Smokehouse: types and step by step instructions

There are a lot of smoked products lovers among us. In order not to spend big money on its purchase in stores, many already use homemade smoking. You can opt for the factory model or make the most similar design.

In this article we will tell you about the types of smoking, types of smokehouse and methods of making them with our own hands.

What it is?

Almost any smokehouse is a box (usually metal), in which a metal grate or hooks for products are placed. Smoking occurs by fumigating them with cold or hot smoke, which gives them a special taste and aroma.

Poultry farms differ from each other in the principle of operation and placement Factory smokehouses are often expensive, but still the demand for them does not fall for many years.Also with the help of smoking, you can extend the shelf life of products several times.

Shops are a huge selection of smoked products, but it clearly can not be compared with home smoked. The fact is that when making products for mass sale, the manufacturer does not pay enough attention to the rules of safe smoking and often uses "liquid smoke" and other questionable additives. And real connoisseurs know that the taste and color of the product depend on the method of pickling or salting before smoking, the wood sawdust and other important factors that are simply not taken into account in mass production.

Smoke can be very different products: meat, fish, poultry, lard, cheese, vegetables, fruits, berries and even nuts. You can improvise endlessly and discover some special recipe.

Special features

Distinguish cold and hot smoked smokehouses. Smoked meats, obtained by the first method, turn out to be more dry and dense in structure. Hot smoked food retains its fat content. When the thought of manufacturing or acquiring a home smokehouse came, it is worthwhile to immediately determine which products are loved most in the family.Based on this, you can already choose the design of the device.

Smokehouses differ from each other in the principle of operation and placement of the furnace. Thus, in a smoke-cured smoking shed, the food chamber is heated using an open flame or electric appliance placed under the appliance. In this way, hot smoke is formed, which envelops the products and brings them to readiness.

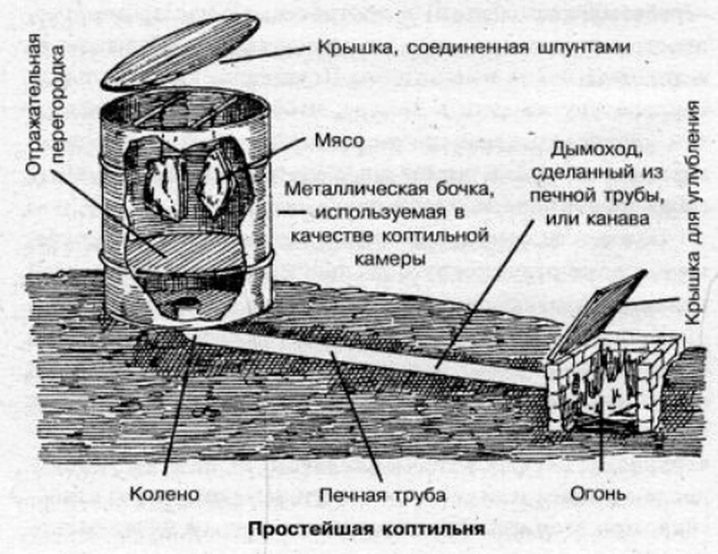

The figure shows the simplest smoking sheds with options for the placement of some parts and products:

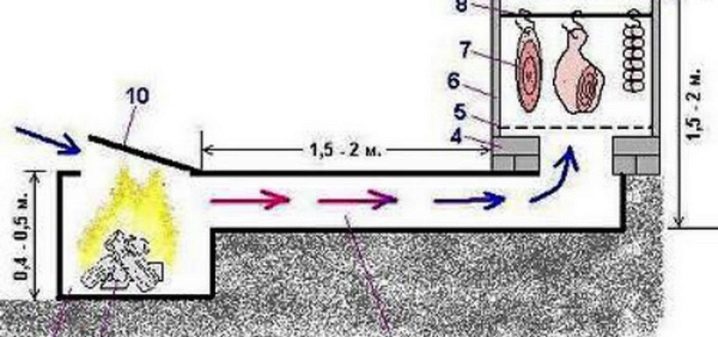

Cold smoking is a very similar way. The main difference is that the smoke has time to cool before it reaches the product. The temperature in such smokehouses is 35-40 degrees, and the process of cold smoking can take several days. Its independent equipment will also be more difficult when compared with the hot smokehouse. But this does not stop fans of homemade smoked meats without any impurities and additives.

