EPDM membranes: advantages and disadvantages of waterproofing products

Waterproofing EPDM membranes, presented on the Russian construction market for about 50 years, enjoy unchanged popularity among consumers. This is sufficient time to conclude on the quality and characteristics of the product. This material is made on the basis of synthetic rubber and is used primarily as a soft roof.

In addition, it is used for waterproofing various structures, such as tunnels, reservoirs, canals, etc.

Composition

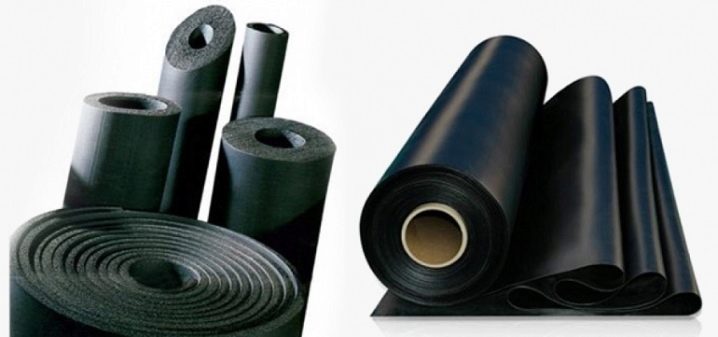

Approximately the third part of the membrane composition is EPDM rubber.It depends on the basic properties of the product. Sixty percent of carbon black allows the material to be tenacious and to resist ultraviolet rays. Clay gives refractory qualities, and the presence of vulcanizers is responsible for elasticity and durability during operation. Technological oils that are in the composition, make the material quite elastic.

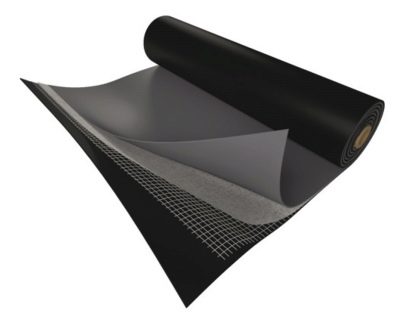

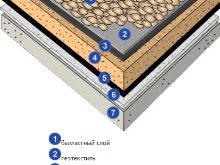

EPDM membranes can be made from composite materials. They are distinguished by several layers of coating with a bituminous polymer base. To make the product more durable, it is reinforced with polyester mesh. Due to this, the material becomes frost-resistant, so it can be used in regions with any climate. All raw materials undergo strict certification, products are manufactured using modern technologies.

Characteristics and key benefits

One of the main advantages caused by the popularity of this type of waterproofing materials is their low price. Other types of membranes are much more expensive. In addition, the product has high strength. The service life of products with preservation of their basic properties is considered a period of about 50 years.This time period is tested in practice.

The membranes are resistant to severe temperature changes, ultraviolet radiation and ozone. They do not lose their qualities, even being in direct sunlight for a long time, they do not crack or deform. The temperature range within which products can be operated ranges from -60 to +100 degrees. Also, when using EPDM membranes, you can use any type of solar cells.

In addition, it is impossible not to note the elasticity of the material. It is able to maintain the contours of the support even when exposed to serious weight, does not break and is not damaged when the building shrinks during its operation. Membranes withstand external stresses rather firmly, are practically non-abrasive, are fire-resistant, non-toxic and eco-friendly. The weight of the web, having a thickness of 0.045 / 1.14 millimeters, is only 1.4 kilograms per square meter.

Installation of membranes of this type is quite simple, it can be carried out at any time of the year. The material is produced in wide rolls with a maximum size of 60x15 meters. After laying the products, they are glued together with double-sided tape.During the installation process, it is not necessary to remove the old bitumen layer. There are several options for mounting membranes.

The material can be used on any type of roof, the slope does not matter. Its size can be adjusted to the base area. In addition, the products are ideal for laying with a "green roof", do not collapse from the effects of germinating roots. With the use of EPDM membranes, waterproofing and cleanliness of the roof covering are achieved.

The disadvantages of this product is not so much. The main disadvantage is the use of glue when laying, since the presence of such a seam can reduce the strength of the material.

Varieties and manufacturers

The modern building materials market offers EPDM membranes produced by several companies. They have some differences, expressed in the price category and characteristics. Among the species can be distinguished single-layer and multilayer materials.

One of the features of multilayer products is that the layer of bitumen, provided it melts to a liquid state, can be used instead of glue.

