How to make a smokehouse?

Smoked meat and fish are famous delicacies. A wide variety of smoked meats can be bought in stores, but how can factory-made products from the store compare with home-made products? Therefore, some dacha owners and owners of private houses who breed poultry and animals or who are keen on hunting and fishing are thinking about purchasing a smokehouse. A serious obstacle to this can be its high cost, but almost everyone can make a smokehouse on their own.To do this, you need only a properly selected drawing, suitable materials and a little time.

Features and benefits

Making a smokehouse is a much less complicated and time consuming process than it might seem at first glance. Of course, it all depends on the type that the owner decides to install on his site, but some options can be made on their own for just a few minutes. Homemade smokehouse in most cases will cost much cheaper than purchased. It can be made from scrap materials, from old things that are no longer used on the farm, but have retained their properties.

You can quickly make a good and convenient smokehouse, corresponding to the size and volume of the wishes of the summer resident with your own hands right at the dacha.

Properly selected wood for smoking and temperature conditions allow you to create on your site completely unique in taste and aroma delicacies, equal to which it is very difficult to find on store shelves.

Types and purpose

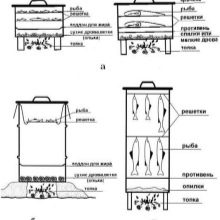

There are two main types of smokehouse, one of which is suitable for hot and the other for cold smoking.They differ from each other mainly in the manufacturing technology of the smokehouse themselves and in the temperature that is maintained in the smoking chambers. Products depending on the method of smoking will also have a slightly different taste. With the same success, these smokehouses can be used for smoking meat, game, fish, bacon, sausages.

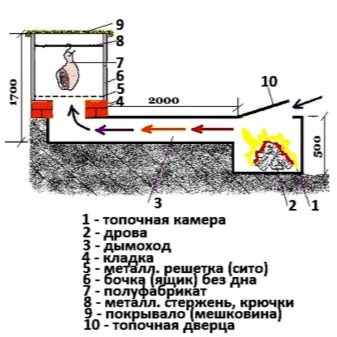

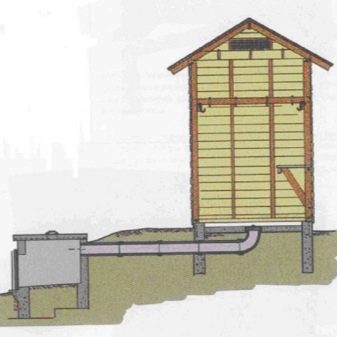

The first is to consider cold-smoked smokehouse. Their main feature is a long elongated chimney, which allows for complete burnout of flue gases.

Such smokehouses, in addition to the chimney, have two main blocks: the firebox and the smoking chamber. All harmful substances are deposited on the walls of the chimney, and the meat acquires a barely noticeable fragrant smoke. It will take from three days to a week to make a product in a similar way, and the shelf life of products produced using such smokehouses can be on average from three to twelve weeks.

In smoke-cured smokers, products are cooked much faster: the whole process takes from a quarter of an hour to several hours, it all depends on the size of the original product.In smokehouses of this type it is customary to use not firewood, but special wood chips, which causes some features of the structure. So, the firebox in these smoking sheds is located directly under the very sealed chamber intended for smoking. The tightness of this chamber provides uniform heating of the entire mass of the product.

In addition, there are universal smokehouse, which is a cross between cold and hot smokehouse.

In addition to the stationary smokehouse, there are also hiking or portable mini-smokehouses: outwardly they resemble a box with a lid. This simple design is very convenient: you can take it with you, for example, for fishing or for a picnic.

What can you build from?

To make a smokehouse with your own hands, you can use a lot of improvised means - suitable household items, which are in large quantities brought to the country in the hope that someday they will find a use.

A wooden barrel is suitable for the smokehouse chamber., and the larger it is, the better, but for a small home production there will be enough capacity of 50-100 liters.However, it is important to remember that in no case should you choose resinous and tar-emitting tree species. Spruce, pine, maple and birch are definitely not suitable. The best options are the same trees such as cherry and apple, oak or alder.