A simple diagram in the figure shows the principle of operation of such a smokehouse:

Necessary tools and accessories

Hot smoking is carried out at a temperature of smoke from 60 to 120 degrees, so it takes much less time than the cold.There is an inversely proportional relationship: as the heat decreases, cooking time increases. All hot smoked smokehouses have a typical design: a container inside which there is a grate (hooks) for food, a metal pan and sawdust at the bottom. This tank is placed on an open fire or preheated oven so that the sawdust begins to smolder, forming the hot smoke needed for smoking.

A tray under the products is needed to drain excess fat into it, which makes cleaning the smokehouse after use very easy.

Another important point: such a smokehouse should be sealed with a lidso that you can control the temperature during the whole process and remove excess smoke from the chamber. Purchased smokehouse models can have a compressor for a smoke generator, fans, a temperature controller, a control unit and special thermometers. But homemade smoking is quite possible without these additional details.

The main difference of the design for cold smoking is an elongated chimney, through which smoke comes from glowing sawdust to the product.Fish and meat prepared in this way can be stored for up to 60 days. The design consists of three main elements: a smoking chamber, a fire chamber and a chimney that connects them. Circulation of smoke can be adjusted using a special damper. Often, the role of the lid or the door in the chamber for ignition.

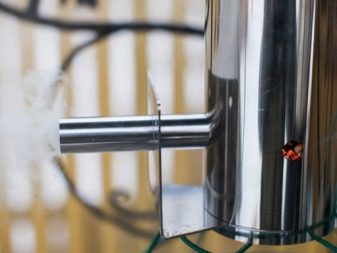

Smoke generator

This is a device that allows smoke to continuously enter the smoking chamber. It is used both at cold smoking, and at hot.

Benefits:

- constant intake of smoke during the entire process;

- less fuel is used to get the right amount of smoke;

- smoke has a constant temperature;

- the process does not require constant monitoring.

The smoke generator is quite simple. It looks like a pipe with hoses that connect the two chambers: with products and with glowing sawdust. Smoke is forced inside the domestic compressor. All that is needed for the smoke generator to work is electricity and fuel smoldering.

This device is quite easy to do with your own hands in order to save money.

Kinds

With sorts of smoke on the way we smoked, we figured out. Now it is worth considering various designs.For hot smoked, there are 4 main varieties. Let us consider in more detail each of them.

Mini Smokehouse

Mini smokehouse won great popularity due to its compactness, low weight and ease of use. They are also called portable or street. Often they are used by hunters, fishermen and tourists, because for them the mobility of the structure is very important. Such designs are made of stainless steel with a thickness of 2-3 cm, because the smokehouse will often heat up. This material is resistant to corrosion and high temperatures. For comparison - a smokehouse of ordinary metal will last 1-2 years, and stainless steel - all 10 years.

This design is easy to make at home.

To do this, you can use a saucepan, a roaster or a metal bucket. The heat in the chamber comes from an open fire or electric stove, the temperature during smoking is from 90 degrees. Thanks to this, the food is cooked very quickly: from 30 to 60 minutes. Mini-smokehouse can be compared with the oven or smoker, in which the product is saturated with hot smoke.

Using this device in the field, you need to immediately use cooked food to prevent spoilage. Externally, these smokehouses are very similar to a microwave.The only drawback is the low-capacity camera, which does not contain many products at a time.

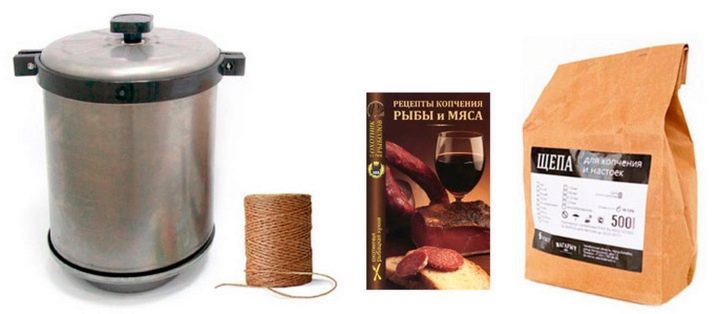

For apartment

For those who do not have a dacha or the possibility of leaving the city, created smokehouses for cooking within the apartment. The principle of operation of this design will be similar to other types, only the source of heating will be an electric stove or gas.

