.

If there is no insulation, then all the moisture will be absorbed into the insulation, which will lead to the destruction of its structure.

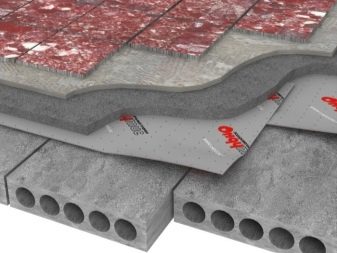

Foundation insulation

Foundation waterproofing consists of two parts: the main and auxiliary layer. The main insulation layer is most often made of a diffusion film, which must not pass moisture. The auxiliary layer is created mainly from polyethylene. The film for the second layer is placed in the gap between the concrete screed and insulation.

Occasionally polyethylene is mounted between the main layer of insulating material and the ground. In rare cases, the material is laid directly under the concrete layer.General practice allows the use of polyethylene and in the main layer of insulation due to the fact that it is resistant to sudden changes in temperature and is not sensitive to moisture.

Floor insulation

Waterproofing the floor is necessary in order to protect the screed from the direct and indirect effects of liquids and fumes, which come from capital overlaps. Sheets of material stack overlap (at each other with a small margin) and sealed with a conventional building dryer. Next you need to make a screed and reinforce the floor. In the final, after everything freezes, the protruding pieces of the film are simply cut off.

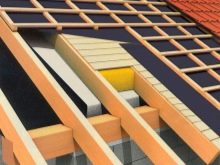

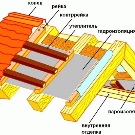

Roof insulation

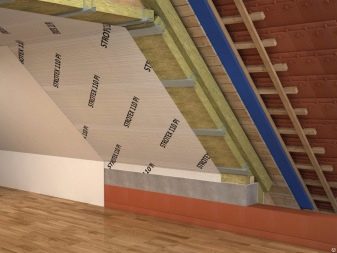

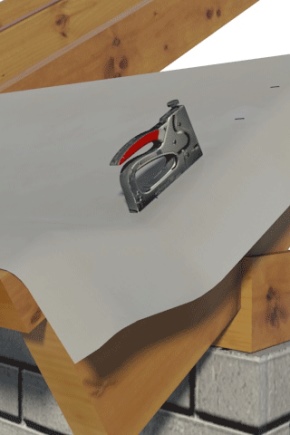

Here you need to do everything very carefully and carefully, mistakes are unacceptable. If you do something wrong, the roof will start leaking. High humidity will lead to the rapid destruction of the integrity of the metal, and the roof will have to be changed. For the roof, the film material is placed directly under the roof or profile sheets. This leaves plenty of room for natural ventilation.

The material will be best mounted on the rafters, but so that it does not come into contact with the insulation (you need to leave a small gap of about 1.5 meters). On top of the insulation layer, lathing and slats for rigid fastening are stuffed.

In no case should the insulation layer sag. The insulation is positioned so that the eaves and overhangs of the gables are covered.

Insulating Material Properties

Waterproofing material should be resistant to sudden changes in temperature (on average from +60 to -40 degrees). The presence of antioxidant properties of the film is also welcome, especially if the material will be used for the roof. If there is no information about the presence of such properties on the package with the film, it is better to refrain from buying and choose something else.

The composition of such insulation includes cellulose, which functionally absorbs and holds a large amount of liquid in itself. This feature allows you to create good conditions in especially windy weather and at high temperatures outside.

The multi-layer insulation film is also a priority parameter. This minimizes damage from any mechanical damage. In the building stores there is a large range of quality products, so that there will be no problems with the choice of a similar film.In addition, the composition of such material is also reinforcement, which significantly strengthens it, and increases the service life.

Plasticity of the material is no less important than the above properties. The material must be pulled so that even in very windy weather it will not burst under the influence of a large flow of water.

How to lay waterproofing

Before starting the installation, carefully level the surface and check that the material does not come into contact with sharp objects or splinters that may damage it. Carefully read the instructions, especially in the part where it is said about insulation positioning on the sides. The fact is that the flat and perforated sides of the film have their own purpose, and if they are mixed up, waterproofing will not work.

Also avoid any contact of the material with insulation, otherwise there simply will not be vapor permeability. Laying material overlap, leave a width of at least 10 centimeters. It is possible to connect the seams with a building tape, glue or a building dryer.

The following video discusses the option of waterproofing the floor using self-adhesive bitumen-polymer roll material.