In addition to the barrel, you can use any large metal box: the old refrigerator will also fit (this will allow you to combine a smoke generator and a dryer in one unit). To make a camera it will turn out, for example, from a gas stove. In the end, the capacity for a portable smokehouse can serve as a regular metal bucket, an old pan, flasks, medical bix or even an old fire extinguisher: two grids are inserted inside, between which there is meat or fish, and the bottom is covered with a thin layer of sawdust.

However, using metal elements in the manufacture of smokehouse, it is necessary to give preference to objects made of stainless steel. Of course, this is a rather fragile and more fragile material that is more difficult to process, but it has a number of undoubted advantages: firstly, it is resistant to the chemical components that smoke carries, secondly, it does not oxidize at high temperatures and rusts, thirdly, it is easy to clean it from soot, soot and traces of fat.

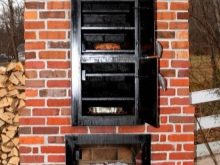

If the smokehouse for the owner is a necessary attribute of a country plot, then you can build a solid brick smokehouse. Its size will meet the wishes of the owner, the main thing is to ensure the correct flow of smoke into the smoke chamber. For the source of heating in such smokehouses are usually used stoves, stoves, connected to the chamber tube.

How to prepare drawings?

If the smokehouse should become a functional element of the decor of a country plot, then, of course, the drawings should be done by yourself. However, if there is no need for this, it is better to use ready-made drawings. This is especially true of non-professionals, as it will help to avoid mistakes and inaccuracies. But even in this case it is necessary to take into account the dimensions of the tank, which it was decided to use under the main chamber. Most likely, the scheme will still have to slightly change.

It is worth remembering that hot smoked smokehouse is convenient due to its small size, and cold rather cumbersome, however, allow you to make products with a richer taste and a long shelf life. Mini-smokehouse is characterized by simplicity of design.

Accessories

Despite the variety of items from which you can make a smokehouse, each design must have several indispensable components to make the smoking process convenient and technologically correct. In addition, during the work, you should have some tools on hand - at least a welding machine and a grinder.

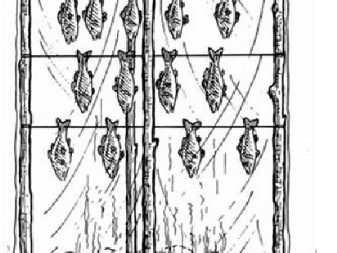

At least one grate should be located in the main chamber of the smokehouse. On it products will be laid out for smoking. Such a grid can be made of fine reinforcement.

The smoking chamber itself must be airtight. This will ensure that the products are uniformly heated, and will also prevent smoke from evaporating ahead of time. In addition, if the dimensions of the smokehouse allow, you should provide the camera with several hooks for smoking.

Under the grate should be located tray for glowing chips and sawdust, and even lower - a box for the ashes. There may also be a source of heat that provides smoldering sawdust. The third important element is the pan, which will drain fats and juices; it must be cleaned after each smoking session.

It is possible to install the smoking shed on a fire, on gas and even, if the sizes allow, on an electric stove.

An important detail of the design is a smoke generator. Of course, small smokehouse, working on the principle of hot-smoked, have it directly in the smokehouse: smoke generation is provided by sawdust, which is carpeted bottom of the chamber. For smoke-cured cold-smoked ones, it is necessary to create artificial conditions for the formation of smoke, because its total temperature should not exceed 35 degrees Celsius. Therefore, an electric heating element with a built-in thermostat and thermal sensors is often used for such smoke generators.

To improve the quality of smoking (in the case of hot type smokehouse) it is possible to install an additional fan or compressor in the design. They will provide additional more powerful pumping smoke, so that smoked products will warm up and cook faster.

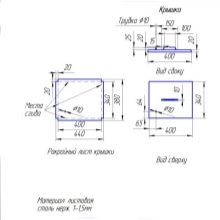

Sometimes a lid with a water seal is added to the smokehouse: it is a small depression located along the perimeter of the smoke chamber into which water is poured.This device creates a barrier that prevents the penetration of air into the chamber and does not release smoke from the chamber.