In the complete set of home smokehouse there are parts that eliminate the inconvenience during cooking.

- Smoke Discharge When smoking a house, it is very important to take the smoke out. For this purpose, a hole is made in the lid with a hose that extends through the window. This method of getting rid of smoke is obligatory, because an ordinary hood can cope with this task, but further on the smoke will go to the neighbors' apartments.

- Water lock. It is necessary to prevent the penetration of smoke and burning outside. This is a kind of chute with water, which is located between the wall of the smoke chamber and the edges of the lid. Water, in turn, does not allow smoke to escape.

- Cap. For apartment smokehouses, only an airtight lid is needed. You can also use a water seal - these are interchangeable parts, but it will be better if both are present.

Factory apparatuses for use in an apartment are made of stainless steel with a thickness of 2-3 mm, they can last up to 12 years. Something similar can be done and most of the old pan, for example. It will not be easy to make a water seal, therefore it is better to ensure the tightness of the cover with rubber gaskets.

Electroctile

Such a device is also well suited for smoking at home - you just need to put sawdust inside, close the lid and connect it to the network.

There are several of its main advantages.

- Compactness. Dimensions of home electroculture allow you to store it in a conventional kitchen cabinet.

- Does not require special skills. It is enough to assemble the device, read the operating instructions and set the desired temperature. The mechanism will do everything himself.

- Quick cooking. Due to its complete tightness, the design retains heat throughout the entire smoking period and you can get the finished products within 30-60 minutes.

- Full set. The presence of all the necessary parts allows you to not care about the smoke removal or temperature control.

- Warranty. When you purchase a poor-quality smokehouse, you can exchange it or return the money. Often the marriage becomes obvious already during the first cooking.

- Affordable price.Now the market provides a fairly large selection of such structures at an affordable price.

Automatic

This smokehouse is powered by electricity and is used to smoke sausages, lard, fish, cheese, meat, vegetables and many other products. In restaurants, such constructions are often used. It's all about the large volume of the smoke chamber: one load can hold up to 200 kg of products. This is very convenient when a large institution.

In addition to professional automatic smokehouse, there are several household models:

- for cold smoking;

- universal models;

- coal smokehouse;

- with an open tubular electric heater - only kind of wood chips or sawdust are suitable for kindling this model.

Automatic smokehouses for domestic use are convenient because they do not require special skills and constant monitoring of the process, such as when smoking on the wood. Among industrial smoking sheds, it is possible to distinguish multifunctional (can be used as a cabinet oven and carry out hot and cold smoking) and stationary smoking ovens (can be two-tier,turn on the hob and perform immediately from 1 to 6 processes).

Designs for cold smoking can be divided into 3 main types - stationary, mobile and marching.

Stationary

Every detail for such a design is made on the basis of long functioning and durability. The smoke generator is often made of old barrels or metal cylinders. It can also be laid out of brick. Often the chimney is placed below the level of both chambers. The dimensions of the smoke chamber depend on the number of blanks that are planned to be made. The best option would be a metal tank for 20-230 liters.

As a smoking chamber, a case from an old refrigerator or a washing machine is well suited. Getting rid of unnecessary elements, you can get the perfect steel container. The chimney must be tightly connected to the chambers and also be stationary. It is important to ensure that its work is not affected by weather conditions. Before equipping the smoke pipe from old pipes, you must make sure that the metal does not harm the products when heated.

Mobile

Folding design with low weight, easy to move.The smoke generator is often made of metal and welded. The manufacture of the smoke chamber is allowed from both metal and wood. The chimney is made of pipe similar to the stationary model.

Marching

Cold smoking in field conditions is greatly simplified. As a smoke generator serves a common pit with sawdust and a sheet of metal. Bottom this sheet is heated by coal or fire. For the equipment of the chimney, a trench is simply pulled out in the ground and covered with some kind of dense improvised material (a board, for example).