One of the popular types are single-layer EPDM membranes. Firestone. They are reinforced with mesh, fire resistant.All rolls have a width of 15 meters, while the length can be up to 61 meters. Distinctive features of the material are resistance to ultraviolet radiation, ozone and temperature extremes. Products are durable and eco-friendly, they can be lengthened in the process of laying.

EPDM membrane Giscolene also are single layered. They are made of propylene, ethylene and diene. The width of the canvases can vary from 1.5 to 20 meters, and the thickness - from 0.5 to 4 millimeters. The material does not pass air and moisture, has soundproofing properties, quietly tolerates heating, temperature changes, exposure to chemicals. Due to its versatility, it can be used on roofs of any kind.

"Elastokow" its properties resemble Firestone membranes. Their thickness is 1.4 millimeters, width - from 3 to 4.5 meters. This material appeared on the market not so long ago. The main difference of the membrane "Carlisle" is that for its bonding can be applied not only adhesives, but also sealant, mastic and self-adhesive tape. The thickness of the rolls is from 1.5 to 2.3 millimeters, and its width can be from 6.1 to 18.3 meters with a roll length of 30-61 meters.

Application

The EPDM-membrane is used in cases when it is necessary to cover large areas of the room with waterproofing, and at the same time the work should be done as quickly and efficiently as possible. Mostly it is used for work with roofing. If the material is used for ponds and reservoirs, you can not worry about the safety of its inhabitants. Due to this, he won immense popularity in this field of application, practically replacing other similar products.

The use of these membranes for waterproofing ponds has its own characteristics. The easiest option is to use a single canvas. Work can also be carried out by gluing the cloths together, which is a much more labor-intensive process.

EPDM-membranes are often used for equipment drain in the baths. This type of work is considered the most economical.

Types of roofing systems

There are several types of roofing systems that can be used with EPDM membranes:

- ballast system;

- mechanical system;

- system with full bonding material.

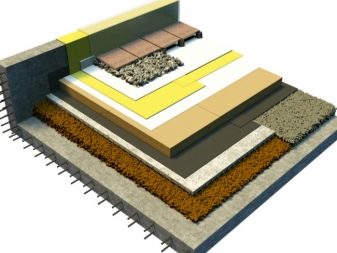

The use of a ballast system is advisable in cases where the roof slope can reach up to 1: 6. It shows its properties and cost-effectiveness especially well when working with flat roofs. The material is excellent for waterproofing concrete foundations.

According to technology, the product should be carefully laid on the surface. Fastening is performed around the perimeter and in those areas where the membranes are adjacent to the vertical planes. To connect the joints, they must be glued with a special tape. In order to protect the material from the wind, it is necessary to provide ballast, which can be concrete blocks, paving slabs, crushed stone and other elements. In ballast roofs, EPDM membranes are used most often.

Their use makes it possible to create a solid roof, ready for additional loads. Also, the use of this system is important in cases where the surface carries a pedestrian load. These can be verandas with access to the roof, viewing platforms and other structures. The variant is ideal for use in harsh climatic conditions.

The mechanical system is used when the roof slope is no more than 1: 3.It is used on weak supporting structures, pitched roofs and in other cases where the creation of a ballast system is not recommended. In this case, the cloths are arranged freely, they are fastened with the help of special screws.

The third type of system is suitable for roofs having any angle. It is suitable for structures whose bearing capacity is limited, and for roofs that have complex outlines and are subject to severe wind loads. In this case, the membranes are first connected to each other, and then laid down on the surface, where they are fixed using a special mounting adhesive. This system is the easiest and wind-resistant.

Stages of work

First of all, before laying the EPDM membrane, it is necessary to prepare the base. It should be thoroughly cleaned from debris and dirt, as well as dried. For these purposes, you can use a primer.

Then comes the turn of the preparation of the material itself. It needs to be rolled out and allowed to rest for a while. After that, you can start laying, trying to avoid wrinkling, sizing seams, as well as carefully fixing the material.

Repair

There are situations when EPDM membranes may require repair. In this case, it is better to turn to professionals, as for the work requires special welding equipment. Experts advise to completely change the waterproofing materials in the damaged areas. If this is done in part, you should try as much as possible to cover those places where the roof is removed.

If the roofing is badly damaged, or the life of the roof expires, a major overhaul may be necessary. This is a much more labor-intensive process, since it requires the replacement of the roofing “pie”, heat insulators, steam insulators and water drains.

In some cases, even the roofing screed and parapets have to be changed. The best solution would be to completely remove the old coating, as moisture accumulates in its residues, the presence of which can damage the new waterproofing layer.

In the next video you will find instructions for gluing the EPDM membrane.