Assembly instructions

The variety of items from which it is possible to make a smokehouse, raises legitimate questions about how to properly make a smokehouse at home. In fact, knowing the general technology and processes that products undergo in the process of smoking, you can independently develop not only the scheme, but also step-by-step assembly instructions. However, for an example, it is worth considering a few of the most common and convenient smoke making options.

The simplest design of the plastic film

For the manufacture of such a cold-smoked smokehouse, you will need two meters of a very dense film, which is stitched together in the form of a bag. Best suited dense film used by summer residents for greenhouses and greenhouses.

Next, you will need to find a flat area of approximately one square meter in size on the plot. The site is upholstered with high wooden stakes to the size of the film about two meters in height, and the stakes themselves are interconnected by thin transverse beams to give the structure stability.Then the opposite pins will need to be connected with diagonal bulkheads of approximately 2-3 rows. After that, the products prepared for smoking are hung on the bars so that they do not touch each other, and the prepared plastic bag is stretched onto the structure - not just to the ground, a small space is left.

Burning coals are poured under the structure and covered with grass, after which the film is stretched to the ground and carefully clamped on all sides to make the entire structure air-tight.

Products for cooking in such a smokehouse will take approximately three hours, after which the bag is removed and the products are aired. Particularly large pieces may need to be re-smoked.

From bucket

To make a similar model smokehouse, you need an old bucket. Inside it is placed one or two stainless steel grids. If there are two grids, then the first, smaller size is set about 10 cm from the bottom of the bucket, and the second is slightly higher. Then the bottom of the bucket is plentifully sprinkled with wood shavings or sawdust.

The smokehouse from the bucket is ready, it remains only to lay out the products for smoking on the nets, put the construction on fire and cover with a lid.

From the barrel

The most traditional and simple option is to make a home smokehouse from a wooden or metal barrel. The principle of its manufacture is the same as in the case of a smokehouse from a bucket; the main difference lies in its much larger size, allowing the barrel to be equipped not only with grills, but also with hooks for smoking.

Smokehouse of both types of smoking can be obtained from the barrelthat can be very convenient. In the first case, the source of heat - the hearth, should be located directly under the barrel. For cold smoking, the barrel is placed in a pit to which a chimney is conducted (approximately two meters long) from the hearth.

You can make a more complex version of the smokehouse, for which you will need not one, but two barrels.

The most convenient option would be to use two identical barrels with a volume of approximately 200 liters. They need to be welded together in the shape of the letter "T". The lower barrel will serve as a container for the future fire, an opening is cut from the side and a door is installed. The valve at the bottom of the furnace will allow you to adjust the intensity of combustion.The upper barrel will serve as a future smoke chamber: it is necessary to firmly and firmly fix a solid grid on which smoked products will later be laid out, besides it will be possible to cook barbecues on it. Plus, it can be used as an oven, placing on the grill dishes for baking or just wrapped in foil products.

In order to smoke, it will be necessary to arrange a brazier for sawdust in the lower firebox, the open fire is bred under it. Sometimes sawdust is poured directly into wood coal, but this is a more laborious method that requires constant monitoring and attention. Otherwise, products can burn and lose the necessary taste.

Then it remains only to suspend the products above the grate, and put a pallet into it, into which the draining fat and juices will collect. The same principle is made of smokehouses from the old gas cylinder.

From the old refrigerator

Many gardeners prefer not to get rid of the old non-working equipment, and take it to the cottage. If you save a non-working refrigerator from the electric filling and other "entrails", then the remaining box can be turned into a convenient and capacious smokehouse.

In the roof it is necessary to make a small hole for the future chimney. Inside the box, on different levels, six corners should be installed in pairs, on which lattices for the pallet and products and hooks for smoking will later be located, as well as a pan for the fat flowing from the products. In addition to the pan for fat, you will also need a tray for sawdust or shavings; it is installed at the very bottom of the structure.

It is also important to ensure that the door of the refrigerator closes as tightly as possible and prevents excess air from entering the chamber.