The smoking chamber can be made by simply wrapping a vertical frame of wooden or metal pegs in polyethylene to make something like a dome. It is important to ensure the tightness of the upper part of the structure. To do this, on top of polyethylene can simply be tightened into a bun and tie a rope. When you need a hole for the hood, you just need to relax the rope.

The main tasks with which self-made marching smoker should cope is a stable temperature during cooking and tightness.

Materials

The material of the smokehouse must withstand high temperaturesDo not react to moisture and be easy to clean. Stainless steel is ideal.

Material advantages:

- It is not subject to corrosion. This is especially important if you plan to use the smokehouse in the open air. For comparison - ferrous metals can collapse to holes in the walls.

- Stainless steel is fairly easy to clean from burning after cooking.

- Does not emit harmful vapors during heating.

The optimum thickness of the steel sheet is 2-3 cm. If it is thinner, it deforms quite quickly, if it is thicker, this will complicate the smoking process and increase the weight of the structure. The stainless steel is used for all types of factory smokers. But there are alternative materials that can be used for self-production. Consider some of them.

Of brick

This option is well suited to those who have a summer cottage and plans to make delicacies for sale. This smokehouse is quite large and can accommodate a lot of products at a time. It can be equipped as an extension to the house or as a separate element. Having determined the size, location on the site and the detailed design of the structure,You can go to the purchase of building materials.

For the construction will need:

- red and silicate bricks;

- cement and sand;

- wooden beam;

- roofing material;

- pipe with a diameter of about 100-150 mm for the equipment of the chimney;

- door and hinges.

It is better to place the smoking chamber above the level of the firebox if there is such an opportunity.

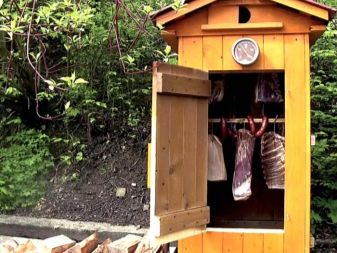

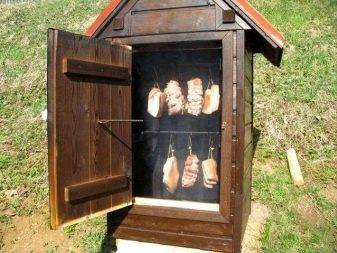

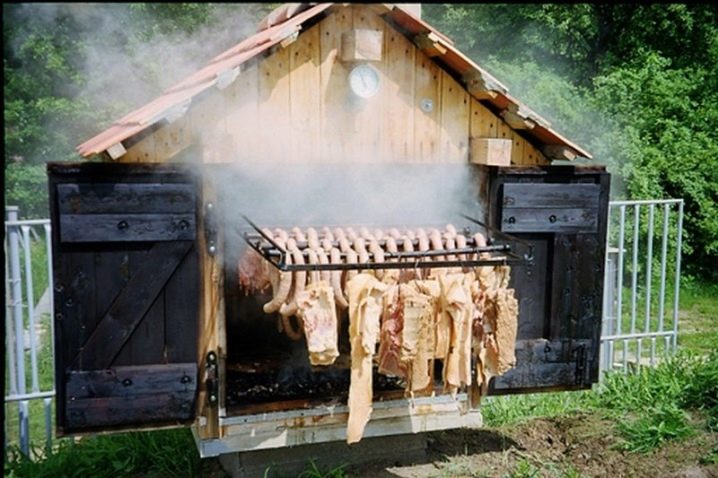

From wood

Wood is an environmentally friendly material that does not emit any harmful toxins and does not emit an unpleasant odor when heated. Oak, alder and apple trees are well suited for making smokehouse. The main requirement for wood is a dense structure and resistance to various weather conditions.

Materials needed for the manufacture of wooden smokehouse.

- wooden beam from which the framework will be erected;

- Finished boards with a thickness of 0.8-1 cm - they will be attached to the frame in two layers to ensure the tightness of the structure;

- roofing material;

- Red brick;

- silicate brick;

- waterproofing material;

- pipes with diameters of 10 cm and 20-25 cm;

- sheet of metal.