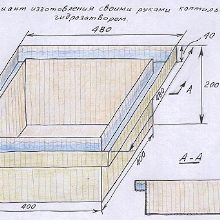

Of metal

This product already requires a more serious approach to itself, but it is easy to cook it yourself. The simplest and most convenient form for the master is a rectangle, but as a material, preference is most often given to stainless steel: it is easy to clean, it is well resistant to high temperatures and has a long service life. But at the same time, "stainless steel" is quite difficult to handle. Another material that you can pay attention to is cold rolled steel: it is rather plastic, withstands temperatures up to 650 degrees Celsius, but is susceptible to oxidation and rust.

By itself, this design resembles a box, the corners of which are welded to the walls with bars mounted on them.

To begin with, you will need two sheets of metal, one of which is divided into four parts, which will be the same if you plan to make a square oil-lamp. You can divide the sheet with the help of the grinder. Then at an angle of 90 degrees (for this, a joiner's angle is used) the sheets are welded to each other, forming a box. In order to ensure future tightness of the oil lamp, it will also be necessary to boil the inner seams of the chamber. From the other metal sheet is cut the bottom of the oil lamp and just as well welded to the box.

Finally, you can begin to make the cover of the camera. For this grinder cut four identical strips of sheet metal (preferably stainless steel) with a size slightly larger than the characteristics of the outer part of the box. Then the resulting cap is welded.

The final parts will be the lower anchorages for the installation of a pallet into which fats and juices will be collected, and the upper ones for placing hooks on which lard, meat, fish or sausages are suspended.It is also worth attaching a pair of handles at the edges of the smokehouse to facilitate carrying.

An ordinary electric stove can be used as a heat source for such a smokehouse. If it is necessary to obtain higher temperatures, the smokehouse can be placed above the fire with the same success.

From gas cylinder or fire extinguisher

The process of making a smokehouse from a gas cylinder is somewhat complicated, but it is quite suitable for those who have this completely unnecessary thing on the farm and want to find at least some use for it.

To begin with, it is worth observing the safety technique to release the remaining gas from the cylinder, and then carefully cut off the trigger valve. The remains of gasoline also merge from the cylinder into any metal container and burned. Then the cylinder is well rinsed, a door is cut into its wall, through which products will be placed inside. The hinges are welded to the cut-out site, on which the door will be held. Metal strips are cut from the bottom of the cylinder and half of the bottom is cut to ensure a future smokehouse. Finally, the furnace itself is made of metal sheets and welded to the cylinder, after which the entire structure must be ignited on the fire.

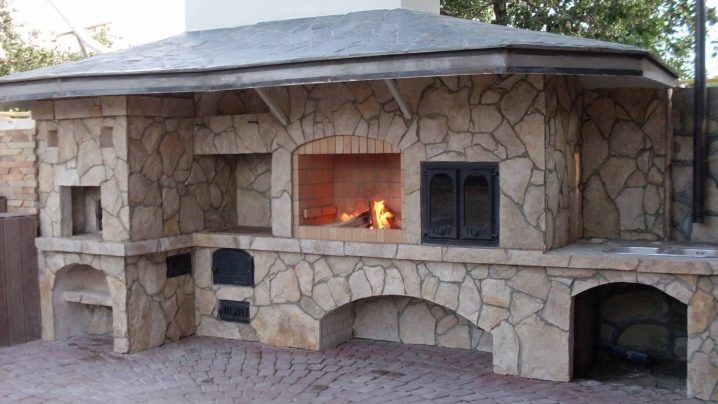

Brick and stone

Such a smokehouse is easy to manufacture, but quite complex in its design. When building does not need to use the grinder and welding machine, however, the slightest mistake in the location of the chimney can result in a finished smokehouse. The advantage of this smokehouse is that it can be adapted for both cold and hot smoking: this dual-mode design turns out to be very convenient and versatile.

First you need to prepare the foundation for the future smokehouse. Due to the fact that brick and stone have a large weight, it is impossible to mount such a structure directly on the ground: the ground may settle and the structure will be destroyed. It will not be superfluous to hold the foundation reinforcement with the help of a reinforcement grating

Then, when the foundation is ready, you can proceed to laying the lower belt of the walls, and after this - the holding of a tunnel chimney. Its length is about two meters, and the pipe itself is well insulated to provide the possibility of both cold and hot smoking. Insulating material can be any mineral insulation that can withstand high temperatures.Suitable, for example, glass wool.

By itself, the design of the future smokehouse should remain hollow. This can be taken into account in the future to use empty niches for storing stocks of sawdust, firewood, etc. The highest temperatures will be observed directly in the firebox and in the furnace, therefore they will need to be made of refractory bricks. The remaining details of the smokehouse can be laid out by any other types of bricks, even decorative ones.

Finally, you can start building a second brick belt. From the first one it will be necessary to separate it with a flat concrete screed or with a concrete slab. Just as in the case of the foundation, it would be better to reinforce the layer with steel reinforcing bars. Two chambers are distinguished, one of which will serve as a smoking chamber, and the second will be the basis for the Russian stove.

After this, the furnace itself is built on. Since there will always be high temperatures here, as mentioned above, it must be built from refractory bricks. The advantage of this design is its versatility: it will serve not only as a heat source for the smokehouse, but will allow baking products and even preparing barbecues.

After the construction of the stove, a smoke chamber is built next to the chimney: it can do without any additional finishing. The only thing you will need to ensure it is a tight hermetic door, better than wood, from hardwood; ideal cherry or apple tree.

Then, when the smoking chamber is built on, a pipe is attached to the top of it, which provides smoke extraction. Adjusting the thrust in the pipe will allow the owner to produce in one smokehouse both cold and hot smoking - everything will depend on the intensity of the burning of sawdust in the firebox. With a low fire and a wide pipe diameter, the smoke will have time to cool enough to ensure cold smoking; if you limit the draft in the pipe and increase the intensity of burning, then hot smoking will be done.

Chimney

Building a chimney for a stationary smokehouse is an important stage that should be considered separately. You should not make it out of bricks and other porous materials, as the brick will actively absorb harmful substances from the smoke and moisture coming through it. By accumulating these substances, with time it will acquire an unpleasant smell, which will adversely affect the quality of the products prepared in the smokehouse.

It is best to fit the metal for the chimney, but even in this case, it will need to be cleaned regularly, to remove the soot accumulated on the walls.

Many owners of domestic smokehouse prefer chimney, which is dug in the ground: Thus, the ground cools the smoke qualitatively (which is especially preferable for cold smoking), and also absorbs condensate formed on the walls. The soil-dwelling bacteria and microorganisms recycle the dangerous carcinogens contained in this condensate.

For the manufacture of a smokehouse with such a chimney at the dacha there is a site with a small slope, or artificially poured, which later will provide the smoke with natural draft. The furnace of the smokehouse is located under the slope, and on the very slope they dig a small groove - the future chimney. It is covered with iron sheets, on top of which a layer of soil is poured, designed to create improved thermal insulation. Such a chimney is brought down to the smoke chamber.

In the next video, you will see how to make a smokehouse from the barrel with your own hands.

Where is the best place?

It is very important to find the right place for a stationary smokehouse: it is not a small portable structure that can be stored at home or in a garage and taken out of necessity.

Choosing a place, it is worth remembering that a large amount of smoke will come from the smokehouse, which should not get into the living quarters at the cottage. In addition, harmful substances can harm trees and other green areas. Therefore, it will be quite difficult to find the perfect place on the leeward side, besides for each house it is purely individual. The resulting products can be stored in the cellar, as long as the room is dry and cool.

Maintenance and Care Tips

The correct smokehouse should take into account three main points, and the gardener, while building such a structure, should also remember them. First, in the smoking chamber, uniform heating and fumigation should be carried out. Secondly, the smoke itself must be very light, not carrying harmful substances and heavy decay products that can give the meat an unpleasant taste. Third, the design must be hermetic,to ensure uniform penetration of smoke into all layers of meat; Additional smoke generators can serve the same purpose.

By the way, the smoke generator can be assembled on its own. A body is made of a metal can, a hole for the ignition of wood chips is drilled from the bottom, and the upper part is tightly closed with a lid. Compressor can be cooler from the computer. The entire structure is assembled using welding air, and then it remains only to ignite sawdust or wood chips and turn on the cooler. The peculiarity of the smoke generator is that the built-in cooler does not push the smoke, but pulls it. Therefore, it is necessary to attach it to the smokehouse directly.