The shape of the smoke chamber is determined by the reservoir, which was taken for its basis.If the equipment is made independently from the beginning to the end, then the form can be chosen independently. Optimal are round, cylindrical or rectangular chambers. Some craftsmen make forged forms for the equipment of the smoke chamber.

How to choose and assemble?

When buying a device, you need to focus on your preferences and plans. In principle, with the assembly of the smokehouse everything is exactly the same way, just have to take into account more features. What is worth deciding before making a smokehouse:

- Material. Obviously, it will be metal, but it is important to decide which one. If a bucket, a barrel or other household items are adapted to the smoke chamber, the choice is obvious. A brick is more often used for the foundation, however, if there is no experience, a leaky structure can be obtained.

- Mobility. This question is the easiest to solve, because few people need two types of smokehouse at once - stationary and portable. It is much more logical to make a universal smokehouse for both types of smoking.

- The size of the capacity of the smoke chamber. It is necessary to decide on products which it would be desirable to smoke.Based on the number of people in the family or plans to sell the product, you can calculate the dimensions.

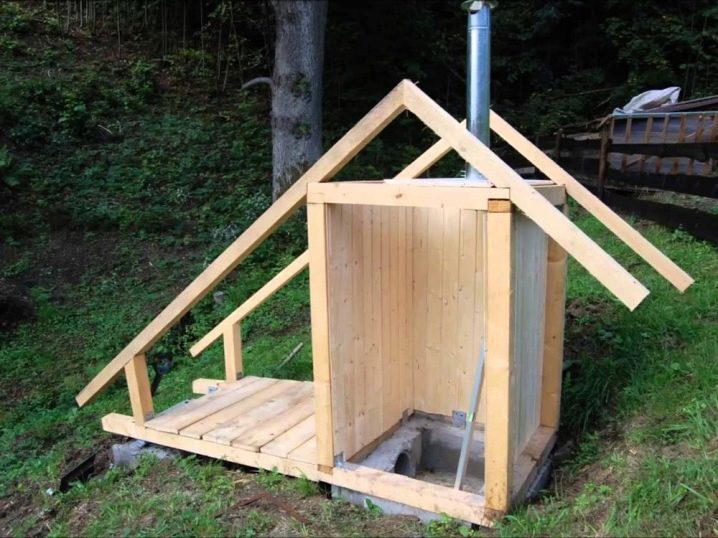

We give a step-by-step instruction on the assembly of cold-smoked smokehouse from wood.

- After a suitable place is chosen, it is necessary to dig two holes at a distance of about 20-25 cm from each other. The first should be located on a hill, then it will be equipped with a smoke chamber. The second is for the firebox, a little lower. The optimal depth of the pit under the smoke chamber is 35-40 cm. This depth will ensure the delay and cooling of smoke.

- Further, these pits are connected by a trench. It will later fit the chimney. The width of the trench is done corresponding to the width of the pipe (with a small allowance).

- It is necessary to properly tamp the bottom of that pit, which is intended for the firebox, and then fall asleep with sand and rubble (6-7 cm).

- Cement mortar is poured onto gravel from above. To strengthen the screed on the cement after complete drying, you need to lay a reinforcing mesh, which is poured with a second layer of cement and sand approximately 40 mm thick.

- At the bottom of the trench is placed a pipe that will serve as a chimney. It should be shorter than the trench, so that later you can attach to it a section of pipe with a large diameter.A chimney equipped in this way will allow the smoke to cool to the optimum temperature. It is important to note that a pipe with a large diameter should go into the reservoir of the smoke chamber by about 15 cm.

- When several rows of bricks of the combustion chamber are laid, it's time to equip the door. The dimensions of the window should be sufficient in order to make it convenient to lay the fuel mixture.

- The foundation for the smoke chamber is laid out of brick. The evenness of the walls is controlled by the building level.

- When the brick base is made, you can fill the trench with the pipe with concrete solution. Particular attention should be paid to the section where two pipes with different diameters are joined and the section of the entrance of the chimney into the combustion chamber. It is not necessary to completely fill the trench with the mortar, because then there will be a layer of soil with a thickness of 7-8 cm. If, after drying, gaps or cracks remain, they should be filled with clay or tamped soil.

- To check that everything goes according to plan, you can set fire to sawdust in the firebox or any other natural material. If everything is equipped correctly, the smoke will go out into the basement hole without obstacles.

- Next is the manufacture of the smoke chamber of wood. First you need to cut all the necessary details (their number and size depends on the dimensions of the structure). The elements can be fastened with screws or nails.

- When covering the board frame, you must first lay it vertically relative to each other, and then horizontally. This will provide the necessary tightness. Do not use lining for plating, since over time it may expand under the influence of high temperatures, which will lead to deformation of the walls. All walls, except the side walls, are sheathed, so that later the rods and hooks on which the products will be suspended can be fixed.

- Next, set the door. It can be purchased or self-made, and the joints can be closed with corners of wood or metal. Some people drill a special hole in the door into which they insert a thermometer. This will allow you to control the temperature inside the smoke chamber, once again without opening the door.

- The bottom should be left open, since it will allow smoke to enter the chamber.

- To increase the resistance of the smoke chamber to the effects of moisture and weather conditions, it should be treated with water-repellent impregnation. It can be found on the shelves of shops with building materials.

- The last step is to install a wooden camera on a brick base. The fastening of two elements can be accomplished with the help of metal brackets, which on the one hand are fixed on the surface of the boards, on the other - on the walls of brick.

It is not necessary to cover the roof with roofing material, but it will not be superfluous. It is possible to choose a professional flooring, metal tile or a soft roof.

Now we will consider all the steps in the manufacture of hot smoked smokehouse, which is based on a conventional household barrel. In this design there is no need to have a smoke chamber and a firebox at a distance, they can be directly above each other.

Smokehouse equipment from the barrel.

- The bottom of the barrel should be drilled in several places. These holes will perform the function of a blower for the firebox and at the same time extra ash will be poured through them.

- Cut a small opening for further installation of the door. A rectangle measuring 20 by 30 cm would be enough. A handle or a lanyard is attached to the door itself, for which it can be opened without burning.

- If you divide the entire barrel into parts, then 2 of 3 will fall on the smoking chamber, and 1 part will be occupied by the firebox.These spaces should be separated by a metal sheet about 4 mm thick, by welding it to the walls of the barrel.

- The chimney is inserted into the hole in the lower part of the chamber and is also welded to the wall of the barrel.

Then everything is according to the standard: installation of a pallet for draining fat, equipment of grids and hooks for hanging products, airtight lid. Schematically, a hot-smoked smokehouse from a barrel looks like this: It is advisable to install a thermometer with a sensor on the barrel. It will help to avoid many errors when testing the device. Having dealt with the basic principles of the operation of the smokehouse and its device, you can improvise with materials and methods of manufacture. In any case, the ideal product from the first time can hardly be obtained and it will take time to make the necessary amendments to the operation of the device.

Tips and tricks

- When building a cold-smoked smokehouse, it is worth remembering that the shorter and wider the trench is, the faster the smoke enters the product chamber. It is necessary to calculate the optimal length for the smoke to cool, otherwise the smoke pipe simply will not perform its main function.

- Making the pipe long, be sure to tilt it by 10-15 degrees. This is necessary so that the smoke does not stagnate for a long time at the upper wall of the pipe and does not cool prematurely.

- In order to avoid the problems described above, you should immediately determine the products that will smoke most often. Smoking protein products (meat, fish) takes more time than vegetable products.

- It is important to take seriously the process of preparing products for smoking. Meat or fish must be rubbed with coarse salt and left in the refrigerator for several days. Salt destroys bacteria, taking away moisture from products. To remove excess salt, soak the product for a couple of hours in clean water. Then it must be dried in a dry place, after which it is already possible to start smoking.

- Smoke is able to influence the taste of the product no less than salt or pepper. For proper smoke need sawdust fruit trees. In principle, many sawdust will fit for smoking, except for conifers: from them the food gets a bitter taste.

- Products cooked by hot smoked lasts about 10 hours. If there is a need to extend this period, you can use vacuum packaging or freezing. But it is obvious that after defrosting the taste of the product will not be so pleasant at all.

- With the equipment of the smokehouse, you can add to the structure an additional pallet on which you can store firewood for kindling. This is especially true for monumental stationary buildings.

- The size of the mini-smokehouse can be absolutely any. The main thing to consider is a gap of a few centimeters from the walls of the smokehouse to the products.