Traction - a prerequisite for smoking. It is not enough just to put the product in a chamber filled with smoke. Otherwise, evaporation of meat / fish will simply occur, as a result of which it will acquire an unpleasant taste. This is critical for cold smoking, in the case of hot, everything is a little different, but it’s still worth observing this rule.

To give the meat a rich taste, you should especially take care to select the correct tree species, the logs of which will be most fragrant when burning.

You should not, for example, use only birch logs in the smokehouse, as the meat may get an undesirable bitter taste. Yes, and birch logs will first have to be cleaned of bark. Also categorically can not be used for smoking conifers. Blame is the abundant tar content. It is best to add juniper twigs and cherry leaves to the logs: they will add pleasant notes to the meat flavor. If there is a need to give the meat a certain color, then you can also use certain tree species. Mahogany will give the meat a golden hue, alder and oak will give a dark yellow color, and deciduous species - a golden-yellow tone.

In general, fruit trees such as apples and pears and cherries have the most pleasant scent. This is especially convenient for gardeners, gardeners, who can use old tree branches for their smokehouse directly from their site.

Also, different types of trees are used for different types of smoked meat: even if these types of trees do not grow in their summer cottage, it will not be difficult to buy the appropriate chips in the store.So, the most versatile remains is alder wood chips, on which almost any meat, lard, fish and even vegetables are smoked. Oak sawdust is used mainly for red meat and game. Willow and birch, which have a specific bitter taste, are used when smoking big game such as an elk or a bear. And on the softest cherries and apples they smoke cheese, nuts, vegetables and fruits.

Firewood and pieces of wood added to the hearth for flavor should not be more than 5-10 cm in size. Larger pieces are harder to heat to the extent that they begin to char.

Before you put a log in the fire, it is not superfluous to slightly moisten it: raw wood gives abundant smoke, which is very important for smokehouse. However, do not overdo it with moisture: if too much steam is formed, the products will be sodden, which will significantly shorten the storage time. In addition, in order to get a good abundant smoke, after the formation of coal in the furnace, it is worthwhile to shut off the pipe valve. At this point, the active burning stops, but sawdust forming smoke begins to smolder.

To improve product quality, it is best to provide the fire with an active supply of oxygen.At the same time, it is impossible to blow a flame in a smokehouse: it is important that firewood smolder, but not burn.

It is very important to provide smoked products with a continuous supply of smoke from the beginning of cooking until its completion. This should be taken into account when placing in the smokehouse pieces of meat or fish of different sizes: small ones will be ready much earlier than large ones. For the latter, it is necessary to additionally pour sawdust and shavings into the pallet, thus maintaining a constant temperature. However, do not forget about the danger of smoking over products: the process must be carefully monitored and periodically checked for product readiness.

Another way, significantly speeding up the process of smoking, is the preliminary boiling of meat or fat in water with salt and spices.

The optimum temperature inside the smoking chamber should vary between 60-90 degrees Celsius. Even without temperature sensors, it is quite simple to adjust the temperature: water in a small container placed on the lid of the smoking chamber should not boil. Slightly lower temperatures are chosen for cold smoking, and higher temperatures for hot ones, sometimes reaching 120 degrees Celsius.

By the way, you can smoke not only meat, fish, bacon or sausage. Smoked nuts, vegetables and fruits have interesting flavors. We should also mention smoked cheeses. It all depends on the temperature inside the smokehouse and used inside sawdust and wood chips.

Before the smoking process, it is better to place the products in a separate oven for some time, which allows you to get rid of excess moisture and thereby increase the shelf life of the product. It is easy to make it yourself: just take a volume box with a tight sealed lid, into the side of which a fan is inserted. Before you put the product in the closet, it is better to pre-pickle. In the closet he will spend from one to three days to complete drying.

Large stationary smokehouse can be installed only at the cottage or, in the case of living in the private sector, in the territory of your own home. Such designs require a lot of free space, and they also produce a lot of smoke, which can harm the plants, enter the house and interfere with the neighbors.

Before you begin active operation of the smokehouse, one procedure of “smoking” without products is done.Due to this, the camera is fed by the natural smell of the firebox and the products will later acquire the best taste and aroma.