- If, during cooking, there is increased humidity in the street, it is possible to make the fire more intense so that cooking does not last for long hours.

- It is important not to overdo it with the wall thickness of the smokehouse. For example, a barrel with walls greater than 3 mm will not work, because in this case the heating process will take a very long time and the result may be disappointing.

- A damaged refrigerator will be suitable as a base for a smokehouse even if there are cracks. It is necessary to make a small repair: to patch them with iron plates.

- In that case, if the smoke is too black, you can add fresh grass to the fuel.

- Some summer residents specially moisten fuel to reduce the amount of soot on food. But professionals advise using only well-dried wood chips,and wrapping products with gauze and dressing before smoking.

- When smoking fish, you must comply with the rule of proportions of the product and used sawdust. For 3 kg of fish (or about 40 liters of smokehouse) only one handful of sawdust is required. This will be quite enough, because the smoke does not fill the chamber immediately, but within 20-25 minutes. During this time, the fish has time to soak up the unique aroma, which is determined by the type of wood for sawdust.

- If you overdo it with the amount of sawdust, it may not be the best way to affect the taste of products and even harm human health.

- Self-made smokehouses quite often completely burn through in the bottom. To avoid this, you need at the very beginning to take care of quality metal for bottom equipment.

- If there is not enough space on the summer cottage to equip a chimney of the required length, it can be made curved or a smoke cooler can be placed on the pipe. With this role, a brass tube can perfectly cope with which you need to wind a chimney. Cold water in this tube will cool the smoke properly.

- Some resort to such tricks as the wet burlap stretched over the combustion chamber.She will be able to skip the smoke, while simultaneously retaining in her the ashes, ashes, and other polluting elements.

- In the absence of a thermometer, you can check the temperature of smoking with the help of water by sprinkling a smokehouse lid on it. If evaporation occurs without hissing - the temperature is permissible. If water spikes on contact with the hull, the temperature must be reduced.

Manufacturers and reviews

The model for cold smoking is quite popular. "Summer resident". The device can be connected to the hood due to the presence of a flexible chimney. The processing of products by smoke is carried out at a temperature of from 20 to 28 degrees, and the smokehouse itself operates from the power grid. Production material - stainless steel.

Items Included:

- tubular electric heater;

- smoke chamber;

- grease tray;

- Temperature regulator;

- timer;

- on / off indicators in the form of small light bulbs;

- grill for products.

This model has an affordable price and, judging by the numerous reviews on the web, this is an excellent ratio of quality and cost. From the factory models for hot smoking, you can select the smokehouse Selmash Saturn. The volume of the smoke chamber allows you to fit about 5 kg of product at a time. Included are metal pins, an airtight lid and a baking tray for draining fat. This smokehouse can be used both on the stove and on an open fire. But there are no such important elements as a thermometer and a chimney. Nevertheless, this model is quite popular among those who like to practice home-smoked.

Another simple Russian model - Smokehouse FireWood. Here the steel thickness is alarming: only 1.5 mm. It is clear that it is not necessary to count on the long service life of such a structure, but for the first experience it is just right. The package bundle includes two tiers for products, and also includes a bimetal thermometer. If we are talking about a professional kitchen and large volumes of smoking, then you should think about the smokehouse TTM Big Smak. It holds up to 35 kg of product at a time, has a mechanical control, 5 grids in a set and meets all the requirements of proper smoking.

Smokehouse "Cedar" immediately attract with its low price, but some models are not even equipped with a pallet to collect fat. So when making a choice in favor of low cost, you need to be ready to finish the construction yourself and bring it to working condition.

When buying, you can also consider the Finnish or German models, but you need to be prepared for the fact that they will not have a reasonable price.

Coming to a specialty store, you need to pay attention to many details when choosing.

- The depth of the smoke chamber. It should correspond to the size of the products that it plans to cook.

- Even with small dimensions of the structure, the distance between the products and the source of heat should be sufficient. Otherwise, smoking can not be carried out in accordance with the rules and recipes.

- Any design should include openings for ventilation. They should be even if the kit does not have hoses for smoke exhaust.

- The lid of the smokehouse must be sealed. Without this, the normal smoking process is simply impossible.

- Must have a tray for draining fat. Otherwise, the fat will drip from the food directly on the chips, it will light up and one of the basic rules of smoking will be violated - slow smoldering of chips.

- The chimney for cold-smoked smokehouse must be made of metal or ceramic pipes.Plastic under the influence of high temperatures begins to emit toxic substances that can get on the products and harm health. This rule applies to the equipment of all other pipes in the structure.

Successful examples and options

You can equip a smokehouse and wood, which will accommodate a special shed for placing and drying firewood. Of course, such a shed cannot protect against rain, but logs can be placed under a shed in sunny weather a couple of hours before cooking. During this time they will have time to dry.

And here is what a full-fledged stationary smokehouse of brick looks like. It includes a powerful chimney, skewers, grates and a dishwashing area. This design can perform all the functions of the summer kitchen.

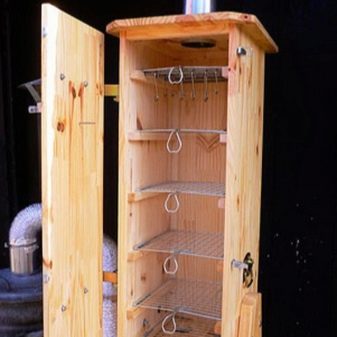

Very interesting smokehouse for hot smoking, which is based on two barrels. It is clear that the construction may take weeks, but in terms of functionality such a device will be close to the factory one, and maybe even better. The main difficulty is to choose barrels with a wall thickness of not more than 3 mm, but not less than 2, and to cut and weld them with the maximum quality. Something like this should look like a simple smoke chamber made of wood.The presence of many tiers will allow you to bookmark up to 10 kilograms of the product, and a well-equipped pipe will allow you not to linger too much smoke inside the tank.

Such a small smokehouse has several names: manual or portable. Its main advantages are mobility and small dimensions. You can take this model with you on trips, fishing or on an expedition.

And this is what a folding smokehouse for cold smoking looks like. Of course, when folded, it will take up more space than a mobile design for hot smoking. But here it is worth coming from the desire to cook something special away from home and from the duration of the hike / journey. It is necessary to correctly calculate the reasonableness of the transportation of such a device, so as not to leave it in the middle of the forest.

Another example of the skillful use of old gas cylinders. This design can serve as a smokehouse, and brazier, and a stove. A small wooden table will make the most convenient cutting of products and their preparation for placement in the unit. Of course, you will have to tinker with the welding of such a smokehouse, but such an apparatus is being made for ages: weather conditions will not affect it, corrosion is not dangerous for it, and it will not deform under the influence of moisture.You can make every effort once so that later children and even grandchildren can master the skills of smoking.

It will not be possible to make such a smokehouse itself, but this is what designs look like for use in large kitchens in restaurants and cafes. The cost of such units can reach unprecedented heights, but the presence of various functions can not but rejoice. It is sterility, energy saving, economical consumption of wood chips, built-in smoke generator, removal of excess smoke and much more. The picture shows the model of domestic production "Electra" for cold smoking.

An example of a wooden smokehouse, in the construction of which all the basic rules of manufacturing are observed: the smoke chamber is sheathed in two layers of wood - vertically and horizontally, the chimney pipe is well attached to the foundation, the door dimensions are sufficient for comfortable work, the smoke chamber is higher than the location of the furnace.

Very successful version of the equipment of the smokehouse from a wooden barrel. In order not to remove the cover every time, a special chain is attached that connects the upper and lower parts of the structure.The distance between the food grate and the source of heat is sufficient so as not to smoke the food and spoil it. Equipped with handles on the sides to move the smokehouse on the site. This model is one of the best options that you can make yourself. It is not as complex as the construction of cylinders and iron barrels, but it can also serve for quite a long time.

One of the simplest designs is a metal smoker placed on an open fire. With this method of cooking it is important to ensure that the chips inside the smokehouse does not ignite, otherwise the product will deteriorate in a matter of minutes. Naturally, cleaning the outer layer of the box after cooking will be very problematic, but few people pay attention to it. Often, the smokehouse is cleaned only from the inside.

How to make a smokehouse from the barrel, see the following video.